UHMWPE in Robotic Joint Design: Flexibility and Strength

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Robotics: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the field of robotics, particularly in joint design. This advanced polymer, known for its exceptional mechanical properties, has been the subject of extensive research and development over the past few decades. The evolution of UHMWPE in robotics can be traced back to its initial applications in medical implants, where its wear resistance and biocompatibility were first recognized.

As robotics technology progressed, engineers and researchers began to explore the potential of UHMWPE in addressing the challenges of joint design. The primary goal of incorporating UHMWPE in robotic joints is to achieve an optimal balance between flexibility and strength, two critical factors in the performance and durability of robotic systems. This balance is essential for creating robots that can perform complex movements with precision while withstanding the stresses of repetitive motion and varying loads.

The technological trajectory of UHMWPE in robotics has been marked by continuous improvements in material processing and manufacturing techniques. Early applications focused on utilizing UHMWPE's inherent properties, while recent advancements have explored methods to enhance its characteristics further through various treatments and composites. These developments aim to push the boundaries of what is possible in robotic joint design, enabling the creation of more agile, robust, and efficient robotic systems.

The objectives of current research on UHMWPE in robotic joint design are multifaceted. Firstly, there is a strong focus on improving the material's wear resistance while maintaining its low friction properties. This is crucial for extending the operational lifespan of robotic joints and reducing maintenance requirements. Secondly, researchers are working on enhancing the material's strength-to-weight ratio, allowing for the development of lighter yet more durable robotic components.

Another key objective is to explore the potential of UHMWPE in creating more compliant joint designs. This aspect is particularly important in the development of collaborative robots and soft robotics, where safe human-robot interaction is paramount. The inherent flexibility of UHMWPE, combined with its strength, makes it an ideal candidate for these applications.

Furthermore, the research aims to understand and optimize the behavior of UHMWPE under various environmental conditions and loading scenarios. This includes studying its performance in extreme temperatures, humid environments, and under cyclic loading, which are common challenges in real-world robotic applications. By addressing these aspects, researchers hope to expand the range of environments and tasks in which UHMWPE-based robotic joints can be effectively utilized.

As robotics technology progressed, engineers and researchers began to explore the potential of UHMWPE in addressing the challenges of joint design. The primary goal of incorporating UHMWPE in robotic joints is to achieve an optimal balance between flexibility and strength, two critical factors in the performance and durability of robotic systems. This balance is essential for creating robots that can perform complex movements with precision while withstanding the stresses of repetitive motion and varying loads.

The technological trajectory of UHMWPE in robotics has been marked by continuous improvements in material processing and manufacturing techniques. Early applications focused on utilizing UHMWPE's inherent properties, while recent advancements have explored methods to enhance its characteristics further through various treatments and composites. These developments aim to push the boundaries of what is possible in robotic joint design, enabling the creation of more agile, robust, and efficient robotic systems.

The objectives of current research on UHMWPE in robotic joint design are multifaceted. Firstly, there is a strong focus on improving the material's wear resistance while maintaining its low friction properties. This is crucial for extending the operational lifespan of robotic joints and reducing maintenance requirements. Secondly, researchers are working on enhancing the material's strength-to-weight ratio, allowing for the development of lighter yet more durable robotic components.

Another key objective is to explore the potential of UHMWPE in creating more compliant joint designs. This aspect is particularly important in the development of collaborative robots and soft robotics, where safe human-robot interaction is paramount. The inherent flexibility of UHMWPE, combined with its strength, makes it an ideal candidate for these applications.

Furthermore, the research aims to understand and optimize the behavior of UHMWPE under various environmental conditions and loading scenarios. This includes studying its performance in extreme temperatures, humid environments, and under cyclic loading, which are common challenges in real-world robotic applications. By addressing these aspects, researchers hope to expand the range of environments and tasks in which UHMWPE-based robotic joints can be effectively utilized.

