Recent Innovations in UHMWPE Recycling Methods

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Recycling Evolution

The recycling of Ultra-High Molecular Weight Polyethylene (UHMWPE) has undergone significant evolution over the past decades. Initially, UHMWPE was considered a challenging material to recycle due to its high molecular weight and unique properties. Early attempts at recycling focused primarily on mechanical grinding and reprocessing, which often resulted in degraded material properties.

In the 1990s, researchers began exploring thermal and chemical methods to break down UHMWPE into more manageable components. These early techniques, while promising, were often energy-intensive and not economically viable on a large scale. The turn of the millennium saw a shift towards more sustainable approaches, with increased emphasis on maintaining the material's valuable properties throughout the recycling process.

The mid-2000s marked a significant milestone in UHMWPE recycling with the development of selective dissolution techniques. These methods allowed for the separation of UHMWPE from other polymers in mixed waste streams, greatly enhancing the purity of recycled material. Concurrently, advances in mechanical recycling technologies improved the quality of recycled UHMWPE, making it suitable for a wider range of applications.

Recent years have witnessed a surge in innovative recycling methods for UHMWPE. One notable development is the use of supercritical fluids, particularly carbon dioxide, to facilitate the breakdown and subsequent reformation of UHMWPE chains. This technique offers the advantage of preserving the material's molecular structure while allowing for easier processing and blending with virgin material.

Another significant advancement has been the application of catalytic depolymerization. This process uses specific catalysts to break down UHMWPE into its constituent monomers or oligomers, which can then be repolymerized into high-quality UHMWPE. This approach not only enables the production of recycled material with properties comparable to virgin UHMWPE but also opens up possibilities for upcycling.

The integration of artificial intelligence and machine learning in recycling processes has further revolutionized UHMWPE recycling. These technologies have enabled more precise sorting of waste materials, optimized process parameters, and improved quality control of recycled products. Additionally, the development of novel additives and compatibilizers has enhanced the performance of recycled UHMWPE, expanding its potential applications in high-value markets.

As environmental concerns continue to drive innovation, the focus has shifted towards developing closed-loop recycling systems for UHMWPE. These systems aim to minimize waste and energy consumption while maximizing the recovery and reuse of valuable materials. The evolution of UHMWPE recycling reflects a broader trend towards circular economy principles, emphasizing the importance of sustainable material management throughout the product lifecycle.

In the 1990s, researchers began exploring thermal and chemical methods to break down UHMWPE into more manageable components. These early techniques, while promising, were often energy-intensive and not economically viable on a large scale. The turn of the millennium saw a shift towards more sustainable approaches, with increased emphasis on maintaining the material's valuable properties throughout the recycling process.

The mid-2000s marked a significant milestone in UHMWPE recycling with the development of selective dissolution techniques. These methods allowed for the separation of UHMWPE from other polymers in mixed waste streams, greatly enhancing the purity of recycled material. Concurrently, advances in mechanical recycling technologies improved the quality of recycled UHMWPE, making it suitable for a wider range of applications.

Recent years have witnessed a surge in innovative recycling methods for UHMWPE. One notable development is the use of supercritical fluids, particularly carbon dioxide, to facilitate the breakdown and subsequent reformation of UHMWPE chains. This technique offers the advantage of preserving the material's molecular structure while allowing for easier processing and blending with virgin material.

Another significant advancement has been the application of catalytic depolymerization. This process uses specific catalysts to break down UHMWPE into its constituent monomers or oligomers, which can then be repolymerized into high-quality UHMWPE. This approach not only enables the production of recycled material with properties comparable to virgin UHMWPE but also opens up possibilities for upcycling.

The integration of artificial intelligence and machine learning in recycling processes has further revolutionized UHMWPE recycling. These technologies have enabled more precise sorting of waste materials, optimized process parameters, and improved quality control of recycled products. Additionally, the development of novel additives and compatibilizers has enhanced the performance of recycled UHMWPE, expanding its potential applications in high-value markets.

