Sodium Acetate: The Future of Resilient Food Preservation

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Preservation Background and Objectives

Food preservation has been a critical concern for human civilization since ancient times. As global populations continue to grow and food security becomes increasingly important, the need for effective and sustainable preservation methods has never been more pressing. Sodium acetate, a compound with unique properties, has emerged as a promising candidate for future food preservation solutions.

Historically, various methods such as drying, salting, and fermentation have been used to extend food shelf life. In recent decades, chemical preservatives and advanced packaging technologies have dominated the industry. However, growing consumer demand for natural, minimally processed foods has sparked interest in alternative preservation techniques. This shift in consumer preferences, coupled with concerns about food waste and the environmental impact of traditional preservation methods, has led researchers to explore innovative solutions.

Sodium acetate, also known as sodium ethanoate, is a salt formed by the combination of acetic acid and sodium hydroxide. It has been used in various industrial applications, including as a de-icer and in textile manufacturing. Its potential in food preservation lies in its ability to inhibit microbial growth and its relatively benign nature compared to some synthetic preservatives.

The primary objective of researching sodium acetate as a food preservation solution is to develop a resilient, effective, and consumer-friendly method that can significantly extend the shelf life of various food products. This research aims to address several key challenges in the food industry, including reducing food waste, improving food safety, and meeting the growing demand for clean label products.

One of the main goals is to understand the mechanisms by which sodium acetate inhibits microbial growth and how it can be optimized for different food matrices. Researchers are investigating its efficacy against various spoilage organisms and foodborne pathogens, as well as its impact on food quality attributes such as texture, flavor, and nutritional value.

Another important objective is to explore the potential synergistic effects of combining sodium acetate with other natural preservatives or preservation techniques. This could lead to the development of multi-hurdle preservation systems that are more effective and versatile than current methods.

Furthermore, the research aims to assess the environmental impact and sustainability of sodium acetate as a food preservative. This includes evaluating its production processes, potential for biodegradation, and overall lifecycle analysis compared to conventional preservatives.

As the food industry continues to evolve, the development of sodium acetate as a preservation solution represents a convergence of technological innovation and consumer-driven demand for safer, more natural food products. The outcomes of this research could potentially revolutionize food preservation practices, contributing to global food security and sustainability efforts.

Historically, various methods such as drying, salting, and fermentation have been used to extend food shelf life. In recent decades, chemical preservatives and advanced packaging technologies have dominated the industry. However, growing consumer demand for natural, minimally processed foods has sparked interest in alternative preservation techniques. This shift in consumer preferences, coupled with concerns about food waste and the environmental impact of traditional preservation methods, has led researchers to explore innovative solutions.

Sodium acetate, also known as sodium ethanoate, is a salt formed by the combination of acetic acid and sodium hydroxide. It has been used in various industrial applications, including as a de-icer and in textile manufacturing. Its potential in food preservation lies in its ability to inhibit microbial growth and its relatively benign nature compared to some synthetic preservatives.

The primary objective of researching sodium acetate as a food preservation solution is to develop a resilient, effective, and consumer-friendly method that can significantly extend the shelf life of various food products. This research aims to address several key challenges in the food industry, including reducing food waste, improving food safety, and meeting the growing demand for clean label products.

One of the main goals is to understand the mechanisms by which sodium acetate inhibits microbial growth and how it can be optimized for different food matrices. Researchers are investigating its efficacy against various spoilage organisms and foodborne pathogens, as well as its impact on food quality attributes such as texture, flavor, and nutritional value.

Another important objective is to explore the potential synergistic effects of combining sodium acetate with other natural preservatives or preservation techniques. This could lead to the development of multi-hurdle preservation systems that are more effective and versatile than current methods.

Furthermore, the research aims to assess the environmental impact and sustainability of sodium acetate as a food preservative. This includes evaluating its production processes, potential for biodegradation, and overall lifecycle analysis compared to conventional preservatives.

As the food industry continues to evolve, the development of sodium acetate as a preservation solution represents a convergence of technological innovation and consumer-driven demand for safer, more natural food products. The outcomes of this research could potentially revolutionize food preservation practices, contributing to global food security and sustainability efforts.

Market Analysis for Advanced Food Preservation Methods

The global food preservation market is experiencing significant growth, driven by increasing consumer demand for longer shelf life, convenience, and food safety. Advanced food preservation methods, including the potential use of sodium acetate, are gaining traction due to their ability to address these consumer needs while also meeting industry requirements for cost-effectiveness and sustainability.

