Zirconia in Electronics: Reducing Thermal Conductivity

Zirconia Thermal Conductivity Background and Objectives

Zirconia, a versatile ceramic material, has gained significant attention in the electronics industry due to its exceptional properties. The research on reducing the thermal conductivity of zirconia in electronics stems from the increasing demand for efficient thermal management solutions in advanced electronic devices. As electronic components continue to shrink in size while simultaneously increasing in power density, the need for materials that can effectively dissipate heat becomes paramount.

The thermal conductivity of zirconia has been a subject of extensive study over the past few decades. Initially, zirconia was primarily valued for its high melting point, excellent mechanical strength, and chemical stability. However, as the electronics industry evolved, the focus shifted towards exploring zirconia's potential as a thermal barrier coating and insulating material. This transition in research objectives aligns with the broader trend of developing multifunctional materials that can address multiple challenges in electronic device design.

The historical development of zirconia research in electronics can be traced back to the 1980s when the material's unique phase transformation properties were first exploited. Since then, the scientific community has made significant strides in understanding the fundamental mechanisms that govern zirconia's thermal behavior. These advancements have paved the way for targeted research aimed at manipulating zirconia's thermal conductivity to suit specific electronic applications.

Current research objectives in this field are multifaceted. Primarily, scientists and engineers are focusing on developing novel methods to reduce zirconia's thermal conductivity without compromising its other desirable properties. This involves exploring various strategies such as doping, nanostructuring, and creating composite materials. The ultimate goal is to achieve a balance between low thermal conductivity and other critical parameters such as electrical insulation, mechanical strength, and chemical stability.

Another key objective is to enhance the scalability and cost-effectiveness of low thermal conductivity zirconia production. As the demand for advanced thermal management solutions in electronics continues to grow, there is a pressing need to develop manufacturing processes that can produce these materials at scale while maintaining consistent quality and performance.

Furthermore, researchers are also investigating the long-term stability and reliability of modified zirconia materials under various operating conditions. This is crucial for ensuring that the reduced thermal conductivity properties remain stable over the lifetime of electronic devices, which often operate under challenging thermal and mechanical stress conditions.

In conclusion, the background and objectives of research on reducing the thermal conductivity of zirconia in electronics reflect a dynamic and evolving field. The ongoing efforts in this area are driven by the ever-increasing demands of the electronics industry for more efficient thermal management solutions. As research progresses, it is expected that new insights and innovations will continue to emerge, potentially revolutionizing thermal management strategies in next-generation electronic devices.

Market Demand for Low Thermal Conductivity Zirconia

The market demand for low thermal conductivity zirconia in electronics is experiencing significant growth, driven by the increasing need for thermal management solutions in advanced electronic devices. As electronic components become more compact and powerful, the challenge of dissipating heat efficiently has become paramount. Zirconia, with its unique properties, has emerged as a promising material for addressing these thermal management issues.

In the semiconductor industry, there is a growing demand for zirconia-based thermal barrier coatings. These coatings are essential for protecting sensitive electronic components from excessive heat generated during operation. The ability to reduce thermal conductivity in zirconia is particularly valuable in high-performance computing, where processors generate substantial heat that must be effectively managed to maintain optimal performance and longevity.

The automotive electronics sector is another key driver of demand for low thermal conductivity zirconia. As vehicles incorporate more advanced electronic systems, including those for electric and hybrid powertrains, the need for effective thermal management solutions has intensified. Zirconia-based materials with reduced thermal conductivity are being sought after for use in various automotive electronic components to enhance reliability and performance under demanding operating conditions.

In the rapidly expanding 5G infrastructure market, the demand for low thermal conductivity zirconia is also on the rise. 5G base stations and related equipment generate significant heat due to their high-power operations. Zirconia-based thermal management solutions are being explored to address these challenges, ensuring the longevity and reliability of 5G network components.

