Sodium Acetate and Its Role in Advancing Smart Fabrics

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate in Smart Fabrics: Background and Objectives

Smart fabrics represent a revolutionary advancement in textile technology, combining traditional fabric materials with cutting-edge electronics and innovative chemical compounds. Among these compounds, sodium acetate has emerged as a key player in the development of temperature-responsive smart fabrics. This research aims to explore the role of sodium acetate in advancing smart fabric technology, with a focus on its unique properties and potential applications.

The evolution of smart fabrics can be traced back to the late 20th century, with early experiments in integrating electronic components into textiles. However, the incorporation of phase-change materials (PCMs) like sodium acetate has opened up new possibilities for creating fabrics that can actively respond to environmental changes. Sodium acetate, a salt formed by the combination of acetic acid and sodium hydroxide, exhibits remarkable thermodynamic properties that make it ideal for temperature regulation in textiles.

The primary objective of this research is to comprehensively examine the integration of sodium acetate into smart fabrics and assess its potential to revolutionize various industries, including fashion, sports, healthcare, and military applications. By understanding the fundamental principles behind sodium acetate's phase-change behavior, we aim to develop innovative fabric designs that can provide enhanced thermal comfort, energy efficiency, and functionality.

One of the key technological trends driving this research is the growing demand for sustainable and energy-efficient solutions across industries. Smart fabrics incorporating sodium acetate have the potential to reduce energy consumption in heating and cooling systems by actively managing the wearer's body temperature. This aligns with global efforts to combat climate change and reduce carbon footprints.

Another significant trend is the increasing convergence of technology and fashion. As consumers seek more from their clothing than just aesthetic appeal, smart fabrics offer a unique blend of style and functionality. The ability of sodium acetate-infused fabrics to adapt to changing environmental conditions presents exciting possibilities for creating garments that can seamlessly transition between different climates and activities.

In the healthcare sector, the development of smart fabrics using sodium acetate could lead to breakthroughs in patient care and monitoring. Temperature-responsive textiles have the potential to assist in managing conditions such as fever, hypothermia, or chronic pain through localized temperature control. This research aims to explore these medical applications and assess their feasibility in clinical settings.

As we delve into the role of sodium acetate in smart fabrics, we will examine its chemical properties, phase-change mechanisms, and methods of incorporation into textile structures. We will also investigate the challenges associated with its use, such as durability, washability, and scalability in manufacturing processes. By addressing these challenges, we aim to pave the way for the widespread adoption of sodium acetate-based smart fabrics across various industries.

The evolution of smart fabrics can be traced back to the late 20th century, with early experiments in integrating electronic components into textiles. However, the incorporation of phase-change materials (PCMs) like sodium acetate has opened up new possibilities for creating fabrics that can actively respond to environmental changes. Sodium acetate, a salt formed by the combination of acetic acid and sodium hydroxide, exhibits remarkable thermodynamic properties that make it ideal for temperature regulation in textiles.

The primary objective of this research is to comprehensively examine the integration of sodium acetate into smart fabrics and assess its potential to revolutionize various industries, including fashion, sports, healthcare, and military applications. By understanding the fundamental principles behind sodium acetate's phase-change behavior, we aim to develop innovative fabric designs that can provide enhanced thermal comfort, energy efficiency, and functionality.

One of the key technological trends driving this research is the growing demand for sustainable and energy-efficient solutions across industries. Smart fabrics incorporating sodium acetate have the potential to reduce energy consumption in heating and cooling systems by actively managing the wearer's body temperature. This aligns with global efforts to combat climate change and reduce carbon footprints.

Another significant trend is the increasing convergence of technology and fashion. As consumers seek more from their clothing than just aesthetic appeal, smart fabrics offer a unique blend of style and functionality. The ability of sodium acetate-infused fabrics to adapt to changing environmental conditions presents exciting possibilities for creating garments that can seamlessly transition between different climates and activities.