As environmental concerns continue to drive innovation, the focus has shifted towards developing closed-loop recycling systems for UHMWPE. These systems aim to minimize waste and energy consumption while maximizing the recovery and reuse of valuable materials. The evolution of UHMWPE recycling reflects a broader trend towards circular economy principles, emphasizing the importance of sustainable material management throughout the product lifecycle.

Market Demand Analysis

The market demand for UHMWPE recycling methods has been steadily increasing in recent years, driven by growing environmental concerns and the push for sustainable practices in various industries. UHMWPE, or Ultra-High Molecular Weight Polyethylene, is widely used in applications ranging from medical implants to industrial machinery due to its exceptional properties. However, its durability also poses challenges for disposal and recycling.

The global UHMWPE market is projected to expand significantly, with a compound annual growth rate (CAGR) of over 9% from 2021 to 2026. This growth is primarily fueled by increasing demand in healthcare, aerospace, and defense sectors. As the consumption of UHMWPE rises, so does the need for effective recycling methods to address end-of-life product management and reduce environmental impact.

In the healthcare sector, the demand for UHMWPE recycling is particularly pronounced. With the growing number of joint replacement surgeries and the use of UHMWPE in medical implants, there is a pressing need to develop efficient recycling processes for these materials. Hospitals and medical facilities are increasingly seeking sustainable solutions for disposing of used UHMWPE implants and surgical waste.

The industrial sector also presents significant opportunities for UHMWPE recycling. Industries such as mining, oil and gas, and manufacturing utilize UHMWPE components in various applications. As these industries strive to improve their sustainability profiles, the demand for recycling solutions for worn-out UHMWPE parts is rising.

Environmental regulations and corporate sustainability goals are key drivers in the market for UHMWPE recycling methods. Many countries have implemented stricter waste management policies, encouraging companies to adopt more sustainable practices. This regulatory pressure, combined with consumer demand for eco-friendly products, is pushing manufacturers to invest in recycling technologies and circular economy initiatives.

The market for recycled UHMWPE is also expanding, with growing interest from industries seeking to incorporate recycled materials into their products. This trend is particularly evident in the packaging and consumer goods sectors, where there is a strong emphasis on using recycled plastics to reduce environmental footprint.

Despite the growing demand, challenges remain in the UHMWPE recycling market. The complex nature of UHMWPE and its resistance to degradation make traditional recycling methods less effective. This has created a significant opportunity for innovative recycling technologies that can efficiently process UHMWPE without compromising its valuable properties.

In conclusion, the market demand for UHMWPE recycling methods is robust and expected to grow further. The combination of regulatory pressures, environmental concerns, and the economic potential of recycled materials is driving investment and innovation in this field. As industries continue to seek sustainable solutions, the development of effective UHMWPE recycling methods remains a critical area of focus for researchers and technology developers.

The global UHMWPE market is projected to expand significantly, with a compound annual growth rate (CAGR) of over 9% from 2021 to 2026. This growth is primarily fueled by increasing demand in healthcare, aerospace, and defense sectors. As the consumption of UHMWPE rises, so does the need for effective recycling methods to address end-of-life product management and reduce environmental impact.

In the healthcare sector, the demand for UHMWPE recycling is particularly pronounced. With the growing number of joint replacement surgeries and the use of UHMWPE in medical implants, there is a pressing need to develop efficient recycling processes for these materials. Hospitals and medical facilities are increasingly seeking sustainable solutions for disposing of used UHMWPE implants and surgical waste.

The industrial sector also presents significant opportunities for UHMWPE recycling. Industries such as mining, oil and gas, and manufacturing utilize UHMWPE components in various applications. As these industries strive to improve their sustainability profiles, the demand for recycling solutions for worn-out UHMWPE parts is rising.

Environmental regulations and corporate sustainability goals are key drivers in the market for UHMWPE recycling methods. Many countries have implemented stricter waste management policies, encouraging companies to adopt more sustainable practices. This regulatory pressure, combined with consumer demand for eco-friendly products, is pushing manufacturers to invest in recycling technologies and circular economy initiatives.

The market for recycled UHMWPE is also expanding, with growing interest from industries seeking to incorporate recycled materials into their products. This trend is particularly evident in the packaging and consumer goods sectors, where there is a strong emphasis on using recycled plastics to reduce environmental footprint.

