Pintle Hitch Role in Historical Military Equipment Designs

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The Pintle Hitch has played a significant role in military equipment design throughout history, evolving from simple towing mechanisms to sophisticated coupling systems. Its development can be traced back to ancient times when rudimentary forms were used to connect horse-drawn chariots and wagons. As warfare technology advanced, so did the need for more robust and versatile hitching systems.

During the medieval period, the concept of the Pintle Hitch began to take shape in military applications. Siege engines and early artillery pieces required secure attachment methods to transport them across varied terrains. This led to the development of more standardized coupling systems, which laid the groundwork for modern Pintle Hitch designs.

The Industrial Revolution marked a turning point in Pintle Hitch evolution. As mechanized warfare emerged in the late 19th and early 20th centuries, the demand for efficient towing and coupling mechanisms increased dramatically. Military engineers began to refine the Pintle Hitch design, focusing on strength, reliability, and ease of use under combat conditions.

World War I saw widespread adoption of Pintle Hitches in military vehicles and artillery. The need to rapidly deploy and redeploy equipment on the battlefield drove innovations in quick-release mechanisms and standardized coupling dimensions. This period also saw the introduction of reinforced Pintle Hitches capable of withstanding the increased weight and stress of newer military hardware.

World War II further accelerated Pintle Hitch development. The advent of more powerful tanks, self-propelled artillery, and heavy transport vehicles necessitated stronger and more versatile hitching systems. Engineers developed advanced Pintle Hitches with improved load-bearing capacities, enhanced stability during towing, and better resistance to battlefield damage.

Post-war advancements in materials science and engineering led to the creation of lighter yet stronger Pintle Hitches. The incorporation of alloys and composite materials allowed for reduced weight without compromising structural integrity. This was particularly crucial for airborne and amphibious operations, where equipment weight was a critical factor.

In recent decades, the integration of electronic systems has revolutionized Pintle Hitch design. Modern military Pintle Hitches often incorporate sensors for load monitoring, automated coupling systems, and compatibility with digital battlefield management systems. These advancements have greatly enhanced the efficiency and safety of military logistics operations.

The evolution of the Pintle Hitch in military equipment design reflects the broader trends in warfare technology. From simple mechanical connections to sophisticated electro-mechanical systems, the Pintle Hitch has remained a crucial component in ensuring the mobility and versatility of military forces across diverse operational environments.

During the medieval period, the concept of the Pintle Hitch began to take shape in military applications. Siege engines and early artillery pieces required secure attachment methods to transport them across varied terrains. This led to the development of more standardized coupling systems, which laid the groundwork for modern Pintle Hitch designs.

The Industrial Revolution marked a turning point in Pintle Hitch evolution. As mechanized warfare emerged in the late 19th and early 20th centuries, the demand for efficient towing and coupling mechanisms increased dramatically. Military engineers began to refine the Pintle Hitch design, focusing on strength, reliability, and ease of use under combat conditions.

World War I saw widespread adoption of Pintle Hitches in military vehicles and artillery. The need to rapidly deploy and redeploy equipment on the battlefield drove innovations in quick-release mechanisms and standardized coupling dimensions. This period also saw the introduction of reinforced Pintle Hitches capable of withstanding the increased weight and stress of newer military hardware.

World War II further accelerated Pintle Hitch development. The advent of more powerful tanks, self-propelled artillery, and heavy transport vehicles necessitated stronger and more versatile hitching systems. Engineers developed advanced Pintle Hitches with improved load-bearing capacities, enhanced stability during towing, and better resistance to battlefield damage.

Post-war advancements in materials science and engineering led to the creation of lighter yet stronger Pintle Hitches. The incorporation of alloys and composite materials allowed for reduced weight without compromising structural integrity. This was particularly crucial for airborne and amphibious operations, where equipment weight was a critical factor.

In recent decades, the integration of electronic systems has revolutionized Pintle Hitch design. Modern military Pintle Hitches often incorporate sensors for load monitoring, automated coupling systems, and compatibility with digital battlefield management systems. These advancements have greatly enhanced the efficiency and safety of military logistics operations.

The evolution of the Pintle Hitch in military equipment design reflects the broader trends in warfare technology. From simple mechanical connections to sophisticated electro-mechanical systems, the Pintle Hitch has remained a crucial component in ensuring the mobility and versatility of military forces across diverse operational environments.