In the healthcare sector, the development of smart fabrics using sodium acetate could lead to breakthroughs in patient care and monitoring. Temperature-responsive textiles have the potential to assist in managing conditions such as fever, hypothermia, or chronic pain through localized temperature control. This research aims to explore these medical applications and assess their feasibility in clinical settings.

As we delve into the role of sodium acetate in smart fabrics, we will examine its chemical properties, phase-change mechanisms, and methods of incorporation into textile structures. We will also investigate the challenges associated with its use, such as durability, washability, and scalability in manufacturing processes. By addressing these challenges, we aim to pave the way for the widespread adoption of sodium acetate-based smart fabrics across various industries.

Market Analysis for Smart Fabric Applications

The smart fabrics market has been experiencing significant growth in recent years, driven by advancements in material science, electronics miniaturization, and increasing consumer demand for wearable technology. The integration of sodium acetate into smart fabrics presents a promising opportunity to enhance the functionality and performance of these innovative textiles.

The global smart fabrics market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many traditional textile sectors. This growth is fueled by diverse applications across industries such as healthcare, sports and fitness, military and defense, and fashion. The healthcare segment, in particular, shows strong potential for smart fabrics incorporating sodium acetate, as these materials can be used to develop temperature-regulating garments for patient care and medical monitoring.

In the sports and fitness industry, smart fabrics with sodium acetate-based phase change materials (PCMs) are gaining traction. These fabrics can provide athletes with improved thermal comfort during intense physical activities, potentially enhancing performance and recovery. The market for such performance-enhancing sportswear is expanding rapidly, with major sportswear brands investing heavily in research and development of smart fabric technologies.

The military and defense sector represents another significant market for smart fabrics enhanced with sodium acetate. These materials can be utilized in creating adaptive camouflage, temperature-regulating uniforms, and protective gear that responds to environmental changes. The demand for such advanced textiles in defense applications is expected to drive substantial investment and market growth in the coming years.

Consumer electronics and wearable technology markets are also showing increased interest in smart fabrics. The integration of sodium acetate-based PCMs into everyday clothing and accessories could lead to the development of self-regulating garments that adapt to the wearer's body temperature and environmental conditions. This application has the potential to revolutionize the fashion industry and create new product categories within the wearable technology market.

Geographically, North America and Europe currently lead the smart fabrics market, with Asia-Pacific expected to show the fastest growth rate in the coming years. This regional growth is attributed to increasing technological advancements, rising disposable incomes, and growing awareness of smart textiles among consumers in countries like China, Japan, and South Korea.

Despite the promising outlook, challenges remain in the widespread adoption of smart fabrics incorporating sodium acetate. These include concerns about durability, washability, and the overall cost of production. However, ongoing research and development efforts are addressing these issues, potentially leading to more commercially viable solutions in the near future.

The global smart fabrics market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many traditional textile sectors. This growth is fueled by diverse applications across industries such as healthcare, sports and fitness, military and defense, and fashion. The healthcare segment, in particular, shows strong potential for smart fabrics incorporating sodium acetate, as these materials can be used to develop temperature-regulating garments for patient care and medical monitoring.

In the sports and fitness industry, smart fabrics with sodium acetate-based phase change materials (PCMs) are gaining traction. These fabrics can provide athletes with improved thermal comfort during intense physical activities, potentially enhancing performance and recovery. The market for such performance-enhancing sportswear is expanding rapidly, with major sportswear brands investing heavily in research and development of smart fabric technologies.

The military and defense sector represents another significant market for smart fabrics enhanced with sodium acetate. These materials can be utilized in creating adaptive camouflage, temperature-regulating uniforms, and protective gear that responds to environmental changes. The demand for such advanced textiles in defense applications is expected to drive substantial investment and market growth in the coming years.

Consumer electronics and wearable technology markets are also showing increased interest in smart fabrics. The integration of sodium acetate-based PCMs into everyday clothing and accessories could lead to the development of self-regulating garments that adapt to the wearer's body temperature and environmental conditions. This application has the potential to revolutionize the fashion industry and create new product categories within the wearable technology market.