Despite the growing demand, challenges remain in the UHMWPE recycling market. The complex nature of UHMWPE and its resistance to degradation make traditional recycling methods less effective. This has created a significant opportunity for innovative recycling technologies that can efficiently process UHMWPE without compromising its valuable properties.

In conclusion, the market demand for UHMWPE recycling methods is robust and expected to grow further. The combination of regulatory pressures, environmental concerns, and the economic potential of recycled materials is driving investment and innovation in this field. As industries continue to seek sustainable solutions, the development of effective UHMWPE recycling methods remains a critical area of focus for researchers and technology developers.

Technical Challenges

Ultra-high molecular weight polyethylene (UHMWPE) recycling presents several significant technical challenges that hinder widespread adoption and efficiency. One of the primary obstacles is the material's high molecular weight and strong intermolecular forces, which make it resistant to melting and processing using conventional recycling methods. This characteristic, while beneficial for its durability in use, complicates the recycling process and limits the potential for mechanical recycling.

The contamination of UHMWPE waste streams poses another major challenge. UHMWPE is often used in applications where it comes into contact with various substances, including oils, chemicals, and biological materials. Removing these contaminants effectively without degrading the polymer's properties is a complex task that requires advanced separation and cleaning technologies.

Cross-linking in UHMWPE, a process used to enhance its wear resistance and mechanical properties, further complicates recycling efforts. Cross-linked UHMWPE cannot be easily remelted or reshaped, making traditional thermal recycling methods ineffective. This necessitates the development of novel techniques that can break down or restructure the cross-linked polymer without significantly compromising its valuable properties.

The energy-intensive nature of UHMWPE recycling processes presents both economic and environmental challenges. The high temperatures and specialized equipment required for processing UHMWPE contribute to increased energy consumption and operational costs, potentially offsetting some of the environmental benefits of recycling.

Quality control and maintaining consistent properties in recycled UHMWPE products remain significant hurdles. The recycling process can lead to changes in molecular weight distribution, crystallinity, and mechanical properties, which may affect the performance of recycled materials in high-demand applications. Developing methods to ensure the quality and reliability of recycled UHMWPE is crucial for expanding its use in various industries.

The lack of established collection and sorting systems specifically for UHMWPE waste is another challenge. Unlike more common plastics, UHMWPE products are often used in specialized applications, making it difficult to implement large-scale collection programs. This results in a limited and inconsistent supply of recyclable UHMWPE material, hindering the development of efficient recycling infrastructures.

Addressing these technical challenges requires a multifaceted approach, combining innovations in material science, chemical engineering, and process technology. Research efforts are focusing on developing new catalysts and solvents for chemical recycling, improving mechanical recycling techniques, and exploring novel methods for breaking down cross-linked structures. Additionally, advancements in sorting and purification technologies are essential for improving the quality and consistency of recycled UHMWPE.

The contamination of UHMWPE waste streams poses another major challenge. UHMWPE is often used in applications where it comes into contact with various substances, including oils, chemicals, and biological materials. Removing these contaminants effectively without degrading the polymer's properties is a complex task that requires advanced separation and cleaning technologies.

Cross-linking in UHMWPE, a process used to enhance its wear resistance and mechanical properties, further complicates recycling efforts. Cross-linked UHMWPE cannot be easily remelted or reshaped, making traditional thermal recycling methods ineffective. This necessitates the development of novel techniques that can break down or restructure the cross-linked polymer without significantly compromising its valuable properties.

The energy-intensive nature of UHMWPE recycling processes presents both economic and environmental challenges. The high temperatures and specialized equipment required for processing UHMWPE contribute to increased energy consumption and operational costs, potentially offsetting some of the environmental benefits of recycling.

Quality control and maintaining consistent properties in recycled UHMWPE products remain significant hurdles. The recycling process can lead to changes in molecular weight distribution, crystallinity, and mechanical properties, which may affect the performance of recycled materials in high-demand applications. Developing methods to ensure the quality and reliability of recycled UHMWPE is crucial for expanding its use in various industries.

