UHMWPE's Use in High-Frequency Signal Transmission

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in HF Signals: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a promising material in the field of high-frequency signal transmission, marking a significant advancement in telecommunications and electronics. This synthetic polymer, known for its exceptional mechanical properties and chemical resistance, has recently garnered attention for its potential applications in high-frequency circuits and antenna systems.

The evolution of UHMWPE in signal transmission can be traced back to the early 2000s when researchers began exploring alternative materials for traditional copper and fiber optic cables. The increasing demand for faster data transmission and the limitations of existing materials in terms of weight, flexibility, and signal loss at high frequencies prompted this exploration.

UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, contributes to its low dielectric constant and low dissipation factor. These properties make it an excellent candidate for high-frequency applications, where signal integrity and minimal loss are crucial. As the telecommunications industry continues to push towards higher frequency bands, particularly in the realm of 5G and beyond, the need for materials that can efficiently transmit signals in the gigahertz range has become more pressing.

The primary objective of utilizing UHMWPE in high-frequency signal transmission is to overcome the limitations of traditional materials. Researchers and engineers aim to develop UHMWPE-based components that can maintain signal quality at higher frequencies while offering advantages in terms of weight reduction, flexibility, and cost-effectiveness. This aligns with the broader industry goals of miniaturization, energy efficiency, and improved performance in electronic devices and communication systems.

Another key objective is to explore UHMWPE's potential in creating novel antenna designs and waveguide structures. The material's unique properties open up possibilities for creating lightweight, conformal antennas that can be integrated into various surfaces and structures, potentially revolutionizing the design of mobile devices, satellite communications, and radar systems.

Furthermore, the research into UHMWPE for high-frequency applications aims to address the growing need for materials that can withstand harsh environmental conditions. The polymer's resistance to chemicals, moisture, and temperature fluctuations makes it an attractive option for outdoor and aerospace applications where reliability under extreme conditions is paramount.

As we delve deeper into the technological landscape of UHMWPE in high-frequency signal transmission, it becomes evident that this field is at the intersection of materials science, electrical engineering, and telecommunications. The ongoing research and development in this area are expected to yield significant advancements in the coming years, potentially reshaping the future of wireless communication and high-speed data transmission technologies.

The evolution of UHMWPE in signal transmission can be traced back to the early 2000s when researchers began exploring alternative materials for traditional copper and fiber optic cables. The increasing demand for faster data transmission and the limitations of existing materials in terms of weight, flexibility, and signal loss at high frequencies prompted this exploration.

UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, contributes to its low dielectric constant and low dissipation factor. These properties make it an excellent candidate for high-frequency applications, where signal integrity and minimal loss are crucial. As the telecommunications industry continues to push towards higher frequency bands, particularly in the realm of 5G and beyond, the need for materials that can efficiently transmit signals in the gigahertz range has become more pressing.

The primary objective of utilizing UHMWPE in high-frequency signal transmission is to overcome the limitations of traditional materials. Researchers and engineers aim to develop UHMWPE-based components that can maintain signal quality at higher frequencies while offering advantages in terms of weight reduction, flexibility, and cost-effectiveness. This aligns with the broader industry goals of miniaturization, energy efficiency, and improved performance in electronic devices and communication systems.

Another key objective is to explore UHMWPE's potential in creating novel antenna designs and waveguide structures. The material's unique properties open up possibilities for creating lightweight, conformal antennas that can be integrated into various surfaces and structures, potentially revolutionizing the design of mobile devices, satellite communications, and radar systems.

Furthermore, the research into UHMWPE for high-frequency applications aims to address the growing need for materials that can withstand harsh environmental conditions. The polymer's resistance to chemicals, moisture, and temperature fluctuations makes it an attractive option for outdoor and aerospace applications where reliability under extreme conditions is paramount.

As we delve deeper into the technological landscape of UHMWPE in high-frequency signal transmission, it becomes evident that this field is at the intersection of materials science, electrical engineering, and telecommunications. The ongoing research and development in this area are expected to yield significant advancements in the coming years, potentially reshaping the future of wireless communication and high-speed data transmission technologies.

Market Analysis for UHMWPE in Signal Transmission

The market for UHMWPE in high-frequency signal transmission applications is experiencing significant growth, driven by the increasing demand for high-performance materials in telecommunications, aerospace, and defense industries. UHMWPE's unique properties, including low dielectric constant, low loss tangent, and excellent mechanical strength, make it an attractive option for signal transmission applications.

In the telecommunications sector, the rollout of 5G networks and the ongoing development of 6G technology are creating a substantial market opportunity for UHMWPE. As these networks require higher frequency transmissions, materials with superior dielectric properties become crucial. UHMWPE's ability to maintain signal integrity at high frequencies positions it as a key material for antenna radomes, waveguides, and other components in advanced communication systems.