Geographically, North America and Europe currently lead the smart fabrics market, with Asia-Pacific expected to show the fastest growth rate in the coming years. This regional growth is attributed to increasing technological advancements, rising disposable incomes, and growing awareness of smart textiles among consumers in countries like China, Japan, and South Korea.

Despite the promising outlook, challenges remain in the widespread adoption of smart fabrics incorporating sodium acetate. These include concerns about durability, washability, and the overall cost of production. However, ongoing research and development efforts are addressing these issues, potentially leading to more commercially viable solutions in the near future.

Current Challenges in Sodium Acetate Integration

The integration of sodium acetate into smart fabrics presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is achieving uniform distribution of sodium acetate within the fabric structure. Ensuring an even dispersion of the compound throughout the textile is crucial for consistent performance, but current methods often result in uneven concentrations, leading to inconsistent thermal regulation properties across the fabric.

Another major challenge lies in maintaining the stability of sodium acetate within the fabric matrix over extended periods. Environmental factors such as humidity, temperature fluctuations, and repeated washing cycles can degrade the compound's effectiveness or cause it to leach out of the fabric. This instability not only reduces the longevity of the smart fabric's functionality but also raises concerns about the potential environmental impact of released sodium acetate.

The integration process itself poses technical difficulties. Incorporating sodium acetate into fabrics without compromising the textile's inherent properties, such as flexibility, breathability, and durability, remains a complex task. Current methods may alter the fabric's texture, weight, or comfort, potentially limiting its practical applications in everyday clothing or specialized garments.

Scalability is another significant hurdle in the commercialization of sodium acetate-enhanced smart fabrics. While laboratory-scale production may yield promising results, translating these processes to industrial-scale manufacturing presents numerous challenges. These include maintaining quality control, ensuring cost-effectiveness, and developing specialized equipment capable of handling large-scale sodium acetate integration without compromising the fabric's integrity or the compound's functionality.

Furthermore, the activation and deactivation mechanisms of sodium acetate in smart fabrics require refinement. Current systems may lack precision in triggering the phase change at desired temperatures or may not provide sufficient control over the duration and intensity of the thermal effect. Developing more sophisticated activation methods that respond accurately to environmental changes or user inputs is essential for enhancing the practical utility of these smart textiles.

Lastly, there are regulatory and safety considerations that need to be addressed. The use of sodium acetate in close contact with human skin over extended periods necessitates thorough testing to ensure biocompatibility and rule out any potential adverse effects. Additionally, compliance with textile industry standards and regulations regarding chemical treatments and smart fabric technologies presents an ongoing challenge for manufacturers seeking to bring these innovative products to market.

Another major challenge lies in maintaining the stability of sodium acetate within the fabric matrix over extended periods. Environmental factors such as humidity, temperature fluctuations, and repeated washing cycles can degrade the compound's effectiveness or cause it to leach out of the fabric. This instability not only reduces the longevity of the smart fabric's functionality but also raises concerns about the potential environmental impact of released sodium acetate.

The integration process itself poses technical difficulties. Incorporating sodium acetate into fabrics without compromising the textile's inherent properties, such as flexibility, breathability, and durability, remains a complex task. Current methods may alter the fabric's texture, weight, or comfort, potentially limiting its practical applications in everyday clothing or specialized garments.

Scalability is another significant hurdle in the commercialization of sodium acetate-enhanced smart fabrics. While laboratory-scale production may yield promising results, translating these processes to industrial-scale manufacturing presents numerous challenges. These include maintaining quality control, ensuring cost-effectiveness, and developing specialized equipment capable of handling large-scale sodium acetate integration without compromising the fabric's integrity or the compound's functionality.