The lack of established collection and sorting systems specifically for UHMWPE waste is another challenge. Unlike more common plastics, UHMWPE products are often used in specialized applications, making it difficult to implement large-scale collection programs. This results in a limited and inconsistent supply of recyclable UHMWPE material, hindering the development of efficient recycling infrastructures.

Addressing these technical challenges requires a multifaceted approach, combining innovations in material science, chemical engineering, and process technology. Research efforts are focusing on developing new catalysts and solvents for chemical recycling, improving mechanical recycling techniques, and exploring novel methods for breaking down cross-linked structures. Additionally, advancements in sorting and purification technologies are essential for improving the quality and consistency of recycled UHMWPE.

Current Recycling Solutions

01 Mechanical recycling methods

Mechanical recycling involves grinding or shredding UHMWPE waste into smaller particles, which can then be reprocessed into new products. This method may include steps such as sorting, washing, and drying before the material is melted and reformed. It's a relatively simple and cost-effective approach for recycling UHMWPE, particularly suitable for clean and homogeneous waste streams.- Mechanical recycling methods: Mechanical recycling methods for UHMWPE involve processes such as grinding, shredding, and pelletizing the waste material. These methods can be used to recycle UHMWPE without significant changes to its molecular structure. The recycled material can then be reprocessed into new products, potentially with the addition of virgin material to maintain desired properties.

- Chemical recycling techniques: Chemical recycling techniques for UHMWPE involve breaking down the polymer into its constituent monomers or other valuable chemical compounds. This can be achieved through processes such as pyrolysis, depolymerization, or solvent-based dissolution. The resulting products can be used as raw materials for new polymer production or other chemical applications.

- Thermal processing for recycling: Thermal processing methods can be used to recycle UHMWPE by melting and reforming the material. This may involve techniques such as compression molding or extrusion. Care must be taken to control the temperature and processing conditions to maintain the desirable properties of UHMWPE, as excessive heat can lead to degradation of the polymer chains.

- Blending and compatibilization: Recycling methods for UHMWPE may involve blending the recycled material with virgin polymer or other compatible materials to improve processability and maintain desired properties. Compatibilizers or coupling agents may be used to enhance the interaction between recycled UHMWPE and other materials, resulting in improved mechanical properties of the final recycled product.

- Surface treatment and modification: Surface treatment and modification techniques can be applied to recycled UHMWPE to improve its properties and compatibility with other materials. This may include plasma treatment, chemical etching, or grafting of functional groups onto the polymer surface. These methods can enhance the adhesion, printability, or other surface properties of recycled UHMWPE for specific applications.

02 Chemical recycling techniques

Chemical recycling methods involve breaking down UHMWPE into its chemical components or precursors. This can be achieved through processes such as pyrolysis, depolymerization, or solvent-based dissolution. These techniques allow for the recovery of base chemicals that can be used to produce new polymers, potentially with properties similar to virgin UHMWPE.Expand Specific Solutions03 Thermal processing for recycling

Thermal processing methods utilize heat to recycle UHMWPE. This can include techniques such as melt processing, where the material is heated to its melting point and then reformed, or thermal depolymerization, where high temperatures are used to break down the polymer chains. These methods can be effective for processing contaminated or mixed UHMWPE waste streams.Expand Specific Solutions04 Blending and compatibilization techniques

This approach involves blending recycled UHMWPE with virgin materials or other polymers to create new composites. Compatibilization techniques may be used to improve the miscibility of different polymers. This method can help maintain or enhance the properties of the recycled material, making it suitable for a wider range of applications.Expand Specific Solutions05 Advanced separation and purification methods

These techniques focus on improving the quality of recycled UHMWPE by removing contaminants and impurities. Methods may include advanced sorting technologies, such as spectroscopic techniques, or novel purification processes like supercritical fluid extraction. These approaches aim to produce high-quality recycled UHMWPE that can be used in more demanding applications.Expand Specific Solutions

Key Industry Players

The recycling of Ultra-High Molecular Weight Polyethylene (UHMWPE) is an emerging field in the advanced materials industry, currently in its early development stage. The market size is relatively small but growing, driven by increasing environmental concerns and circular economy initiatives. Technologically, UHMWPE recycling methods are still evolving, with varying levels of maturity across different approaches. Key players like Sichuan University, Shanghai Research Institute of Chemical Industry, and Wanhua Chemical Group are actively researching and developing innovative recycling techniques. Companies such as Procter & Gamble and PetroChina are also exploring sustainable solutions, indicating a growing interest from major industry players in this eco-friendly technology.

