Pintle Hitch Integration with Sensor Technology for Enhanced Safety

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Sensor Tech Evolution and Objectives

The integration of sensor technology with pintle hitches represents a significant evolution in vehicle safety and towing capabilities. This technological advancement has its roots in the early 2000s when basic electronic stability control systems were first introduced in commercial vehicles. The primary objective of this integration is to enhance safety, improve towing efficiency, and provide real-time monitoring of critical towing parameters.

The evolution of pintle hitch sensor technology has been driven by the increasing demand for safer and more reliable towing solutions in various industries, including construction, agriculture, and logistics. Initially, the focus was on basic load sensing and stability control. However, as technology progressed, more sophisticated sensors and data processing capabilities were incorporated.

One of the key milestones in this evolution was the introduction of wireless communication between the towing vehicle and the trailer. This advancement allowed for real-time data transmission, enabling more accurate and responsive safety systems. The integration of GPS technology further enhanced the capabilities of these systems, providing location-based alerts and optimizing route planning for heavy-duty towing operations.

The current state of pintle hitch sensor technology encompasses a wide range of functionalities. These include load distribution monitoring, sway detection and mitigation, tire pressure monitoring for both the towing vehicle and trailer, and advanced brake control systems. The integration of artificial intelligence and machine learning algorithms has also begun to play a crucial role in predictive maintenance and adaptive safety features.

Looking forward, the objectives of pintle hitch sensor technology integration are multifaceted. One primary goal is to achieve seamless connectivity and data sharing between the towing vehicle, trailer, and fleet management systems. This would enable comprehensive monitoring and optimization of towing operations on a larger scale.

Another important objective is the development of more robust and reliable sensor systems that can withstand harsh environmental conditions and provide accurate data in diverse operating scenarios. This includes improving sensor accuracy in extreme weather conditions and developing fail-safe mechanisms to ensure continuous operation.

Furthermore, there is a growing emphasis on integrating pintle hitch sensor technology with autonomous driving systems. The aim is to create intelligent towing solutions that can adapt to changing road conditions, traffic patterns, and payload characteristics without human intervention. This integration poses significant technical challenges but holds immense potential for revolutionizing the transportation and logistics industries.

In conclusion, the evolution of pintle hitch sensor technology has been marked by continuous innovation aimed at enhancing safety and efficiency in towing operations. The future objectives focus on achieving greater integration, reliability, and autonomy, paving the way for smarter and safer transportation solutions.

The evolution of pintle hitch sensor technology has been driven by the increasing demand for safer and more reliable towing solutions in various industries, including construction, agriculture, and logistics. Initially, the focus was on basic load sensing and stability control. However, as technology progressed, more sophisticated sensors and data processing capabilities were incorporated.

One of the key milestones in this evolution was the introduction of wireless communication between the towing vehicle and the trailer. This advancement allowed for real-time data transmission, enabling more accurate and responsive safety systems. The integration of GPS technology further enhanced the capabilities of these systems, providing location-based alerts and optimizing route planning for heavy-duty towing operations.

The current state of pintle hitch sensor technology encompasses a wide range of functionalities. These include load distribution monitoring, sway detection and mitigation, tire pressure monitoring for both the towing vehicle and trailer, and advanced brake control systems. The integration of artificial intelligence and machine learning algorithms has also begun to play a crucial role in predictive maintenance and adaptive safety features.

Looking forward, the objectives of pintle hitch sensor technology integration are multifaceted. One primary goal is to achieve seamless connectivity and data sharing between the towing vehicle, trailer, and fleet management systems. This would enable comprehensive monitoring and optimization of towing operations on a larger scale.

Another important objective is the development of more robust and reliable sensor systems that can withstand harsh environmental conditions and provide accurate data in diverse operating scenarios. This includes improving sensor accuracy in extreme weather conditions and developing fail-safe mechanisms to ensure continuous operation.

Furthermore, there is a growing emphasis on integrating pintle hitch sensor technology with autonomous driving systems. The aim is to create intelligent towing solutions that can adapt to changing road conditions, traffic patterns, and payload characteristics without human intervention. This integration poses significant technical challenges but holds immense potential for revolutionizing the transportation and logistics industries.