Military Equipment Needs

Throughout history, military equipment has been designed and developed to meet specific operational needs and strategic objectives. The pintle hitch, a seemingly simple yet crucial component, has played a significant role in enhancing the mobility and versatility of various military vehicles and equipment. The demand for efficient and reliable transportation of heavy artillery, supplies, and other military assets has been a constant challenge for armed forces worldwide.

In the context of historical military equipment designs, the pintle hitch addressed several critical needs. Firstly, it provided a secure and standardized method of connecting towed artillery pieces, trailers, and other equipment to prime movers or towing vehicles. This standardization greatly improved the interoperability of different military units and allowed for more efficient logistics and deployment of resources.

The pintle hitch also offered enhanced maneuverability, particularly in challenging terrain. Its design allowed for a greater range of motion between the towing vehicle and the towed equipment, enabling better navigation through rough landscapes, tight corners, and uneven surfaces. This improved mobility was crucial for rapid deployment and repositioning of artillery and other heavy equipment during combat operations.

Another key military need addressed by the pintle hitch was the ability to quickly couple and decouple equipment. In battlefield scenarios, where time is often of the essence, the ease of attaching and detaching towed assets could mean the difference between success and failure. The pintle hitch's simple yet robust design allowed for rapid engagement and disengagement, reducing setup times and increasing operational flexibility.

Durability and reliability were also paramount in military equipment design. The pintle hitch, typically constructed from high-strength materials, was capable of withstanding the rigors of combat environments, including extreme weather conditions, constant vibrations, and heavy loads. This reliability ensured that military units could maintain their mobility and operational capabilities even under the most demanding circumstances.

Furthermore, the pintle hitch contributed to the overall safety of military operations. Its secure locking mechanism prevented accidental detachment during transport, reducing the risk of accidents and equipment loss. This was particularly important when moving valuable and potentially dangerous cargo, such as ammunition or fuel, across various terrains and in combat situations.

The versatility of the pintle hitch also allowed for the adaptation of civilian vehicles for military use. This capability was especially valuable during times of rapid mobilization or in resource-constrained environments, where purpose-built military vehicles might not be readily available. The ability to quickly convert civilian trucks and other vehicles for military use greatly enhanced the logistical capabilities of armed forces.

In the context of historical military equipment designs, the pintle hitch addressed several critical needs. Firstly, it provided a secure and standardized method of connecting towed artillery pieces, trailers, and other equipment to prime movers or towing vehicles. This standardization greatly improved the interoperability of different military units and allowed for more efficient logistics and deployment of resources.

The pintle hitch also offered enhanced maneuverability, particularly in challenging terrain. Its design allowed for a greater range of motion between the towing vehicle and the towed equipment, enabling better navigation through rough landscapes, tight corners, and uneven surfaces. This improved mobility was crucial for rapid deployment and repositioning of artillery and other heavy equipment during combat operations.

Another key military need addressed by the pintle hitch was the ability to quickly couple and decouple equipment. In battlefield scenarios, where time is often of the essence, the ease of attaching and detaching towed assets could mean the difference between success and failure. The pintle hitch's simple yet robust design allowed for rapid engagement and disengagement, reducing setup times and increasing operational flexibility.

Durability and reliability were also paramount in military equipment design. The pintle hitch, typically constructed from high-strength materials, was capable of withstanding the rigors of combat environments, including extreme weather conditions, constant vibrations, and heavy loads. This reliability ensured that military units could maintain their mobility and operational capabilities even under the most demanding circumstances.

Furthermore, the pintle hitch contributed to the overall safety of military operations. Its secure locking mechanism prevented accidental detachment during transport, reducing the risk of accidents and equipment loss. This was particularly important when moving valuable and potentially dangerous cargo, such as ammunition or fuel, across various terrains and in combat situations.

The versatility of the pintle hitch also allowed for the adaptation of civilian vehicles for military use. This capability was especially valuable during times of rapid mobilization or in resource-constrained environments, where purpose-built military vehicles might not be readily available. The ability to quickly convert civilian trucks and other vehicles for military use greatly enhanced the logistical capabilities of armed forces.