Market Analysis for UHMWPE in Robotic Joints

The market for Ultra-High Molecular Weight Polyethylene (UHMWPE) in robotic joint design is experiencing significant growth, driven by the increasing demand for advanced materials in robotics and automation industries. UHMWPE's unique combination of flexibility and strength makes it an attractive option for robotic joint applications, where durability and precision are paramount.

The global robotics market is projected to reach $260 billion by 2030, with a compound annual growth rate (CAGR) of 17.45% from 2023 to 2030. Within this broader market, the demand for specialized materials like UHMWPE is expected to grow proportionally. The industrial robotics sector, which includes manufacturing, automotive, and electronics industries, is currently the largest consumer of UHMWPE in robotic joints.

Key market drivers for UHMWPE in robotic joints include the material's excellent wear resistance, low friction coefficient, and high impact strength. These properties contribute to extended joint life, reduced maintenance requirements, and improved overall performance of robotic systems. Additionally, the lightweight nature of UHMWPE allows for the design of more energy-efficient robots, aligning with the growing emphasis on sustainability in industrial applications.

The healthcare robotics segment is emerging as a promising market for UHMWPE in joint design. Surgical robots and rehabilitation devices benefit from the material's biocompatibility and resistance to sterilization processes. As the global population ages and healthcare systems seek innovative solutions, this sector is expected to drive significant demand for UHMWPE in robotic joints.

Geographically, Asia-Pacific leads the market for UHMWPE in robotic joints, with China and Japan being the primary contributors. The region's dominance is attributed to its robust manufacturing sector and rapid adoption of automation technologies. North America and Europe follow closely, with strong demand from aerospace, automotive, and medical industries.

Despite the positive outlook, the market faces challenges such as the high initial cost of UHMWPE compared to traditional materials and the complexity of integrating it into existing robotic designs. However, ongoing research and development efforts are focused on enhancing the material's properties and developing cost-effective production methods, which are expected to address these challenges in the coming years.

As the robotics industry continues to evolve, the market for UHMWPE in robotic joints is anticipated to expand into new applications. Collaborative robots (cobots) and autonomous mobile robots (AMRs) represent emerging opportunities, where the material's properties can significantly enhance human-robot interaction and operational flexibility.

The global robotics market is projected to reach $260 billion by 2030, with a compound annual growth rate (CAGR) of 17.45% from 2023 to 2030. Within this broader market, the demand for specialized materials like UHMWPE is expected to grow proportionally. The industrial robotics sector, which includes manufacturing, automotive, and electronics industries, is currently the largest consumer of UHMWPE in robotic joints.

Key market drivers for UHMWPE in robotic joints include the material's excellent wear resistance, low friction coefficient, and high impact strength. These properties contribute to extended joint life, reduced maintenance requirements, and improved overall performance of robotic systems. Additionally, the lightweight nature of UHMWPE allows for the design of more energy-efficient robots, aligning with the growing emphasis on sustainability in industrial applications.

The healthcare robotics segment is emerging as a promising market for UHMWPE in joint design. Surgical robots and rehabilitation devices benefit from the material's biocompatibility and resistance to sterilization processes. As the global population ages and healthcare systems seek innovative solutions, this sector is expected to drive significant demand for UHMWPE in robotic joints.

Geographically, Asia-Pacific leads the market for UHMWPE in robotic joints, with China and Japan being the primary contributors. The region's dominance is attributed to its robust manufacturing sector and rapid adoption of automation technologies. North America and Europe follow closely, with strong demand from aerospace, automotive, and medical industries.

Despite the positive outlook, the market faces challenges such as the high initial cost of UHMWPE compared to traditional materials and the complexity of integrating it into existing robotic designs. However, ongoing research and development efforts are focused on enhancing the material's properties and developing cost-effective production methods, which are expected to address these challenges in the coming years.

As the robotics industry continues to evolve, the market for UHMWPE in robotic joints is anticipated to expand into new applications. Collaborative robots (cobots) and autonomous mobile robots (AMRs) represent emerging opportunities, where the material's properties can significantly enhance human-robot interaction and operational flexibility.