In conclusion, the evolution of pintle hitch sensor technology has been marked by continuous innovation aimed at enhancing safety and efficiency in towing operations. The future objectives focus on achieving greater integration, reliability, and autonomy, paving the way for smarter and safer transportation solutions.

Market Analysis for Smart Towing Solutions

The smart towing solutions market is experiencing significant growth, driven by increasing demand for enhanced safety features in towing operations. As vehicle owners seek more secure and efficient ways to transport trailers and other towed equipment, the integration of sensor technology with traditional pintle hitches presents a promising opportunity for market expansion.

The global towing equipment market, which includes smart towing solutions, is projected to grow steadily over the next few years. This growth is attributed to several factors, including the rising popularity of recreational activities such as camping and boating, which often require towing capabilities. Additionally, the commercial sector's need for efficient and safe towing solutions in industries like construction, agriculture, and logistics is fueling market demand.

Consumer awareness of safety issues related to towing has increased, leading to a greater willingness to invest in advanced towing technologies. This trend is particularly evident in regions with strict towing regulations and high rates of recreational vehicle ownership, such as North America and Europe. These markets are likely to be early adopters of smart towing solutions that incorporate sensor technology into pintle hitches.

The integration of sensors with pintle hitches offers numerous benefits that appeal to both individual consumers and commercial users. These smart systems can provide real-time data on trailer weight distribution, sway detection, and hitch alignment, significantly reducing the risk of accidents caused by improper towing practices. The ability to monitor towing conditions through smartphone apps or in-vehicle displays adds an extra layer of convenience and safety that consumers increasingly value.

Market segmentation for smart towing solutions reveals opportunities across various vehicle types, including passenger cars, light commercial vehicles, and heavy-duty trucks. Each segment presents unique challenges and requirements, necessitating tailored solutions that cater to specific towing needs and capacities.

Competition in the smart towing solutions market is intensifying as both established automotive suppliers and new technology startups enter the space. Companies with expertise in sensor technology, data analytics, and automotive engineering are well-positioned to capitalize on this emerging market. Collaborations between traditional towing equipment manufacturers and tech firms are becoming more common, driving innovation and accelerating product development.

The regulatory landscape is also shaping market dynamics, with governments worldwide implementing stricter safety standards for towing operations. This regulatory push is likely to accelerate the adoption of smart towing technologies, as vehicle manufacturers and fleet operators seek to comply with new safety requirements.

The global towing equipment market, which includes smart towing solutions, is projected to grow steadily over the next few years. This growth is attributed to several factors, including the rising popularity of recreational activities such as camping and boating, which often require towing capabilities. Additionally, the commercial sector's need for efficient and safe towing solutions in industries like construction, agriculture, and logistics is fueling market demand.

Consumer awareness of safety issues related to towing has increased, leading to a greater willingness to invest in advanced towing technologies. This trend is particularly evident in regions with strict towing regulations and high rates of recreational vehicle ownership, such as North America and Europe. These markets are likely to be early adopters of smart towing solutions that incorporate sensor technology into pintle hitches.

The integration of sensors with pintle hitches offers numerous benefits that appeal to both individual consumers and commercial users. These smart systems can provide real-time data on trailer weight distribution, sway detection, and hitch alignment, significantly reducing the risk of accidents caused by improper towing practices. The ability to monitor towing conditions through smartphone apps or in-vehicle displays adds an extra layer of convenience and safety that consumers increasingly value.

Market segmentation for smart towing solutions reveals opportunities across various vehicle types, including passenger cars, light commercial vehicles, and heavy-duty trucks. Each segment presents unique challenges and requirements, necessitating tailored solutions that cater to specific towing needs and capacities.

Competition in the smart towing solutions market is intensifying as both established automotive suppliers and new technology startups enter the space. Companies with expertise in sensor technology, data analytics, and automotive engineering are well-positioned to capitalize on this emerging market. Collaborations between traditional towing equipment manufacturers and tech firms are becoming more common, driving innovation and accelerating product development.