The market for advanced food preservation methods is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is fueled by several factors, including the rising global population, urbanization, and changing dietary habits. Consumers are increasingly seeking minimally processed foods with extended shelf life, creating opportunities for innovative preservation techniques.

Sodium acetate, as a potential future solution for resilient food preservation, aligns well with current market trends. Its natural origin and versatile applications make it an attractive option for food manufacturers looking to meet clean label demands. The market for clean label ingredients is expected to reach a value of $51.14 billion by 2024, indicating a strong potential for sodium acetate adoption.

The food and beverage industry, which is the primary end-user of advanced preservation methods, is witnessing a shift towards more natural and sustainable solutions. This trend is particularly pronounced in developed markets such as North America and Europe, where consumers are increasingly conscious of food additives and their potential health impacts. As a result, there is growing interest in alternatives to traditional chemical preservatives, creating a favorable market environment for sodium acetate-based solutions.

Emerging economies in Asia-Pacific and Latin America present significant growth opportunities for advanced food preservation methods. These regions are experiencing rapid urbanization and a growing middle class, leading to increased demand for processed and packaged foods with extended shelf life. The Asia-Pacific region, in particular, is expected to be the fastest-growing market for food preservatives, with a CAGR of 5.2% from 2021 to 2026.

The COVID-19 pandemic has further accelerated the demand for food preservation solutions, as consumers prioritize food safety and longer shelf life. This has led to increased investment in research and development of novel preservation techniques, including those based on sodium acetate. The global food safety testing market, which is closely linked to preservation methods, is projected to reach $24.4 billion by 2025, reflecting the growing emphasis on food safety and quality.

However, the market for advanced food preservation methods also faces challenges. Stringent regulations regarding food additives and preservatives, particularly in developed markets, may impact the adoption of new technologies. Additionally, consumer skepticism towards food additives and the growing preference for fresh, minimally processed foods could pose barriers to market growth. These factors underscore the importance of developing preservation solutions that are not only effective but also perceived as natural and safe by consumers.

The market for advanced food preservation methods is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is fueled by several factors, including the rising global population, urbanization, and changing dietary habits. Consumers are increasingly seeking minimally processed foods with extended shelf life, creating opportunities for innovative preservation techniques.

Sodium acetate, as a potential future solution for resilient food preservation, aligns well with current market trends. Its natural origin and versatile applications make it an attractive option for food manufacturers looking to meet clean label demands. The market for clean label ingredients is expected to reach a value of $51.14 billion by 2024, indicating a strong potential for sodium acetate adoption.

The food and beverage industry, which is the primary end-user of advanced preservation methods, is witnessing a shift towards more natural and sustainable solutions. This trend is particularly pronounced in developed markets such as North America and Europe, where consumers are increasingly conscious of food additives and their potential health impacts. As a result, there is growing interest in alternatives to traditional chemical preservatives, creating a favorable market environment for sodium acetate-based solutions.

Emerging economies in Asia-Pacific and Latin America present significant growth opportunities for advanced food preservation methods. These regions are experiencing rapid urbanization and a growing middle class, leading to increased demand for processed and packaged foods with extended shelf life. The Asia-Pacific region, in particular, is expected to be the fastest-growing market for food preservatives, with a CAGR of 5.2% from 2021 to 2026.

The COVID-19 pandemic has further accelerated the demand for food preservation solutions, as consumers prioritize food safety and longer shelf life. This has led to increased investment in research and development of novel preservation techniques, including those based on sodium acetate. The global food safety testing market, which is closely linked to preservation methods, is projected to reach $24.4 billion by 2025, reflecting the growing emphasis on food safety and quality.

However, the market for advanced food preservation methods also faces challenges. Stringent regulations regarding food additives and preservatives, particularly in developed markets, may impact the adoption of new technologies. Additionally, consumer skepticism towards food additives and the growing preference for fresh, minimally processed foods could pose barriers to market growth. These factors underscore the importance of developing preservation solutions that are not only effective but also perceived as natural and safe by consumers.

Current Challenges in Sodium Acetate Food Preservation

Despite the promising potential of sodium acetate as a food preservative, several challenges currently hinder its widespread adoption and effectiveness in the food industry. One of the primary concerns is the impact on food taste and texture. Sodium acetate, when used in high concentrations, can impart a slightly salty or vinegary flavor to food products, potentially altering their organoleptic properties. This challenge is particularly pronounced in delicate or mildly flavored foods, where even subtle changes in taste can be noticeable to consumers.

