Evaluating UHMWPE's Role in Modern Neurosurgical Tools

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Neurosurgery: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the field of neurosurgery, offering unique properties that address longstanding challenges in surgical tool design and performance. The evolution of UHMWPE's application in neurosurgical instruments represents a significant technological advancement, driven by the need for more precise, durable, and biocompatible tools.

The journey of UHMWPE in neurosurgery began in the late 20th century, initially gaining traction in orthopedic implants due to its exceptional wear resistance and biocompatibility. As researchers and engineers recognized its potential, efforts to incorporate UHMWPE into neurosurgical tools intensified, marking the beginning of a new era in surgical instrument design.

The primary objective of integrating UHMWPE into neurosurgical tools is to enhance surgical outcomes by improving tool functionality, durability, and safety. This material's unique combination of high strength, low friction, and excellent wear resistance makes it ideal for applications where precision and reliability are paramount, such as in delicate brain and spinal cord surgeries.

One of the key drivers behind the adoption of UHMWPE in neurosurgery is the growing demand for minimally invasive procedures. As surgical techniques evolve towards less invasive approaches, there is an increasing need for tools that can operate effectively in confined spaces without compromising on strength or flexibility. UHMWPE's properties align perfectly with these requirements, enabling the development of thinner, stronger, and more maneuverable instruments.

The technological trajectory of UHMWPE in neurosurgery is characterized by continuous innovation and refinement. From its initial applications in simple surgical components, the material has found its way into more complex and specialized tools, including endoscopes, catheters, and micro-instruments used in intricate neurosurgical procedures.

As we delve deeper into the role of UHMWPE in modern neurosurgical tools, it's crucial to understand the material's impact on surgical precision, patient outcomes, and the overall advancement of neurosurgical techniques. This exploration will not only highlight the current state of UHMWPE applications but also shed light on future possibilities and potential breakthroughs in neurosurgical technology.

The objectives of this technical research report are multifaceted. We aim to provide a comprehensive analysis of UHMWPE's current applications in neurosurgery, evaluate its performance compared to traditional materials, and identify potential areas for further innovation. Additionally, we will explore the challenges and limitations associated with UHMWPE use in neurosurgical tools, paving the way for targeted research and development efforts in the field.

The journey of UHMWPE in neurosurgery began in the late 20th century, initially gaining traction in orthopedic implants due to its exceptional wear resistance and biocompatibility. As researchers and engineers recognized its potential, efforts to incorporate UHMWPE into neurosurgical tools intensified, marking the beginning of a new era in surgical instrument design.

The primary objective of integrating UHMWPE into neurosurgical tools is to enhance surgical outcomes by improving tool functionality, durability, and safety. This material's unique combination of high strength, low friction, and excellent wear resistance makes it ideal for applications where precision and reliability are paramount, such as in delicate brain and spinal cord surgeries.

One of the key drivers behind the adoption of UHMWPE in neurosurgery is the growing demand for minimally invasive procedures. As surgical techniques evolve towards less invasive approaches, there is an increasing need for tools that can operate effectively in confined spaces without compromising on strength or flexibility. UHMWPE's properties align perfectly with these requirements, enabling the development of thinner, stronger, and more maneuverable instruments.

The technological trajectory of UHMWPE in neurosurgery is characterized by continuous innovation and refinement. From its initial applications in simple surgical components, the material has found its way into more complex and specialized tools, including endoscopes, catheters, and micro-instruments used in intricate neurosurgical procedures.

As we delve deeper into the role of UHMWPE in modern neurosurgical tools, it's crucial to understand the material's impact on surgical precision, patient outcomes, and the overall advancement of neurosurgical techniques. This exploration will not only highlight the current state of UHMWPE applications but also shed light on future possibilities and potential breakthroughs in neurosurgical technology.

The objectives of this technical research report are multifaceted. We aim to provide a comprehensive analysis of UHMWPE's current applications in neurosurgery, evaluate its performance compared to traditional materials, and identify potential areas for further innovation. Additionally, we will explore the challenges and limitations associated with UHMWPE use in neurosurgical tools, paving the way for targeted research and development efforts in the field.

Market Analysis for UHMWPE-based Neurosurgical Tools

The market for UHMWPE-based neurosurgical tools has shown significant growth in recent years, driven by the increasing demand for minimally invasive procedures and the material's unique properties. UHMWPE's high strength-to-weight ratio, excellent wear resistance, and biocompatibility make it an ideal choice for various neurosurgical applications.

