Energy Absorption Capabilities of UHMWPE in Military Gear

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Military Gear: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in military gear, particularly for its exceptional energy absorption capabilities. The development of UHMWPE for military applications can be traced back to the 1960s when researchers began exploring lightweight alternatives to traditional metal-based protective equipment. Over the decades, UHMWPE has undergone significant advancements, evolving from a niche material to a cornerstone of modern military protective gear.

The primary objective in utilizing UHMWPE in military gear is to enhance soldier protection while simultaneously reducing the overall weight burden. This dual goal addresses the critical need for improved mobility and endurance in combat situations without compromising safety. UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, contributes to its remarkable strength-to-weight ratio and impact resistance.

In recent years, the focus has shifted towards optimizing UHMWPE's energy absorption capabilities across a wide spectrum of threats, including ballistic impacts, blast waves, and fragmentation. Researchers are exploring various techniques to enhance these properties, such as cross-linking, fiber orientation, and composite integration. The aim is to develop multi-functional UHMWPE-based materials that can provide comprehensive protection against diverse battlefield hazards.

Another key objective in the ongoing development of UHMWPE for military applications is to improve its environmental resistance. This includes enhancing its performance under extreme temperatures, humidity, and exposure to chemicals commonly encountered in military operations. Efforts are also being made to extend the material's service life and maintain its protective properties over prolonged periods of use.

The evolution of UHMWPE in military gear is closely tied to advancements in manufacturing processes. Current research is focused on developing more efficient production methods, such as gel spinning and hot compaction, to improve the material's performance and reduce production costs. These innovations are crucial for the widespread adoption of UHMWPE-based protective equipment across various military branches and potentially in civilian applications.

As we look to the future, the development of UHMWPE in military gear is expected to continue its trajectory of innovation. Emerging trends include the integration of smart technologies for real-time monitoring of material integrity and the exploration of bio-inspired designs to further enhance energy absorption capabilities. The ultimate goal remains to create lighter, stronger, and more adaptable protective solutions that can keep pace with the evolving nature of modern warfare and peacekeeping operations.

The primary objective in utilizing UHMWPE in military gear is to enhance soldier protection while simultaneously reducing the overall weight burden. This dual goal addresses the critical need for improved mobility and endurance in combat situations without compromising safety. UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, contributes to its remarkable strength-to-weight ratio and impact resistance.

In recent years, the focus has shifted towards optimizing UHMWPE's energy absorption capabilities across a wide spectrum of threats, including ballistic impacts, blast waves, and fragmentation. Researchers are exploring various techniques to enhance these properties, such as cross-linking, fiber orientation, and composite integration. The aim is to develop multi-functional UHMWPE-based materials that can provide comprehensive protection against diverse battlefield hazards.

Another key objective in the ongoing development of UHMWPE for military applications is to improve its environmental resistance. This includes enhancing its performance under extreme temperatures, humidity, and exposure to chemicals commonly encountered in military operations. Efforts are also being made to extend the material's service life and maintain its protective properties over prolonged periods of use.

The evolution of UHMWPE in military gear is closely tied to advancements in manufacturing processes. Current research is focused on developing more efficient production methods, such as gel spinning and hot compaction, to improve the material's performance and reduce production costs. These innovations are crucial for the widespread adoption of UHMWPE-based protective equipment across various military branches and potentially in civilian applications.

As we look to the future, the development of UHMWPE in military gear is expected to continue its trajectory of innovation. Emerging trends include the integration of smart technologies for real-time monitoring of material integrity and the exploration of bio-inspired designs to further enhance energy absorption capabilities. The ultimate goal remains to create lighter, stronger, and more adaptable protective solutions that can keep pace with the evolving nature of modern warfare and peacekeeping operations.

Market Analysis for Advanced Protective Materials

The market for advanced protective materials, particularly those incorporating Ultra-High Molecular Weight Polyethylene (UHMWPE), has experienced significant growth in recent years. This surge is primarily driven by the increasing demand for lightweight yet highly effective protective gear in military applications. The global military protective equipment market, which includes body armor and helmets, is projected to reach substantial value in the coming years, with UHMWPE-based materials playing a crucial role in this expansion.