Another significant hurdle is the limited understanding of sodium acetate's interactions with various food matrices. Different food compositions can affect the preservative's efficacy and stability, leading to inconsistent results across various product types. This variability makes it challenging for food manufacturers to establish standardized protocols for sodium acetate application across their product lines.

The regulatory landscape surrounding sodium acetate usage in food preservation also presents obstacles. While generally recognized as safe (GRAS) by the FDA, there are still variations in regulations and acceptable usage levels across different countries and regions. This regulatory inconsistency complicates the global distribution of food products preserved with sodium acetate, potentially limiting its adoption by multinational food companies.

From a technical standpoint, the solubility and distribution of sodium acetate within food products pose challenges. Ensuring uniform distribution throughout the food matrix is crucial for effective preservation, but achieving this can be difficult, especially in complex, multi-component food systems. Inadequate distribution may lead to localized areas of high concentration, affecting taste, or areas of low concentration, compromising preservative efficacy.

The stability of sodium acetate under various processing and storage conditions is another area of concern. Extreme temperatures, pH fluctuations, and interactions with other food ingredients can potentially affect its preservative properties. This instability may necessitate additional protective measures or formulation adjustments, adding complexity to food production processes.

Furthermore, there is a growing consumer demand for "clean label" products with minimal additives. While sodium acetate is a relatively simple compound, its chemical-sounding name may deter some consumers seeking more "natural" preservation methods. This perception challenge requires careful consideration in product marketing and labeling strategies.

Lastly, the cost-effectiveness of sodium acetate compared to traditional preservatives remains a point of debate. While it shows promise in extending shelf life, the overall economic impact of its implementation, including potential changes in packaging, storage, and distribution practices, needs further evaluation to justify widespread adoption in the food industry.

Another significant hurdle is the limited understanding of sodium acetate's interactions with various food matrices. Different food compositions can affect the preservative's efficacy and stability, leading to inconsistent results across various product types. This variability makes it challenging for food manufacturers to establish standardized protocols for sodium acetate application across their product lines.

The regulatory landscape surrounding sodium acetate usage in food preservation also presents obstacles. While generally recognized as safe (GRAS) by the FDA, there are still variations in regulations and acceptable usage levels across different countries and regions. This regulatory inconsistency complicates the global distribution of food products preserved with sodium acetate, potentially limiting its adoption by multinational food companies.

From a technical standpoint, the solubility and distribution of sodium acetate within food products pose challenges. Ensuring uniform distribution throughout the food matrix is crucial for effective preservation, but achieving this can be difficult, especially in complex, multi-component food systems. Inadequate distribution may lead to localized areas of high concentration, affecting taste, or areas of low concentration, compromising preservative efficacy.

The stability of sodium acetate under various processing and storage conditions is another area of concern. Extreme temperatures, pH fluctuations, and interactions with other food ingredients can potentially affect its preservative properties. This instability may necessitate additional protective measures or formulation adjustments, adding complexity to food production processes.

Furthermore, there is a growing consumer demand for "clean label" products with minimal additives. While sodium acetate is a relatively simple compound, its chemical-sounding name may deter some consumers seeking more "natural" preservation methods. This perception challenge requires careful consideration in product marketing and labeling strategies.

Lastly, the cost-effectiveness of sodium acetate compared to traditional preservatives remains a point of debate. While it shows promise in extending shelf life, the overall economic impact of its implementation, including potential changes in packaging, storage, and distribution practices, needs further evaluation to justify widespread adoption in the food industry.

Existing Sodium Acetate Preservation Solutions

01 Sodium acetate in heat storage materials

Sodium acetate is used in heat storage materials due to its phase change properties. It can absorb and release heat during phase transitions, making it suitable for thermal energy storage applications. These materials can be used in various industries for temperature regulation and energy conservation.- Sodium acetate in heat storage materials: Sodium acetate is utilized in heat storage materials due to its phase change properties. It can absorb and release heat during phase transitions, making it suitable for thermal energy storage applications. These materials can be used in various industries for temperature regulation and energy conservation.

- Sodium acetate in resilient compositions: Sodium acetate is incorporated into resilient compositions to enhance their mechanical properties. These compositions can be used in various applications where resilience and durability are required, such as in construction materials or protective coatings.