The regulatory landscape is also shaping market dynamics, with governments worldwide implementing stricter safety standards for towing operations. This regulatory push is likely to accelerate the adoption of smart towing technologies, as vehicle manufacturers and fleet operators seek to comply with new safety requirements.

Current Challenges in Pintle Hitch Sensor Integration

The integration of sensor technology with pintle hitches presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is the harsh operating environment in which pintle hitches function. These devices are exposed to extreme weather conditions, vibrations, and physical impacts, which can adversely affect the performance and longevity of sensitive electronic components and sensors.

Ensuring the durability and reliability of sensors in such demanding conditions is a major hurdle. The sensors must be able to withstand constant exposure to dust, moisture, and temperature fluctuations while maintaining accurate readings. This necessitates the development of robust sensor housings and protective coatings that do not interfere with sensor functionality.

Another challenge lies in the power supply for these sensor systems. Traditional wired solutions are often impractical due to the mobile nature of trailers and the need for quick coupling and uncoupling. Developing efficient, long-lasting battery systems or exploring energy harvesting technologies to power the sensors autonomously is an area of ongoing research.

Data transmission and connectivity pose additional difficulties. The sensors need to communicate reliably with the towing vehicle's systems, often over varying distances and through potential interference from other electronic devices. Establishing a stable, low-latency wireless connection that can handle real-time data transmission is crucial for safety-critical applications.

The integration of sensor data with existing vehicle systems presents another layer of complexity. Ensuring compatibility and seamless communication between the sensor-equipped pintle hitch and the vehicle's onboard computers requires standardization efforts and the development of robust communication protocols.

Calibration and accuracy of sensors in dynamic towing situations is yet another challenge. The sensors must be able to provide precise measurements despite constant movement, changes in load distribution, and varying road conditions. Developing algorithms that can account for these variables and provide reliable data is an ongoing area of research.

Cost-effectiveness is also a significant consideration. While advanced sensor technologies can greatly enhance safety, they must be economically viable for widespread adoption in the commercial trucking industry. Balancing the cost of implementation with the potential safety benefits is a key challenge for manufacturers and researchers alike.

Lastly, regulatory compliance and standardization present hurdles in the development and implementation of sensor-integrated pintle hitches. Ensuring that these systems meet safety standards across different jurisdictions and can be universally adopted requires collaboration between industry stakeholders and regulatory bodies.

Ensuring the durability and reliability of sensors in such demanding conditions is a major hurdle. The sensors must be able to withstand constant exposure to dust, moisture, and temperature fluctuations while maintaining accurate readings. This necessitates the development of robust sensor housings and protective coatings that do not interfere with sensor functionality.

Another challenge lies in the power supply for these sensor systems. Traditional wired solutions are often impractical due to the mobile nature of trailers and the need for quick coupling and uncoupling. Developing efficient, long-lasting battery systems or exploring energy harvesting technologies to power the sensors autonomously is an area of ongoing research.

Data transmission and connectivity pose additional difficulties. The sensors need to communicate reliably with the towing vehicle's systems, often over varying distances and through potential interference from other electronic devices. Establishing a stable, low-latency wireless connection that can handle real-time data transmission is crucial for safety-critical applications.

The integration of sensor data with existing vehicle systems presents another layer of complexity. Ensuring compatibility and seamless communication between the sensor-equipped pintle hitch and the vehicle's onboard computers requires standardization efforts and the development of robust communication protocols.

Calibration and accuracy of sensors in dynamic towing situations is yet another challenge. The sensors must be able to provide precise measurements despite constant movement, changes in load distribution, and varying road conditions. Developing algorithms that can account for these variables and provide reliable data is an ongoing area of research.

Cost-effectiveness is also a significant consideration. While advanced sensor technologies can greatly enhance safety, they must be economically viable for widespread adoption in the commercial trucking industry. Balancing the cost of implementation with the potential safety benefits is a key challenge for manufacturers and researchers alike.

