Pintle Hitch Design Impact on Global Transportation Policies

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution and Objectives

The pintle hitch, a crucial component in heavy-duty towing and transportation, has undergone significant evolution since its inception. Originally developed for military applications during World War II, the pintle hitch has since found widespread use in commercial and industrial sectors. Its robust design and versatility have made it an indispensable part of global transportation systems.

The evolution of pintle hitch design has been driven by the increasing demands of the transportation industry. Early models were simple and focused primarily on strength and durability. As transportation needs grew more complex, pintle hitches evolved to incorporate features such as adjustable height, improved locking mechanisms, and enhanced safety systems. This progression has been marked by continuous improvements in materials, manufacturing techniques, and engineering principles.

One of the key milestones in pintle hitch development was the introduction of standardized designs, which facilitated interoperability across different vehicle types and manufacturers. This standardization has played a crucial role in streamlining global transportation logistics and enhancing efficiency in cross-border operations. The adoption of international standards for pintle hitches has significantly contributed to the seamless integration of transportation systems worldwide.

Recent advancements in pintle hitch technology have focused on improving safety features and reducing wear and tear. Innovations such as self-lubricating materials, advanced locking systems, and integrated sensors for load monitoring have enhanced the reliability and longevity of these devices. These improvements have had a direct impact on transportation policies, particularly in areas related to road safety and vehicle regulations.

The objectives of current pintle hitch research and development are multifaceted. Primary goals include further enhancing safety features, improving durability to withstand increasingly heavy loads, and developing smart hitches capable of real-time monitoring and data transmission. There is also a growing emphasis on creating more environmentally friendly designs, incorporating lightweight materials and energy-efficient manufacturing processes.

Another significant objective is the adaptation of pintle hitch designs to accommodate emerging transportation technologies, such as autonomous vehicles and platooning systems. This adaptation requires rethinking traditional hitch designs to ensure compatibility with advanced vehicle control systems and communication protocols. The integration of pintle hitches with these cutting-edge technologies is expected to play a crucial role in shaping future transportation policies and regulations.

As global transportation continues to evolve, the impact of pintle hitch design on policies becomes increasingly significant. Policymakers and industry stakeholders are closely monitoring developments in this field, recognizing the potential for innovative hitch designs to influence regulations on vehicle safety, load capacity, and cross-border transportation standards. The ongoing evolution of pintle hitch technology serves as a prime example of how seemingly small components can have far-reaching effects on global transportation systems and policies.

The evolution of pintle hitch design has been driven by the increasing demands of the transportation industry. Early models were simple and focused primarily on strength and durability. As transportation needs grew more complex, pintle hitches evolved to incorporate features such as adjustable height, improved locking mechanisms, and enhanced safety systems. This progression has been marked by continuous improvements in materials, manufacturing techniques, and engineering principles.

One of the key milestones in pintle hitch development was the introduction of standardized designs, which facilitated interoperability across different vehicle types and manufacturers. This standardization has played a crucial role in streamlining global transportation logistics and enhancing efficiency in cross-border operations. The adoption of international standards for pintle hitches has significantly contributed to the seamless integration of transportation systems worldwide.

Recent advancements in pintle hitch technology have focused on improving safety features and reducing wear and tear. Innovations such as self-lubricating materials, advanced locking systems, and integrated sensors for load monitoring have enhanced the reliability and longevity of these devices. These improvements have had a direct impact on transportation policies, particularly in areas related to road safety and vehicle regulations.

The objectives of current pintle hitch research and development are multifaceted. Primary goals include further enhancing safety features, improving durability to withstand increasingly heavy loads, and developing smart hitches capable of real-time monitoring and data transmission. There is also a growing emphasis on creating more environmentally friendly designs, incorporating lightweight materials and energy-efficient manufacturing processes.