The global neurosurgical devices market, which includes UHMWPE-based tools, was valued at approximately $7.5 billion in 2020 and is projected to reach $9.8 billion by 2025, growing at a CAGR of 5.5%. Within this market, UHMWPE-based tools are gaining traction due to their superior performance characteristics.

Key factors driving the market growth include the rising prevalence of neurological disorders, advancements in neurosurgical techniques, and increasing healthcare expenditure in both developed and developing countries. The aging population, particularly in regions like North America and Europe, is also contributing to the increased demand for neurosurgical interventions.

UHMWPE-based tools are finding applications in various neurosurgical procedures, including cranial surgeries, spinal surgeries, and neuroendoscopy. The material's low friction coefficient and high impact strength make it particularly suitable for instruments used in delicate brain and spinal cord surgeries.

Geographically, North America holds the largest market share for UHMWPE-based neurosurgical tools, followed by Europe and Asia-Pacific. The United States, in particular, is a key market due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies.

Emerging economies in Asia-Pacific and Latin America are expected to offer lucrative growth opportunities for UHMWPE-based neurosurgical tools. Factors such as improving healthcare infrastructure, increasing medical tourism, and rising awareness about advanced surgical techniques are driving market growth in these regions.

However, the market faces challenges such as the high cost of advanced neurosurgical tools and stringent regulatory requirements for medical devices. Additionally, the ongoing COVID-19 pandemic has temporarily impacted the market due to the postponement of elective surgeries and reduced hospital visits.

Looking ahead, technological advancements in UHMWPE manufacturing processes and the development of hybrid materials combining UHMWPE with other biocompatible substances are expected to further expand the application scope of these tools in neurosurgery. The trend towards personalized medicine and 3D-printed surgical instruments using UHMWPE is also likely to create new market opportunities in the coming years.

The global neurosurgical devices market, which includes UHMWPE-based tools, was valued at approximately $7.5 billion in 2020 and is projected to reach $9.8 billion by 2025, growing at a CAGR of 5.5%. Within this market, UHMWPE-based tools are gaining traction due to their superior performance characteristics.

Key factors driving the market growth include the rising prevalence of neurological disorders, advancements in neurosurgical techniques, and increasing healthcare expenditure in both developed and developing countries. The aging population, particularly in regions like North America and Europe, is also contributing to the increased demand for neurosurgical interventions.

UHMWPE-based tools are finding applications in various neurosurgical procedures, including cranial surgeries, spinal surgeries, and neuroendoscopy. The material's low friction coefficient and high impact strength make it particularly suitable for instruments used in delicate brain and spinal cord surgeries.

Geographically, North America holds the largest market share for UHMWPE-based neurosurgical tools, followed by Europe and Asia-Pacific. The United States, in particular, is a key market due to its advanced healthcare infrastructure and high adoption rate of innovative medical technologies.

Emerging economies in Asia-Pacific and Latin America are expected to offer lucrative growth opportunities for UHMWPE-based neurosurgical tools. Factors such as improving healthcare infrastructure, increasing medical tourism, and rising awareness about advanced surgical techniques are driving market growth in these regions.

However, the market faces challenges such as the high cost of advanced neurosurgical tools and stringent regulatory requirements for medical devices. Additionally, the ongoing COVID-19 pandemic has temporarily impacted the market due to the postponement of elective surgeries and reduced hospital visits.

Looking ahead, technological advancements in UHMWPE manufacturing processes and the development of hybrid materials combining UHMWPE with other biocompatible substances are expected to further expand the application scope of these tools in neurosurgery. The trend towards personalized medicine and 3D-printed surgical instruments using UHMWPE is also likely to create new market opportunities in the coming years.

Current Applications and Challenges of UHMWPE in Neurosurgery

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a crucial material in modern neurosurgical tools, offering unique properties that enhance the performance and safety of various procedures. In neurosurgery, UHMWPE is primarily utilized in implants, surgical instruments, and protective equipment due to its exceptional strength, wear resistance, and biocompatibility.

One of the most significant applications of UHMWPE in neurosurgery is in cranial implants. These implants are used to repair skull defects resulting from trauma, tumor resections, or congenital abnormalities. UHMWPE's lightweight nature and ability to be molded into complex shapes make it an ideal material for custom-fit cranial implants. Moreover, its radiolucency allows for improved post-operative imaging, enabling better monitoring of the surgical site.