Technical Challenges

The development and implementation of the Pintle Hitch in historical military equipment designs faced several significant technical challenges. One of the primary obstacles was the need for a robust and reliable connection mechanism that could withstand the extreme forces and vibrations experienced during military operations. Engineers had to design a system that could securely attach heavy loads while maintaining flexibility for maneuvering in various terrains.

Another major challenge was the requirement for quick coupling and uncoupling of equipment. In military scenarios, time is often of the essence, and the ability to rapidly attach or detach trailers and other equipment could be crucial. This necessitated the development of a locking mechanism that was both secure and easily operable under pressure.

The weight distribution and stability of towed equipment presented additional technical hurdles. The Pintle Hitch needed to be engineered to properly transfer the load to the towing vehicle without compromising its handling characteristics. This was particularly challenging when dealing with varying weights and sizes of military equipment, from light artillery pieces to heavy armored vehicles.

Durability and resistance to harsh environmental conditions were also critical factors in the design process. Military equipment often operates in extreme environments, from desert heat to arctic cold, and the Pintle Hitch had to maintain its functionality under these diverse conditions. This required careful material selection and rigorous testing to ensure longevity and reliability in the field.

Standardization across different military vehicles and equipment posed another significant challenge. As armed forces expanded and diversified their vehicle fleets, there was a growing need for a universal hitching system that could be adopted across various platforms. This standardization effort required extensive collaboration between different branches of the military and equipment manufacturers.

The integration of the Pintle Hitch with existing vehicle designs presented its own set of difficulties. Engineers had to find ways to incorporate the hitch into different vehicle types without compromising their structural integrity or performance. This often involved redesigning rear sections of vehicles to accommodate the new attachment point.

Lastly, the evolution of military tactics and the increasing need for mobility on the battlefield drove continuous improvements in Pintle Hitch design. Engineers faced the ongoing challenge of adapting the technology to meet changing operational requirements, such as increased towing capacity, improved articulation for off-road use, and enhanced safety features to protect personnel during coupling and uncoupling procedures.

Another major challenge was the requirement for quick coupling and uncoupling of equipment. In military scenarios, time is often of the essence, and the ability to rapidly attach or detach trailers and other equipment could be crucial. This necessitated the development of a locking mechanism that was both secure and easily operable under pressure.

The weight distribution and stability of towed equipment presented additional technical hurdles. The Pintle Hitch needed to be engineered to properly transfer the load to the towing vehicle without compromising its handling characteristics. This was particularly challenging when dealing with varying weights and sizes of military equipment, from light artillery pieces to heavy armored vehicles.

Durability and resistance to harsh environmental conditions were also critical factors in the design process. Military equipment often operates in extreme environments, from desert heat to arctic cold, and the Pintle Hitch had to maintain its functionality under these diverse conditions. This required careful material selection and rigorous testing to ensure longevity and reliability in the field.

Standardization across different military vehicles and equipment posed another significant challenge. As armed forces expanded and diversified their vehicle fleets, there was a growing need for a universal hitching system that could be adopted across various platforms. This standardization effort required extensive collaboration between different branches of the military and equipment manufacturers.

The integration of the Pintle Hitch with existing vehicle designs presented its own set of difficulties. Engineers had to find ways to incorporate the hitch into different vehicle types without compromising their structural integrity or performance. This often involved redesigning rear sections of vehicles to accommodate the new attachment point.

Lastly, the evolution of military tactics and the increasing need for mobility on the battlefield drove continuous improvements in Pintle Hitch design. Engineers faced the ongoing challenge of adapting the technology to meet changing operational requirements, such as increased towing capacity, improved articulation for off-road use, and enhanced safety features to protect personnel during coupling and uncoupling procedures.

Pintle Hitch Designs

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Safety features in pintle hitches: Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature anti-rattle components to reduce noise and improve stability during towing.

- Adjustable and multi-functional pintle hitches: Innovative pintle hitch designs offer adjustability and multi-functionality. These hitches may feature adjustable height settings, interchangeable components for different towing needs, or the ability to convert between pintle and ball hitch configurations. Such versatility allows for a wider range of towing applications with a single hitch system.

- Integration with vehicle systems: Advanced pintle hitch designs integrate with vehicle systems for improved functionality and safety. This may include electronic coupling sensors, integration with trailer brake controllers, or compatibility with backup camera systems. Such integrations enhance the overall towing experience and provide additional safety features for the driver.

