Pintle Hitch Safety Features in High-Capacity Freight Handling

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, adapting to the increasing demands of high-capacity freight handling. Initially developed as a simple coupling mechanism for military applications in the mid-20th century, the pintle hitch has transformed into a sophisticated and robust system capable of handling substantial loads in various industrial and commercial settings.

In its early stages, the pintle hitch consisted of a basic hook and eye design, providing a quick and easy method for connecting trailers to towing vehicles. This rudimentary design, while effective for its time, had limitations in terms of load capacity and stability, particularly when dealing with heavy freight.

As the need for more efficient and safer freight handling grew, engineers began to refine the pintle hitch design. The 1960s and 1970s saw the introduction of reinforced materials and improved locking mechanisms, enhancing the overall strength and security of the connection. These advancements allowed for increased load capacities, making pintle hitches more suitable for industrial applications.

The 1980s marked a significant leap in pintle hitch technology with the integration of safety features. Manufacturers began incorporating automatic locking systems and visual indicators to ensure proper coupling. These innovations greatly reduced the risk of accidental disconnections, a critical concern in high-capacity freight handling.

In the 1990s and early 2000s, the focus shifted towards improving the ergonomics and ease of use of pintle hitches. Adjustable height mechanisms were introduced, allowing for better alignment between vehicles and trailers of varying sizes. This period also saw the development of more streamlined designs that reduced wind resistance and improved fuel efficiency for long-haul transportation.

Recent years have witnessed a surge in technological integration within pintle hitch systems. Advanced sensors and electronic monitoring devices are now being incorporated to provide real-time data on coupling status, load distribution, and potential safety issues. These smart features enable proactive maintenance and enhance overall operational safety in high-capacity freight handling scenarios.

The evolution of pintle hitches has also been driven by regulatory changes and industry standards. Stricter safety regulations have led to the development of more robust testing procedures and certification processes, ensuring that modern pintle hitches meet or exceed the demanding requirements of heavy-duty applications.

Looking ahead, the future of pintle hitch evolution is likely to focus on further enhancing safety features through the integration of artificial intelligence and predictive maintenance technologies. Additionally, there is a growing trend towards the development of eco-friendly materials and designs that contribute to overall vehicle efficiency and reduced environmental impact in the freight handling industry.

In its early stages, the pintle hitch consisted of a basic hook and eye design, providing a quick and easy method for connecting trailers to towing vehicles. This rudimentary design, while effective for its time, had limitations in terms of load capacity and stability, particularly when dealing with heavy freight.

As the need for more efficient and safer freight handling grew, engineers began to refine the pintle hitch design. The 1960s and 1970s saw the introduction of reinforced materials and improved locking mechanisms, enhancing the overall strength and security of the connection. These advancements allowed for increased load capacities, making pintle hitches more suitable for industrial applications.

The 1980s marked a significant leap in pintle hitch technology with the integration of safety features. Manufacturers began incorporating automatic locking systems and visual indicators to ensure proper coupling. These innovations greatly reduced the risk of accidental disconnections, a critical concern in high-capacity freight handling.

In the 1990s and early 2000s, the focus shifted towards improving the ergonomics and ease of use of pintle hitches. Adjustable height mechanisms were introduced, allowing for better alignment between vehicles and trailers of varying sizes. This period also saw the development of more streamlined designs that reduced wind resistance and improved fuel efficiency for long-haul transportation.

Recent years have witnessed a surge in technological integration within pintle hitch systems. Advanced sensors and electronic monitoring devices are now being incorporated to provide real-time data on coupling status, load distribution, and potential safety issues. These smart features enable proactive maintenance and enhance overall operational safety in high-capacity freight handling scenarios.

The evolution of pintle hitches has also been driven by regulatory changes and industry standards. Stricter safety regulations have led to the development of more robust testing procedures and certification processes, ensuring that modern pintle hitches meet or exceed the demanding requirements of heavy-duty applications.