Furthermore, the activation and deactivation mechanisms of sodium acetate in smart fabrics require refinement. Current systems may lack precision in triggering the phase change at desired temperatures or may not provide sufficient control over the duration and intensity of the thermal effect. Developing more sophisticated activation methods that respond accurately to environmental changes or user inputs is essential for enhancing the practical utility of these smart textiles.

Lastly, there are regulatory and safety considerations that need to be addressed. The use of sodium acetate in close contact with human skin over extended periods necessitates thorough testing to ensure biocompatibility and rule out any potential adverse effects. Additionally, compliance with textile industry standards and regulations regarding chemical treatments and smart fabric technologies presents an ongoing challenge for manufacturers seeking to bring these innovative products to market.

Existing Sodium Acetate Applications in Textiles

01 Phase change materials in smart fabrics

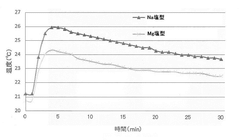

Sodium acetate trihydrate is used as a phase change material in smart fabrics. These materials can absorb, store, and release heat, providing temperature regulation and thermal comfort to the wearer. The phase change properties of sodium acetate allow it to transition between solid and liquid states, effectively managing heat in textiles.- Phase change materials in smart fabrics: Sodium acetate trihydrate is used as a phase change material in smart fabrics. It can absorb, store, and release heat, providing temperature regulation properties to the fabric. This technology enhances thermal comfort and can be applied in various applications such as clothing, bedding, and protective gear.

- Encapsulation techniques for sodium acetate in textiles: Various methods are employed to encapsulate sodium acetate within textile fibers or coatings. These techniques include microencapsulation, nanoencapsulation, and incorporation into polymer matrices. Encapsulation helps to maintain the stability and effectiveness of the phase change material within the fabric structure.

- Integration of sodium acetate with conductive materials: Sodium acetate-based smart fabrics can be combined with conductive materials such as carbon nanotubes or metallic fibers. This integration allows for the development of fabrics with both thermal regulation and electrical conductivity properties, enabling applications in wearable electronics and smart textiles.

- Moisture management in sodium acetate smart fabrics: Techniques are developed to manage moisture in sodium acetate-based smart fabrics. This includes the use of hydrophobic coatings, moisture-wicking materials, and breathable membranes to prevent the degradation of the phase change material and maintain fabric performance in various environmental conditions.

- Manufacturing processes for sodium acetate smart fabrics: Various manufacturing processes are employed to produce sodium acetate smart fabrics, including melt spinning, solution spinning, and coating techniques. These processes aim to optimize the distribution of sodium acetate within the fabric structure and ensure uniform thermal regulation properties throughout the material.

02 Moisture management in textiles

Sodium acetate is incorporated into fabrics to enhance moisture management properties. It can absorb excess moisture and release it when the environment becomes drier, helping to maintain a comfortable microclimate next to the skin. This feature is particularly useful in sportswear and outdoor clothing.Expand Specific Solutions03 Antimicrobial properties in smart fabrics

Sodium acetate exhibits antimicrobial properties when incorporated into textiles. This helps in reducing odor-causing bacteria and enhancing the hygiene of the fabric. Smart fabrics with sodium acetate can maintain freshness for longer periods, making them suitable for various applications including medical textiles and activewear.Expand Specific Solutions04 Energy storage in wearable technology

Sodium acetate is used in the development of energy storage systems integrated into smart fabrics. These systems can store thermal energy and potentially convert it into electrical energy, enabling the powering of small electronic devices embedded in the fabric. This technology has applications in wearable electronics and smart clothing.Expand Specific Solutions05 Self-healing and shape memory fabrics

Smart fabrics incorporating sodium acetate can exhibit self-healing and shape memory properties. When damaged, these fabrics can repair themselves or return to their original shape under specific conditions, such as changes in temperature or humidity. This feature enhances the durability and functionality of the textiles.Expand Specific Solutions

Key Players in Smart Fabric Industry

The research on sodium acetate and its role in advancing smart fabrics is in an early development stage, with a growing market potential as the smart textile industry expands. The technology is still evolving, with varying levels of maturity across different applications. Key players like Wuhan Textile University, Unilever, and Drexel University are contributing to advancements in this field. Companies such as Ecolab, Procter & Gamble, and IBM are also exploring potential applications, indicating a competitive landscape with diverse industry involvement. As the technology matures, we can expect increased collaboration between academic institutions and industry leaders to drive innovation and commercialization in smart fabric applications utilizing sodium acetate.