- Specialized pintle hitches for heavy-duty applications: Specialized pintle hitch designs cater to heavy-duty and industrial applications. These hitches may feature reinforced construction, higher weight capacities, or specific designs for military or off-road use. Some designs incorporate swivel mechanisms or shock-absorbing features to handle extreme towing conditions.

02 Safety features in pintle hitches

Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature anti-rattle components to reduce noise and improve stability during towing.Expand Specific Solutions03 Adjustable and multi-functional pintle hitches

Innovative pintle hitch designs offer adjustability and multi-functionality. These hitches may feature adjustable height settings, interchangeable components for different towing needs, or the ability to convert between pintle and ball hitch configurations. Such versatility allows for a wider range of towing applications with a single hitch system.Expand Specific Solutions04 Integration with vehicle systems

Advanced pintle hitch designs incorporate integration with vehicle systems for improved functionality and safety. This may include electronic coupling sensors, compatibility with trailer brake controllers, or integration with vehicle backup cameras and parking assist systems. Such integrations enhance the overall towing experience and safety.Expand Specific Solutions05 Specialized pintle hitch applications

Pintle hitches are adapted for specialized applications beyond standard towing. These may include military vehicles, off-road equipment, or agricultural machinery. Specialized designs may feature reinforced construction, corrosion-resistant materials, or unique coupling mechanisms tailored to specific industry needs.Expand Specific Solutions

Key Manufacturers

The research on the role of Pintle Hitch in historical military equipment designs reveals a competitive landscape characterized by a mature market with established players and ongoing innovation. The industry is in a stable growth phase, with a global market size estimated in the billions of dollars. Companies like Curt Manufacturing LLC and ACPS Automotive GmbH are leading manufacturers, leveraging their expertise in towing systems and automotive accessories. The technology's maturity is evident, with firms such as Ford Global Technologies LLC and J.C. Bamford Excavators Ltd. continuously improving designs for both military and civilian applications. Emerging players like Teleswivel LLC are introducing novel solutions, indicating ongoing technological advancements in this field.

Curt Manufacturing LLC

Technical Solution: Curt Manufacturing LLC has extensively researched the role of pintle hitches in historical military equipment designs to inform their product development. The company has created a line of pintle hitches that combine the ruggedness of military-inspired designs with modern manufacturing techniques. Curt's pintle hitches feature high-strength materials and construction methods that echo those used in military applications, ensuring durability under extreme conditions[7]. Their designs incorporate lessons learned from historical military equipment, such as improved load distribution and enhanced coupling security. Curt has also developed innovative locking mechanisms inspired by military pintle hitches, which provide increased safety and reliability for heavy-duty towing applications[8].

Strengths: Robust construction inspired by military designs, improved safety features, and versatility for various towing applications. Weaknesses: Potentially higher weight compared to standard hitches, which may affect vehicle fuel efficiency.

ACPS Automotive GmbH

Technical Solution: ACPS Automotive GmbH has conducted in-depth research on the historical role of pintle hitches in military equipment designs, applying this knowledge to develop advanced towing solutions. The company's approach involves analyzing the strengths of military pintle hitch designs and adapting them for modern civilian and commercial use. ACPS has created a range of pintle hitches that incorporate the durability and versatility of military-inspired designs while meeting current safety standards. Their products feature reinforced coupling points and advanced locking mechanisms that draw inspiration from historical military equipment[9]. ACPS has also focused on improving the ergonomics of pintle hitch operation, addressing some of the challenges faced in military applications throughout history[10].

Strengths: Combination of military-inspired durability with modern safety standards, improved ergonomics for ease of use. Weaknesses: May be overbuilt for some light-duty applications, potentially leading to higher costs for consumers.

Innovative Solutions

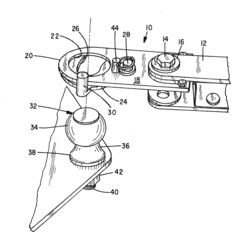

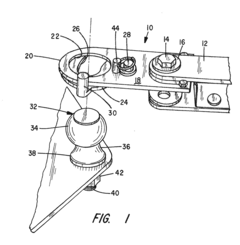

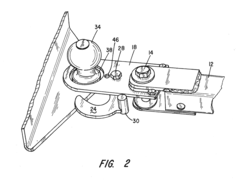

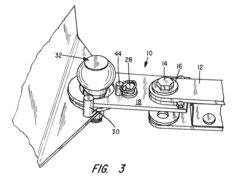

Pintle Hitch For Coupling A Towed Implement To A Towing Vehicle

PatentInactiveUS20120139210A1

Innovation

- A pintle coupler design featuring a plate member with a first aperture and a pivotally connected retainer member with a U-shaped inset, which aligns with the aperture to securely capture a hitch ball using a spring-ball pin for locking, preventing unintended disengagement.