Current Challenges in UHMWPE Joint Applications

The application of Ultra-High Molecular Weight Polyethylene (UHMWPE) in robotic joint design presents several significant challenges that researchers and engineers must address. One of the primary issues is the balance between flexibility and strength, which is crucial for optimal joint performance in robotics.

UHMWPE's inherent properties, while beneficial in many aspects, can pose difficulties in achieving the desired mechanical characteristics for robotic joints. The material's high molecular weight and long polymer chains contribute to its excellent wear resistance and impact strength, but also result in a relatively low elastic modulus. This low stiffness can lead to excessive deformation under load, potentially compromising the precision and stability required in robotic applications.

Another challenge lies in the creep behavior of UHMWPE. Under sustained stress, the material tends to deform permanently over time, a phenomenon known as cold flow. This property can affect the long-term dimensional stability of robotic joints, potentially leading to increased clearances and reduced accuracy in motion control. Mitigating creep while maintaining the material's beneficial properties remains a significant hurdle in UHMWPE joint applications.

The integration of UHMWPE with other materials in robotic joint design also presents challenges. Achieving strong and durable bonds between UHMWPE and metals or other polymers is difficult due to its low surface energy and chemical inertness. This complicates the design of multi-material joint structures that aim to leverage the unique properties of UHMWPE alongside other materials.

Temperature sensitivity is another concern in UHMWPE joint applications. The material's mechanical properties can vary significantly with temperature changes, affecting joint performance across different operating conditions. This sensitivity necessitates careful consideration of thermal management in robotic systems utilizing UHMWPE components.

Furthermore, the processing and manufacturing of UHMWPE for precise robotic joint applications pose technical challenges. The material's high viscosity in its molten state makes it difficult to process using conventional injection molding techniques. Achieving the required dimensional accuracy and surface finish for robotic joints often requires specialized manufacturing processes, which can increase production complexity and costs.

Lastly, the long-term performance and degradation of UHMWPE in robotic joint applications remain areas of ongoing research. While the material exhibits excellent wear resistance, the effects of cyclic loading, environmental factors, and potential oxidative degradation on its long-term mechanical properties and performance in robotic joints are not fully understood and require further investigation.

UHMWPE's inherent properties, while beneficial in many aspects, can pose difficulties in achieving the desired mechanical characteristics for robotic joints. The material's high molecular weight and long polymer chains contribute to its excellent wear resistance and impact strength, but also result in a relatively low elastic modulus. This low stiffness can lead to excessive deformation under load, potentially compromising the precision and stability required in robotic applications.

Another challenge lies in the creep behavior of UHMWPE. Under sustained stress, the material tends to deform permanently over time, a phenomenon known as cold flow. This property can affect the long-term dimensional stability of robotic joints, potentially leading to increased clearances and reduced accuracy in motion control. Mitigating creep while maintaining the material's beneficial properties remains a significant hurdle in UHMWPE joint applications.

The integration of UHMWPE with other materials in robotic joint design also presents challenges. Achieving strong and durable bonds between UHMWPE and metals or other polymers is difficult due to its low surface energy and chemical inertness. This complicates the design of multi-material joint structures that aim to leverage the unique properties of UHMWPE alongside other materials.

Temperature sensitivity is another concern in UHMWPE joint applications. The material's mechanical properties can vary significantly with temperature changes, affecting joint performance across different operating conditions. This sensitivity necessitates careful consideration of thermal management in robotic systems utilizing UHMWPE components.

Furthermore, the processing and manufacturing of UHMWPE for precise robotic joint applications pose technical challenges. The material's high viscosity in its molten state makes it difficult to process using conventional injection molding techniques. Achieving the required dimensional accuracy and surface finish for robotic joints often requires specialized manufacturing processes, which can increase production complexity and costs.