The aerospace and defense industries also contribute significantly to the market demand for UHMWPE in signal transmission applications. With the increasing use of advanced radar systems, satellite communications, and electronic warfare equipment, there is a growing need for materials that can withstand harsh environments while maintaining excellent signal transmission properties. UHMWPE's lightweight nature and resistance to extreme temperatures further enhance its appeal in these sectors.

Market analysts project a compound annual growth rate (CAGR) for UHMWPE in signal transmission applications to exceed the overall UHMWPE market growth rate over the next five years. This accelerated growth is attributed to the material's expanding use in high-tech applications and the continuous innovation in signal transmission technologies.

The automotive industry is emerging as another potential growth area for UHMWPE in signal transmission. As vehicles become more connected and autonomous, the demand for high-performance materials in automotive radar and communication systems is expected to rise. UHMWPE's properties align well with the requirements of these advanced automotive technologies, potentially opening up new market opportunities.

Despite the positive market outlook, challenges remain. The relatively high cost of UHMWPE compared to traditional materials used in signal transmission applications may limit its adoption in price-sensitive markets. Additionally, the need for specialized processing techniques to incorporate UHMWPE into complex signal transmission components could pose barriers to widespread implementation.

In the telecommunications sector, the rollout of 5G networks and the ongoing development of 6G technology are creating a substantial market opportunity for UHMWPE. As these networks require higher frequency transmissions, materials with superior dielectric properties become crucial. UHMWPE's ability to maintain signal integrity at high frequencies positions it as a key material for antenna radomes, waveguides, and other components in advanced communication systems.

The aerospace and defense industries also contribute significantly to the market demand for UHMWPE in signal transmission applications. With the increasing use of advanced radar systems, satellite communications, and electronic warfare equipment, there is a growing need for materials that can withstand harsh environments while maintaining excellent signal transmission properties. UHMWPE's lightweight nature and resistance to extreme temperatures further enhance its appeal in these sectors.

Market analysts project a compound annual growth rate (CAGR) for UHMWPE in signal transmission applications to exceed the overall UHMWPE market growth rate over the next five years. This accelerated growth is attributed to the material's expanding use in high-tech applications and the continuous innovation in signal transmission technologies.

The automotive industry is emerging as another potential growth area for UHMWPE in signal transmission. As vehicles become more connected and autonomous, the demand for high-performance materials in automotive radar and communication systems is expected to rise. UHMWPE's properties align well with the requirements of these advanced automotive technologies, potentially opening up new market opportunities.

Despite the positive market outlook, challenges remain. The relatively high cost of UHMWPE compared to traditional materials used in signal transmission applications may limit its adoption in price-sensitive markets. Additionally, the need for specialized processing techniques to incorporate UHMWPE into complex signal transmission components could pose barriers to widespread implementation.

Technical Challenges in UHMWPE Signal Applications

The integration of Ultra-High Molecular Weight Polyethylene (UHMWPE) in high-frequency signal transmission applications presents several significant technical challenges. One of the primary obstacles is the inherent dielectric properties of UHMWPE. While the material offers excellent mechanical and chemical resistance, its dielectric constant and loss tangent are not inherently optimized for high-frequency signal propagation. This necessitates careful engineering and modification of the material to achieve the desired electrical performance.

Another critical challenge lies in the processing and fabrication of UHMWPE for signal transmission applications. The material's high molecular weight and long polymer chains, which contribute to its exceptional mechanical properties, also make it difficult to process using conventional methods. Achieving the necessary precision and consistency in manufacturing UHMWPE components for high-frequency applications requires advanced processing techniques and stringent quality control measures.

The interface between UHMWPE and other materials in the signal transmission system poses additional challenges. Ensuring proper adhesion and electrical continuity between UHMWPE components and metal conductors or other dielectric materials is crucial for maintaining signal integrity. This often requires the development of specialized surface treatment techniques or the use of compatible adhesives that do not compromise the electrical performance of the system.

Temperature stability is another significant concern in UHMWPE signal applications. The material's thermal expansion characteristics and potential changes in dielectric properties with temperature fluctuations can impact signal transmission reliability. Engineers must design systems that can maintain consistent performance across a wide range of operating temperatures, which may involve the use of composite structures or temperature compensation mechanisms.

Signal loss and attenuation present ongoing challenges in UHMWPE-based transmission systems. While UHMWPE offers advantages in terms of weight and flexibility, it may not match the low-loss characteristics of traditional high-frequency materials like PTFE. Overcoming this limitation requires innovative approaches to material formulation, such as the incorporation of low-loss fillers or the development of novel UHMWPE composites tailored for high-frequency applications.