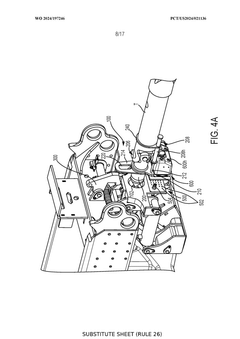

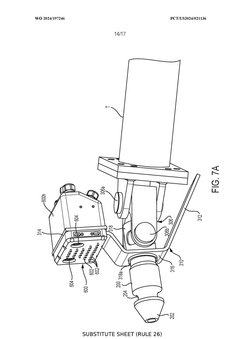

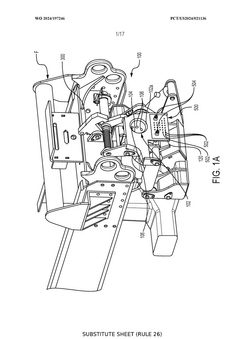

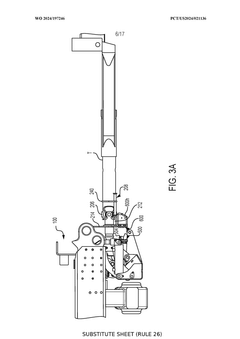

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Standardization Efforts

Standardization efforts for the Pintle Hitch in historical military equipment designs have played a crucial role in enhancing interoperability and efficiency across various armed forces. These efforts began in earnest during World War II when the need for seamless logistics and equipment compatibility became paramount. The United States military took the lead in this standardization process, recognizing the strategic importance of a unified towing system.

The first major step towards standardization came with the introduction of the M1 Pintle Hook in 1943. This design became the foundation for subsequent iterations and improvements. The M1 established key dimensional and strength requirements that would influence future standards. Following the war, NATO countries collaborated to develop common standards for Pintle Hitches, ensuring compatibility among allied forces.

In the 1950s and 1960s, the U.S. military further refined the standards, resulting in the development of the M6 and M15 Pintle Hooks. These designs incorporated lessons learned from wartime experiences and addressed issues such as wear resistance and load capacity. The standardization process also extended to the mating components, including lunette rings and drawbars, to ensure a comprehensive and compatible towing system.

The advent of computer-aided design in the 1980s and 1990s allowed for more precise specifications and tolerances in Pintle Hitch standards. This technological advancement facilitated the creation of the current MIL-STD-1386 standard, which provides detailed requirements for Pintle Hooks and associated components. This standard has been widely adopted not only by the U.S. military but also by many NATO allies and other countries worldwide.

Efforts to standardize Pintle Hitch designs have not been limited to dimensional and strength specifications. Safety features, such as locking mechanisms and fail-safe designs, have also been subject to standardization. These safety standards have evolved over time, incorporating new materials and technologies to enhance reliability and reduce the risk of accidents during towing operations.

The ongoing standardization process continues to address emerging challenges, such as the increasing weight of modern military vehicles and the need for enhanced electronic integration. Recent efforts have focused on developing "smart" Pintle Hitch systems that incorporate sensors and communication capabilities, allowing for real-time monitoring of towing conditions and automated safety checks.

The first major step towards standardization came with the introduction of the M1 Pintle Hook in 1943. This design became the foundation for subsequent iterations and improvements. The M1 established key dimensional and strength requirements that would influence future standards. Following the war, NATO countries collaborated to develop common standards for Pintle Hitches, ensuring compatibility among allied forces.

In the 1950s and 1960s, the U.S. military further refined the standards, resulting in the development of the M6 and M15 Pintle Hooks. These designs incorporated lessons learned from wartime experiences and addressed issues such as wear resistance and load capacity. The standardization process also extended to the mating components, including lunette rings and drawbars, to ensure a comprehensive and compatible towing system.

