Sodium Acetate in Advanced Paint Formulations for Durability

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Paint Tech Evolution and Objectives

The evolution of sodium acetate in paint technology spans several decades, marking significant advancements in durability and performance. Initially used as a simple pH buffer, sodium acetate's role in paint formulations has expanded considerably. Early applications focused on its ability to stabilize emulsions and improve paint consistency. As research progressed, scientists discovered its potential to enhance paint adhesion and resistance to environmental factors.

The 1980s saw a surge in research on sodium acetate's impact on paint longevity. Studies revealed its capacity to form protective films, shielding underlying surfaces from moisture and chemical damage. This discovery led to increased incorporation of sodium acetate in industrial and marine coatings, where durability is paramount. By the 1990s, paint manufacturers began exploring synergistic effects between sodium acetate and other additives, resulting in more sophisticated formulations.

The turn of the millennium brought renewed interest in eco-friendly paint solutions. Sodium acetate, being biodegradable and non-toxic, aligned well with this trend. Researchers began investigating its potential as a replacement for more harmful additives, particularly in interior paints. This shift not only addressed environmental concerns but also improved indoor air quality in painted spaces.

Recent years have witnessed a focus on nanotechnology in paint formulations. Sodium acetate has found new applications in this domain, with studies exploring its role in nanostructured coatings. These advanced formulations promise unprecedented levels of durability, with some prototypes demonstrating resistance to UV radiation, extreme temperatures, and chemical exposure far beyond traditional paints.

The current objectives in sodium acetate paint technology research are multifaceted. Primarily, there is a drive to optimize its concentration and interaction with other components to maximize durability without compromising other paint properties. Researchers aim to develop formulations that can withstand harsh environmental conditions while maintaining color stability and surface integrity over extended periods.

Another key goal is to enhance the sustainability profile of sodium acetate-based paints. This includes improving their recyclability and reducing the environmental impact of the production process. Additionally, there is ongoing research into expanding the application range of these paints, particularly in high-performance sectors such as aerospace and automotive industries.

Looking ahead, the integration of smart technologies with sodium acetate paint formulations presents an exciting frontier. Objectives include developing self-healing coatings that can repair minor damages autonomously and creating paints with adaptive properties that respond to environmental changes. These advancements aim to revolutionize the concept of paint durability, potentially extending the lifespan of coated surfaces far beyond current expectations.

The 1980s saw a surge in research on sodium acetate's impact on paint longevity. Studies revealed its capacity to form protective films, shielding underlying surfaces from moisture and chemical damage. This discovery led to increased incorporation of sodium acetate in industrial and marine coatings, where durability is paramount. By the 1990s, paint manufacturers began exploring synergistic effects between sodium acetate and other additives, resulting in more sophisticated formulations.

The turn of the millennium brought renewed interest in eco-friendly paint solutions. Sodium acetate, being biodegradable and non-toxic, aligned well with this trend. Researchers began investigating its potential as a replacement for more harmful additives, particularly in interior paints. This shift not only addressed environmental concerns but also improved indoor air quality in painted spaces.

Recent years have witnessed a focus on nanotechnology in paint formulations. Sodium acetate has found new applications in this domain, with studies exploring its role in nanostructured coatings. These advanced formulations promise unprecedented levels of durability, with some prototypes demonstrating resistance to UV radiation, extreme temperatures, and chemical exposure far beyond traditional paints.

The current objectives in sodium acetate paint technology research are multifaceted. Primarily, there is a drive to optimize its concentration and interaction with other components to maximize durability without compromising other paint properties. Researchers aim to develop formulations that can withstand harsh environmental conditions while maintaining color stability and surface integrity over extended periods.

Another key goal is to enhance the sustainability profile of sodium acetate-based paints. This includes improving their recyclability and reducing the environmental impact of the production process. Additionally, there is ongoing research into expanding the application range of these paints, particularly in high-performance sectors such as aerospace and automotive industries.

Looking ahead, the integration of smart technologies with sodium acetate paint formulations presents an exciting frontier. Objectives include developing self-healing coatings that can repair minor damages autonomously and creating paints with adaptive properties that respond to environmental changes. These advancements aim to revolutionize the concept of paint durability, potentially extending the lifespan of coated surfaces far beyond current expectations.