The long-term stability and aging characteristics of UHMWPE in high-frequency environments are also areas of concern. Exposure to electromagnetic radiation, temperature cycling, and mechanical stress over time can potentially alter the material's properties. Ensuring consistent performance throughout the expected lifetime of the signal transmission system demands extensive testing and the development of predictive models for material behavior under various operating conditions.

Lastly, the challenge of scalability and cost-effectiveness in UHMWPE signal applications cannot be overlooked. As the demand for high-performance, lightweight signal transmission solutions grows, developing economically viable production methods for UHMWPE-based components becomes crucial. This involves optimizing manufacturing processes, exploring new fabrication technologies, and potentially developing hybrid materials that combine the benefits of UHMWPE with other high-performance polymers or composites.

Another critical challenge lies in the processing and fabrication of UHMWPE for signal transmission applications. The material's high molecular weight and long polymer chains, which contribute to its exceptional mechanical properties, also make it difficult to process using conventional methods. Achieving the necessary precision and consistency in manufacturing UHMWPE components for high-frequency applications requires advanced processing techniques and stringent quality control measures.

The interface between UHMWPE and other materials in the signal transmission system poses additional challenges. Ensuring proper adhesion and electrical continuity between UHMWPE components and metal conductors or other dielectric materials is crucial for maintaining signal integrity. This often requires the development of specialized surface treatment techniques or the use of compatible adhesives that do not compromise the electrical performance of the system.

Temperature stability is another significant concern in UHMWPE signal applications. The material's thermal expansion characteristics and potential changes in dielectric properties with temperature fluctuations can impact signal transmission reliability. Engineers must design systems that can maintain consistent performance across a wide range of operating temperatures, which may involve the use of composite structures or temperature compensation mechanisms.

Signal loss and attenuation present ongoing challenges in UHMWPE-based transmission systems. While UHMWPE offers advantages in terms of weight and flexibility, it may not match the low-loss characteristics of traditional high-frequency materials like PTFE. Overcoming this limitation requires innovative approaches to material formulation, such as the incorporation of low-loss fillers or the development of novel UHMWPE composites tailored for high-frequency applications.

The long-term stability and aging characteristics of UHMWPE in high-frequency environments are also areas of concern. Exposure to electromagnetic radiation, temperature cycling, and mechanical stress over time can potentially alter the material's properties. Ensuring consistent performance throughout the expected lifetime of the signal transmission system demands extensive testing and the development of predictive models for material behavior under various operating conditions.

Lastly, the challenge of scalability and cost-effectiveness in UHMWPE signal applications cannot be overlooked. As the demand for high-performance, lightweight signal transmission solutions grows, developing economically viable production methods for UHMWPE-based components becomes crucial. This involves optimizing manufacturing processes, exploring new fabrication technologies, and potentially developing hybrid materials that combine the benefits of UHMWPE with other high-performance polymers or composites.

Current UHMWPE Signal Transmission Solutions

01 UHMWPE fiber optic cables for signal transmission

Ultra-High Molecular Weight Polyethylene (UHMWPE) is used to create fiber optic cables for signal transmission. These cables offer advantages such as high strength, low weight, and excellent resistance to environmental factors, making them suitable for various applications including telecommunications and data transmission.- UHMWPE fiber optic cables for signal transmission: Ultra-High Molecular Weight Polyethylene (UHMWPE) is used in the production of fiber optic cables for signal transmission. These cables offer advantages such as high strength, low weight, and excellent resistance to environmental factors, making them suitable for various applications including telecommunications and data transmission.

- UHMWPE composites for electromagnetic shielding: UHMWPE-based composites are developed for electromagnetic shielding applications. These materials combine the mechanical properties of UHMWPE with conductive additives to create effective barriers against electromagnetic interference, enhancing signal integrity in electronic devices and communication systems.

- UHMWPE in antenna systems: UHMWPE is utilized in the construction of antenna systems for signal transmission and reception. Its low dielectric constant and excellent mechanical properties make it suitable for radome applications, protecting antennas while allowing efficient signal propagation.

- UHMWPE coatings for signal cables: Coatings made from UHMWPE are applied to signal cables to enhance their durability and performance. These coatings provide protection against abrasion, chemicals, and environmental factors, ensuring reliable signal transmission in harsh conditions.

- UHMWPE in high-frequency circuit boards: UHMWPE is incorporated into high-frequency circuit board materials for improved signal transmission. Its low dielectric loss and stable electrical properties contribute to reduced signal attenuation and improved performance in high-speed communication applications.