Another significant objective is the adaptation of pintle hitch designs to accommodate emerging transportation technologies, such as autonomous vehicles and platooning systems. This adaptation requires rethinking traditional hitch designs to ensure compatibility with advanced vehicle control systems and communication protocols. The integration of pintle hitches with these cutting-edge technologies is expected to play a crucial role in shaping future transportation policies and regulations.

As global transportation continues to evolve, the impact of pintle hitch design on policies becomes increasingly significant. Policymakers and industry stakeholders are closely monitoring developments in this field, recognizing the potential for innovative hitch designs to influence regulations on vehicle safety, load capacity, and cross-border transportation standards. The ongoing evolution of pintle hitch technology serves as a prime example of how seemingly small components can have far-reaching effects on global transportation systems and policies.

Global Market Analysis for Pintle Hitch Systems

The global market for pintle hitch systems has experienced significant growth in recent years, driven by the increasing demand for efficient and versatile towing solutions across various industries. The transportation sector, in particular, has been a major contributor to this growth, as pintle hitches offer superior strength and flexibility for heavy-duty towing applications. The market is characterized by a diverse range of products, including fixed, swivel, and combination pintle hitches, catering to different vehicle types and towing requirements.

North America currently dominates the pintle hitch market, accounting for a substantial share of global revenue. This can be attributed to the region's robust transportation infrastructure, high adoption of heavy-duty vehicles, and stringent safety regulations. Europe follows closely, with countries like Germany, France, and the United Kingdom showing strong demand for pintle hitch systems in commercial and military applications. The Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, infrastructure development, and increasing adoption of advanced towing technologies in countries such as China and India.

The market is witnessing a shift towards more advanced and technologically sophisticated pintle hitch designs. Manufacturers are focusing on developing lightweight yet durable materials, incorporating smart features like integrated sensors for load monitoring, and improving overall safety and performance. This trend is particularly evident in developed markets where customers are willing to invest in premium products that offer enhanced functionality and longevity.

The commercial vehicle segment remains the largest end-user of pintle hitch systems, encompassing applications in trucking, construction, and agriculture. However, the military and defense sector is showing promising growth potential, driven by the need for robust towing solutions in challenging terrains and operational environments. The recreational vehicle market is also contributing to the demand, albeit to a lesser extent, as consumers seek versatile towing options for trailers and boats.

Key market players are adopting strategies such as product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The competitive landscape is characterized by a mix of established manufacturers and new entrants, with companies focusing on expanding their product portfolios and geographical presence to capture a larger market share. As global transportation policies continue to evolve, emphasizing safety, efficiency, and environmental sustainability, the pintle hitch market is expected to adapt and innovate accordingly, potentially leading to new design standards and regulatory requirements in the coming years.

North America currently dominates the pintle hitch market, accounting for a substantial share of global revenue. This can be attributed to the region's robust transportation infrastructure, high adoption of heavy-duty vehicles, and stringent safety regulations. Europe follows closely, with countries like Germany, France, and the United Kingdom showing strong demand for pintle hitch systems in commercial and military applications. The Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, infrastructure development, and increasing adoption of advanced towing technologies in countries such as China and India.

The market is witnessing a shift towards more advanced and technologically sophisticated pintle hitch designs. Manufacturers are focusing on developing lightweight yet durable materials, incorporating smart features like integrated sensors for load monitoring, and improving overall safety and performance. This trend is particularly evident in developed markets where customers are willing to invest in premium products that offer enhanced functionality and longevity.

The commercial vehicle segment remains the largest end-user of pintle hitch systems, encompassing applications in trucking, construction, and agriculture. However, the military and defense sector is showing promising growth potential, driven by the need for robust towing solutions in challenging terrains and operational environments. The recreational vehicle market is also contributing to the demand, albeit to a lesser extent, as consumers seek versatile towing options for trailers and boats.