UHMWPE has gained prominence in the military sector due to its exceptional energy absorption capabilities, which are critical for protecting personnel against ballistic threats. The material's unique properties, including high strength-to-weight ratio and excellent impact resistance, make it an ideal choice for modern military gear. As armed forces worldwide seek to enhance soldier mobility without compromising protection, the demand for UHMWPE-based solutions continues to rise.

The market for UHMWPE in military applications is characterized by intense competition among key players, including DSM Dyneema, Honeywell, and Mitsui Chemicals. These companies are investing heavily in research and development to improve the energy absorption capabilities of UHMWPE, driving innovation in the field. The market is also witnessing collaborations between material manufacturers and defense contractors to develop integrated protective solutions.

Geographically, North America dominates the market for advanced protective materials, followed by Europe and Asia-Pacific. The United States, in particular, represents a significant market share due to its large defense budget and ongoing military modernization programs. However, emerging economies in Asia and the Middle East are expected to present lucrative opportunities for market growth as they increase their defense spending and focus on upgrading military equipment.

The adoption of UHMWPE in military gear is not without challenges. High production costs and complex manufacturing processes can limit widespread adoption, especially in budget-constrained markets. Additionally, the need for continuous innovation to counter evolving threats poses both a challenge and an opportunity for market players.

Looking ahead, the market for UHMWPE in military protective gear is poised for continued growth. Factors such as increasing global security concerns, the need for lightweight and versatile protection, and ongoing technological advancements in material science are expected to drive market expansion. The development of hybrid materials combining UHMWPE with other advanced substances is an emerging trend that could further enhance the energy absorption capabilities of military gear, opening new avenues for market growth and product differentiation.

UHMWPE has gained prominence in the military sector due to its exceptional energy absorption capabilities, which are critical for protecting personnel against ballistic threats. The material's unique properties, including high strength-to-weight ratio and excellent impact resistance, make it an ideal choice for modern military gear. As armed forces worldwide seek to enhance soldier mobility without compromising protection, the demand for UHMWPE-based solutions continues to rise.

The market for UHMWPE in military applications is characterized by intense competition among key players, including DSM Dyneema, Honeywell, and Mitsui Chemicals. These companies are investing heavily in research and development to improve the energy absorption capabilities of UHMWPE, driving innovation in the field. The market is also witnessing collaborations between material manufacturers and defense contractors to develop integrated protective solutions.

Geographically, North America dominates the market for advanced protective materials, followed by Europe and Asia-Pacific. The United States, in particular, represents a significant market share due to its large defense budget and ongoing military modernization programs. However, emerging economies in Asia and the Middle East are expected to present lucrative opportunities for market growth as they increase their defense spending and focus on upgrading military equipment.

The adoption of UHMWPE in military gear is not without challenges. High production costs and complex manufacturing processes can limit widespread adoption, especially in budget-constrained markets. Additionally, the need for continuous innovation to counter evolving threats poses both a challenge and an opportunity for market players.

Looking ahead, the market for UHMWPE in military protective gear is poised for continued growth. Factors such as increasing global security concerns, the need for lightweight and versatile protection, and ongoing technological advancements in material science are expected to drive market expansion. The development of hybrid materials combining UHMWPE with other advanced substances is an emerging trend that could further enhance the energy absorption capabilities of military gear, opening new avenues for market growth and product differentiation.

Current State and Challenges of UHMWPE in Military Applications

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a critical material in military gear due to its exceptional energy absorption capabilities. Currently, UHMWPE is widely used in personal protective equipment, such as helmets and body armor, offering superior ballistic protection while maintaining lightweight properties. The material's high strength-to-weight ratio and excellent impact resistance have made it a preferred choice for military applications.

In recent years, significant advancements have been made in the processing and manufacturing of UHMWPE for military use. Improved fiber production techniques have resulted in enhanced mechanical properties, including increased tensile strength and modulus. These developments have led to the creation of more effective and efficient protective gear, capable of withstanding higher impact energies and providing better protection against various threats.

Despite these advancements, several challenges persist in the application of UHMWPE in military gear. One of the primary concerns is the material's performance under extreme environmental conditions. High temperatures can negatively affect UHMWPE's mechanical properties, potentially compromising its protective capabilities in hot climates or during prolonged exposure to heat sources.