Lastly, the long-term performance and degradation of UHMWPE in robotic joint applications remain areas of ongoing research. While the material exhibits excellent wear resistance, the effects of cyclic loading, environmental factors, and potential oxidative degradation on its long-term mechanical properties and performance in robotic joints are not fully understood and require further investigation.

Existing UHMWPE Solutions for Robotic Joints

01 Enhancing UHMWPE flexibility through blending

UHMWPE's flexibility can be improved by blending it with other polymers or additives. This process can create a balance between flexibility and strength, making the material suitable for various applications. The blending technique allows for customization of the material's properties to meet specific requirements.- Molecular structure and properties of UHMWPE: UHMWPE is characterized by its long molecular chains, which contribute to its high strength and flexibility. The unique molecular structure allows for excellent wear resistance, impact strength, and chemical resistance. These properties make UHMWPE suitable for various applications requiring both flexibility and strength.

- Blending and composite materials with UHMWPE: Blending UHMWPE with other materials or creating composites can enhance its flexibility and strength. This approach allows for tailoring the properties of the final material to meet specific application requirements. Additives, fillers, or other polymers can be incorporated to improve specific characteristics while maintaining the inherent benefits of UHMWPE.

- Processing techniques for UHMWPE: Various processing techniques can be employed to enhance the flexibility and strength of UHMWPE. These may include compression molding, ram extrusion, or gel spinning. The choice of processing method can significantly impact the final properties of the material, allowing for optimization of both flexibility and strength for specific applications.

- Cross-linking and radiation treatment of UHMWPE: Cross-linking and radiation treatment can be used to modify the properties of UHMWPE. These processes can improve wear resistance and mechanical strength while maintaining flexibility. The degree of cross-linking can be controlled to achieve the desired balance between strength and flexibility for specific applications.

- Application-specific UHMWPE formulations: Tailored UHMWPE formulations can be developed for specific applications requiring a balance of flexibility and strength. This may involve adjusting molecular weight, incorporating specific additives, or using specialized processing techniques. Such formulations can be optimized for use in areas like medical implants, industrial components, or high-performance fibers.

02 Improving UHMWPE strength through crosslinking

Crosslinking techniques can significantly enhance the strength of UHMWPE. This process involves creating chemical bonds between polymer chains, resulting in a more robust material. Various methods, such as radiation or chemical crosslinking, can be employed to achieve desired strength properties while maintaining other beneficial characteristics of UHMWPE.Expand Specific Solutions03 UHMWPE fiber reinforcement for enhanced properties

Incorporating UHMWPE fibers into composite materials can significantly improve both flexibility and strength. These fibers can be used to reinforce various matrices, resulting in lightweight yet high-performance materials. The orientation and distribution of UHMWPE fibers within the composite play crucial roles in determining the final properties of the material.Expand Specific Solutions04 Processing techniques for optimized UHMWPE properties

Advanced processing techniques, such as gel spinning, compression molding, and ram extrusion, can be utilized to optimize the flexibility and strength of UHMWPE. These methods allow for better control over the material's molecular structure and orientation, resulting in improved mechanical properties. The choice of processing technique depends on the desired end-use application and property requirements.Expand Specific Solutions05 Nanocomposite formulations for enhanced UHMWPE performance

Incorporating nanoparticles or nanostructures into UHMWPE can lead to significant improvements in both flexibility and strength. These nanocomposite formulations can enhance the material's overall performance by improving its mechanical properties, wear resistance, and thermal stability. The type, size, and distribution of nanoparticles within the UHMWPE matrix are critical factors in achieving the desired property enhancements.Expand Specific Solutions

Key Players in UHMWPE and Robotic Joint Industry

The research on UHMWPE in robotic joint design is in a growth phase, with increasing market potential due to the rising demand for advanced robotics in various industries. The global market for robotic components is expanding, driven by automation trends across manufacturing, healthcare, and service sectors. Technologically, UHMWPE application in robotic joints is progressing, with companies like Howmedica Osteonics Corp. and Smith & Nephew Orthopaedics GmbH leading in orthopedic applications. Academic institutions such as the University of Southern California and Sichuan University are contributing to fundamental research, while industrial players like Kyocera Corp. and OMRON Corp. are likely focusing on practical implementations, indicating a collaborative ecosystem advancing the technology's maturity.