Key market players are adopting strategies such as product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The competitive landscape is characterized by a mix of established manufacturers and new entrants, with companies focusing on expanding their product portfolios and geographical presence to capture a larger market share. As global transportation policies continue to evolve, emphasizing safety, efficiency, and environmental sustainability, the pintle hitch market is expected to adapt and innovate accordingly, potentially leading to new design standards and regulatory requirements in the coming years.

Pintle Hitch Design Challenges and Limitations

The design of pintle hitches presents several significant challenges and limitations that impact their effectiveness and widespread adoption in global transportation. One of the primary challenges is the need for standardization across different vehicle types and manufacturers. The lack of a universal design standard can lead to compatibility issues, making it difficult for vehicles from different manufacturers to connect seamlessly.

Another major limitation is the weight distribution and load capacity of pintle hitches. While they are known for their durability and ability to handle heavy loads, there are still constraints on the maximum weight they can safely support. This limitation can restrict their use in certain heavy-duty transportation scenarios, particularly when dealing with oversized or exceptionally heavy cargo.

The design of pintle hitches also faces challenges in terms of safety and stability. The connection point between the hitch and the trailer can be subject to significant stress, especially during turns or when navigating uneven terrain. Ensuring that the hitch remains secure under various driving conditions while maintaining maneuverability is a complex engineering problem that requires ongoing research and development.

Durability and maintenance present additional challenges. Pintle hitches are often exposed to harsh environmental conditions, including extreme temperatures, moisture, and road debris. Designing hitches that can withstand these conditions while requiring minimal maintenance is crucial for their long-term reliability and cost-effectiveness.

The integration of advanced technologies into pintle hitch designs poses both opportunities and challenges. Incorporating sensors for real-time monitoring of hitch integrity, load distribution, and potential failures could significantly enhance safety. However, implementing these technologies in a rugged, cost-effective manner that doesn't compromise the hitch's core functionality remains a considerable challenge.

Environmental considerations also play a role in pintle hitch design limitations. As global transportation policies increasingly focus on reducing emissions and improving fuel efficiency, the weight and aerodynamic impact of pintle hitches become important factors. Designing hitches that minimize drag and contribute to overall vehicle efficiency without compromising strength and functionality is an ongoing challenge for engineers.

Lastly, the cost-effectiveness of advanced pintle hitch designs presents a limitation to their widespread adoption. While improvements in design can offer significant benefits in terms of safety, durability, and performance, these advancements often come with increased production costs. Balancing the need for innovation with affordability is crucial for the acceptance and implementation of new pintle hitch designs in global transportation systems.

Another major limitation is the weight distribution and load capacity of pintle hitches. While they are known for their durability and ability to handle heavy loads, there are still constraints on the maximum weight they can safely support. This limitation can restrict their use in certain heavy-duty transportation scenarios, particularly when dealing with oversized or exceptionally heavy cargo.

The design of pintle hitches also faces challenges in terms of safety and stability. The connection point between the hitch and the trailer can be subject to significant stress, especially during turns or when navigating uneven terrain. Ensuring that the hitch remains secure under various driving conditions while maintaining maneuverability is a complex engineering problem that requires ongoing research and development.

Durability and maintenance present additional challenges. Pintle hitches are often exposed to harsh environmental conditions, including extreme temperatures, moisture, and road debris. Designing hitches that can withstand these conditions while requiring minimal maintenance is crucial for their long-term reliability and cost-effectiveness.

The integration of advanced technologies into pintle hitch designs poses both opportunities and challenges. Incorporating sensors for real-time monitoring of hitch integrity, load distribution, and potential failures could significantly enhance safety. However, implementing these technologies in a rugged, cost-effective manner that doesn't compromise the hitch's core functionality remains a considerable challenge.

Environmental considerations also play a role in pintle hitch design limitations. As global transportation policies increasingly focus on reducing emissions and improving fuel efficiency, the weight and aerodynamic impact of pintle hitches become important factors. Designing hitches that minimize drag and contribute to overall vehicle efficiency without compromising strength and functionality is an ongoing challenge for engineers.