- Sodium acetate in chemical processes: Sodium acetate is used in various chemical processes as a reagent or catalyst. It plays a role in reactions such as esterification, saponification, and as a pH buffer. Its use in these processes can improve efficiency and yield in industrial applications.

- Sodium acetate in food preservation: Sodium acetate is employed as a food preservative and flavor enhancer. It helps to control acidity and inhibit microbial growth in food products, extending their shelf life. This application is particularly useful in the food industry for maintaining product quality and safety.

- Sodium acetate in environmental applications: Sodium acetate is utilized in environmental applications such as wastewater treatment and air pollution control. It can act as a neutralizing agent, pH buffer, or assist in the removal of contaminants. These applications contribute to environmental protection and sustainability efforts.

02 Sodium acetate in resilient compositions

Sodium acetate is incorporated into resilient compositions to enhance their mechanical properties. These compositions can be used in various applications where resilience and durability are required, such as in construction materials, automotive parts, or consumer products.Expand Specific Solutions03 Sodium acetate in chemical processes

Sodium acetate is utilized in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as esterification, saponification, and pH control. The compound's properties make it valuable in industrial chemical applications and laboratory settings.Expand Specific Solutions04 Sodium acetate in food and pharmaceutical applications

Sodium acetate is used in food and pharmaceutical industries as a preservative, flavoring agent, and pH regulator. It can enhance the shelf life of products, contribute to flavor profiles, and maintain the stability of formulations in various consumable and medicinal products.Expand Specific Solutions05 Sodium acetate in environmental applications

Sodium acetate finds applications in environmental technologies, such as wastewater treatment, air purification, and soil remediation. Its properties allow it to act as a neutralizing agent, adsorbent, or microbial nutrient in various environmental processes aimed at pollution control and ecosystem restoration.Expand Specific Solutions

Key Players in Food Preservation Industry

The research on sodium acetate as a future solution for resilient food preservation is in its early stages, indicating an emerging market with significant growth potential. The global food preservatives market, valued at $2.5 billion in 2020, is expected to expand rapidly due to increasing demand for processed foods and extended shelf life. While sodium acetate technology is not yet fully mature, several key players are actively involved in its development. Companies like Purac Biochem BV, Chemische Fabrik Budenheim KG, and AQUANOVA AG are leading research efforts, leveraging their expertise in food additives and preservation technologies. Traditional food industry giants such as Kraft Foods Group Brands LLC and Kewpie Corp. are also exploring sodium acetate applications, signaling growing interest from established market leaders.

Purac Biochem BV

Technical Solution: Purac Biochem BV has developed an innovative approach to using sodium acetate for food preservation. Their technology involves incorporating sodium acetate into a controlled release system, which allows for a gradual and sustained release of the preservative compound. This method enhances the antimicrobial efficacy of sodium acetate while minimizing its impact on food taste and texture. The company has also explored combining sodium acetate with other natural preservatives to create synergistic effects, potentially reducing the overall amount of preservatives needed[1][3]. Additionally, Purac has invested in research to optimize the production of sodium acetate from renewable resources, aligning with sustainability goals in the food industry[5].

Strengths: Enhanced antimicrobial efficacy, controlled release technology, potential for reduced preservative use. Weaknesses: May require specialized packaging or application methods, potentially higher production costs compared to traditional preservatives.

Asama Chemical Co. Ltd.

Technical Solution: Asama Chemical Co. Ltd. has focused on developing high-purity sodium acetate formulations specifically tailored for food preservation applications. Their research has led to the creation of a proprietary crystallization process that produces sodium acetate with exceptionally low impurity levels, enhancing its safety profile for food use. The company has also explored the use of sodium acetate in combination with other food-grade acids to create buffered systems that maintain optimal pH levels in various food products. This approach not only extends shelf life but also helps preserve the organoleptic properties of treated foods[2][4]. Asama Chemical has conducted extensive stability studies to demonstrate the long-term efficacy of their sodium acetate formulations under various storage conditions[6].

Strengths: High-purity formulations, pH buffering capabilities, extensive stability data. Weaknesses: May be more expensive than standard sodium acetate, potentially limited to specific food applications.

Core Innovations in Sodium Acetate Preservation

Acetate powder and method for the preparation thereof

PatentWO2019091970A1

Innovation

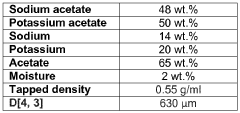

- A process involving the production of coated acetate particles with a high sodium acetate core and a potassium acetate coating, achieving a stable and free-flowing powder with a specific molar ratio and particle size range, which is achieved through a fluidized bed spray coating and drying method.