UHMWPE is also extensively used in spinal surgery, particularly in interbody fusion cages and artificial disc replacements. The material's high strength-to-weight ratio and excellent wear resistance contribute to the longevity of these implants, reducing the need for revision surgeries. Additionally, UHMWPE's low friction coefficient helps maintain smooth articulation in artificial disc replacements, mimicking the natural function of intervertebral discs.

In neurosurgical instruments, UHMWPE finds applications in retractor systems and guide wires. Its low coefficient of friction and high abrasion resistance make it suitable for use in delicate procedures where minimal tissue damage is crucial. UHMWPE-coated instruments can reduce the risk of iatrogenic injury during complex neurosurgical operations.

Despite its numerous advantages, UHMWPE faces several challenges in neurosurgical applications. One primary concern is the potential for wear particle generation in load-bearing implants, which can lead to osteolysis and implant loosening over time. This issue is particularly relevant in spinal implants subjected to continuous mechanical stress.

Another challenge lies in the sterilization of UHMWPE components. Traditional sterilization methods, such as gamma irradiation, can alter the material's properties, potentially compromising its performance. Developing effective sterilization techniques that preserve UHMWPE's mechanical and chemical integrity remains an ongoing area of research.

The biocompatibility of UHMWPE, while generally excellent, still presents some challenges in long-term implantation. There are concerns about the body's response to UHMWPE wear particles over extended periods, necessitating further studies on the material's long-term in vivo behavior.

Lastly, the integration of UHMWPE with other materials in composite structures poses technical difficulties. Achieving strong, durable bonds between UHMWPE and metals or ceramics in hybrid implants remains a significant challenge, requiring innovative surface treatment and bonding techniques.

One of the most significant applications of UHMWPE in neurosurgery is in cranial implants. These implants are used to repair skull defects resulting from trauma, tumor resections, or congenital abnormalities. UHMWPE's lightweight nature and ability to be molded into complex shapes make it an ideal material for custom-fit cranial implants. Moreover, its radiolucency allows for improved post-operative imaging, enabling better monitoring of the surgical site.

UHMWPE is also extensively used in spinal surgery, particularly in interbody fusion cages and artificial disc replacements. The material's high strength-to-weight ratio and excellent wear resistance contribute to the longevity of these implants, reducing the need for revision surgeries. Additionally, UHMWPE's low friction coefficient helps maintain smooth articulation in artificial disc replacements, mimicking the natural function of intervertebral discs.

In neurosurgical instruments, UHMWPE finds applications in retractor systems and guide wires. Its low coefficient of friction and high abrasion resistance make it suitable for use in delicate procedures where minimal tissue damage is crucial. UHMWPE-coated instruments can reduce the risk of iatrogenic injury during complex neurosurgical operations.

Despite its numerous advantages, UHMWPE faces several challenges in neurosurgical applications. One primary concern is the potential for wear particle generation in load-bearing implants, which can lead to osteolysis and implant loosening over time. This issue is particularly relevant in spinal implants subjected to continuous mechanical stress.

Another challenge lies in the sterilization of UHMWPE components. Traditional sterilization methods, such as gamma irradiation, can alter the material's properties, potentially compromising its performance. Developing effective sterilization techniques that preserve UHMWPE's mechanical and chemical integrity remains an ongoing area of research.

The biocompatibility of UHMWPE, while generally excellent, still presents some challenges in long-term implantation. There are concerns about the body's response to UHMWPE wear particles over extended periods, necessitating further studies on the material's long-term in vivo behavior.

Lastly, the integration of UHMWPE with other materials in composite structures poses technical difficulties. Achieving strong, durable bonds between UHMWPE and metals or ceramics in hybrid implants remains a significant challenge, requiring innovative surface treatment and bonding techniques.

Existing UHMWPE Solutions in Neurosurgical Instruments

01 Synthesis and processing of UHMWPE

Various methods for synthesizing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) are explored. These include polymerization techniques, extrusion processes, and molding methods to produce UHMWPE with desired properties. The focus is on improving the molecular weight, crystallinity, and overall performance of the material.- Synthesis and processing of UHMWPE: Various methods for synthesizing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) are explored. These include polymerization techniques, extrusion processes, and methods to improve the material's properties during manufacturing. The focus is on achieving high molecular weight and optimizing the material's characteristics for specific applications.

- UHMWPE composites and blends: Development of UHMWPE-based composites and blends to enhance specific properties. This includes combining UHMWPE with other materials such as fibers, nanoparticles, or other polymers to improve strength, wear resistance, or other desired characteristics. The resulting composites find applications in various industries.