Lastly, regulatory compliance and standardization present hurdles in the development and implementation of sensor-integrated pintle hitches. Ensuring that these systems meet safety standards across different jurisdictions and can be universally adopted requires collaboration between industry stakeholders and regulatory bodies.

Existing Sensor-Integrated Pintle Hitch Solutions

01 Locking mechanisms for pintle hitches

Various locking mechanisms are employed to enhance the safety of pintle hitches. These include spring-loaded locks, automatic locking systems, and secondary locking devices. These mechanisms ensure secure coupling between the towing vehicle and the trailer, preventing accidental disconnection during travel.- Locking mechanisms for pintle hitches: Various locking mechanisms are employed to enhance the safety of pintle hitches. These include spring-loaded locks, automatic locking systems, and secondary locking devices. Such mechanisms ensure secure coupling between the towing vehicle and the trailer, preventing accidental disconnection during transit.

- Safety indicators and warning systems: Safety indicators and warning systems are integrated into pintle hitches to alert users of proper engagement. These may include visual indicators, audible alarms, or electronic sensors that provide real-time feedback on the hitch's status, reducing the risk of improper coupling.

- Reinforced construction and materials: Pintle hitches are designed with reinforced construction and high-strength materials to withstand heavy loads and stress. This includes the use of durable alloys, heat-treated components, and structural reinforcements to enhance overall safety and longevity of the hitch.

- Anti-theft features: Anti-theft features are incorporated into pintle hitch designs to prevent unauthorized use or theft of trailers. These may include keyed locks, removable components, or integration with vehicle security systems, adding an extra layer of safety and security.

- Adjustable and ergonomic designs: Pintle hitches with adjustable and ergonomic designs improve safety by allowing for proper alignment and reducing user strain. Features such as height-adjustable mounts, swivel mechanisms, and easy-to-operate handles contribute to safer and more efficient coupling processes.

02 Safety indicators and warning systems

Safety indicators and warning systems are integrated into pintle hitches to alert users of proper engagement. These may include visual indicators, audible alarms, or electronic sensors that provide feedback on the hitch's status, reducing the risk of improper coupling.Expand Specific Solutions03 Reinforced construction and materials

Pintle hitches are designed with reinforced construction and high-strength materials to withstand heavy loads and stress. This includes the use of durable alloys, heat-treated components, and structural reinforcements to enhance overall safety and longevity of the hitch.Expand Specific Solutions04 Anti-theft features

Anti-theft features are incorporated into pintle hitch designs to prevent unauthorized use or theft. These may include keyed locks, removable components, or integration with vehicle security systems, adding an extra layer of safety when the vehicle is parked or unattended.Expand Specific Solutions05 Ergonomic and user-friendly designs

Pintle hitches are designed with ergonomic considerations to improve ease of use and reduce the risk of injury during coupling and uncoupling. This includes features such as easy-grip handles, smooth operating mechanisms, and clear instructions or markings on the hitch itself.Expand Specific Solutions

Key Players in Smart Towing and Sensor Industries

The integration of pintle hitch with sensor technology for enhanced safety is in its early development stage, indicating a nascent market with significant growth potential. The market size is expected to expand as automotive safety regulations become more stringent globally. Technologically, the field is still evolving, with companies like Honda Motor Co., Ltd., Ford Global Technologies LLC, and WESTFALIA-Automotive GmbH leading the way in research and development. These firms are leveraging their expertise in automotive systems and sensor technology to create innovative solutions. However, the technology's maturity varies among players, with some still in the experimental phase while others are closer to commercial implementation.

Honda Motor Co., Ltd.

Technical Solution: Honda has innovated in the field of Pintle Hitch safety by developing a smart hitch system that combines sensor technology with adaptive vehicle dynamics. Their solution utilizes an array of sensors, including accelerometers and gyroscopes, to detect trailer sway and implement corrective measures through the vehicle's stability control system[1]. Honda's technology also incorporates a unique weight distribution system that automatically adjusts the vehicle's suspension based on the trailer's load[2]. Furthermore, they have developed an AI-powered predictive maintenance system that monitors the hitch and surrounding components for wear and potential failures[3].