02 UHMWPE composites for electromagnetic shielding

UHMWPE-based composites are developed for electromagnetic shielding applications. These materials combine the properties of UHMWPE with conductive additives to create effective barriers against electromagnetic interference, enhancing signal integrity in electronic devices and communication systems.Expand Specific Solutions03 UHMWPE in antenna systems

UHMWPE is utilized in the construction of antenna systems for signal transmission and reception. Its low dielectric constant and excellent mechanical properties make it suitable for creating radomes and other antenna components, improving overall system performance and durability.Expand Specific Solutions04 UHMWPE coatings for signal transmission cables

Coatings made from UHMWPE are applied to signal transmission cables to enhance their durability and performance. These coatings provide protection against abrasion, chemicals, and environmental factors, extending the lifespan of cables used in various signal transmission applications.Expand Specific Solutions05 UHMWPE in high-frequency signal transmission

UHMWPE is employed in high-frequency signal transmission applications due to its low dielectric loss and excellent insulation properties. It is used in the fabrication of components for high-frequency circuits, connectors, and transmission lines, contributing to improved signal quality and reduced interference.Expand Specific Solutions

Key Players in UHMWPE and HF Signal Industry

The competitive landscape for UHMWPE's use in high-frequency signal transmission is in an early development stage, with a growing market potential as 5G and advanced communications technologies expand. The market size is still relatively small but expected to increase significantly in the coming years. Technologically, it's in the research and early application phase, with major players like NTT Docomo, Samsung Electronics, Huawei, and Ericsson leading innovation efforts. These companies are exploring UHMWPE's unique properties for enhancing signal transmission in next-generation wireless networks. Other tech giants like Qualcomm, Apple, and Intel are also likely to be involved in R&D, potentially driving the technology towards commercialization and wider adoption in the telecommunications industry.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a novel approach to using UHMWPE in high-frequency signal transmission for consumer electronics and mobile devices. Their technology involves creating nanoporous UHMWPE films that further reduce the dielectric constant while maintaining mechanical strength. Samsung's research has demonstrated that these nanoporous UHMWPE films can achieve a dielectric constant as low as 1.5, significantly lower than solid UHMWPE[7]. The company has also integrated UHMWPE-based flexible printed circuits (FPCs) in their latest smartphone designs, allowing for improved signal integrity in compact form factors[8].

Strengths: Excellent performance in compact devices, potential for flexible and foldable electronics, and improved thermal management. Weaknesses: Higher production costs and potential challenges in scaling up nanoporous film production.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced UHMWPE-based materials for high-frequency signal transmission in 5G and beyond networks. Their approach involves creating ultra-thin UHMWPE films with precisely controlled molecular orientation to enhance signal propagation. The company has implemented a proprietary manufacturing process that allows for the production of UHMWPE sheets with thicknesses down to 10 microns, significantly reducing signal loss in high-frequency applications[1]. Huawei's research has shown that their UHMWPE-based transmission lines can achieve up to 30% lower insertion loss compared to traditional materials at frequencies above 100 GHz[2].

Strengths: Superior signal integrity at high frequencies, reduced power consumption, and improved thermal management. Weaknesses: Higher production costs and potential challenges in large-scale manufacturing.

Innovations in UHMWPE for HF Signal Transmission

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

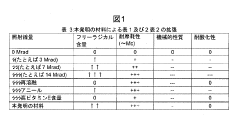

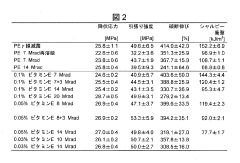

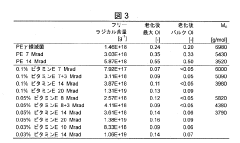

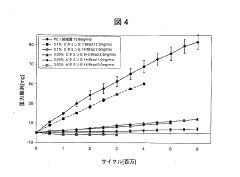

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Ultra-High Molecular Weight Polyethylene (UHMWPE)Inorganic Nanocomposite Material and High Performance Fiber Manufacturing Method Thereof