Sichuan University

Technical Solution: Sichuan University has developed a novel UHMWPE recycling method using supercritical CO2 as a solvent. This process involves dissolving UHMWPE in supercritical CO2 at high pressure and temperature, followed by rapid depressurization to precipitate the polymer. The method achieves a recovery rate of up to 95% and maintains the molecular weight and mechanical properties of the recycled UHMWPE[1]. Additionally, they have implemented a continuous extrusion process that incorporates reactive compatibilizers to improve the blend properties of recycled UHMWPE with virgin materials, resulting in enhanced tensile strength and impact resistance[2][3].

Strengths: High recovery rate, preservation of material properties, and environmentally friendly solvent. Weaknesses: High energy consumption due to supercritical conditions and potential scalability challenges for industrial applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has pioneered a chemical recycling approach for UHMWPE using catalytic pyrolysis. Their process employs a proprietary catalyst system that selectively breaks down UHMWPE into valuable chemical feedstocks at lower temperatures compared to traditional thermal pyrolysis. This method achieves a conversion efficiency of over 80% and produces a mixture of light olefins and waxes that can be directly reintegrated into the petrochemical production chain[4]. Sinopec has also developed a solvent-based purification step to remove contaminants from recycled UHMWPE, enabling its use in high-value applications such as medical devices and food packaging[5].

Strengths: High conversion efficiency, production of valuable chemical feedstocks, and ability to handle contaminated UHMWPE. Weaknesses: Energy-intensive process and potential catalyst deactivation issues in long-term operation.

Innovative Techniques

Method for recycling products containing polyethylene fibres with an ultra-high molecular weight

PatentInactiveEP2272903A1

Innovation

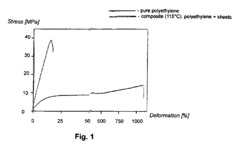

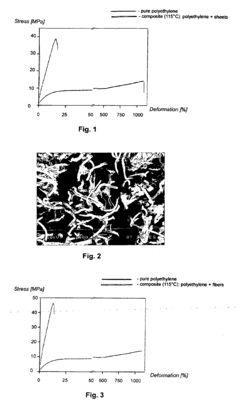

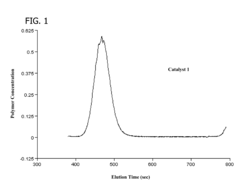

- A method involving comminution of UHMW-PE fiber waste, mixing with low or average density polyethylene, and processing below the UHMW-PE melting point to create a composite with enhanced mechanical properties, optionally using a thermoplastic binder for injection molding or extrusion.

Method for producing very-high or ultra-high molecular weight polyethylene

PatentActiveUS20100184931A1

Innovation

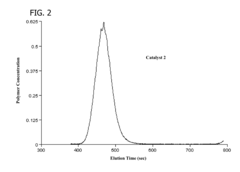

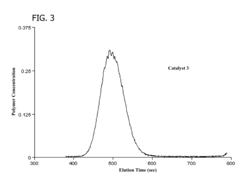

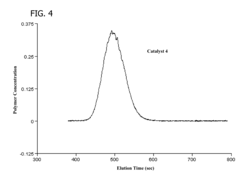

- A slurry polymerization method using supported catalysts comprising a support, a metal-ligand complex, and an activator, which allows for the production of UHMWPE with a bimodal molecular weight distribution, enabling improved melt flow properties and fiber applications without the need for blending.

Environmental Impact

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) recycling methods has become a critical focus in recent years, as industries strive to reduce waste and promote sustainability. Traditional disposal methods for UHMWPE, such as landfilling or incineration, have significant negative environmental consequences, including soil and water pollution, greenhouse gas emissions, and resource depletion.