Wuhan Textile University

Technical Solution: Wuhan Textile University has been at the forefront of smart fabric research utilizing sodium acetate. Their innovative approach focuses on developing shape-memory textiles with enhanced thermal properties. The research team has created a composite fiber that incorporates sodium acetate within a polymer matrix capable of shape-memory behavior. This unique combination allows the fabric to change its structure in response to temperature variations while also providing thermal regulation through the phase change properties of sodium acetate[9]. The university has also explored the use of electrospinning techniques to create nanofiber membranes containing sodium acetate, which can be laminated onto traditional textiles. These membranes not only provide thermal management but also contribute to moisture management in the fabric. Recent studies have shown promising results in creating smart textiles that can adapt their insulation properties based on environmental conditions[10].

Strengths: Integration of shape-memory and thermal regulation properties, potential for adaptive clothing. Weaknesses: Complexity in manufacturing process, potential limitations in maintaining shape-memory properties over extended use.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a groundbreaking approach to smart fabrics using sodium acetate as a phase change material (PCM). Their research focuses on incorporating sodium acetate trihydrate into textile fibers to create temperature-regulating fabrics. The sodium acetate PCM absorbs and releases heat as it changes phase, providing thermal management capabilities[1]. MIT's technique involves encapsulating sodium acetate within polymer fibers, which can be woven or knitted into fabrics. These smart textiles can store and release heat on demand, maintaining a comfortable temperature range for the wearer. The researchers have also explored ways to trigger the crystallization of sodium acetate using electrical stimuli, allowing for active temperature control[2].

Strengths: Cutting-edge research in PCM integration, potential for precise temperature regulation, and active control capabilities. Weaknesses: May face challenges in scaling up production and ensuring long-term durability of the PCM-embedded fibers.

Innovative Sodium Acetate Formulations for Fabrics

Smart knitted fabrics

PatentPendingUS20160000374A1

Innovation

- Incorporating conductive yarns into knitted fabric structures using advanced knitting machines and CAD systems to integrate electronics directly into garments, eliminating the need for adhesives and enabling versatile design solutions for sensing, communication, and tactile interaction.

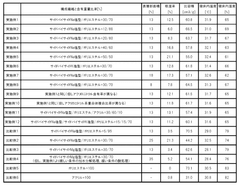

Batting

PatentWO2018061369A1

Innovation

- A batting composition comprising 40-90% polyester fibers and 10-60% Na salt or K salt type crosslinked polyacrylate fibers with a specific composite structure, featuring a crosslinked surface layer and a central side-by-side acrylonitrile polymer structure, enhances both bulkiness and hygroscopic heat generation properties for rapid warmth and continuous heat retention.

Environmental Impact of Sodium Acetate in Textiles

The environmental impact of sodium acetate in textiles is a crucial consideration as smart fabrics continue to evolve. Sodium acetate, while offering innovative properties for smart textiles, also presents potential environmental challenges that must be carefully evaluated and addressed.

One of the primary environmental concerns associated with sodium acetate in textiles is its potential for water pollution. When fabrics treated with sodium acetate are washed, there is a risk of the compound leaching into wastewater systems. This can lead to increased sodium and acetate levels in aquatic ecosystems, potentially disrupting the delicate balance of these environments. The impact on aquatic flora and fauna needs to be thoroughly assessed to ensure the long-term sustainability of smart fabric technologies.