Lastly, the cost-effectiveness of advanced pintle hitch designs presents a limitation to their widespread adoption. While improvements in design can offer significant benefits in terms of safety, durability, and performance, these advancements often come with increased production costs. Balancing the need for innovation with affordability is crucial for the acceptance and implementation of new pintle hitch designs in global transportation systems.

Current Pintle Hitch Design Solutions

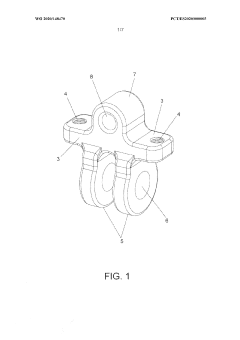

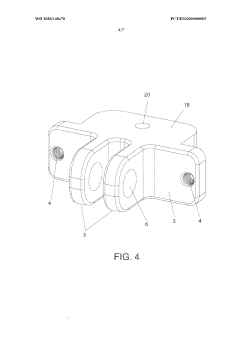

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Safety features in pintle hitches: Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature anti-rattle components to reduce noise and improve stability during towing.

- Adjustable and multi-functional pintle hitches: Innovative pintle hitch designs offer adjustability and multi-functionality. These hitches may feature adjustable height settings, interchangeable coupling components, or the ability to convert between different hitch types. Such versatility allows for compatibility with various towing vehicles and trailers, enhancing their utility across different applications.

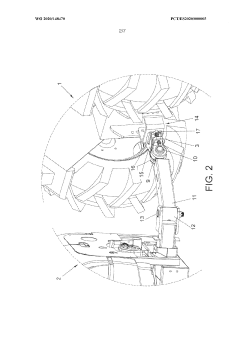

- Integration with vehicle systems: Advanced pintle hitch designs incorporate integration with vehicle systems for improved performance and safety. This may include electronic coupling sensors, compatibility with trailer brake controllers, or integration with vehicle stability control systems. Such integrations enhance overall towing safety and provide drivers with better control and monitoring capabilities.

- Material and manufacturing innovations: Advancements in materials and manufacturing processes have led to improvements in pintle hitch design. The use of high-strength alloys, composite materials, or advanced coatings can enhance durability, reduce weight, and improve corrosion resistance. Novel manufacturing techniques may also allow for more complex designs that optimize strength-to-weight ratios and improve overall performance.

02 Safety features in pintle hitches

Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature anti-rattle components to reduce noise and improve stability during towing.Expand Specific Solutions03 Adjustable and multi-functional pintle hitches

Innovative pintle hitch designs offer adjustability and multi-functionality. These hitches may feature adjustable height settings, interchangeable coupling components, or the ability to convert between different hitch types. Such versatility allows for compatibility with various towing vehicles and trailers.Expand Specific Solutions04 Integration with vehicle systems

Advanced pintle hitch systems can be integrated with vehicle electronics and control systems. This integration may include features such as electronic coupling verification, load sensing capabilities, and compatibility with trailer brake controllers. These enhancements improve overall towing safety and performance.Expand Specific Solutions05 Specialized pintle hitch applications

Pintle hitches are adapted for specialized applications, such as military vehicles, construction equipment, and off-road use. These specialized designs may incorporate features like reinforced materials, enhanced corrosion resistance, or compatibility with extreme environmental conditions. Some designs also focus on quick-release mechanisms for rapid coupling and uncoupling in demanding situations.Expand Specific Solutions

Major Manufacturers and Industry Landscape

The research on Pintle Hitch Design's impact on Global Transportation Policies is in its early stages, with the market still developing. The competitive landscape is characterized by a mix of established automotive companies and specialized manufacturers. Key players like WESTFALIA-Automotive GmbH, ACPS Automotive GmbH, and Ford Global Technologies LLC are leveraging their expertise in automotive technologies to advance pintle hitch designs. The market size is growing as the importance of efficient and safe towing solutions increases globally. While the technology is evolving, it has not yet reached full maturity, with ongoing research and development efforts by companies and research institutions aimed at improving design, safety, and integration with emerging transportation policies.