Recent innovations in UHMWPE recycling methods have shown promising results in mitigating these environmental concerns. Mechanical recycling techniques, which involve grinding and reprocessing UHMWPE waste, have been refined to produce high-quality recycled materials with minimal energy consumption. This approach significantly reduces the carbon footprint associated with virgin UHMWPE production and helps conserve natural resources.

Chemical recycling methods, particularly solvent-based techniques, have demonstrated remarkable potential in recovering UHMWPE from complex waste streams. These processes enable the separation of UHMWPE from other materials, facilitating more efficient recycling and reducing contamination. By minimizing the need for raw material extraction, chemical recycling contributes to the conservation of fossil fuel resources and reduces the overall environmental impact of UHMWPE production.

Advanced thermal recycling technologies have also emerged as environmentally friendly alternatives to traditional incineration. These methods utilize controlled pyrolysis to break down UHMWPE into valuable chemical feedstocks, which can be used to produce new polymers or other industrial chemicals. This approach not only diverts waste from landfills but also reduces the demand for virgin petrochemical resources.

The implementation of these innovative recycling methods has led to significant reductions in greenhouse gas emissions associated with UHMWPE production and disposal. Studies have shown that recycling UHMWPE can result in up to 80% lower carbon dioxide emissions compared to the production of virgin material. Additionally, the energy savings achieved through recycling contribute to overall environmental sustainability.

Water conservation is another crucial environmental benefit of modern UHMWPE recycling methods. Closed-loop recycling systems have been developed to minimize water consumption and prevent the release of pollutants into aquatic ecosystems. These systems not only reduce the environmental impact of the recycling process itself but also help preserve water resources for other essential uses.

As UHMWPE recycling technologies continue to advance, their positive environmental impact is expected to grow. The development of more efficient and scalable recycling methods will further reduce the material's ecological footprint, promoting a circular economy approach to UHMWPE production and use. This shift towards sustainable practices in UHMWPE management aligns with global efforts to combat climate change and preserve natural resources for future generations.

Recent innovations in UHMWPE recycling methods have shown promising results in mitigating these environmental concerns. Mechanical recycling techniques, which involve grinding and reprocessing UHMWPE waste, have been refined to produce high-quality recycled materials with minimal energy consumption. This approach significantly reduces the carbon footprint associated with virgin UHMWPE production and helps conserve natural resources.

Chemical recycling methods, particularly solvent-based techniques, have demonstrated remarkable potential in recovering UHMWPE from complex waste streams. These processes enable the separation of UHMWPE from other materials, facilitating more efficient recycling and reducing contamination. By minimizing the need for raw material extraction, chemical recycling contributes to the conservation of fossil fuel resources and reduces the overall environmental impact of UHMWPE production.

Advanced thermal recycling technologies have also emerged as environmentally friendly alternatives to traditional incineration. These methods utilize controlled pyrolysis to break down UHMWPE into valuable chemical feedstocks, which can be used to produce new polymers or other industrial chemicals. This approach not only diverts waste from landfills but also reduces the demand for virgin petrochemical resources.

The implementation of these innovative recycling methods has led to significant reductions in greenhouse gas emissions associated with UHMWPE production and disposal. Studies have shown that recycling UHMWPE can result in up to 80% lower carbon dioxide emissions compared to the production of virgin material. Additionally, the energy savings achieved through recycling contribute to overall environmental sustainability.

Water conservation is another crucial environmental benefit of modern UHMWPE recycling methods. Closed-loop recycling systems have been developed to minimize water consumption and prevent the release of pollutants into aquatic ecosystems. These systems not only reduce the environmental impact of the recycling process itself but also help preserve water resources for other essential uses.

As UHMWPE recycling technologies continue to advance, their positive environmental impact is expected to grow. The development of more efficient and scalable recycling methods will further reduce the material's ecological footprint, promoting a circular economy approach to UHMWPE production and use. This shift towards sustainable practices in UHMWPE management aligns with global efforts to combat climate change and preserve natural resources for future generations.