Another environmental aspect to consider is the production process of sodium acetate itself. The manufacturing of this compound involves chemical reactions that may generate byproducts and require energy inputs. As the demand for smart fabrics increases, the scale of sodium acetate production is likely to grow, potentially leading to increased industrial emissions and resource consumption. It is essential to evaluate and optimize these production processes to minimize their environmental footprint.

The disposal of smart fabrics containing sodium acetate at the end of their lifecycle also raises environmental concerns. If not properly managed, these textiles may contribute to landfill waste, where the sodium acetate could potentially leach into soil and groundwater. Developing effective recycling and disposal methods for smart fabrics is crucial to mitigate these risks and promote a circular economy approach in the textile industry.

On the positive side, the use of sodium acetate in smart fabrics may offer some environmental benefits. For instance, if the technology enables the creation of more durable and long-lasting textiles, it could reduce the overall consumption of clothing and textiles, thereby decreasing the environmental impact associated with textile production and disposal. Additionally, if sodium acetate-based smart fabrics can enhance energy efficiency in clothing (e.g., through improved thermal regulation), they may indirectly contribute to reduced energy consumption and associated carbon emissions.

To fully understand and address the environmental impact of sodium acetate in textiles, comprehensive life cycle assessments (LCAs) are necessary. These assessments should consider all stages of the smart fabric's life, from raw material extraction and production to use and disposal. Such analyses will help identify key areas for environmental improvement and guide the development of more sustainable smart fabric technologies.

As research in this field progresses, it is imperative to explore alternative, more environmentally friendly compounds that can provide similar smart functionalities to sodium acetate. This may involve investigating bio-based or biodegradable alternatives that offer comparable performance while minimizing environmental impact. Collaboration between materials scientists, environmental researchers, and textile engineers will be crucial in driving these innovations forward.

One of the primary environmental concerns associated with sodium acetate in textiles is its potential for water pollution. When fabrics treated with sodium acetate are washed, there is a risk of the compound leaching into wastewater systems. This can lead to increased sodium and acetate levels in aquatic ecosystems, potentially disrupting the delicate balance of these environments. The impact on aquatic flora and fauna needs to be thoroughly assessed to ensure the long-term sustainability of smart fabric technologies.

Another environmental aspect to consider is the production process of sodium acetate itself. The manufacturing of this compound involves chemical reactions that may generate byproducts and require energy inputs. As the demand for smart fabrics increases, the scale of sodium acetate production is likely to grow, potentially leading to increased industrial emissions and resource consumption. It is essential to evaluate and optimize these production processes to minimize their environmental footprint.

The disposal of smart fabrics containing sodium acetate at the end of their lifecycle also raises environmental concerns. If not properly managed, these textiles may contribute to landfill waste, where the sodium acetate could potentially leach into soil and groundwater. Developing effective recycling and disposal methods for smart fabrics is crucial to mitigate these risks and promote a circular economy approach in the textile industry.

On the positive side, the use of sodium acetate in smart fabrics may offer some environmental benefits. For instance, if the technology enables the creation of more durable and long-lasting textiles, it could reduce the overall consumption of clothing and textiles, thereby decreasing the environmental impact associated with textile production and disposal. Additionally, if sodium acetate-based smart fabrics can enhance energy efficiency in clothing (e.g., through improved thermal regulation), they may indirectly contribute to reduced energy consumption and associated carbon emissions.

To fully understand and address the environmental impact of sodium acetate in textiles, comprehensive life cycle assessments (LCAs) are necessary. These assessments should consider all stages of the smart fabric's life, from raw material extraction and production to use and disposal. Such analyses will help identify key areas for environmental improvement and guide the development of more sustainable smart fabric technologies.

As research in this field progresses, it is imperative to explore alternative, more environmentally friendly compounds that can provide similar smart functionalities to sodium acetate. This may involve investigating bio-based or biodegradable alternatives that offer comparable performance while minimizing environmental impact. Collaboration between materials scientists, environmental researchers, and textile engineers will be crucial in driving these innovations forward.