Strengths: Integration with vehicle dynamics systems, automated load adjustment, and predictive maintenance capabilities. Weaknesses: May be limited to higher-end vehicle models, potentially increasing overall vehicle cost.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Pintle Hitch system integrated with sensor technology for enhanced safety. Their solution incorporates multiple sensors, including load cells and strain gauges, to monitor the trailer's weight distribution and coupling forces in real-time[1]. The system uses machine learning algorithms to analyze sensor data and predict potential instability or unsafe conditions[2]. Ford's technology also includes a camera-based system for automated hitching and unhitching, improving ease of use and reducing the risk of improper attachment[3]. Additionally, they have implemented wireless communication between the vehicle and trailer to provide the driver with real-time information on trailer status and any potential issues[4].

Strengths: Comprehensive sensor integration, predictive analytics for safety, and user-friendly automated features. Weaknesses: Potentially higher cost due to advanced technology, and may require specialized maintenance.

Innovative Sensor Technologies for Pintle Hitches

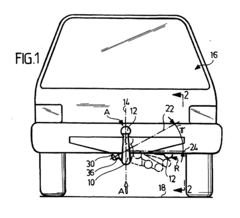

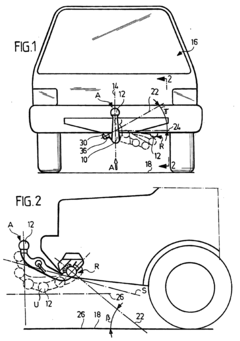

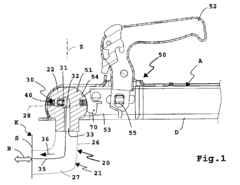

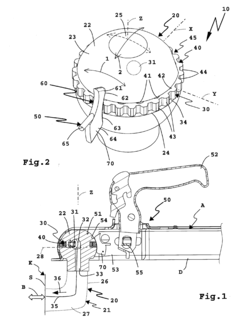

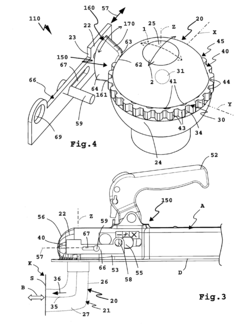

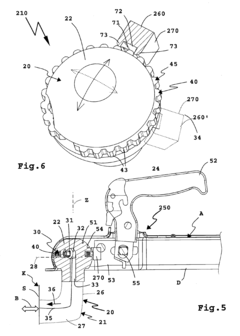

Trailer coupling

PatentInactiveEP1160105A2

Innovation

- Incorporating a sensor system that detects objects interacting with the hitch ball, generating signals to activate or deactivate safety features and ensure reliable engagement or disengagement, with possible sensor arrangements on the ball neck, socket, or hitch ball, using various detection methods such as ultrasonic, infrared, or mechanical actuation.

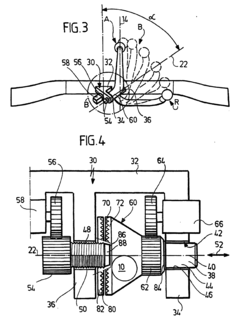

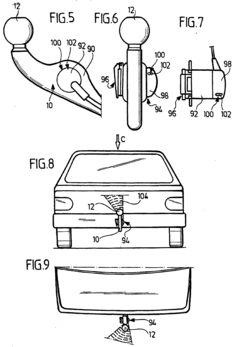

Coupling system with a tow bar and a trailer coupling

PatentActiveEP2674306A1

Innovation

- The implementation of an engagement element arrangement with projections or recesses on the coupling body and the actuating driver, ensuring a secure rotary entrainment through a defined form fit, allowing the actuating driver to continuously and permanently engage with the sensor driver, even during rotations about multiple axes, thereby maintaining accurate angle detection.