Looking ahead, the future of pintle hitch evolution is likely to focus on further enhancing safety features through the integration of artificial intelligence and predictive maintenance technologies. Additionally, there is a growing trend towards the development of eco-friendly materials and designs that contribute to overall vehicle efficiency and reduced environmental impact in the freight handling industry.

Freight Market Demands

The global freight market has been experiencing significant growth and transformation, driven by increasing international trade, e-commerce expansion, and evolving supply chain dynamics. This growth has led to a surge in demand for high-capacity freight handling solutions, particularly in the trucking and logistics sectors. The pintle hitch, a crucial component in heavy-duty towing applications, has become a focal point for safety improvements due to the increasing loads and frequencies of freight transportation.

Market analysis indicates that the global freight and logistics market is projected to reach substantial values in the coming years, with a compound annual growth rate (CAGR) outpacing many other industries. This growth is particularly pronounced in regions with rapidly developing economies and expanding infrastructure, such as Asia-Pacific and parts of Africa. The demand for efficient and safe freight handling solutions is not only driven by volume but also by regulatory pressures and industry standards aimed at improving road safety and reducing accidents related to heavy-duty towing.

In the context of pintle hitch safety features for high-capacity freight handling, market demands are multifaceted. Firstly, there is a strong emphasis on increased load capacity without compromising safety. As freight volumes grow, carriers are seeking solutions that allow them to transport heavier loads efficiently, necessitating innovations in pintle hitch design and materials to withstand greater stresses.

Secondly, there is a growing demand for smart, connected solutions in freight handling equipment. This includes pintle hitches with integrated sensors and monitoring systems that can provide real-time data on load distribution, stress levels, and potential safety issues. Such features align with the broader trend of digitalization in the logistics industry, enabling predictive maintenance and enhancing overall operational efficiency.

Thirdly, the market is showing increased interest in modular and adaptable pintle hitch systems. This demand stems from the need for versatility in handling different types of trailers and loads, allowing freight companies to optimize their fleet utilization and adapt to varying customer requirements without compromising on safety.

Environmental considerations are also shaping market demands, with a growing emphasis on lightweight yet durable materials for pintle hitches. This aligns with broader efforts to reduce fuel consumption and emissions in the freight sector, as lighter components contribute to overall vehicle efficiency.

Lastly, there is a significant market pull for enhanced safety features beyond the basic structural integrity of pintle hitches. This includes advanced locking mechanisms, fail-safe systems, and improved ergonomics for easier and safer coupling and uncoupling processes. These safety enhancements are driven not only by regulatory requirements but also by the industry's focus on reducing workplace injuries and improving overall operational safety.

Market analysis indicates that the global freight and logistics market is projected to reach substantial values in the coming years, with a compound annual growth rate (CAGR) outpacing many other industries. This growth is particularly pronounced in regions with rapidly developing economies and expanding infrastructure, such as Asia-Pacific and parts of Africa. The demand for efficient and safe freight handling solutions is not only driven by volume but also by regulatory pressures and industry standards aimed at improving road safety and reducing accidents related to heavy-duty towing.

In the context of pintle hitch safety features for high-capacity freight handling, market demands are multifaceted. Firstly, there is a strong emphasis on increased load capacity without compromising safety. As freight volumes grow, carriers are seeking solutions that allow them to transport heavier loads efficiently, necessitating innovations in pintle hitch design and materials to withstand greater stresses.

Secondly, there is a growing demand for smart, connected solutions in freight handling equipment. This includes pintle hitches with integrated sensors and monitoring systems that can provide real-time data on load distribution, stress levels, and potential safety issues. Such features align with the broader trend of digitalization in the logistics industry, enabling predictive maintenance and enhancing overall operational efficiency.

Thirdly, the market is showing increased interest in modular and adaptable pintle hitch systems. This demand stems from the need for versatility in handling different types of trailers and loads, allowing freight companies to optimize their fleet utilization and adapt to varying customer requirements without compromising on safety.