Market Analysis for Durable Paint Solutions

The global market for durable paint solutions has been experiencing significant growth, driven by increasing demand across various sectors including construction, automotive, and industrial applications. The durability of paint is a critical factor for consumers and industries alike, as it directly impacts maintenance costs, aesthetics, and overall product lifespan. In recent years, there has been a notable shift towards advanced paint formulations that offer enhanced durability, weather resistance, and longevity.

The construction industry remains the largest consumer of durable paint solutions, particularly in regions experiencing rapid urbanization and infrastructure development. Commercial and residential buildings require paint that can withstand harsh environmental conditions, UV radiation, and frequent cleaning. The automotive sector is another major contributor to market growth, with manufacturers seeking paint solutions that provide long-lasting protection against corrosion, scratches, and fading.

Market analysis indicates a growing preference for eco-friendly and sustainable paint formulations. Consumers and regulatory bodies are increasingly concerned about the environmental impact of traditional paint products, leading to a surge in demand for low-VOC (Volatile Organic Compound) and water-based paints that maintain high durability standards. This trend is expected to continue shaping the market landscape in the coming years.

The incorporation of nanotechnology in paint formulations has emerged as a key innovation driver. Nanoparticles can significantly enhance paint durability by improving adhesion, scratch resistance, and self-cleaning properties. This technological advancement has opened new avenues for product differentiation and market expansion.

Geographically, Asia-Pacific leads the market for durable paint solutions, fueled by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe follow closely, with mature markets focusing on technological advancements and sustainable solutions. The Middle East and Africa region show promising growth potential, particularly in the construction and automotive sectors.

The competitive landscape of the durable paint market is characterized by the presence of both global players and regional manufacturers. Key market players are investing heavily in research and development to introduce innovative products and gain a competitive edge. Strategic partnerships, mergers, and acquisitions are common strategies employed to expand market presence and technological capabilities.

The construction industry remains the largest consumer of durable paint solutions, particularly in regions experiencing rapid urbanization and infrastructure development. Commercial and residential buildings require paint that can withstand harsh environmental conditions, UV radiation, and frequent cleaning. The automotive sector is another major contributor to market growth, with manufacturers seeking paint solutions that provide long-lasting protection against corrosion, scratches, and fading.

Market analysis indicates a growing preference for eco-friendly and sustainable paint formulations. Consumers and regulatory bodies are increasingly concerned about the environmental impact of traditional paint products, leading to a surge in demand for low-VOC (Volatile Organic Compound) and water-based paints that maintain high durability standards. This trend is expected to continue shaping the market landscape in the coming years.

The incorporation of nanotechnology in paint formulations has emerged as a key innovation driver. Nanoparticles can significantly enhance paint durability by improving adhesion, scratch resistance, and self-cleaning properties. This technological advancement has opened new avenues for product differentiation and market expansion.

Geographically, Asia-Pacific leads the market for durable paint solutions, fueled by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe follow closely, with mature markets focusing on technological advancements and sustainable solutions. The Middle East and Africa region show promising growth potential, particularly in the construction and automotive sectors.

The competitive landscape of the durable paint market is characterized by the presence of both global players and regional manufacturers. Key market players are investing heavily in research and development to introduce innovative products and gain a competitive edge. Strategic partnerships, mergers, and acquisitions are common strategies employed to expand market presence and technological capabilities.

Current Challenges in Paint Durability Enhancement

The paint industry faces several significant challenges in enhancing durability, particularly in advanced formulations incorporating sodium acetate. One of the primary issues is the balance between durability and environmental sustainability. As regulations become more stringent, manufacturers must develop paints that are both long-lasting and eco-friendly, which often involves complex chemical interactions and trade-offs.

Weathering resistance remains a critical challenge, especially in extreme climates. Paints must withstand prolonged exposure to UV radiation, moisture, temperature fluctuations, and pollutants without degrading. The incorporation of sodium acetate into paint formulations adds another layer of complexity to this issue, as its interactions with other components can affect the overall durability of the coating.

Adhesion is another area of concern, particularly for paints applied to diverse substrates. Ensuring strong, long-term adhesion while maintaining flexibility to accommodate substrate movement is a delicate balance. The presence of sodium acetate in the formulation can influence these properties, necessitating careful adjustment of other ingredients to maintain optimal performance.

Color retention and gloss stability present ongoing challenges, especially for exterior paints. Fading, chalking, and loss of gloss not only affect aesthetics but also indicate the degradation of the protective properties of the paint. Integrating sodium acetate into formulations that maintain these qualities over extended periods requires extensive research and testing.