PatentInactiveUS20110082262A1

Innovation

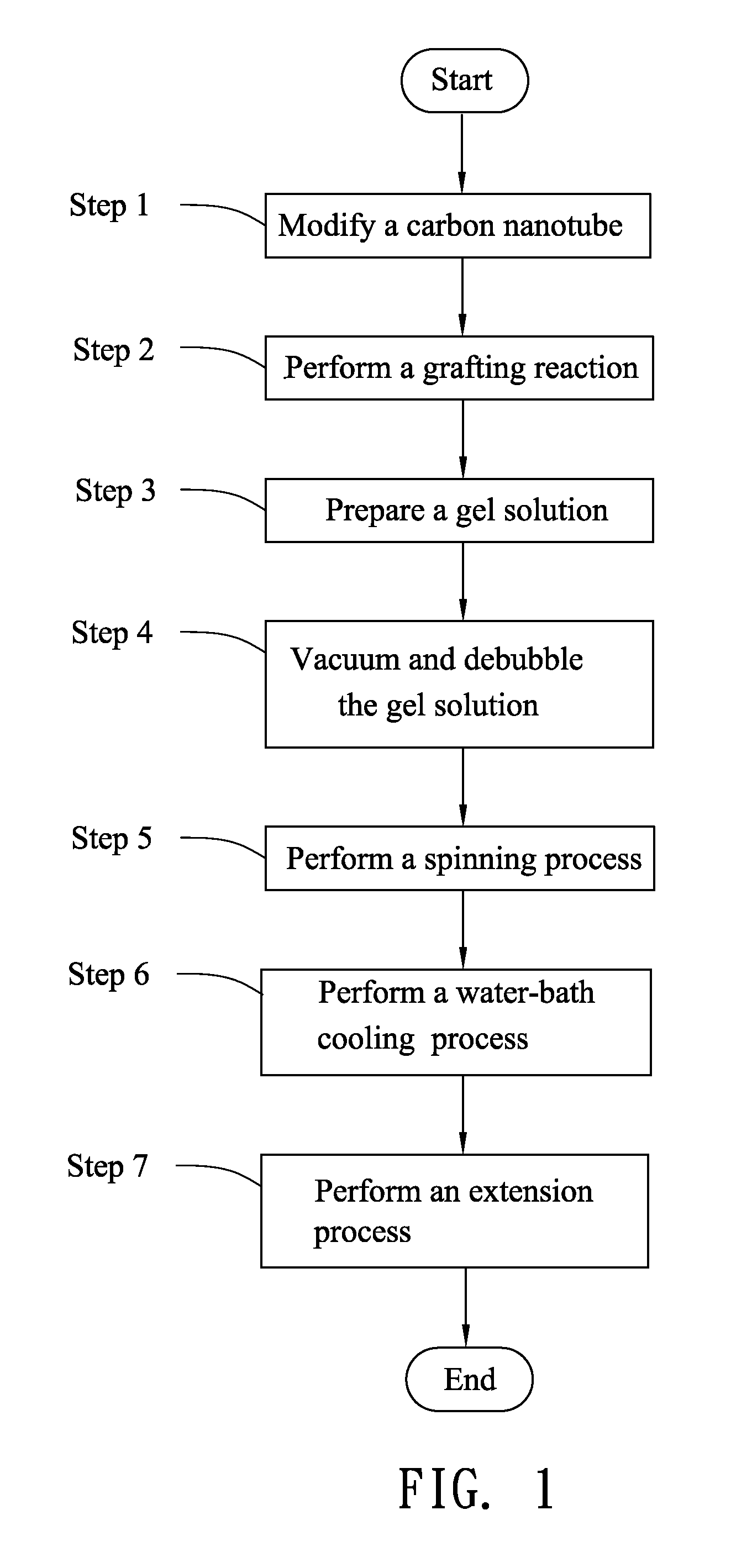

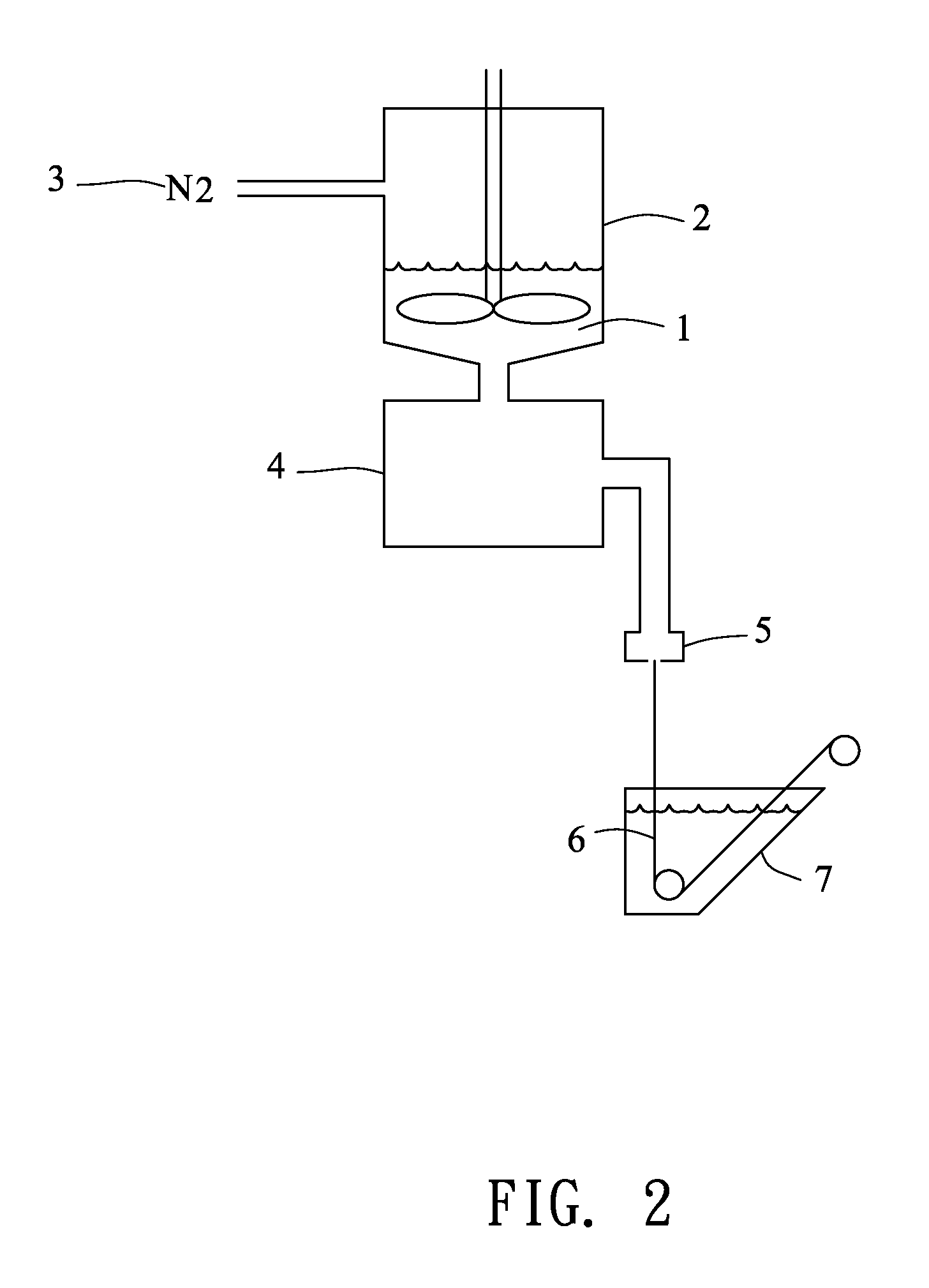

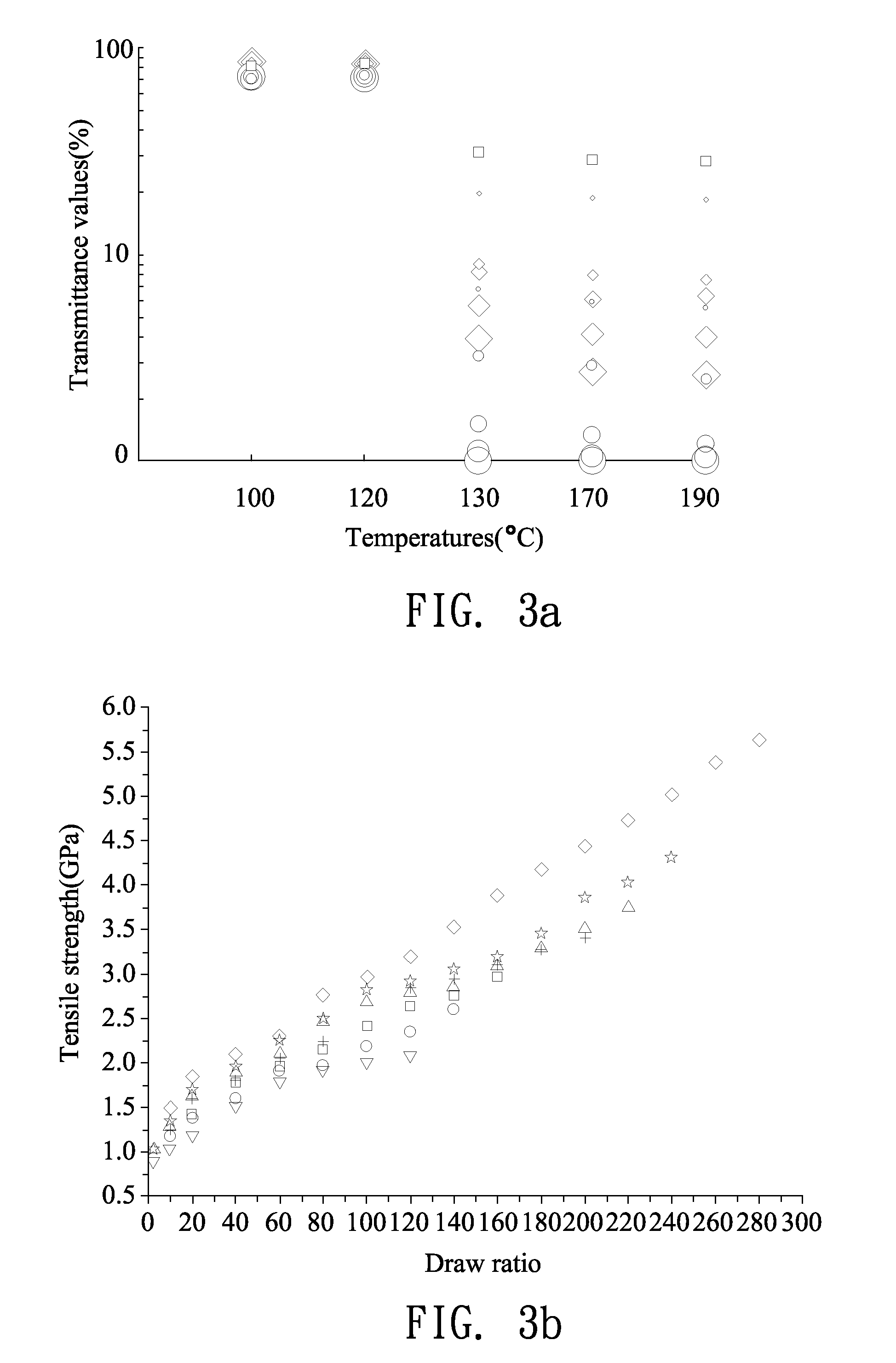

- A novel manufacturing process involving the uniform dispersion of inorganic nano substances like attapulgite, carbon nano-tubes, sepiolite, and wollastonite into UHMWPE gel solutions, followed by specific processing steps including sudden air cooling, water-phase solidification, and multi-stage temperature-changing drawing to produce high-tenacity fibers with reduced crimp, light transmittance, and improved strength.

Environmental Impact of UHMWPE in Electronics

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in electronics, particularly in high-frequency signal transmission applications, is a complex and multifaceted issue that requires careful consideration. UHMWPE, known for its exceptional mechanical properties and chemical resistance, has found increasing use in electronic components and transmission lines due to its low dielectric constant and excellent insulation characteristics.

One of the primary environmental concerns associated with UHMWPE in electronics is its long-term persistence in the environment. As a synthetic polymer, UHMWPE is not biodegradable and can potentially contribute to plastic pollution if not properly managed at the end of its lifecycle. This is particularly relevant in the context of electronic waste (e-waste), which is a growing global environmental challenge.