Environmental considerations are also shaping market demands, with a growing emphasis on lightweight yet durable materials for pintle hitches. This aligns with broader efforts to reduce fuel consumption and emissions in the freight sector, as lighter components contribute to overall vehicle efficiency.

Lastly, there is a significant market pull for enhanced safety features beyond the basic structural integrity of pintle hitches. This includes advanced locking mechanisms, fail-safe systems, and improved ergonomics for easier and safer coupling and uncoupling processes. These safety enhancements are driven not only by regulatory requirements but also by the industry's focus on reducing workplace injuries and improving overall operational safety.

Safety Challenges

The safety challenges associated with pintle hitch systems in high-capacity freight handling are multifaceted and require careful consideration. One of the primary concerns is the potential for coupling failure, which can lead to catastrophic accidents. The immense loads placed on these hitches during transportation of heavy freight increase the risk of material fatigue and structural weakness over time.

Another significant challenge is the proper alignment and secure connection between the pintle hook and lunette ring. Misalignment or incomplete coupling can result in unexpected detachment during transit, posing severe risks to both the vehicle operators and other road users. The dynamic forces experienced during acceleration, braking, and cornering further exacerbate these risks, especially in high-capacity freight scenarios.

Corrosion and wear present ongoing safety challenges for pintle hitch systems. The harsh environmental conditions often encountered in freight operations, including exposure to road salt, moisture, and temperature fluctuations, can accelerate the degradation of critical components. This deterioration may compromise the integrity of the hitch, leading to potential failure points that are not always easily detectable through visual inspection alone.

The human factor also plays a crucial role in pintle hitch safety. Operator error during coupling and uncoupling procedures can lead to accidents or equipment damage. The complexity of high-capacity freight handling often requires specialized knowledge and training to ensure proper use of pintle hitch systems, presenting a challenge in maintaining a workforce that is consistently well-versed in safe operating procedures.

Regulatory compliance and standardization pose additional challenges in the realm of pintle hitch safety. As freight capacities increase, ensuring that hitch systems meet or exceed evolving safety standards becomes more complex. The variability in regulations across different jurisdictions can create confusion and potential safety gaps, particularly for freight operations that span multiple regions or countries.

Monitoring and maintenance of pintle hitch systems present ongoing challenges, especially in high-volume freight operations where downtime must be minimized. Developing effective inspection protocols that can reliably detect wear, damage, or potential failure points without significantly impacting operational efficiency is a persistent challenge in the industry.

Lastly, the integration of advanced safety features, such as electronic monitoring systems or automated coupling mechanisms, introduces new complexities. While these technologies offer the potential for enhanced safety, they also bring challenges related to reliability, compatibility with existing equipment, and the need for specialized maintenance and troubleshooting skills.

Another significant challenge is the proper alignment and secure connection between the pintle hook and lunette ring. Misalignment or incomplete coupling can result in unexpected detachment during transit, posing severe risks to both the vehicle operators and other road users. The dynamic forces experienced during acceleration, braking, and cornering further exacerbate these risks, especially in high-capacity freight scenarios.

Corrosion and wear present ongoing safety challenges for pintle hitch systems. The harsh environmental conditions often encountered in freight operations, including exposure to road salt, moisture, and temperature fluctuations, can accelerate the degradation of critical components. This deterioration may compromise the integrity of the hitch, leading to potential failure points that are not always easily detectable through visual inspection alone.

The human factor also plays a crucial role in pintle hitch safety. Operator error during coupling and uncoupling procedures can lead to accidents or equipment damage. The complexity of high-capacity freight handling often requires specialized knowledge and training to ensure proper use of pintle hitch systems, presenting a challenge in maintaining a workforce that is consistently well-versed in safe operating procedures.

Regulatory compliance and standardization pose additional challenges in the realm of pintle hitch safety. As freight capacities increase, ensuring that hitch systems meet or exceed evolving safety standards becomes more complex. The variability in regulations across different jurisdictions can create confusion and potential safety gaps, particularly for freight operations that span multiple regions or countries.