Politecnico di Milano

Technical Solution: Politecnico di Milano's research on UHMWPE in robotic joint design focuses on biomimetic approaches and advanced manufacturing techniques. They have developed a method for creating hierarchical structures in UHMWPE that mimic natural joint materials, enhancing both flexibility and strength[13]. Their studies include the use of electrospinning to create UHMWPE nanofibers with improved mechanical properties for use in lightweight robotic joint components[14]. Recent work has explored the development of self-healing UHMWPE composites, incorporating microcapsules with healing agents to extend the lifespan of robotic joint materials under repetitive stress[15]. The university has also investigated the use of UHMWPE in energy-harvesting mechanisms for self-powered robotic joints, leveraging the material's piezoelectric properties when combined with certain additives[16].

Strengths: Innovative biomimetic approaches and focus on multifunctional materials. Weaknesses: Some advanced concepts may require further development for practical implementation in robotic systems.

Biomet Manufacturing LLC

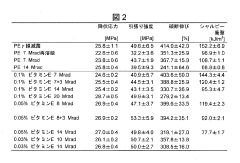

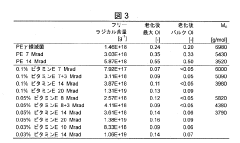

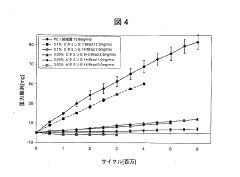

Technical Solution: Biomet Manufacturing has focused on leveraging UHMWPE in robotic joint design, particularly for orthopedic applications that can be translated to robotics. Their research involves the development of highly cross-linked UHMWPE, which offers improved wear resistance and mechanical properties[2]. They have explored electron beam and gamma irradiation techniques to enhance cross-linking while maintaining the material's flexibility. Biomet has also investigated the incorporation of antioxidants, such as vitamin E, into UHMWPE to improve its long-term stability and performance in dynamic joint applications[4]. Their latest research includes the development of UHMWPE-based composites with carbon fibers to further enhance strength and reduce wear in high-stress robotic joint components[6].

Strengths: Excellent wear resistance and long-term stability in dynamic applications. Weaknesses: Potential reduction in ductility and impact strength due to cross-linking processes.

Core Innovations in UHMWPE for Flexibility and Strength

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

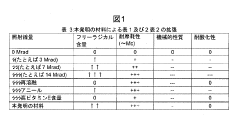

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Ultra-high molecular weight polyethylene

PatentWO2011089017A1

Innovation

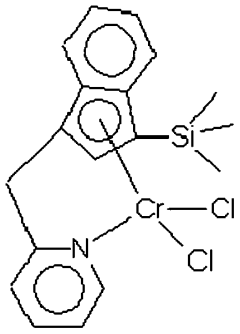

- The use of a blend of two metallocene-type catalysts, with Hafnium (Hf) and Chromium (Cr) as catalyst residues, to produce UHMW-PE with medium density and enhanced Charpy impact resistance, achieving a synergistic effect that improves both abrasion and impact resistance, and maintaining a suitable average grain size.

Environmental Impact of UHMWPE in Robotics

The use of Ultra-High Molecular Weight Polyethylene (UHMWPE) in robotic joint design has significant environmental implications that warrant careful consideration. UHMWPE, while offering excellent mechanical properties, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of UHMWPE in robotics is its durability and longevity. The material's high wear resistance and low friction coefficient contribute to extended component lifespans, reducing the frequency of replacements and, consequently, the overall environmental impact associated with manufacturing and disposal of robotic parts. This longevity aligns well with sustainable design principles, promoting resource efficiency and waste reduction in the robotics industry.