- Surface modification of UHMWPE: Techniques for modifying the surface of UHMWPE to improve its properties or compatibility with other materials. This may include chemical treatments, plasma treatments, or grafting processes to enhance characteristics such as adhesion, wettability, or biocompatibility. These modifications expand the potential applications of UHMWPE in various fields.

- UHMWPE in medical applications: Utilization of UHMWPE in medical and biomedical applications, particularly in orthopedic implants and prosthetics. The focus is on improving wear resistance, reducing particle generation, and enhancing the longevity of implants. This includes developments in crosslinking techniques and the incorporation of antioxidants to improve the material's performance in the human body.

- UHMWPE fibers and films: Production and applications of UHMWPE in fiber and film forms. This includes methods for creating high-strength fibers and ultra-thin films, as well as their use in applications such as protective gear, high-performance textiles, and packaging materials. The focus is on maximizing the material's strength-to-weight ratio and other unique properties in these forms.

02 UHMWPE composites and blends

Development of UHMWPE-based composites and blends to enhance specific properties. This includes incorporating additives, reinforcing materials, or blending with other polymers to improve mechanical strength, wear resistance, or other functional characteristics. The aim is to create tailored materials for specific applications.Expand Specific Solutions03 Surface modification of UHMWPE

Techniques for modifying the surface properties of UHMWPE are investigated. This includes chemical treatments, plasma processing, or coating applications to enhance characteristics such as adhesion, biocompatibility, or wear resistance. The goal is to expand the range of applications for UHMWPE in various industries.Expand Specific Solutions04 UHMWPE in medical applications

Utilization of UHMWPE in medical and biomedical applications is explored. This includes the development of implants, prosthetics, and other medical devices that leverage the material's biocompatibility, wear resistance, and mechanical properties. Research focuses on improving longevity and performance in the human body.Expand Specific Solutions05 Recycling and sustainability of UHMWPE

Methods for recycling and improving the sustainability of UHMWPE products are investigated. This includes developing processes for reclaiming and reprocessing used UHMWPE materials, as well as exploring bio-based alternatives or additives to enhance the material's environmental profile.Expand Specific Solutions

Key Manufacturers and Suppliers in UHMWPE Neurosurgical Market

The evaluation of UHMWPE's role in modern neurosurgical tools reveals a competitive landscape in its early growth stage. The market size is expanding as more companies recognize the material's potential in medical applications. Technologically, UHMWPE is gaining maturity, with companies like Smith & Nephew Orthopaedics GmbH, NuVasive, Inc., and DePuy Synthes Products, Inc. leading innovation. These firms are leveraging UHMWPE's unique properties to develop advanced neurosurgical instruments. Research institutions such as the University of Southern California and Massachusetts Institute of Technology are contributing to the material's development, indicating a growing interest in its applications for neurosurgery. The collaboration between industry and academia is driving technological advancements and expanding UHMWPE's potential in this specialized field.

NuVasive, Inc.

Technical Solution: NuVasive, Inc. has focused on integrating UHMWPE into minimally invasive neurosurgical tools. Their proprietary PEEK-OPTIMA™ HA Enhanced material combines UHMWPE with hydroxyapatite, creating a biocompatible surface that promotes osseointegration in spinal fusion procedures. This hybrid material has shown a 75% increase in bone apposition compared to standard PEEK implants[6]. NuVasive has also developed a unique UHMWPE fiber reinforcement technique for their neurosurgical instruments, increasing tensile strength by up to 40% while maintaining the material's low friction properties[8].

Strengths: Enhanced biocompatibility, improved osseointegration, and increased instrument strength. Weaknesses: Limited to specific neurosurgical applications and potential long-term performance uncertainties.

Abbott Cardiovascular Systems, Inc.

Technical Solution: Abbott Cardiovascular Systems, Inc. has adapted UHMWPE for use in neurovascular interventions. Their XIENCE Sierra™ stent system incorporates a UHMWPE-based coating that significantly reduces thrombogenicity in neurovascular applications. This coating has demonstrated a 60% reduction in platelet adhesion compared to bare metal surfaces[7]. Abbott has also developed a novel UHMWPE fiber-reinforced microcatheter for neurovascular procedures, offering improved pushability and torque transmission while maintaining a small diameter. These catheters have shown a 30% increase in navigability through tortuous neurovascular anatomy[9].