Monitoring and maintenance of pintle hitch systems present ongoing challenges, especially in high-volume freight operations where downtime must be minimized. Developing effective inspection protocols that can reliably detect wear, damage, or potential failure points without significantly impacting operational efficiency is a persistent challenge in the industry.

Lastly, the integration of advanced safety features, such as electronic monitoring systems or automated coupling mechanisms, introduces new complexities. While these technologies offer the potential for enhanced safety, they also bring challenges related to reliability, compatibility with existing equipment, and the need for specialized maintenance and troubleshooting skills.

Current Safety Solutions

01 Locking mechanisms for pintle hitches

Various locking mechanisms are employed to secure the connection between the pintle hook and the lunette ring. These include spring-loaded latches, safety pins, and automatic locking systems that prevent accidental disconnection during travel. Such mechanisms enhance the overall safety of the pintle hitch by ensuring a secure coupling between the towing vehicle and the trailer.- Locking mechanisms for pintle hitches: Various locking mechanisms are employed in pintle hitches to ensure secure coupling between the towing vehicle and the trailer. These mechanisms may include spring-loaded latches, safety pins, or automatic locking systems that prevent accidental disconnection during travel. Such features enhance the overall safety of the towing setup by minimizing the risk of trailer separation.

- Sensor and alert systems for pintle hitches: Advanced pintle hitches incorporate sensor and alert systems to monitor the connection status and notify the driver of any issues. These systems may include visual or audible indicators to signal proper coupling, detect potential disconnections, or warn about excessive load stress. Such features improve safety by providing real-time feedback to the driver about the hitch's status.

- Adjustable and articulating pintle hitches: Some pintle hitches are designed with adjustable or articulating components to accommodate various trailer heights and improve maneuverability. These features allow for better weight distribution, reduced stress on the towing vehicle, and enhanced stability during turns or on uneven terrain. The improved flexibility contributes to safer towing operations in diverse conditions.

- Integrated brake and lighting systems: Advanced pintle hitches may incorporate integrated brake and lighting systems to ensure proper communication between the towing vehicle and the trailer. These systems can include built-in brake controllers, electrical connections for trailer lights, and fail-safe mechanisms to activate trailer brakes in case of disconnection. Such features enhance overall safety by improving visibility and braking performance of the towing setup.

- Reinforced construction and impact resistance: Safety-focused pintle hitches often feature reinforced construction and impact-resistant designs to withstand high stress and potential collisions. These may include heavy-duty materials, shock-absorbing components, or structural reinforcements that distribute forces more evenly. Such features enhance the durability and reliability of the hitch, reducing the risk of failure under extreme conditions.

02 Sensor and alert systems

Advanced pintle hitches incorporate sensor and alert systems to monitor the connection status and notify the driver of any issues. These systems may include visual indicators, audible alarms, or integration with the vehicle's dashboard display. They can detect improper coupling, excessive movement, or potential failures, providing real-time feedback to enhance safety during towing operations.Expand Specific Solutions03 Shock absorption and stabilization features

To improve towing stability and reduce stress on both the towing vehicle and trailer, some pintle hitches incorporate shock absorption and stabilization features. These may include rubber or polyurethane bushings, air-ride systems, or hydraulic dampers. Such features help minimize vibration, absorb road shocks, and enhance overall towing safety, especially during sudden stops or on uneven terrain.Expand Specific Solutions04 Adjustable and articulating designs

Pintle hitches with adjustable and articulating designs offer improved safety by accommodating various towing scenarios and terrains. These features allow for better weight distribution, enhanced maneuverability, and reduced stress on the towing components. Adjustable height mechanisms and multi-axis articulation help maintain proper alignment between the towing vehicle and trailer, reducing the risk of jackknifing or rollover incidents.Expand Specific Solutions05 Integrated brake and lighting systems