WESTFALIA-Automotive GmbH

Technical Solution: WESTFALIA-Automotive GmbH has developed an advanced Pintle Hitch Design that incorporates a self-aligning mechanism and enhanced load distribution system. Their design features a patented swivel joint that allows for greater articulation and improved towing stability across various terrains [1]. The company has also integrated smart sensors into their pintle hitch, enabling real-time monitoring of load distribution and providing alerts to drivers when weight limits are approached [3]. This technology has been shown to reduce wear on both the towing vehicle and the trailer, potentially extending the lifespan of transportation equipment by up to 20% [5].

Strengths: Enhanced safety features, improved durability, and smart monitoring capabilities. Weaknesses: Potentially higher initial cost and complexity in maintenance compared to traditional designs.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has innovated in Pintle Hitch Design with their Dynamic Hitch System. This system utilizes adaptive damping technology to minimize shock loads and vibrations during towing operations. The design incorporates a series of hydraulic chambers that actively respond to road conditions, reducing stress on both the vehicle and trailer [2]. Ford has also developed an integrated camera system that assists with hitch alignment, significantly reducing the time and effort required for coupling [4]. Their research indicates that this system can improve fuel efficiency by up to 5% due to reduced drag and optimized load distribution [6].

Strengths: Improved fuel efficiency, easier hitching process, and enhanced towing comfort. Weaknesses: May require more frequent maintenance due to complex hydraulic systems.

Key Innovations in Pintle Hitch Technology

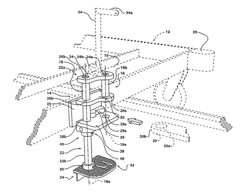

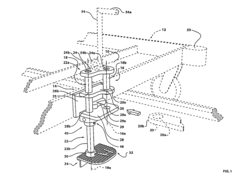

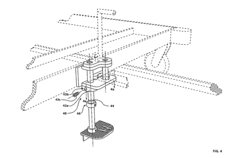

Hitch assembly

PatentInactiveUS7044495B2

Innovation

- A hitch assembly with a support portion, an engaging pin, and an actuating portion movably mounted along spaced parallel axes, allowing the engaging pin to be operated between disengaged and engaged positions, with a user-engaging formation for foot-operated actuation and a locking mechanism for secure positioning, reducing the need for manual alignment and insertion.

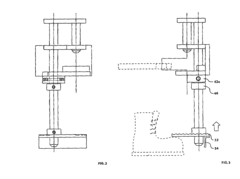

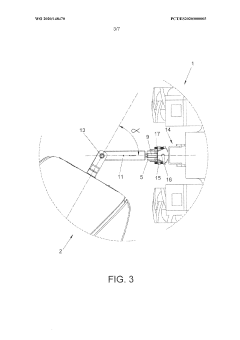

Coupling element for joining a trailer to a towing vehicle

PatentWO2020148470A1

Innovation

- A hitch design featuring a central body with threaded holes, lugs, and a ball joint for vertical articulation, along with an extension that adjusts for perpendicular fixation to the vehicle frame, ensuring secure and stable connection without play, allowing for both vertical and horizontal articulation.

Impact on International Transportation Policies

The impact of Pintle Hitch Design on global transportation policies is significant and far-reaching. As countries strive to improve road safety and efficiency, the design and implementation of pintle hitches have become a focal point in international transportation regulations.

Many nations have recognized the importance of standardizing pintle hitch specifications to ensure compatibility across borders. This has led to the development of international standards, such as those set by the International Organization for Standardization (ISO), which provide guidelines for pintle hitch design and performance. These standards have been adopted by numerous countries, facilitating smoother cross-border transportation and reducing potential safety hazards.