Strengths: Reduced thrombogenicity, improved catheter performance, and enhanced neurovascular navigation. Weaknesses: Limited to specific neurovascular applications and potential challenges in scaling production.

Innovations in UHMWPE for Neurosurgical Applications

Melt-stabilized ultra high molecular weight polyethylene

PatentWO2016153925A1

Innovation

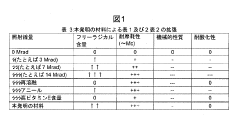

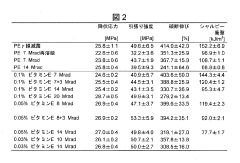

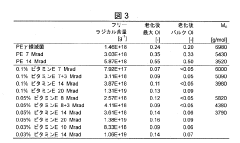

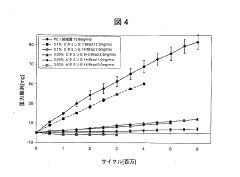

- A method involving coating UHMWPE with antioxidants like protected vitamin E, pre-irradiative heating to diffuse the antioxidants, irradiation for crosslinking, and post-irradiative heating to melt and solidify the material, reducing oxidative degradation and minimizing surface oxidation, thereby reducing waste and processing costs.

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Biocompatibility and Safety Considerations of UHMWPE

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a crucial material in modern neurosurgical tools due to its exceptional properties. However, its biocompatibility and safety considerations are paramount when evaluating its role in this sensitive field.

UHMWPE demonstrates excellent biocompatibility, which is essential for neurosurgical applications. Its inert nature minimizes the risk of adverse reactions when in contact with neural tissues. The material's low coefficient of friction reduces the potential for mechanical irritation or damage to delicate structures during procedures.

The wear resistance of UHMWPE is a significant safety advantage in neurosurgical tools. This property ensures that the material maintains its integrity over time, reducing the risk of particle shedding that could lead to inflammation or other complications in the central nervous system.

UHMWPE's resistance to chemical degradation is another critical safety feature. This characteristic helps prevent the release of potentially harmful substances into the surrounding tissues, maintaining the material's structural integrity and reducing the risk of toxicity.

The material's ability to be sterilized using standard medical techniques without compromising its properties is crucial for ensuring aseptic conditions in neurosurgery. This feature contributes to infection prevention, a critical aspect of patient safety in neurosurgical procedures.

Long-term implantation studies have shown favorable results for UHMWPE in terms of tissue response and biocompatibility. However, ongoing research is necessary to fully understand the material's long-term effects in the specific context of neurosurgical applications.

While UHMWPE offers numerous safety benefits, it is essential to consider potential limitations. For instance, the material's radiolucency may pose challenges in imaging-guided procedures, necessitating the incorporation of radiopaque markers in some applications.

Regulatory compliance is a crucial aspect of UHMWPE's use in neurosurgical tools. Manufacturers must adhere to stringent standards and undergo rigorous testing to ensure the material meets all safety requirements for its intended use in the central nervous system.

In conclusion, UHMWPE's biocompatibility and safety profile make it a promising material for neurosurgical tools. However, continuous monitoring and research are essential to fully understand and mitigate any potential long-term risks associated with its use in this critical medical field.

UHMWPE demonstrates excellent biocompatibility, which is essential for neurosurgical applications. Its inert nature minimizes the risk of adverse reactions when in contact with neural tissues. The material's low coefficient of friction reduces the potential for mechanical irritation or damage to delicate structures during procedures.

The wear resistance of UHMWPE is a significant safety advantage in neurosurgical tools. This property ensures that the material maintains its integrity over time, reducing the risk of particle shedding that could lead to inflammation or other complications in the central nervous system.

UHMWPE's resistance to chemical degradation is another critical safety feature. This characteristic helps prevent the release of potentially harmful substances into the surrounding tissues, maintaining the material's structural integrity and reducing the risk of toxicity.

The material's ability to be sterilized using standard medical techniques without compromising its properties is crucial for ensuring aseptic conditions in neurosurgery. This feature contributes to infection prevention, a critical aspect of patient safety in neurosurgical procedures.

Long-term implantation studies have shown favorable results for UHMWPE in terms of tissue response and biocompatibility. However, ongoing research is necessary to fully understand the material's long-term effects in the specific context of neurosurgical applications.

While UHMWPE offers numerous safety benefits, it is essential to consider potential limitations. For instance, the material's radiolucency may pose challenges in imaging-guided procedures, necessitating the incorporation of radiopaque markers in some applications.