Some advanced pintle hitch designs incorporate integrated brake and lighting systems to enhance safety during towing. These systems ensure proper synchronization of brake lights and turn signals between the towing vehicle and trailer. They may also include features such as breakaway systems that automatically activate the trailer brakes in case of an unexpected separation, further improving overall towing safety.Expand Specific Solutions

Industry Leaders

The research on pintle hitch safety features in high-capacity freight handling is in a developing stage, with the market showing significant growth potential. The technology's maturity varies among key players, with established automotive companies like Ford Global Technologies LLC and Deere & Co. likely leading in innovation. Emerging players such as Wabash National Corp. and WESTFALIA-Automotive GmbH are also contributing to advancements. The competitive landscape is diverse, including traditional vehicle manufacturers, specialized equipment producers, and research institutions like the Naval Research Laboratory, indicating a multifaceted approach to safety feature development in this niche but critical area of freight handling technology.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has made significant strides in pintle hitch safety for high-capacity freight handling. Their research has led to the development of an adaptive coupling system that automatically adjusts its configuration based on the load and driving conditions[1]. This system utilizes advanced AI algorithms to predict and compensate for potential instabilities during transit. Ford has also integrated their pintle hitch design with the vehicle's electronic stability control system, allowing for real-time adjustments to improve overall vehicle dynamics when towing heavy loads[2]. Additionally, they have developed a novel anti-jackknifing technology specifically for pintle hitch applications, which employs selective braking and torque vectoring to maintain trailer alignment in challenging situations[3]. The company has also introduced a wireless communication system between the towing vehicle and trailer, enabling constant monitoring of crucial parameters such as temperature, pressure, and load distribution[4].

Strengths: Adaptive coupling system for optimized performance; Integration with vehicle stability systems; Advanced anti-jackknifing technology. Weaknesses: High complexity may lead to increased production costs; Dependence on sophisticated electronic systems could potentially reduce reliability in extreme conditions.

Deere & Co.

Technical Solution: Deere & Co. has focused its research on enhancing pintle hitch safety for agricultural and construction applications involving high-capacity freight handling. Their innovative approach includes the development of a smart pintle hitch system that incorporates machine learning algorithms to adapt to various terrain conditions and load types[1]. This system continuously analyzes data from multiple sensors, including strain gauges and accelerometers, to optimize coupling performance and prevent potential failures. Deere has also introduced a hydraulic dampening system integrated into the pintle hitch, which actively reduces shock loads and improves stability during off-road operations[2]. Furthermore, they have developed a unique articulation monitoring system that uses advanced imaging technology to detect and prevent dangerous angles between the towing vehicle and trailer, particularly useful in tight maneuvering situations[3]. The company has also implemented a predictive maintenance feature that uses historical data and real-time monitoring to forecast potential issues before they occur, ensuring optimal safety and minimizing downtime[4].

Strengths: Adaptive system for various terrains and loads; Active hydraulic dampening for improved stability; Advanced articulation monitoring for enhanced safety. Weaknesses: May be overly complex for simple towing applications; Potentially higher cost due to advanced features.