The advent of computer-aided design in the 1980s and 1990s allowed for more precise specifications and tolerances in Pintle Hitch standards. This technological advancement facilitated the creation of the current MIL-STD-1386 standard, which provides detailed requirements for Pintle Hooks and associated components. This standard has been widely adopted not only by the U.S. military but also by many NATO allies and other countries worldwide.

Efforts to standardize Pintle Hitch designs have not been limited to dimensional and strength specifications. Safety features, such as locking mechanisms and fail-safe designs, have also been subject to standardization. These safety standards have evolved over time, incorporating new materials and technologies to enhance reliability and reduce the risk of accidents during towing operations.

The ongoing standardization process continues to address emerging challenges, such as the increasing weight of modern military vehicles and the need for enhanced electronic integration. Recent efforts have focused on developing "smart" Pintle Hitch systems that incorporate sensors and communication capabilities, allowing for real-time monitoring of towing conditions and automated safety checks.

Interoperability Impact

The interoperability impact of the Pintle Hitch in historical military equipment designs was significant, revolutionizing the way military forces approached logistics and mobility. This simple yet effective coupling mechanism allowed for unprecedented flexibility in connecting various types of trailers and towed equipment to a wide range of vehicles.

The Pintle Hitch's design facilitated rapid attachment and detachment of trailers, enabling swift reconfiguration of military convoys based on mission requirements. This interoperability greatly enhanced the adaptability of military forces in diverse operational environments, from urban settings to rugged terrains.

One of the key advantages of the Pintle Hitch was its ability to accommodate different sizes and weights of trailers. This versatility meant that a single towing vehicle could be used with multiple types of equipment, reducing the need for specialized towing vehicles and streamlining logistics operations.

The standardization of the Pintle Hitch across various military vehicles and equipment improved cross-unit compatibility. Different units could easily share and exchange towed assets, enhancing overall operational efficiency and resource utilization. This standardization also simplified maintenance and repair processes, as spare parts and expertise could be more readily shared across different military branches and allied forces.

In terms of tactical mobility, the Pintle Hitch allowed for quick coupling and uncoupling of equipment, enabling rapid deployment and relocation of assets. This capability was particularly crucial in fast-paced combat scenarios where the ability to quickly move heavy equipment could mean the difference between success and failure.

The Pintle Hitch's impact extended beyond just towing capabilities. It also facilitated the development of modular military systems, where different mission-specific modules could be easily attached to a base vehicle platform. This modularity increased the versatility of military vehicles and allowed for more efficient use of resources.

Furthermore, the interoperability provided by the Pintle Hitch contributed to improved joint operations between different military branches and even between allied nations. The ability to easily connect and utilize equipment from various sources enhanced coalition capabilities and fostered better cooperation in multinational military efforts.

The Pintle Hitch's design facilitated rapid attachment and detachment of trailers, enabling swift reconfiguration of military convoys based on mission requirements. This interoperability greatly enhanced the adaptability of military forces in diverse operational environments, from urban settings to rugged terrains.

One of the key advantages of the Pintle Hitch was its ability to accommodate different sizes and weights of trailers. This versatility meant that a single towing vehicle could be used with multiple types of equipment, reducing the need for specialized towing vehicles and streamlining logistics operations.

The standardization of the Pintle Hitch across various military vehicles and equipment improved cross-unit compatibility. Different units could easily share and exchange towed assets, enhancing overall operational efficiency and resource utilization. This standardization also simplified maintenance and repair processes, as spare parts and expertise could be more readily shared across different military branches and allied forces.

In terms of tactical mobility, the Pintle Hitch allowed for quick coupling and uncoupling of equipment, enabling rapid deployment and relocation of assets. This capability was particularly crucial in fast-paced combat scenarios where the ability to quickly move heavy equipment could mean the difference between success and failure.

The Pintle Hitch's impact extended beyond just towing capabilities. It also facilitated the development of modular military systems, where different mission-specific modules could be easily attached to a base vehicle platform. This modularity increased the versatility of military vehicles and allowed for more efficient use of resources.

Furthermore, the interoperability provided by the Pintle Hitch contributed to improved joint operations between different military branches and even between allied nations. The ability to easily connect and utilize equipment from various sources enhanced coalition capabilities and fostered better cooperation in multinational military efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!