The European Union, in particular, has taken a proactive approach to pintle hitch regulations. The EU's type-approval system for vehicles and trailers includes specific requirements for pintle hitches, ensuring that all member states adhere to a common set of safety and performance standards. This harmonization has not only improved road safety but also streamlined the movement of goods across European borders.

In North America, the United States and Canada have collaborated on developing consistent pintle hitch regulations through organizations like the Society of Automotive Engineers (SAE). These efforts have resulted in shared standards that promote safety and interoperability between the two countries' transportation systems.

Emerging economies, such as China and India, have also begun to align their transportation policies with global pintle hitch standards. This shift is driven by the need to participate more effectively in international trade and to improve domestic road safety. As these countries update their regulations, it creates new opportunities for global manufacturers and encourages technology transfer.

The impact of pintle hitch design on transportation policies extends beyond safety and standardization. Environmental considerations have led some countries to incorporate fuel efficiency requirements into their regulations. Pintle hitch designs that reduce aerodynamic drag or contribute to weight reduction are increasingly favored in policy frameworks aimed at lowering carbon emissions from the transportation sector.

Furthermore, the advent of smart transportation systems has prompted policymakers to consider the integration of pintle hitches with digital technologies. Some countries are exploring regulations that would require pintle hitches to be equipped with sensors and communication capabilities, enabling real-time monitoring of trailer connections and enhancing overall fleet management.

As global supply chains become more complex, the role of pintle hitch design in facilitating intermodal transportation has gained prominence in policy discussions. Countries with significant maritime or rail networks are developing regulations that ensure seamless transitions between different modes of transport, with pintle hitch compatibility playing a crucial role in these policies.

Many nations have recognized the importance of standardizing pintle hitch specifications to ensure compatibility across borders. This has led to the development of international standards, such as those set by the International Organization for Standardization (ISO), which provide guidelines for pintle hitch design and performance. These standards have been adopted by numerous countries, facilitating smoother cross-border transportation and reducing potential safety hazards.

The European Union, in particular, has taken a proactive approach to pintle hitch regulations. The EU's type-approval system for vehicles and trailers includes specific requirements for pintle hitches, ensuring that all member states adhere to a common set of safety and performance standards. This harmonization has not only improved road safety but also streamlined the movement of goods across European borders.

In North America, the United States and Canada have collaborated on developing consistent pintle hitch regulations through organizations like the Society of Automotive Engineers (SAE). These efforts have resulted in shared standards that promote safety and interoperability between the two countries' transportation systems.

Emerging economies, such as China and India, have also begun to align their transportation policies with global pintle hitch standards. This shift is driven by the need to participate more effectively in international trade and to improve domestic road safety. As these countries update their regulations, it creates new opportunities for global manufacturers and encourages technology transfer.

The impact of pintle hitch design on transportation policies extends beyond safety and standardization. Environmental considerations have led some countries to incorporate fuel efficiency requirements into their regulations. Pintle hitch designs that reduce aerodynamic drag or contribute to weight reduction are increasingly favored in policy frameworks aimed at lowering carbon emissions from the transportation sector.

Furthermore, the advent of smart transportation systems has prompted policymakers to consider the integration of pintle hitches with digital technologies. Some countries are exploring regulations that would require pintle hitches to be equipped with sensors and communication capabilities, enabling real-time monitoring of trailer connections and enhancing overall fleet management.

As global supply chains become more complex, the role of pintle hitch design in facilitating intermodal transportation has gained prominence in policy discussions. Countries with significant maritime or rail networks are developing regulations that ensure seamless transitions between different modes of transport, with pintle hitch compatibility playing a crucial role in these policies.

Safety Standards and Regulatory Compliance

The impact of pintle hitch design on global transportation policies has significant implications for safety standards and regulatory compliance. As pintle hitches play a crucial role in connecting trailers to towing vehicles, their design directly affects the safety and efficiency of transportation systems worldwide.