Another challenge lies in the integration of UHMWPE with other materials to create multi-functional protective systems. While UHMWPE excels in energy absorption, it may lack other desirable properties such as fire resistance or electromagnetic shielding. Developing effective hybrid systems that combine UHMWPE with complementary materials without sacrificing its core benefits remains an ongoing research focus.

The long-term durability of UHMWPE in military applications is also a concern. Repeated impacts and exposure to various environmental factors can potentially degrade the material's performance over time. Ensuring consistent protection throughout the lifecycle of military gear is crucial, and efforts are being made to improve the material's resistance to aging and degradation.

Furthermore, the manufacturing process of UHMWPE fibers and composites for military applications is complex and energy-intensive. Streamlining production methods to reduce costs and environmental impact while maintaining or improving performance is an ongoing challenge for researchers and manufacturers in the field.

Lastly, as threats evolve, there is a constant need to enhance the energy absorption capabilities of UHMWPE-based military gear. Researchers are exploring novel fiber architectures, composite designs, and surface treatments to further improve the material's ability to dissipate impact energy and protect against emerging threats.

In recent years, significant advancements have been made in the processing and manufacturing of UHMWPE for military use. Improved fiber production techniques have resulted in enhanced mechanical properties, including increased tensile strength and modulus. These developments have led to the creation of more effective and efficient protective gear, capable of withstanding higher impact energies and providing better protection against various threats.

Despite these advancements, several challenges persist in the application of UHMWPE in military gear. One of the primary concerns is the material's performance under extreme environmental conditions. High temperatures can negatively affect UHMWPE's mechanical properties, potentially compromising its protective capabilities in hot climates or during prolonged exposure to heat sources.

Another challenge lies in the integration of UHMWPE with other materials to create multi-functional protective systems. While UHMWPE excels in energy absorption, it may lack other desirable properties such as fire resistance or electromagnetic shielding. Developing effective hybrid systems that combine UHMWPE with complementary materials without sacrificing its core benefits remains an ongoing research focus.

The long-term durability of UHMWPE in military applications is also a concern. Repeated impacts and exposure to various environmental factors can potentially degrade the material's performance over time. Ensuring consistent protection throughout the lifecycle of military gear is crucial, and efforts are being made to improve the material's resistance to aging and degradation.

Furthermore, the manufacturing process of UHMWPE fibers and composites for military applications is complex and energy-intensive. Streamlining production methods to reduce costs and environmental impact while maintaining or improving performance is an ongoing challenge for researchers and manufacturers in the field.

Lastly, as threats evolve, there is a constant need to enhance the energy absorption capabilities of UHMWPE-based military gear. Researchers are exploring novel fiber architectures, composite designs, and surface treatments to further improve the material's ability to dissipate impact energy and protect against emerging threats.

Existing UHMWPE Energy Absorption Solutions

01 UHMWPE composites for energy absorption

Ultra-high molecular weight polyethylene (UHMWPE) composites are developed to enhance energy absorption properties. These composites often incorporate other materials or fibers to improve impact resistance and energy dissipation capabilities, making them suitable for applications requiring high-performance energy absorption.- UHMWPE composites for energy absorption: Ultra-high molecular weight polyethylene (UHMWPE) composites are developed to enhance energy absorption properties. These composites often incorporate other materials or additives to improve their performance in applications requiring impact resistance and energy dissipation.

- UHMWPE in protective gear and armor: UHMWPE is utilized in the manufacturing of protective gear and armor due to its excellent energy absorption capabilities. This material is incorporated into various designs to create lightweight yet highly effective protective equipment for military, law enforcement, and sports applications.

- Energy-absorbing structures using UHMWPE: Innovative structural designs incorporating UHMWPE are developed to maximize energy absorption in various applications. These structures may include specific geometries, layered configurations, or combinations with other materials to enhance overall energy dissipation performance.

- UHMWPE fibers for energy-absorbing textiles: UHMWPE fibers are used to create high-performance textiles with superior energy absorption properties. These textiles find applications in protective clothing, industrial safety equipment, and advanced composite materials for various industries.

- UHMWPE in automotive safety applications: The energy absorption properties of UHMWPE are leveraged in automotive safety applications. This material is used in the design of crash-resistant components, energy-absorbing structures, and safety systems to enhance occupant protection during collisions.