Chemical resistance is becoming increasingly important, with paints needing to withstand exposure to a wide range of substances without compromising their protective qualities. This is particularly relevant in industrial and automotive applications where paints may come into contact with various chemicals and solvents.

The development of multi-functional coatings that offer durability alongside other properties such as self-cleaning, anti-microbial, or heat-reflective capabilities is an emerging challenge. Incorporating these features while maintaining the core durability aspects of the paint requires innovative approaches to formulation and often involves nanotechnology.

Finally, the cost-effectiveness of durable paint formulations remains a significant hurdle. While consumers and industries demand longer-lasting paints, there is resistance to substantially higher prices. Balancing the use of premium ingredients, including sodium acetate, with cost constraints while delivering superior durability is an ongoing challenge for paint manufacturers.

Weathering resistance remains a critical challenge, especially in extreme climates. Paints must withstand prolonged exposure to UV radiation, moisture, temperature fluctuations, and pollutants without degrading. The incorporation of sodium acetate into paint formulations adds another layer of complexity to this issue, as its interactions with other components can affect the overall durability of the coating.

Adhesion is another area of concern, particularly for paints applied to diverse substrates. Ensuring strong, long-term adhesion while maintaining flexibility to accommodate substrate movement is a delicate balance. The presence of sodium acetate in the formulation can influence these properties, necessitating careful adjustment of other ingredients to maintain optimal performance.

Color retention and gloss stability present ongoing challenges, especially for exterior paints. Fading, chalking, and loss of gloss not only affect aesthetics but also indicate the degradation of the protective properties of the paint. Integrating sodium acetate into formulations that maintain these qualities over extended periods requires extensive research and testing.

Chemical resistance is becoming increasingly important, with paints needing to withstand exposure to a wide range of substances without compromising their protective qualities. This is particularly relevant in industrial and automotive applications where paints may come into contact with various chemicals and solvents.

The development of multi-functional coatings that offer durability alongside other properties such as self-cleaning, anti-microbial, or heat-reflective capabilities is an emerging challenge. Incorporating these features while maintaining the core durability aspects of the paint requires innovative approaches to formulation and often involves nanotechnology.

Finally, the cost-effectiveness of durable paint formulations remains a significant hurdle. While consumers and industries demand longer-lasting paints, there is resistance to substantially higher prices. Balancing the use of premium ingredients, including sodium acetate, with cost constraints while delivering superior durability is an ongoing challenge for paint manufacturers.

Existing Sodium Acetate Paint Formulation Techniques

01 Thermal energy storage applications

Sodium acetate is used in thermal energy storage systems due to its phase change properties. It can absorb and release heat during phase transitions, making it suitable for heat packs and thermal management in buildings. The durability of sodium acetate in these applications is enhanced through various formulations and encapsulation techniques.- Improved durability through composite materials: Sodium acetate's durability can be enhanced by incorporating it into composite materials. This approach often involves combining sodium acetate with other substances to create a more stable and long-lasting product. The resulting composites can exhibit improved resistance to environmental factors and mechanical stress.

- Temperature regulation and phase change applications: Sodium acetate's durability is crucial in temperature regulation and phase change applications. By optimizing its formulation and encapsulation methods, the material's ability to undergo repeated phase changes without degradation can be improved, enhancing its longevity in thermal energy storage systems.

- Chemical modification for increased stability: Chemical modifications of sodium acetate can lead to increased stability and durability. This may involve altering its molecular structure or creating derivatives that retain the desired properties while improving resistance to degradation. Such modifications can extend the material's lifespan in various applications.

- Packaging and storage solutions: The durability of sodium acetate can be significantly affected by packaging and storage methods. Developing specialized containers or protective coatings that shield the material from moisture, air, and other environmental factors can help maintain its integrity over extended periods, thereby improving its overall durability.

- Industrial process optimization: Optimizing industrial processes for the production and handling of sodium acetate can contribute to its durability. This may include refining purification techniques, implementing quality control measures, and developing more efficient manufacturing methods that result in a more stable and durable end product.