Safety Standards and Regulations for Smart Towing

The integration of smart towing technologies, particularly those involving pintle hitch and sensor systems, necessitates adherence to a comprehensive set of safety standards and regulations. These guidelines are crucial for ensuring the safe operation of towing vehicles and trailers equipped with advanced sensing and communication capabilities.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a pivotal role in establishing and enforcing safety standards for towing equipment. The Federal Motor Vehicle Safety Standards (FMVSS) provide specific requirements for vehicle components, including those related to towing. For smart towing systems, FMVSS No. 111 on rearview mirrors and backup cameras is particularly relevant, as it may need to be adapted to accommodate additional sensors and display systems.

The Society of Automotive Engineers (SAE) has developed several standards that are applicable to smart towing technologies. SAE J684 outlines the requirements for fifth wheel and pintle hook mounting, which may need to be updated to include provisions for integrated sensor systems. SAE J2807 establishes towing performance requirements and could be expanded to address the performance of smart towing features.

In Europe, the United Nations Economic Commission for Europe (UNECE) regulations govern vehicle safety standards. Regulation No. 55 on mechanical coupling components between vehicles and trailers may require amendments to incorporate smart towing technologies. The European New Car Assessment Programme (Euro NCAP) could potentially introduce new testing protocols to evaluate the safety benefits of sensor-integrated towing systems.

As smart towing systems often involve wireless communication between the towing vehicle and trailer, compliance with electromagnetic compatibility (EMC) regulations is essential. In the US, the Federal Communications Commission (FCC) regulates EMC, while in Europe, the EMC Directive 2014/30/EU applies. These regulations ensure that smart towing systems do not interfere with other electronic devices or vehicle systems.

Data privacy and cybersecurity are also critical considerations for smart towing technologies. The General Data Protection Regulation (GDPR) in Europe and various state-level privacy laws in the US may impact the collection and processing of data from sensor-equipped towing systems. Additionally, cybersecurity guidelines such as those provided by the Auto-ISAC (Automotive Information Sharing and Analysis Center) should be considered to protect smart towing systems from potential cyber threats.

As the technology evolves, it is likely that new standards and regulations will be developed specifically for smart towing systems. Industry stakeholders, including manufacturers, regulators, and safety organizations, will need to collaborate to establish comprehensive guidelines that address the unique challenges and opportunities presented by sensor-integrated pintle hitch technologies.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a pivotal role in establishing and enforcing safety standards for towing equipment. The Federal Motor Vehicle Safety Standards (FMVSS) provide specific requirements for vehicle components, including those related to towing. For smart towing systems, FMVSS No. 111 on rearview mirrors and backup cameras is particularly relevant, as it may need to be adapted to accommodate additional sensors and display systems.

The Society of Automotive Engineers (SAE) has developed several standards that are applicable to smart towing technologies. SAE J684 outlines the requirements for fifth wheel and pintle hook mounting, which may need to be updated to include provisions for integrated sensor systems. SAE J2807 establishes towing performance requirements and could be expanded to address the performance of smart towing features.

In Europe, the United Nations Economic Commission for Europe (UNECE) regulations govern vehicle safety standards. Regulation No. 55 on mechanical coupling components between vehicles and trailers may require amendments to incorporate smart towing technologies. The European New Car Assessment Programme (Euro NCAP) could potentially introduce new testing protocols to evaluate the safety benefits of sensor-integrated towing systems.

As smart towing systems often involve wireless communication between the towing vehicle and trailer, compliance with electromagnetic compatibility (EMC) regulations is essential. In the US, the Federal Communications Commission (FCC) regulates EMC, while in Europe, the EMC Directive 2014/30/EU applies. These regulations ensure that smart towing systems do not interfere with other electronic devices or vehicle systems.

Data privacy and cybersecurity are also critical considerations for smart towing technologies. The General Data Protection Regulation (GDPR) in Europe and various state-level privacy laws in the US may impact the collection and processing of data from sensor-equipped towing systems. Additionally, cybersecurity guidelines such as those provided by the Auto-ISAC (Automotive Information Sharing and Analysis Center) should be considered to protect smart towing systems from potential cyber threats.