The consumer electronics market, including smartphones, tablets, and wearable devices, represents another significant area of demand. As these devices become more powerful and feature-rich, managing heat dissipation within their compact form factors has become increasingly challenging. Low thermal conductivity zirconia is being investigated for use in thermal management systems and as a component in advanced packaging materials to address these issues.

The aerospace and defense sectors are also showing interest in low thermal conductivity zirconia for electronic applications. In these industries, electronic systems often operate in extreme environments, making effective thermal management critical for ensuring reliability and performance. Zirconia-based solutions are being explored for use in avionics, communication systems, and other mission-critical electronic components.

As the Internet of Things (IoT) continues to expand, the demand for low thermal conductivity zirconia in small, distributed electronic devices is expected to grow. These devices often operate in challenging environments and require robust thermal management solutions to ensure long-term reliability and performance.

Current Challenges in Reducing Zirconia Thermal Conductivity

Reducing the thermal conductivity of zirconia in electronics presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is maintaining the structural integrity and mechanical properties of zirconia while simultaneously decreasing its thermal conductivity. Zirconia is valued for its high strength and toughness, and any modifications to reduce thermal conductivity must not compromise these essential characteristics.

Another major challenge lies in the inherent nature of zirconia's crystal structure. The material's thermal conductivity is closely tied to its atomic arrangement and phonon transport mechanisms. Altering these fundamental properties without introducing detrimental effects on other desirable attributes requires precise control at the nanoscale level, which is technologically demanding and often difficult to achieve in large-scale production.

The development of effective doping strategies presents yet another hurdle. While doping zirconia with various elements can potentially reduce thermal conductivity, finding the optimal dopants and concentrations that maximize thermal resistance without negatively impacting electrical properties or introducing unwanted phase transitions is a complex task. Moreover, ensuring uniform distribution of dopants throughout the zirconia matrix remains a significant manufacturing challenge.

Researchers also face difficulties in accurately measuring and characterizing the thermal properties of modified zirconia at the micro and nanoscale. Traditional measurement techniques may not be suitable for thin films or nanostructured materials, necessitating the development of new, more sensitive measurement methodologies.

The trade-off between reducing thermal conductivity and maintaining other critical properties for electronic applications, such as dielectric strength and reliability under high-temperature conditions, poses an ongoing challenge. Balancing these competing requirements often involves complex material design and engineering solutions that are not easily achieved.

Furthermore, the cost-effectiveness and scalability of potential solutions remain significant barriers. Many promising approaches for reducing zirconia's thermal conductivity, such as creating nanostructured composites or engineered defects, are currently limited by high production costs or difficulties in scaling up to industrial levels.

Lastly, the integration of thermally optimized zirconia into existing electronic manufacturing processes presents its own set of challenges. Compatibility with current fabrication techniques, thermal management systems, and device architectures must be carefully considered to ensure the successful implementation of any new zirconia-based materials in electronic applications.

Existing Methods for Reducing Zirconia Thermal Conductivity

01 Thermal conductivity enhancement of zirconia

Various methods are employed to enhance the thermal conductivity of zirconia-based materials. These include doping with other elements, controlling the microstructure, and creating composite materials. Such enhancements are crucial for applications requiring improved heat transfer properties while maintaining zirconia's other beneficial characteristics.- Thermal conductivity enhancement of zirconia: Various methods are employed to enhance the thermal conductivity of zirconia-based materials. These include doping with other elements, controlling the microstructure, and creating composite materials. The goal is to improve heat transfer properties while maintaining other desirable characteristics of zirconia.

- Zirconia coatings for thermal barrier applications: Zirconia coatings are developed for use as thermal barriers in high-temperature environments. These coatings are designed to have low thermal conductivity while providing protection against heat and corrosion. The composition and structure of the coatings are optimized to achieve the desired thermal properties.

- Measurement and characterization of zirconia thermal conductivity: Various techniques and methods are developed to accurately measure and characterize the thermal conductivity of zirconia materials. These include both experimental and theoretical approaches, allowing for a better understanding of the material's thermal behavior under different conditions.