However, the durability and longevity of UHMWPE can also be viewed as an environmental advantage in certain applications. In high-frequency signal transmission systems, the use of UHMWPE can lead to longer-lasting components and reduced need for frequent replacements. This, in turn, may result in less overall material consumption and waste generation over time.

The production process of UHMWPE for electronic applications also has environmental implications. While the polymer itself is derived from petrochemicals, the manufacturing process is relatively energy-efficient compared to some other high-performance materials. Additionally, UHMWPE production generates minimal harmful byproducts or emissions, which is a positive factor from an environmental perspective.

In terms of energy efficiency, UHMWPE's use in high-frequency signal transmission can contribute to reduced power losses and improved signal integrity. This can lead to more energy-efficient electronic systems, potentially offsetting some of the environmental impacts associated with its production and disposal.

Recycling and end-of-life management of UHMWPE in electronic applications present both challenges and opportunities. While UHMWPE is theoretically recyclable, the practical implementation of recycling processes for electronic components containing UHMWPE can be complex due to the need for separation from other materials and potential contamination issues.

As the electronics industry continues to evolve, there is growing interest in developing more sustainable alternatives to traditional materials. This includes research into bio-based polymers that could potentially replace or complement UHMWPE in certain applications, offering similar performance characteristics with reduced environmental impact.

In conclusion, while UHMWPE offers significant performance benefits in high-frequency signal transmission applications, its environmental impact in electronics is a nuanced issue. Balancing the material's durability, performance, and potential for recycling against its non-biodegradable nature and production-related impacts is crucial for sustainable development in the electronics industry.

One of the primary environmental concerns associated with UHMWPE in electronics is its long-term persistence in the environment. As a synthetic polymer, UHMWPE is not biodegradable and can potentially contribute to plastic pollution if not properly managed at the end of its lifecycle. This is particularly relevant in the context of electronic waste (e-waste), which is a growing global environmental challenge.

However, the durability and longevity of UHMWPE can also be viewed as an environmental advantage in certain applications. In high-frequency signal transmission systems, the use of UHMWPE can lead to longer-lasting components and reduced need for frequent replacements. This, in turn, may result in less overall material consumption and waste generation over time.

The production process of UHMWPE for electronic applications also has environmental implications. While the polymer itself is derived from petrochemicals, the manufacturing process is relatively energy-efficient compared to some other high-performance materials. Additionally, UHMWPE production generates minimal harmful byproducts or emissions, which is a positive factor from an environmental perspective.