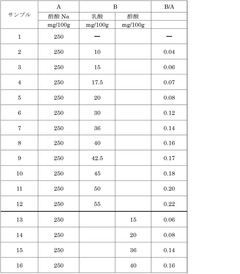

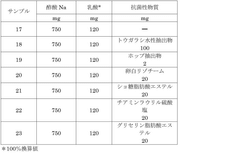

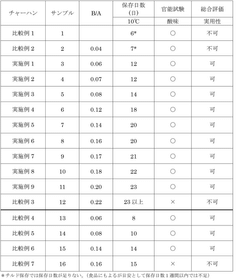

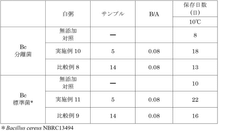

Lactic-acid-containing sodium acetate composition, food shelf life improving agent containing lactic-acid-containing sodium acetate composition, and method for improving shelf life of food

PatentWO2021199455A1

Innovation

- A lactic acid-containing sodium acetate composition with a lactic acid/sodium acetate mass ratio of 0.06 to 0.20, which exhibits antibacterial activity at chilled temperatures while minimizing flavor impact, is used as a food shelf life improver, either in liquid or powder form, and can be added to foods before, during, or after cooking.

Food Safety Regulations and Compliance

The implementation of sodium acetate as a food preservative must adhere to stringent food safety regulations and compliance standards. In the United States, the Food and Drug Administration (FDA) regulates the use of food additives, including preservatives, under the Federal Food, Drug, and Cosmetic Act. Sodium acetate is currently recognized as Generally Recognized as Safe (GRAS) by the FDA, which allows its use in food products without premarket approval.

However, manufacturers must ensure that the use of sodium acetate complies with Good Manufacturing Practices (GMPs) and does not exceed the maximum levels permitted in various food categories. The European Food Safety Authority (EFSA) has also evaluated sodium acetate and approved its use as a food additive (E262) within the European Union. The EFSA has established specific purity criteria and maximum usage levels for different food categories.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. These standards include guidelines for the use of food additives, including sodium acetate, to ensure food safety and facilitate international trade.

Manufacturers considering the use of sodium acetate in food preservation must conduct thorough safety assessments and provide scientific evidence to support its efficacy and safety. This may include toxicological studies, stability tests, and shelf-life evaluations. Additionally, proper labeling is crucial to comply with regulations. In many jurisdictions, sodium acetate must be declared on the ingredient list, either by its specific name or by its E-number (E262).

As food safety regulations continue to evolve, companies must stay informed about any changes in the regulatory landscape. This includes monitoring updates from regulatory bodies, participating in industry forums, and engaging with food safety experts. Compliance with these regulations not only ensures legal adherence but also builds consumer trust in the safety and quality of food products.

Furthermore, as the use of sodium acetate expands in food preservation, regulatory bodies may require additional safety data or impose new restrictions. Companies investing in this technology should be prepared to conduct ongoing research and provide updated safety information as requested by regulatory authorities. This proactive approach will help maintain compliance and support the long-term viability of sodium acetate as a food preservation solution.

However, manufacturers must ensure that the use of sodium acetate complies with Good Manufacturing Practices (GMPs) and does not exceed the maximum levels permitted in various food categories. The European Food Safety Authority (EFSA) has also evaluated sodium acetate and approved its use as a food additive (E262) within the European Union. The EFSA has established specific purity criteria and maximum usage levels for different food categories.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that many countries use as a reference. These standards include guidelines for the use of food additives, including sodium acetate, to ensure food safety and facilitate international trade.

Manufacturers considering the use of sodium acetate in food preservation must conduct thorough safety assessments and provide scientific evidence to support its efficacy and safety. This may include toxicological studies, stability tests, and shelf-life evaluations. Additionally, proper labeling is crucial to comply with regulations. In many jurisdictions, sodium acetate must be declared on the ingredient list, either by its specific name or by its E-number (E262).

As food safety regulations continue to evolve, companies must stay informed about any changes in the regulatory landscape. This includes monitoring updates from regulatory bodies, participating in industry forums, and engaging with food safety experts. Compliance with these regulations not only ensures legal adherence but also builds consumer trust in the safety and quality of food products.