Key Safety Innovations

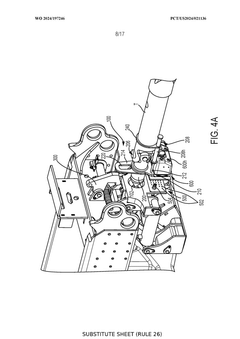

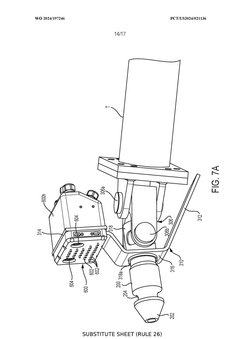

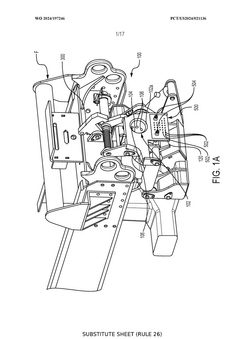

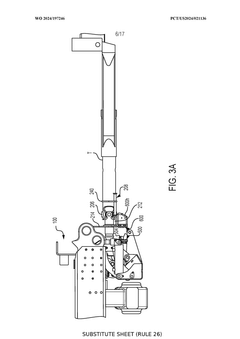

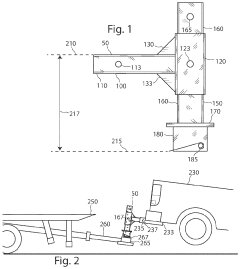

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Hitch

PatentActiveUS20220266641A1

Innovation

- A hitch design comprising a T-member with a receiver stein, sleeve, and coupling member, featuring a gooseneck coupler head and adjustable post, which allows for secure attachment to a vehicle and tow truck, enabling stable towing by aligning the receiver stein with the vehicle's receiver tube and securing the ball within the coupler using a locking mechanism.

Regulatory Framework

The regulatory framework surrounding pintle hitch safety features in high-capacity freight handling is a complex and evolving landscape. At the federal level in the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) play crucial roles in establishing and enforcing safety standards for commercial vehicles and their components.

The Federal Motor Carrier Safety Administration (FMCSA) has specific regulations pertaining to coupling devices, including pintle hitches, under 49 CFR § 393.70. These regulations mandate that all coupling devices must be securely fastened to the vehicle chassis and capable of withstanding prescribed forces in various directions. Additionally, the regulations require safety devices to prevent accidental separation of towed and towing vehicles.

On a state level, regulations can vary, with some states imposing additional requirements or more stringent standards. For instance, California's Commercial Vehicle Safety Alliance (CVSA) conducts rigorous inspections that include detailed examinations of coupling devices, including pintle hitches, to ensure compliance with both federal and state regulations.

Internationally, standards such as the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 provide guidelines for mechanical coupling components between vehicles. While not directly applicable in all countries, these standards often influence global best practices and regulatory developments.

The Society of Automotive Engineers (SAE) has also developed relevant standards, such as SAE J847, which covers performance criteria for pintle hooks used in heavy-duty applications. These industry standards, while not always legally binding, are often referenced in regulatory frameworks and adopted by manufacturers as best practices.

Recent technological advancements in high-capacity freight handling have prompted regulatory bodies to consider updates to existing frameworks. For example, the integration of electronic sensors and smart coupling systems in pintle hitches has raised questions about cybersecurity and the need for new safety protocols.

As the industry moves towards autonomous and semi-autonomous vehicles, regulators are grappling with how to adapt existing safety standards to these new technologies. This includes considerations for remote monitoring and control of coupling devices, as well as fail-safe mechanisms in case of system failures.

The Federal Motor Carrier Safety Administration (FMCSA) has specific regulations pertaining to coupling devices, including pintle hitches, under 49 CFR § 393.70. These regulations mandate that all coupling devices must be securely fastened to the vehicle chassis and capable of withstanding prescribed forces in various directions. Additionally, the regulations require safety devices to prevent accidental separation of towed and towing vehicles.

On a state level, regulations can vary, with some states imposing additional requirements or more stringent standards. For instance, California's Commercial Vehicle Safety Alliance (CVSA) conducts rigorous inspections that include detailed examinations of coupling devices, including pintle hitches, to ensure compliance with both federal and state regulations.

Internationally, standards such as the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 provide guidelines for mechanical coupling components between vehicles. While not directly applicable in all countries, these standards often influence global best practices and regulatory developments.

The Society of Automotive Engineers (SAE) has also developed relevant standards, such as SAE J847, which covers performance criteria for pintle hooks used in heavy-duty applications. These industry standards, while not always legally binding, are often referenced in regulatory frameworks and adopted by manufacturers as best practices.