Economic Feasibility

The economic feasibility of recent innovations in UHMWPE recycling methods is a critical factor in determining their potential for widespread adoption and commercial success. These innovations have shown promising results in terms of material recovery and quality, but their economic viability remains a key consideration for industry stakeholders.

One of the primary economic drivers for UHMWPE recycling is the potential cost savings associated with raw material procurement. As virgin UHMWPE is relatively expensive, recycled alternatives can offer significant cost reductions for manufacturers. However, the economic benefits must be weighed against the costs of implementing and operating new recycling technologies.

Recent advancements in mechanical recycling methods have demonstrated improved efficiency and lower energy consumption compared to traditional processes. This translates to reduced operational costs and potentially higher profit margins for recyclers. Additionally, the ability to maintain material properties close to those of virgin UHMWPE enhances the market value of recycled products, further improving economic feasibility.

Chemical recycling innovations, while still in early stages of development, show promise in terms of producing high-quality recycled UHMWPE. The economic viability of these methods depends on factors such as process scalability, chemical reagent costs, and energy requirements. As research progresses, optimizations in these areas could lead to more cost-effective solutions.

The market demand for recycled UHMWPE plays a crucial role in economic feasibility. Growing environmental awareness and regulatory pressures are driving increased interest in sustainable materials, potentially expanding the market for recycled UHMWPE. This trend could justify investments in advanced recycling technologies and infrastructure.

However, challenges remain in terms of collection and sorting of UHMWPE waste. Establishing efficient reverse logistics systems and improving waste separation techniques are essential for ensuring a steady supply of recyclable material at reasonable costs. Innovations in these areas could significantly impact the overall economic viability of UHMWPE recycling.

Government incentives and policies supporting circular economy initiatives may also influence the economic landscape for UHMWPE recycling. Tax breaks, grants, or regulatory requirements favoring recycled content could tip the scales in favor of investing in advanced recycling technologies.

In conclusion, while recent innovations in UHMWPE recycling methods show technical promise, their economic feasibility depends on a complex interplay of factors including operational costs, market demand, supply chain efficiency, and policy support. Continued research and development efforts focused on cost reduction and process optimization will be crucial in enhancing the economic viability of these innovative recycling methods.

One of the primary economic drivers for UHMWPE recycling is the potential cost savings associated with raw material procurement. As virgin UHMWPE is relatively expensive, recycled alternatives can offer significant cost reductions for manufacturers. However, the economic benefits must be weighed against the costs of implementing and operating new recycling technologies.

Recent advancements in mechanical recycling methods have demonstrated improved efficiency and lower energy consumption compared to traditional processes. This translates to reduced operational costs and potentially higher profit margins for recyclers. Additionally, the ability to maintain material properties close to those of virgin UHMWPE enhances the market value of recycled products, further improving economic feasibility.

Chemical recycling innovations, while still in early stages of development, show promise in terms of producing high-quality recycled UHMWPE. The economic viability of these methods depends on factors such as process scalability, chemical reagent costs, and energy requirements. As research progresses, optimizations in these areas could lead to more cost-effective solutions.

The market demand for recycled UHMWPE plays a crucial role in economic feasibility. Growing environmental awareness and regulatory pressures are driving increased interest in sustainable materials, potentially expanding the market for recycled UHMWPE. This trend could justify investments in advanced recycling technologies and infrastructure.

However, challenges remain in terms of collection and sorting of UHMWPE waste. Establishing efficient reverse logistics systems and improving waste separation techniques are essential for ensuring a steady supply of recyclable material at reasonable costs. Innovations in these areas could significantly impact the overall economic viability of UHMWPE recycling.

Government incentives and policies supporting circular economy initiatives may also influence the economic landscape for UHMWPE recycling. Tax breaks, grants, or regulatory requirements favoring recycled content could tip the scales in favor of investing in advanced recycling technologies.

In conclusion, while recent innovations in UHMWPE recycling methods show technical promise, their economic feasibility depends on a complex interplay of factors including operational costs, market demand, supply chain efficiency, and policy support. Continued research and development efforts focused on cost reduction and process optimization will be crucial in enhancing the economic viability of these innovative recycling methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!