However, the production of UHMWPE involves energy-intensive processes, primarily due to its high molecular weight and the specialized manufacturing techniques required. The energy consumption during production contributes to carbon emissions, which must be factored into the overall environmental assessment of UHMWPE use in robotics.

Recycling UHMWPE presents another environmental challenge. While the material is theoretically recyclable, its high molecular weight and cross-linked structure make the recycling process complex and energy-intensive. This complexity often leads to downcycling rather than true recycling, where the material is repurposed for lower-grade applications, potentially limiting its circular economy potential in the robotics sector.

On the positive side, the lightweight nature of UHMWPE can contribute to energy efficiency in robotic operations. Lighter components in robotic joints can lead to reduced power consumption during movement, potentially offsetting some of the environmental costs associated with production over the robot's operational lifetime.

The chemical stability of UHMWPE is a double-edged sword from an environmental standpoint. While it resists degradation from most chemicals and UV radiation, ensuring long-term performance in various environments, this stability also means that UHMWPE does not readily biodegrade. Proper end-of-life management is crucial to prevent potential environmental contamination.

Advancements in bio-based and biodegradable alternatives to UHMWPE are emerging, driven by environmental concerns. These materials aim to maintain similar mechanical properties while offering improved environmental profiles. However, their adoption in robotic applications is still in early stages and requires further research and development to match the performance of UHMWPE.

In conclusion, while UHMWPE offers significant benefits in robotic joint design, its environmental impact is complex and multifaceted. Balancing its performance advantages with environmental considerations will be crucial for sustainable robotics development. Future research should focus on improving production efficiency, enhancing recyclability, and exploring eco-friendly alternatives to optimize the environmental footprint of robotic joint materials.

One of the primary environmental benefits of UHMWPE in robotics is its durability and longevity. The material's high wear resistance and low friction coefficient contribute to extended component lifespans, reducing the frequency of replacements and, consequently, the overall environmental impact associated with manufacturing and disposal of robotic parts. This longevity aligns well with sustainable design principles, promoting resource efficiency and waste reduction in the robotics industry.

However, the production of UHMWPE involves energy-intensive processes, primarily due to its high molecular weight and the specialized manufacturing techniques required. The energy consumption during production contributes to carbon emissions, which must be factored into the overall environmental assessment of UHMWPE use in robotics.

Recycling UHMWPE presents another environmental challenge. While the material is theoretically recyclable, its high molecular weight and cross-linked structure make the recycling process complex and energy-intensive. This complexity often leads to downcycling rather than true recycling, where the material is repurposed for lower-grade applications, potentially limiting its circular economy potential in the robotics sector.

On the positive side, the lightweight nature of UHMWPE can contribute to energy efficiency in robotic operations. Lighter components in robotic joints can lead to reduced power consumption during movement, potentially offsetting some of the environmental costs associated with production over the robot's operational lifetime.

The chemical stability of UHMWPE is a double-edged sword from an environmental standpoint. While it resists degradation from most chemicals and UV radiation, ensuring long-term performance in various environments, this stability also means that UHMWPE does not readily biodegrade. Proper end-of-life management is crucial to prevent potential environmental contamination.

Advancements in bio-based and biodegradable alternatives to UHMWPE are emerging, driven by environmental concerns. These materials aim to maintain similar mechanical properties while offering improved environmental profiles. However, their adoption in robotic applications is still in early stages and requires further research and development to match the performance of UHMWPE.

In conclusion, while UHMWPE offers significant benefits in robotic joint design, its environmental impact is complex and multifaceted. Balancing its performance advantages with environmental considerations will be crucial for sustainable robotics development. Future research should focus on improving production efficiency, enhancing recyclability, and exploring eco-friendly alternatives to optimize the environmental footprint of robotic joint materials.