Furthermore, as the use of sodium acetate expands in food preservation, regulatory bodies may require additional safety data or impose new restrictions. Companies investing in this technology should be prepared to conduct ongoing research and provide updated safety information as requested by regulatory authorities. This proactive approach will help maintain compliance and support the long-term viability of sodium acetate as a food preservation solution.

Environmental Impact of Sodium Acetate Preservation

The environmental impact of sodium acetate as a food preservative is a crucial consideration in its potential adoption as a future solution for resilient food preservation. Sodium acetate, while offering promising benefits in food preservation, also presents several environmental implications that warrant careful examination.

One of the primary environmental advantages of sodium acetate is its biodegradability. As an organic compound, it can be broken down naturally by microorganisms in the environment, reducing long-term accumulation and potential ecological disruption. This characteristic makes it a more environmentally friendly option compared to some synthetic preservatives that may persist in ecosystems for extended periods.

However, the production process of sodium acetate requires careful scrutiny. The manufacturing of this compound typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These processes can be energy-intensive and may contribute to carbon emissions if not managed sustainably. The sourcing of raw materials for production, particularly acetic acid, also needs to be considered in terms of its environmental footprint.

Water usage and potential water pollution are additional factors to evaluate. The production and application of sodium acetate in food preservation may involve significant water consumption. Moreover, improper disposal or accidental release of sodium acetate solutions into water bodies could potentially alter local pH levels and impact aquatic ecosystems, although its biodegradability mitigates long-term effects.

From a waste management perspective, the use of sodium acetate in food preservation could contribute to reducing food waste, which is a significant environmental concern globally. By extending the shelf life of various food products, it may help decrease the amount of food that ends up in landfills, thereby reducing methane emissions associated with food decomposition.

The packaging implications of sodium acetate preservation also merit consideration. If this preservation method allows for less reliance on energy-intensive cold storage or reduces the need for certain types of packaging materials, it could lead to a decrease in overall packaging waste and energy consumption in the food supply chain.

In terms of transportation and distribution, the potential for sodium acetate to enhance food resilience could lead to more efficient logistics. This might result in fewer food shipments and reduced fuel consumption, contributing to lower greenhouse gas emissions in the food distribution sector.

As research into sodium acetate as a food preservative progresses, it is essential to conduct comprehensive life cycle assessments to fully understand its environmental impact. These assessments should compare sodium acetate with current preservation methods, considering factors such as energy use, water consumption, waste generation, and overall carbon footprint throughout the entire product lifecycle.

One of the primary environmental advantages of sodium acetate is its biodegradability. As an organic compound, it can be broken down naturally by microorganisms in the environment, reducing long-term accumulation and potential ecological disruption. This characteristic makes it a more environmentally friendly option compared to some synthetic preservatives that may persist in ecosystems for extended periods.

However, the production process of sodium acetate requires careful scrutiny. The manufacturing of this compound typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These processes can be energy-intensive and may contribute to carbon emissions if not managed sustainably. The sourcing of raw materials for production, particularly acetic acid, also needs to be considered in terms of its environmental footprint.

Water usage and potential water pollution are additional factors to evaluate. The production and application of sodium acetate in food preservation may involve significant water consumption. Moreover, improper disposal or accidental release of sodium acetate solutions into water bodies could potentially alter local pH levels and impact aquatic ecosystems, although its biodegradability mitigates long-term effects.

From a waste management perspective, the use of sodium acetate in food preservation could contribute to reducing food waste, which is a significant environmental concern globally. By extending the shelf life of various food products, it may help decrease the amount of food that ends up in landfills, thereby reducing methane emissions associated with food decomposition.

The packaging implications of sodium acetate preservation also merit consideration. If this preservation method allows for less reliance on energy-intensive cold storage or reduces the need for certain types of packaging materials, it could lead to a decrease in overall packaging waste and energy consumption in the food supply chain.

In terms of transportation and distribution, the potential for sodium acetate to enhance food resilience could lead to more efficient logistics. This might result in fewer food shipments and reduced fuel consumption, contributing to lower greenhouse gas emissions in the food distribution sector.

As research into sodium acetate as a food preservative progresses, it is essential to conduct comprehensive life cycle assessments to fully understand its environmental impact. These assessments should compare sodium acetate with current preservation methods, considering factors such as energy use, water consumption, waste generation, and overall carbon footprint throughout the entire product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!