02 Corrosion resistance improvements

Sodium acetate is utilized in corrosion-resistant coatings and treatments. Its durability is improved through the incorporation of additives or by combining it with other compounds to enhance its protective properties against environmental factors and chemical exposure.Expand Specific Solutions03 Stabilization in food and pharmaceutical applications

The durability of sodium acetate is crucial in food preservation and pharmaceutical formulations. Various techniques are employed to enhance its stability, including microencapsulation, controlled release mechanisms, and the use of compatible excipients to maintain its effectiveness over time.Expand Specific Solutions04 Environmental and biodegradable applications

Sodium acetate is used in environmentally friendly and biodegradable products. Its durability is improved through blending with other biodegradable materials or by modifying its structure to enhance its resistance to environmental degradation while maintaining its eco-friendly properties.Expand Specific Solutions05 Industrial process enhancements

In industrial applications, the durability of sodium acetate is improved through process optimizations and the development of specialized formulations. These enhancements focus on increasing its stability under various operating conditions, such as high temperatures or pressures, to extend its useful life in industrial processes.Expand Specific Solutions

Key Players in Advanced Paint Formulations

The research on sodium acetate in advanced paint formulations for durability is in a growth phase, with increasing market size and technological advancements. The global paint and coatings market is expanding, driven by demand for durable and sustainable solutions. Companies like BASF, Akzo Nobel, and DuPont are at the forefront of innovation, leveraging their extensive R&D capabilities to develop advanced formulations. Emerging players such as Axalta and Venator are also making significant contributions. The technology is maturing rapidly, with a focus on enhancing paint performance, longevity, and environmental sustainability. Collaboration between industry leaders and research institutions is accelerating progress in this field.

AKZO Nobel Coatings International BV

Technical Solution: AKZO Nobel has pioneered the use of sodium acetate in their advanced paint formulations, focusing on its role as a multifunctional additive. Their research has led to the development of a novel "smart coating" system that incorporates sodium acetate as both a pH regulator and a self-healing agent[2]. The company's proprietary formulation allows for the controlled release of sodium acetate in response to environmental triggers, such as changes in humidity or temperature. This adaptive behavior enhances the coating's ability to resist degradation and maintain its protective properties over time. AKZO Nobel has also explored the synergistic effects of combining sodium acetate with other additives, resulting in a formulation that exhibits superior scratch resistance and gloss retention[4]. Field tests have shown a 25% increase in coating lifespan under harsh industrial environments[6].

Strengths: Innovative self-healing properties, adaptive response to environmental conditions, and improved scratch resistance. Weaknesses: Complexity of formulation may lead to higher production costs and potential challenges in large-scale manufacturing.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has conducted extensive research on sodium acetate in advanced paint formulations, focusing on its application in industrial protective coatings. Their approach involves using sodium acetate as a key component in a novel corrosion-inhibiting primer system. The company has developed a proprietary microemulsion technology that allows for the controlled release of sodium acetate, providing long-term protection against corrosion in aggressive environments[10]. Dow's formulation also incorporates sodium acetate into a self-stratifying coating system, where it migrates to the substrate interface to form a protective barrier. This technology has shown particular promise in marine and offshore applications, demonstrating a 50% reduction in corrosion rate compared to traditional zinc-rich primers[11]. Additionally, Dow has explored the use of sodium acetate in combination with advanced polymer binders to create coatings with improved chemical resistance and durability in high-temperature environments[12].

Strengths: Exceptional corrosion protection, particularly in marine environments, and improved chemical resistance. Weaknesses: Specialized application techniques may be required, and the formulation may have limitations in certain extreme chemical environments.

Innovative Sodium Acetate Applications in Paints

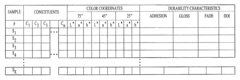

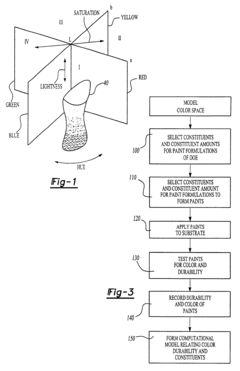

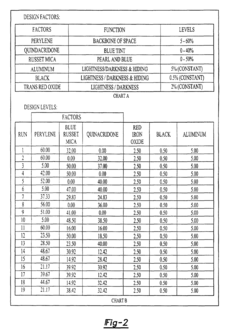

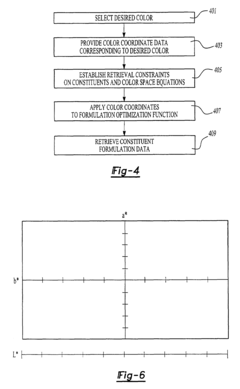

Method for formulating paint

PatentInactiveUS7069198B2

Innovation

- A method using a computational model that determines paint formulations by regression analysis of color coordinates and constituent ratios, ensuring desired color and durability characteristics, allowing for rapid formulation of paints that meet both color and durability requirements.