In terms of energy efficiency, UHMWPE's use in high-frequency signal transmission can contribute to reduced power losses and improved signal integrity. This can lead to more energy-efficient electronic systems, potentially offsetting some of the environmental impacts associated with its production and disposal.

Recycling and end-of-life management of UHMWPE in electronic applications present both challenges and opportunities. While UHMWPE is theoretically recyclable, the practical implementation of recycling processes for electronic components containing UHMWPE can be complex due to the need for separation from other materials and potential contamination issues.

As the electronics industry continues to evolve, there is growing interest in developing more sustainable alternatives to traditional materials. This includes research into bio-based polymers that could potentially replace or complement UHMWPE in certain applications, offering similar performance characteristics with reduced environmental impact.

In conclusion, while UHMWPE offers significant performance benefits in high-frequency signal transmission applications, its environmental impact in electronics is a nuanced issue. Balancing the material's durability, performance, and potential for recycling against its non-biodegradable nature and production-related impacts is crucial for sustainable development in the electronics industry.

Standardization Efforts for UHMWPE in HF Applications

Standardization efforts for Ultra-High Molecular Weight Polyethylene (UHMWPE) in high-frequency (HF) applications are gaining momentum as the material's potential in signal transmission becomes increasingly apparent. These initiatives aim to establish uniform guidelines and specifications for UHMWPE's use in HF environments, ensuring consistency and reliability across various applications.

Several industry bodies and standards organizations have recognized the need for a cohesive approach to UHMWPE implementation in HF systems. The Institute of Electrical and Electronics Engineers (IEEE) has formed a working group dedicated to developing standards for UHMWPE in high-frequency signal transmission. This group is focusing on creating guidelines for material properties, testing methodologies, and performance benchmarks specific to HF applications.

Concurrently, the International Electrotechnical Commission (IEC) is working on incorporating UHMWPE-specific standards into its existing framework for dielectric materials used in high-frequency systems. These efforts aim to provide manufacturers and engineers with clear specifications for UHMWPE selection and implementation in HF circuits and components.

The standardization process involves extensive collaboration between material scientists, electrical engineers, and industry stakeholders. Key areas of focus include defining acceptable ranges for dielectric properties, establishing protocols for measuring signal loss in UHMWPE-based transmission lines, and determining durability requirements for UHMWPE components in various operating conditions.

One significant aspect of these standardization efforts is the development of uniform testing procedures. This includes standardized methods for evaluating UHMWPE's performance under different frequencies, temperatures, and environmental conditions. Such standardized tests will enable more accurate comparisons between different UHMWPE formulations and facilitate quality control in manufacturing processes.

Additionally, efforts are underway to standardize the terminology and nomenclature used in describing UHMWPE's properties and applications in HF systems. This will help ensure clear communication among researchers, manufacturers, and end-users, reducing the potential for misunderstandings or misapplications of the material.

As these standardization efforts progress, they are expected to accelerate the adoption of UHMWPE in high-frequency applications. By providing a common framework for material specifications and performance expectations, these standards will enhance confidence in UHMWPE-based solutions and facilitate innovation in HF signal transmission technologies.

Several industry bodies and standards organizations have recognized the need for a cohesive approach to UHMWPE implementation in HF systems. The Institute of Electrical and Electronics Engineers (IEEE) has formed a working group dedicated to developing standards for UHMWPE in high-frequency signal transmission. This group is focusing on creating guidelines for material properties, testing methodologies, and performance benchmarks specific to HF applications.

Concurrently, the International Electrotechnical Commission (IEC) is working on incorporating UHMWPE-specific standards into its existing framework for dielectric materials used in high-frequency systems. These efforts aim to provide manufacturers and engineers with clear specifications for UHMWPE selection and implementation in HF circuits and components.

The standardization process involves extensive collaboration between material scientists, electrical engineers, and industry stakeholders. Key areas of focus include defining acceptable ranges for dielectric properties, establishing protocols for measuring signal loss in UHMWPE-based transmission lines, and determining durability requirements for UHMWPE components in various operating conditions.

One significant aspect of these standardization efforts is the development of uniform testing procedures. This includes standardized methods for evaluating UHMWPE's performance under different frequencies, temperatures, and environmental conditions. Such standardized tests will enable more accurate comparisons between different UHMWPE formulations and facilitate quality control in manufacturing processes.

Additionally, efforts are underway to standardize the terminology and nomenclature used in describing UHMWPE's properties and applications in HF systems. This will help ensure clear communication among researchers, manufacturers, and end-users, reducing the potential for misunderstandings or misapplications of the material.

As these standardization efforts progress, they are expected to accelerate the adoption of UHMWPE in high-frequency applications. By providing a common framework for material specifications and performance expectations, these standards will enhance confidence in UHMWPE-based solutions and facilitate innovation in HF signal transmission technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!