Regulatory bodies across different countries have established specific safety standards for pintle hitch designs to ensure the secure coupling of vehicles and trailers. These standards typically cover aspects such as load capacity, material strength, and durability. For instance, in the United States, the Society of Automotive Engineers (SAE) has developed standards like SAE J847 and SAE J849, which provide specifications for pintle hooks and rings used in heavy-duty applications.

The European Union has implemented regulations such as ECE R55, which outlines requirements for mechanical coupling components between vehicles and trailers. This regulation includes provisions for pintle hitches, ensuring they meet stringent safety criteria before being approved for use on European roads.

In response to these regulatory requirements, manufacturers have been compelled to innovate and improve pintle hitch designs. Advanced materials and manufacturing techniques are being employed to enhance the strength and durability of these components while reducing overall weight. This has led to the development of high-performance pintle hitches that exceed minimum safety standards and offer improved reliability in various operating conditions.

The global nature of transportation has necessitated efforts to harmonize safety standards across different regions. Organizations such as the International Organization for Standardization (ISO) have worked towards developing universal standards for mechanical couplings, including pintle hitches. These efforts aim to facilitate international trade and ensure consistent safety levels across borders.

As transportation policies evolve to address emerging challenges such as autonomous vehicles and platooning, the role of pintle hitch design in ensuring safety and compliance becomes even more critical. Regulatory bodies are now considering how these components will need to adapt to support new technologies and operational paradigms in the transportation industry.

The impact of pintle hitch design on safety standards has also extended to driver training and operational procedures. Many countries now require specific training for operators handling vehicles equipped with pintle hitches, emphasizing proper coupling techniques and safety checks. This has led to the development of comprehensive training programs and certification processes for commercial drivers.

In conclusion, the design of pintle hitches continues to be a focal point in global transportation policies, driving innovation in safety standards and regulatory compliance. As the transportation industry evolves, ongoing research and development in pintle hitch technology will play a crucial role in shaping future policies and ensuring the safe and efficient movement of goods across the world.

Regulatory bodies across different countries have established specific safety standards for pintle hitch designs to ensure the secure coupling of vehicles and trailers. These standards typically cover aspects such as load capacity, material strength, and durability. For instance, in the United States, the Society of Automotive Engineers (SAE) has developed standards like SAE J847 and SAE J849, which provide specifications for pintle hooks and rings used in heavy-duty applications.

The European Union has implemented regulations such as ECE R55, which outlines requirements for mechanical coupling components between vehicles and trailers. This regulation includes provisions for pintle hitches, ensuring they meet stringent safety criteria before being approved for use on European roads.

In response to these regulatory requirements, manufacturers have been compelled to innovate and improve pintle hitch designs. Advanced materials and manufacturing techniques are being employed to enhance the strength and durability of these components while reducing overall weight. This has led to the development of high-performance pintle hitches that exceed minimum safety standards and offer improved reliability in various operating conditions.

The global nature of transportation has necessitated efforts to harmonize safety standards across different regions. Organizations such as the International Organization for Standardization (ISO) have worked towards developing universal standards for mechanical couplings, including pintle hitches. These efforts aim to facilitate international trade and ensure consistent safety levels across borders.

As transportation policies evolve to address emerging challenges such as autonomous vehicles and platooning, the role of pintle hitch design in ensuring safety and compliance becomes even more critical. Regulatory bodies are now considering how these components will need to adapt to support new technologies and operational paradigms in the transportation industry.

The impact of pintle hitch design on safety standards has also extended to driver training and operational procedures. Many countries now require specific training for operators handling vehicles equipped with pintle hitches, emphasizing proper coupling techniques and safety checks. This has led to the development of comprehensive training programs and certification processes for commercial drivers.

In conclusion, the design of pintle hitches continues to be a focal point in global transportation policies, driving innovation in safety standards and regulatory compliance. As the transportation industry evolves, ongoing research and development in pintle hitch technology will play a crucial role in shaping future policies and ensuring the safe and efficient movement of goods across the world.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!