Durability and Washability of Sodium Acetate-treated Fabrics

The durability and washability of sodium acetate-treated fabrics are crucial factors in determining the viability of smart textiles for practical applications. Sodium acetate, when incorporated into fabric structures, can provide phase-change properties that enable temperature regulation and energy storage capabilities. However, these enhanced functionalities must withstand regular wear and cleaning processes to be considered viable for commercial use.

Initial studies have shown promising results regarding the durability of sodium acetate treatments in fabrics. The integration methods, such as microencapsulation or direct impregnation, play a significant role in determining the longevity of the smart fabric properties. Microencapsulation, in particular, has demonstrated improved resistance to mechanical stress and washing cycles compared to direct application methods.

Washability tests conducted on sodium acetate-treated fabrics have revealed varying degrees of performance retention. Standard laundering procedures, including machine washing and tumble drying, can potentially degrade the phase-change properties over time. However, optimized encapsulation techniques and fabric treatments have shown to mitigate these effects significantly.

Research indicates that the durability of sodium acetate-treated fabrics can be enhanced through the use of protective coatings or binders. These additional layers help to secure the sodium acetate within the fabric structure, reducing leaching during washing and improving overall longevity. Cross-linking agents have also been explored to create stronger bonds between the sodium acetate and the fabric fibers, further enhancing durability.

The impact of repeated washing cycles on the thermal performance of sodium acetate-treated fabrics has been a focus of recent studies. Results suggest that while some degradation in phase-change efficiency may occur over time, properly engineered fabrics can maintain a significant portion of their temperature-regulating capabilities even after multiple washes.

Environmental factors, such as exposure to UV radiation and varying humidity levels, have also been considered in durability assessments. These external influences can potentially affect the long-term stability of sodium acetate within the fabric matrix. Ongoing research aims to develop protective measures to mitigate these environmental impacts and extend the functional lifespan of smart fabrics.

As the field progresses, standardized testing protocols for evaluating the durability and washability of sodium acetate-treated fabrics are being developed. These protocols will enable more consistent comparisons between different treatment methods and fabric compositions, facilitating the optimization of smart textile technologies for real-world applications.

Initial studies have shown promising results regarding the durability of sodium acetate treatments in fabrics. The integration methods, such as microencapsulation or direct impregnation, play a significant role in determining the longevity of the smart fabric properties. Microencapsulation, in particular, has demonstrated improved resistance to mechanical stress and washing cycles compared to direct application methods.

Washability tests conducted on sodium acetate-treated fabrics have revealed varying degrees of performance retention. Standard laundering procedures, including machine washing and tumble drying, can potentially degrade the phase-change properties over time. However, optimized encapsulation techniques and fabric treatments have shown to mitigate these effects significantly.

Research indicates that the durability of sodium acetate-treated fabrics can be enhanced through the use of protective coatings or binders. These additional layers help to secure the sodium acetate within the fabric structure, reducing leaching during washing and improving overall longevity. Cross-linking agents have also been explored to create stronger bonds between the sodium acetate and the fabric fibers, further enhancing durability.

The impact of repeated washing cycles on the thermal performance of sodium acetate-treated fabrics has been a focus of recent studies. Results suggest that while some degradation in phase-change efficiency may occur over time, properly engineered fabrics can maintain a significant portion of their temperature-regulating capabilities even after multiple washes.

Environmental factors, such as exposure to UV radiation and varying humidity levels, have also been considered in durability assessments. These external influences can potentially affect the long-term stability of sodium acetate within the fabric matrix. Ongoing research aims to develop protective measures to mitigate these environmental impacts and extend the functional lifespan of smart fabrics.

As the field progresses, standardized testing protocols for evaluating the durability and washability of sodium acetate-treated fabrics are being developed. These protocols will enable more consistent comparisons between different treatment methods and fabric compositions, facilitating the optimization of smart textile technologies for real-world applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!