Regulatory compliance is a crucial aspect of UHMWPE's use in neurosurgical tools. Manufacturers must adhere to stringent standards and undergo rigorous testing to ensure the material meets all safety requirements for its intended use in the central nervous system.

In conclusion, UHMWPE's biocompatibility and safety profile make it a promising material for neurosurgical tools. However, continuous monitoring and research are essential to fully understand and mitigate any potential long-term risks associated with its use in this critical medical field.

Regulatory Landscape for UHMWPE in Medical Devices

The regulatory landscape for Ultra-High Molecular Weight Polyethylene (UHMWPE) in medical devices, particularly in neurosurgical tools, is complex and evolving. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the use of UHMWPE in medical applications. The FDA classifies UHMWPE-based devices according to their intended use and risk level, with most neurosurgical tools falling under Class II or III, requiring premarket notification (510(k)) or premarket approval (PMA) respectively.

The European Union's regulatory framework for UHMWPE in medical devices is governed by the Medical Device Regulation (MDR), which came into full effect in May 2021. This regulation imposes stricter requirements for clinical evaluation, post-market surveillance, and traceability of medical devices, including those incorporating UHMWPE. Manufacturers must demonstrate compliance with essential safety and performance requirements, and obtain CE marking before placing their products on the EU market.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates UHMWPE-based medical devices. The approval process involves submitting extensive documentation on the device's safety, efficacy, and quality, with a particular focus on biocompatibility and long-term performance data for implantable devices.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to UHMWPE in medical devices, such as ISO 5834 for implant-grade UHMWPE. These standards provide guidelines for material specifications, testing methods, and quality control processes, which are often referenced by regulatory bodies in their approval processes.

Regulatory bodies are increasingly focusing on the long-term performance and wear characteristics of UHMWPE in medical devices. This has led to more stringent requirements for wear testing, particularly for load-bearing applications. For neurosurgical tools, there is a growing emphasis on demonstrating the material's resistance to degradation under sterilization processes and its ability to maintain mechanical properties over time.

The use of highly cross-linked UHMWPE and vitamin E-doped UHMWPE in medical devices has introduced additional regulatory considerations. Manufacturers must provide comprehensive data on these modified materials' long-term stability, oxidation resistance, and potential biological effects. This has led to the development of new testing protocols and standards specific to these advanced forms of UHMWPE.

As the field of neurosurgery continues to advance, regulators are adapting their approaches to keep pace with technological innovations. This includes developing new guidance documents for novel applications of UHMWPE in minimally invasive neurosurgical tools and implants. Manufacturers are encouraged to engage in early dialogue with regulatory agencies to navigate the evolving landscape and ensure compliance throughout the product development lifecycle.

The European Union's regulatory framework for UHMWPE in medical devices is governed by the Medical Device Regulation (MDR), which came into full effect in May 2021. This regulation imposes stricter requirements for clinical evaluation, post-market surveillance, and traceability of medical devices, including those incorporating UHMWPE. Manufacturers must demonstrate compliance with essential safety and performance requirements, and obtain CE marking before placing their products on the EU market.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates UHMWPE-based medical devices. The approval process involves submitting extensive documentation on the device's safety, efficacy, and quality, with a particular focus on biocompatibility and long-term performance data for implantable devices.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to UHMWPE in medical devices, such as ISO 5834 for implant-grade UHMWPE. These standards provide guidelines for material specifications, testing methods, and quality control processes, which are often referenced by regulatory bodies in their approval processes.

Regulatory bodies are increasingly focusing on the long-term performance and wear characteristics of UHMWPE in medical devices. This has led to more stringent requirements for wear testing, particularly for load-bearing applications. For neurosurgical tools, there is a growing emphasis on demonstrating the material's resistance to degradation under sterilization processes and its ability to maintain mechanical properties over time.

The use of highly cross-linked UHMWPE and vitamin E-doped UHMWPE in medical devices has introduced additional regulatory considerations. Manufacturers must provide comprehensive data on these modified materials' long-term stability, oxidation resistance, and potential biological effects. This has led to the development of new testing protocols and standards specific to these advanced forms of UHMWPE.

As the field of neurosurgery continues to advance, regulators are adapting their approaches to keep pace with technological innovations. This includes developing new guidance documents for novel applications of UHMWPE in minimally invasive neurosurgical tools and implants. Manufacturers are encouraged to engage in early dialogue with regulatory agencies to navigate the evolving landscape and ensure compliance throughout the product development lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!