As the technology evolves, it is likely that new standards and regulations will be developed specifically for smart towing systems. Industry stakeholders, including manufacturers, regulators, and safety organizations, will need to collaborate to establish comprehensive guidelines that address the unique challenges and opportunities presented by sensor-integrated pintle hitch technologies.

Cost-Benefit Analysis of Sensor-Integrated Hitches

The integration of sensor technology with pintle hitches represents a significant advancement in towing safety and efficiency. To evaluate the cost-benefit ratio of this innovation, it is crucial to consider both the initial investment and long-term savings potential.

The upfront costs associated with sensor-integrated hitches include the development, manufacturing, and installation of advanced sensors and related electronic systems. These components typically encompass proximity sensors, load cells, and communication modules. While the initial price point may be higher than traditional hitches, economies of scale and technological advancements are expected to gradually reduce production costs over time.

On the benefit side, the enhanced safety features of sensor-integrated hitches offer substantial value. By providing real-time data on trailer alignment, weight distribution, and potential hazards, these systems can significantly reduce the risk of accidents. This translates to lower insurance premiums for fleet operators and individual users alike. Moreover, the prevention of accidents leads to reduced downtime, fewer repair costs, and improved overall operational efficiency.

The improved coupling process enabled by sensor technology contributes to time savings during hitching and unhitching operations. This increased efficiency can result in notable productivity gains, especially for businesses that frequently engage in towing activities. The precise alignment feedback provided by sensors also minimizes wear and tear on both the towing vehicle and trailer, potentially extending the lifespan of equipment and reducing maintenance costs.

From an environmental perspective, sensor-integrated hitches can contribute to fuel efficiency by ensuring optimal weight distribution and reducing aerodynamic drag. Over time, this can lead to substantial fuel savings, particularly for long-haul operations or frequent towing scenarios.

The data collected by these advanced hitches can be leveraged for predictive maintenance, allowing for timely interventions before major issues arise. This proactive approach to maintenance can significantly reduce repair costs and extend the operational life of towing equipment.

While the initial investment in sensor-integrated hitches may be higher, the long-term benefits in terms of safety improvements, operational efficiency, and cost savings present a compelling case for adoption. As the technology matures and becomes more widespread, the cost-benefit ratio is expected to become increasingly favorable, making sensor-integrated hitches an attractive option for both commercial and personal use.

The upfront costs associated with sensor-integrated hitches include the development, manufacturing, and installation of advanced sensors and related electronic systems. These components typically encompass proximity sensors, load cells, and communication modules. While the initial price point may be higher than traditional hitches, economies of scale and technological advancements are expected to gradually reduce production costs over time.

On the benefit side, the enhanced safety features of sensor-integrated hitches offer substantial value. By providing real-time data on trailer alignment, weight distribution, and potential hazards, these systems can significantly reduce the risk of accidents. This translates to lower insurance premiums for fleet operators and individual users alike. Moreover, the prevention of accidents leads to reduced downtime, fewer repair costs, and improved overall operational efficiency.

The improved coupling process enabled by sensor technology contributes to time savings during hitching and unhitching operations. This increased efficiency can result in notable productivity gains, especially for businesses that frequently engage in towing activities. The precise alignment feedback provided by sensors also minimizes wear and tear on both the towing vehicle and trailer, potentially extending the lifespan of equipment and reducing maintenance costs.

From an environmental perspective, sensor-integrated hitches can contribute to fuel efficiency by ensuring optimal weight distribution and reducing aerodynamic drag. Over time, this can lead to substantial fuel savings, particularly for long-haul operations or frequent towing scenarios.

The data collected by these advanced hitches can be leveraged for predictive maintenance, allowing for timely interventions before major issues arise. This proactive approach to maintenance can significantly reduce repair costs and extend the operational life of towing equipment.

While the initial investment in sensor-integrated hitches may be higher, the long-term benefits in terms of safety improvements, operational efficiency, and cost savings present a compelling case for adoption. As the technology matures and becomes more widespread, the cost-benefit ratio is expected to become increasingly favorable, making sensor-integrated hitches an attractive option for both commercial and personal use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!