- Zirconia-based composites for improved thermal properties: Composite materials incorporating zirconia are developed to achieve specific thermal conductivity characteristics. These composites may combine zirconia with other ceramics, metals, or polymers to tailor the overall thermal properties for specific applications.

- Influence of crystal structure on zirconia thermal conductivity: The relationship between the crystal structure of zirconia and its thermal conductivity is investigated. Different phases and crystalline forms of zirconia are studied to understand how they affect heat transfer properties, leading to the development of materials with optimized thermal characteristics.

02 Zirconia-based thermal barrier coatings

Zirconia is widely used in thermal barrier coatings due to its low thermal conductivity. Research focuses on optimizing the composition and structure of these coatings to further reduce thermal conductivity while maintaining mechanical stability at high temperatures. This is particularly important in aerospace and gas turbine applications.Expand Specific Solutions03 Measurement and characterization of zirconia thermal conductivity

Accurate measurement and characterization of zirconia's thermal conductivity are essential for material development and quality control. Various techniques and instruments are used to determine thermal conductivity under different conditions, including temperature ranges and material compositions.Expand Specific Solutions04 Influence of porosity on zirconia thermal conductivity

The porosity of zirconia materials significantly affects their thermal conductivity. Research explores the relationship between pore structure, size distribution, and overall porosity on the thermal properties of zirconia. This understanding is crucial for designing materials with specific thermal insulation characteristics.Expand Specific Solutions05 Applications utilizing zirconia's thermal properties

Zirconia's unique thermal properties are exploited in various applications beyond thermal barrier coatings. These include electronic components, fuel cells, and high-temperature sensors. The material's combination of low thermal conductivity and high temperature stability makes it valuable in diverse technological fields.Expand Specific Solutions

Key Players in Zirconia-based Electronic Materials

The research on reducing thermal conductivity of Zirconia in electronics is in a growth phase, with increasing market demand driven by the need for improved thermal management in electronic devices. The global market for advanced ceramics, including Zirconia, is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Kyocera Corp., Saint-Gobain Ceramics & Plastics, Inc., and CoorsTek, Inc. leading innovation. Academic institutions such as Zhejiang University and the University of Electronic Science & Technology of China are also contributing to advancements. The involvement of major players like Toshiba Corp. and Mitsubishi Materials Corp. suggests a high level of industry interest and investment in this technology.

Kyocera Corp.

CoorsTek, Inc.

Innovative Approaches in Zirconia Thermal Engineering

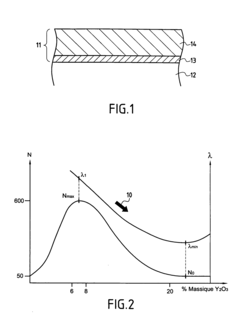

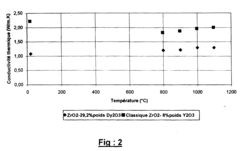

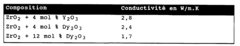

- A novel zirconia-based thermal barrier composition is developed, incorporating a trivalent oxide to stabilize zirconia and introduce oxygen vacancies, combined with a pentavalent oxide to control the oxygen vacancy content, resulting in a partially stabilized zirconia structure with reduced thermal conductivity and enhanced high-temperature strength.

- A new ceramic composition combining zirconia with dysprosium oxide, which stabilizes the zirconia and introduces point defects to reduce phonon thermal conductivity, is developed, along with a method involving a bonding sub-layer for deposition on superalloy parts.

Environmental Impact of Zirconia in Electronics

The environmental impact of zirconia in electronics is a critical consideration as the use of this material continues to expand in various electronic applications. Zirconia, known for its excellent thermal and electrical insulation properties, has become increasingly prevalent in electronic components and devices. However, its widespread adoption raises concerns about potential environmental consequences throughout its lifecycle.