Recent technological advancements in high-capacity freight handling have prompted regulatory bodies to consider updates to existing frameworks. For example, the integration of electronic sensors and smart coupling systems in pintle hitches has raised questions about cybersecurity and the need for new safety protocols.

As the industry moves towards autonomous and semi-autonomous vehicles, regulators are grappling with how to adapt existing safety standards to these new technologies. This includes considerations for remote monitoring and control of coupling devices, as well as fail-safe mechanisms in case of system failures.

Economic Impact

The economic impact of enhanced pintle hitch safety features in high-capacity freight handling extends far beyond the immediate transportation sector. Improved safety mechanisms can lead to significant cost savings for freight companies by reducing accidents, minimizing cargo damage, and lowering insurance premiums. These savings can potentially be passed on to consumers, contributing to overall economic efficiency.

The implementation of advanced safety features in pintle hitches may initially increase manufacturing costs. However, this investment is likely to yield long-term benefits through reduced maintenance expenses and extended equipment lifespan. As safety standards evolve, manufacturers who lead in innovation may gain a competitive edge, potentially expanding their market share and stimulating job growth in the industry.

Enhanced safety features can also have ripple effects on related industries. For instance, improved stability and security in freight transport could lead to increased confidence in just-in-time delivery systems, benefiting industries that rely on precise logistics. This could result in more efficient supply chains and inventory management across various sectors of the economy.

The reduction in accidents and cargo losses due to improved pintle hitch safety can have broader economic implications. Fewer road incidents involving heavy freight vehicles can lead to decreased traffic congestion and reduced infrastructure damage, potentially lowering public expenditure on road maintenance and emergency services. This, in turn, could allow for more efficient allocation of public resources.

Furthermore, the development and implementation of advanced safety technologies in freight handling can drive innovation in related fields. This may spur research and development activities, creating new opportunities for technological advancements and potentially opening up new markets for safety-related products and services.

From a global perspective, countries and regions that adopt stringent safety standards for high-capacity freight handling may gain a reputation for reliability and efficiency in international trade. This could attract more business and investment, contributing to economic growth and competitiveness in the global market.

In conclusion, while the initial costs of implementing advanced pintle hitch safety features may be substantial, the long-term economic benefits are likely to be significant and far-reaching. These benefits extend beyond the immediate transportation sector, potentially impacting various aspects of the economy through improved efficiency, reduced costs, and stimulated innovation.

The implementation of advanced safety features in pintle hitches may initially increase manufacturing costs. However, this investment is likely to yield long-term benefits through reduced maintenance expenses and extended equipment lifespan. As safety standards evolve, manufacturers who lead in innovation may gain a competitive edge, potentially expanding their market share and stimulating job growth in the industry.

Enhanced safety features can also have ripple effects on related industries. For instance, improved stability and security in freight transport could lead to increased confidence in just-in-time delivery systems, benefiting industries that rely on precise logistics. This could result in more efficient supply chains and inventory management across various sectors of the economy.

The reduction in accidents and cargo losses due to improved pintle hitch safety can have broader economic implications. Fewer road incidents involving heavy freight vehicles can lead to decreased traffic congestion and reduced infrastructure damage, potentially lowering public expenditure on road maintenance and emergency services. This, in turn, could allow for more efficient allocation of public resources.

Furthermore, the development and implementation of advanced safety technologies in freight handling can drive innovation in related fields. This may spur research and development activities, creating new opportunities for technological advancements and potentially opening up new markets for safety-related products and services.

From a global perspective, countries and regions that adopt stringent safety standards for high-capacity freight handling may gain a reputation for reliability and efficiency in international trade. This could attract more business and investment, contributing to economic growth and competitiveness in the global market.

In conclusion, while the initial costs of implementing advanced pintle hitch safety features may be substantial, the long-term economic benefits are likely to be significant and far-reaching. These benefits extend beyond the immediate transportation sector, potentially impacting various aspects of the economy through improved efficiency, reduced costs, and stimulated innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!