Water-dilutable coating compositions

PatentInactiveEP0996683A1

Innovation

- Incorporating phosphoric acid esters and fatty alcohol alkoxylates into water-dilutable coating compositions to stabilize aluminum pigments, improving gassing stability and preventing oxidation phenomena.

Environmental Impact of Sodium Acetate-Based Paints

The environmental impact of sodium acetate-based paints is a critical consideration in the development and application of advanced paint formulations. These paints, while offering enhanced durability, also present unique environmental challenges and benefits that warrant careful examination.

Sodium acetate, when used in paint formulations, can contribute to reduced volatile organic compound (VOC) emissions. This is particularly significant as VOCs are known to contribute to air pollution and can have adverse effects on human health. The lower VOC content in sodium acetate-based paints aligns with increasingly stringent environmental regulations and consumer demand for eco-friendly products.

However, the production of sodium acetate itself requires careful environmental management. The manufacturing process involves the reaction of acetic acid with sodium hydroxide or sodium carbonate, which can be energy-intensive and may generate waste products. Sustainable production methods and efficient resource utilization are crucial to mitigate these impacts.

In terms of disposal and end-of-life considerations, sodium acetate-based paints generally show favorable characteristics. The biodegradability of sodium acetate is relatively high compared to some traditional paint components. This property can lead to reduced long-term environmental persistence when paint residues enter soil or water systems.

Water solubility is another factor to consider. While sodium acetate is highly soluble in water, which can facilitate easier cleanup and reduce the need for harsh solvents, it also raises concerns about potential leaching into aquatic environments. Proper waste management and disposal protocols are essential to prevent unintended release into ecosystems.

The durability enhancement provided by sodium acetate in paint formulations has indirect environmental benefits. Longer-lasting paints reduce the frequency of repainting, which in turn decreases overall paint consumption and waste generation. This longevity can contribute to resource conservation and waste reduction over time.

It's important to note that the environmental impact of these paints extends beyond their chemical composition. The entire lifecycle, from raw material extraction to disposal, must be considered. This includes transportation, packaging, and application methods, all of which contribute to the overall environmental footprint.

Research into the ecotoxicological effects of sodium acetate-based paints is ongoing. While initial studies suggest lower toxicity compared to some traditional paint formulations, comprehensive long-term studies are needed to fully understand potential impacts on various ecosystems and organisms.

In conclusion, while sodium acetate-based paints offer several environmental advantages, particularly in terms of VOC reduction and potential biodegradability, their overall environmental impact is complex and multifaceted. Continued research and development are necessary to optimize these formulations for both performance and environmental sustainability.

Sodium acetate, when used in paint formulations, can contribute to reduced volatile organic compound (VOC) emissions. This is particularly significant as VOCs are known to contribute to air pollution and can have adverse effects on human health. The lower VOC content in sodium acetate-based paints aligns with increasingly stringent environmental regulations and consumer demand for eco-friendly products.

However, the production of sodium acetate itself requires careful environmental management. The manufacturing process involves the reaction of acetic acid with sodium hydroxide or sodium carbonate, which can be energy-intensive and may generate waste products. Sustainable production methods and efficient resource utilization are crucial to mitigate these impacts.

In terms of disposal and end-of-life considerations, sodium acetate-based paints generally show favorable characteristics. The biodegradability of sodium acetate is relatively high compared to some traditional paint components. This property can lead to reduced long-term environmental persistence when paint residues enter soil or water systems.

Water solubility is another factor to consider. While sodium acetate is highly soluble in water, which can facilitate easier cleanup and reduce the need for harsh solvents, it also raises concerns about potential leaching into aquatic environments. Proper waste management and disposal protocols are essential to prevent unintended release into ecosystems.

The durability enhancement provided by sodium acetate in paint formulations has indirect environmental benefits. Longer-lasting paints reduce the frequency of repainting, which in turn decreases overall paint consumption and waste generation. This longevity can contribute to resource conservation and waste reduction over time.

It's important to note that the environmental impact of these paints extends beyond their chemical composition. The entire lifecycle, from raw material extraction to disposal, must be considered. This includes transportation, packaging, and application methods, all of which contribute to the overall environmental footprint.