During the production phase of zirconia-based electronic components, the extraction and processing of zirconium minerals can lead to significant environmental disruptions. Mining activities often result in habitat destruction, soil erosion, and water pollution. The refining process to obtain high-purity zirconia involves energy-intensive methods and chemical treatments, contributing to greenhouse gas emissions and the generation of hazardous waste materials.

In the manufacturing stage, the incorporation of zirconia into electronic devices presents additional environmental challenges. The production of zirconia-based components typically requires high-temperature sintering processes, consuming substantial amounts of energy and potentially releasing harmful emissions. Moreover, the use of various additives and dopants to enhance zirconia's properties may introduce toxic substances into the manufacturing waste stream.

The operational phase of zirconia-containing electronics generally has a lower environmental impact compared to production. Zirconia's excellent thermal insulation properties can contribute to improved energy efficiency in electronic devices, potentially reducing overall energy consumption and associated carbon emissions during use. However, the long-term durability of zirconia components may lead to extended product lifespans, which could delay the adoption of more environmentally friendly technologies.

End-of-life management of zirconia-based electronics poses significant environmental concerns. The recycling of zirconia from electronic waste is challenging due to its high melting point and chemical stability. Consequently, many zirconia-containing components end up in landfills or incinerators, contributing to soil and air pollution. The potential leaching of zirconium and associated elements from discarded electronics into groundwater systems presents long-term environmental risks.

To mitigate these environmental impacts, several strategies are being explored. Research into more sustainable zirconia production methods, such as using renewable energy sources and developing closed-loop manufacturing processes, aims to reduce the carbon footprint of zirconia-based electronics. Additionally, efforts to improve recycling technologies for zirconia-containing devices are underway, focusing on efficient separation and recovery techniques to minimize waste and promote circular economy principles in the electronics industry.

Zirconia Thermal Properties Testing and Standardization

The standardization of zirconia thermal properties testing is crucial for ensuring consistent and reliable measurements across the electronics industry. This process involves establishing uniform testing protocols, defining specific measurement techniques, and creating reference materials to calibrate testing equipment. The primary focus is on accurately determining the thermal conductivity of zirconia, which is a critical parameter for its application in electronic components.

One of the key aspects of standardization is the development of precise testing methodologies. These methods must account for various factors that can influence thermal conductivity measurements, such as sample preparation, temperature control, and environmental conditions. For instance, the ASTM C1470 standard provides guidelines for thermal conductivity testing of ceramics using the guarded-hot-plate method, which can be adapted for zirconia testing.

To ensure reproducibility and comparability of results, it is essential to establish reference materials with known thermal properties. These materials serve as benchmarks for calibrating testing equipment and validating measurement techniques. The National Institute of Standards and Technology (NIST) has developed several standard reference materials for thermal conductivity, which can be used as a basis for creating zirconia-specific standards.

Interlaboratory comparison studies play a vital role in the standardization process. These studies involve multiple laboratories performing thermal conductivity measurements on identical zirconia samples using standardized procedures. The results are then analyzed to assess the consistency and accuracy of the testing methods across different facilities. Such studies help identify potential sources of variability and refine testing protocols.

The development of specialized testing equipment for zirconia thermal properties is another critical aspect of standardization. This may include the design of custom sample holders, temperature control systems, and measurement devices tailored to the unique characteristics of zirconia. Standardizing the equipment specifications ensures that measurements are consistent regardless of the specific apparatus used.

As the electronics industry continues to evolve, it is essential to regularly review and update testing standards to accommodate new applications and emerging technologies. This may involve incorporating advanced measurement techniques, such as laser flash analysis or transient plane source methods, which offer improved accuracy or faster testing times for zirconia thermal conductivity measurements.

Collaboration between industry stakeholders, research institutions, and standards organizations is crucial for developing comprehensive and widely accepted testing standards. This collaborative approach ensures that the standards meet the needs of both manufacturers and end-users while incorporating the latest scientific knowledge and technological advancements in the field of zirconia thermal properties testing.