Standardization and Testing Protocols for UHMWPE Joints

Standardization and testing protocols for UHMWPE joints in robotic applications are crucial for ensuring consistent performance, reliability, and safety. These protocols aim to establish uniform methods for evaluating the mechanical properties, wear resistance, and longevity of UHMWPE components used in robotic joint designs.

One key aspect of standardization is the development of specific test methods tailored to the unique requirements of robotic joints. These methods should simulate the dynamic loading conditions, repetitive motions, and environmental factors that UHMWPE components experience in real-world robotic applications. Standardized tests may include cyclic loading, wear resistance, impact resistance, and fatigue testing under various temperature and humidity conditions.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established several standards relevant to UHMWPE testing, such as ASTM F2565 for characterization of UHMWPE and ISO 5834 for implant-grade UHMWPE. However, these standards may need to be adapted or expanded to address the specific needs of robotic joint applications.

Developing standardized protocols for UHMWPE joints in robotics requires collaboration between material scientists, robotics engineers, and standards organizations. This collaborative effort should focus on defining key performance indicators, establishing acceptable ranges for mechanical properties, and creating reproducible testing methodologies that can be widely adopted across the industry.

One critical area for standardization is the evaluation of wear characteristics in UHMWPE joints. This includes developing methods to measure wear rates, particle generation, and changes in surface properties over time. Standardized protocols should also address the potential impact of different lubricants and environmental contaminants on UHMWPE performance in robotic joints.

Another important aspect of standardization is the development of accelerated aging protocols that can predict the long-term performance of UHMWPE components in robotic joints. These protocols should consider factors such as oxidation, cross-linking, and potential degradation mechanisms specific to robotic applications.

Implementing standardized testing protocols will enable more accurate comparisons between different UHMWPE formulations and joint designs. This, in turn, will facilitate informed decision-making in the selection of materials and design approaches for robotic joints, ultimately leading to improved performance and reliability in robotic systems.

As the field of robotics continues to evolve, it is essential that standardization and testing protocols for UHMWPE joints remain adaptable and responsive to new technological developments and application requirements. Regular review and updates to these protocols will ensure their continued relevance and effectiveness in supporting the advancement of robotic joint design.

One key aspect of standardization is the development of specific test methods tailored to the unique requirements of robotic joints. These methods should simulate the dynamic loading conditions, repetitive motions, and environmental factors that UHMWPE components experience in real-world robotic applications. Standardized tests may include cyclic loading, wear resistance, impact resistance, and fatigue testing under various temperature and humidity conditions.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established several standards relevant to UHMWPE testing, such as ASTM F2565 for characterization of UHMWPE and ISO 5834 for implant-grade UHMWPE. However, these standards may need to be adapted or expanded to address the specific needs of robotic joint applications.

Developing standardized protocols for UHMWPE joints in robotics requires collaboration between material scientists, robotics engineers, and standards organizations. This collaborative effort should focus on defining key performance indicators, establishing acceptable ranges for mechanical properties, and creating reproducible testing methodologies that can be widely adopted across the industry.

One critical area for standardization is the evaluation of wear characteristics in UHMWPE joints. This includes developing methods to measure wear rates, particle generation, and changes in surface properties over time. Standardized protocols should also address the potential impact of different lubricants and environmental contaminants on UHMWPE performance in robotic joints.

Another important aspect of standardization is the development of accelerated aging protocols that can predict the long-term performance of UHMWPE components in robotic joints. These protocols should consider factors such as oxidation, cross-linking, and potential degradation mechanisms specific to robotic applications.

Implementing standardized testing protocols will enable more accurate comparisons between different UHMWPE formulations and joint designs. This, in turn, will facilitate informed decision-making in the selection of materials and design approaches for robotic joints, ultimately leading to improved performance and reliability in robotic systems.

As the field of robotics continues to evolve, it is essential that standardization and testing protocols for UHMWPE joints remain adaptable and responsive to new technological developments and application requirements. Regular review and updates to these protocols will ensure their continued relevance and effectiveness in supporting the advancement of robotic joint design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!