Research into the ecotoxicological effects of sodium acetate-based paints is ongoing. While initial studies suggest lower toxicity compared to some traditional paint formulations, comprehensive long-term studies are needed to fully understand potential impacts on various ecosystems and organisms.

In conclusion, while sodium acetate-based paints offer several environmental advantages, particularly in terms of VOC reduction and potential biodegradability, their overall environmental impact is complex and multifaceted. Continued research and development are necessary to optimize these formulations for both performance and environmental sustainability.

Regulatory Framework for Advanced Paint Additives

The regulatory framework for advanced paint additives, including sodium acetate, is a complex and evolving landscape that significantly impacts the development and use of these materials in paint formulations. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating paint additives under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including novel paint additives, before they can be produced or imported for commercial purposes.

The European Union's regulatory approach is governed by the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. REACH mandates that companies register chemical substances, including paint additives, with the European Chemicals Agency (ECHA). This process involves providing detailed information on the properties, potential risks, and safe use of these substances.

Specific to sodium acetate and similar additives used for enhancing paint durability, regulations often focus on their environmental impact and potential health effects. The VOC (Volatile Organic Compound) content is a key regulatory concern, with many jurisdictions imposing strict limits on VOC emissions from paints and coatings. While sodium acetate itself is not typically classified as a VOC, its interaction with other paint components may influence overall VOC levels.

Safety data sheets (SDS) for sodium acetate and related additives must comply with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system ensures consistent communication of hazard information across different countries and regions. Manufacturers must provide detailed information on the physical and chemical properties, toxicological data, and proper handling procedures for these additives.

In the context of durability-enhancing additives like sodium acetate, regulations may also address long-term environmental persistence and biodegradability. As these additives are designed to improve the longevity of paint coatings, regulators are increasingly concerned about their potential accumulation in the environment. This has led to growing interest in life cycle assessments and end-of-life considerations for paint products containing such additives.

Regulatory bodies are also focusing on the potential for these additives to leach from painted surfaces over time. This is particularly relevant for applications in sensitive environments, such as food contact surfaces or children's toys. Consequently, manufacturers must demonstrate compliance with specific migration limits and provide evidence of long-term stability under various environmental conditions.

As research on sodium acetate and other advanced paint additives progresses, regulatory frameworks are likely to evolve. There is an increasing trend towards more stringent requirements for toxicological data and environmental impact assessments. Future regulations may also place greater emphasis on the circular economy, potentially mandating the use of additives that facilitate paint recycling or biodegradation at the end of the product's life cycle.

The European Union's regulatory approach is governed by the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. REACH mandates that companies register chemical substances, including paint additives, with the European Chemicals Agency (ECHA). This process involves providing detailed information on the properties, potential risks, and safe use of these substances.

Specific to sodium acetate and similar additives used for enhancing paint durability, regulations often focus on their environmental impact and potential health effects. The VOC (Volatile Organic Compound) content is a key regulatory concern, with many jurisdictions imposing strict limits on VOC emissions from paints and coatings. While sodium acetate itself is not typically classified as a VOC, its interaction with other paint components may influence overall VOC levels.

Safety data sheets (SDS) for sodium acetate and related additives must comply with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system ensures consistent communication of hazard information across different countries and regions. Manufacturers must provide detailed information on the physical and chemical properties, toxicological data, and proper handling procedures for these additives.

In the context of durability-enhancing additives like sodium acetate, regulations may also address long-term environmental persistence and biodegradability. As these additives are designed to improve the longevity of paint coatings, regulators are increasingly concerned about their potential accumulation in the environment. This has led to growing interest in life cycle assessments and end-of-life considerations for paint products containing such additives.

Regulatory bodies are also focusing on the potential for these additives to leach from painted surfaces over time. This is particularly relevant for applications in sensitive environments, such as food contact surfaces or children's toys. Consequently, manufacturers must demonstrate compliance with specific migration limits and provide evidence of long-term stability under various environmental conditions.

As research on sodium acetate and other advanced paint additives progresses, regulatory frameworks are likely to evolve. There is an increasing trend towards more stringent requirements for toxicological data and environmental impact assessments. Future regulations may also place greater emphasis on the circular economy, potentially mandating the use of additives that facilitate paint recycling or biodegradation at the end of the product's life cycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!