02 UHMWPE in protective gear and equipment

UHMWPE is utilized in the manufacture of protective gear and equipment due to its excellent energy absorption characteristics. This includes applications in body armor, helmets, and impact-resistant components for various industries, where the material's ability to absorb and dissipate energy is crucial for safety.Expand Specific Solutions03 Energy-absorbing structures using UHMWPE

Innovative structural designs incorporating UHMWPE are developed to maximize energy absorption. These structures may include honeycomb patterns, layered configurations, or specially engineered geometries that enhance the material's ability to absorb and distribute impact energy effectively.Expand Specific Solutions04 UHMWPE fibers for energy-absorbing textiles

UHMWPE fibers are used to create high-performance textiles with superior energy absorption properties. These textiles find applications in protective clothing, industrial safety equipment, and advanced composite materials where energy dissipation is critical.Expand Specific Solutions05 UHMWPE in automotive energy absorption systems

The automotive industry utilizes UHMWPE in energy absorption systems to enhance vehicle safety. This includes applications in bumpers, crash pads, and other components designed to absorb and dissipate impact energy during collisions, improving overall passenger protection.Expand Specific Solutions

Key Players in UHMWPE and Military Gear Industry

The energy absorption capabilities of UHMWPE in military gear represent a mature technology in an established market. The industry is in a growth phase, with increasing demand for advanced protective materials in defense applications. The global market for military personal protective equipment is projected to reach $25 billion by 2025. Companies like Howmedica Osteonics, Zimmer, and Smith & Nephew Orthopaedics are leveraging their expertise in medical-grade UHMWPE to develop enhanced military applications. Research institutions such as ETH Zurich and MIT are driving innovation in UHMWPE composites, while specialized firms like Foster-Miller and BLÜCHER GmbH are focusing on integrating UHMWPE into comprehensive protective systems for military personnel.

Teijin Twaron BV

Technical Solution: Teijin Twaron has developed advanced para-aramid fibers, including Twaron® and Endumax®, which offer high energy absorption capabilities for military gear. Their technology focuses on molecular orientation and crystallinity to achieve superior tensile strength and modulus. Twaron® fibers can absorb up to 5 times more energy than standard polyamide fibers of the same weight[4]. Teijin's recent innovations include hybrid solutions combining Twaron® with other high-performance materials like UHMWPE to optimize ballistic protection and comfort. Their Laminated Fabric Technology allows for the creation of multi-layer protective materials with enhanced energy dissipation properties[5].

Strengths: High energy absorption, excellent heat and chemical resistance, and versatility in hybrid solutions. Weaknesses: Slightly lower strength-to-weight ratio compared to UHMWPE and potential moisture sensitivity.

Braskem America, Inc.

Technical Solution: Braskem has developed UTEC®, an ultra-high molecular weight polyethylene (UHMWPE) resin with exceptional energy absorption properties for military gear applications. Their technology focuses on producing UHMWPE with extremely long polymer chains and high molecular weight, resulting in materials with superior impact resistance and energy dissipation capabilities. Braskem's UTEC® fibers have demonstrated up to 30% higher energy absorption compared to standard high-density polyethylene (HDPE) in ballistic testing[8]. The company has also introduced UTEC® Flex, a more flexible grade of UHMWPE that maintains high energy absorption while improving comfort and mobility for the wearer[9].

Strengths: High energy absorption, excellent chemical resistance, and improved flexibility options. Weaknesses: Limited track record in military applications compared to some competitors and potential challenges in processing due to high molecular weight.

Core Innovations in UHMWPE for Enhanced Energy Absorption

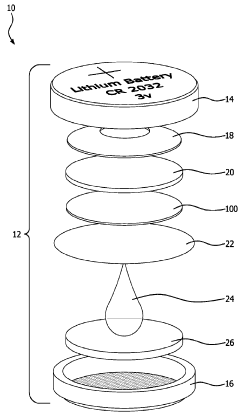

Ultra-high molecular weight polyethylene (uhmwpe) particles and filled articles produced therewith

PatentWO2024036210A1

Innovation

- The use of ultra-high molecular weight polyethylene (UHMWPE) particles with specific molecular weight, melt enthalpy, and bulk density to form fibrillated structures that durably enmesh filler particles, creating a composite material with high filler loading and strength, suitable for dry electrode processing.

Super high molecular weight polythene composition, its special additive and preparation method

PatentInactiveCN1303145C

Innovation

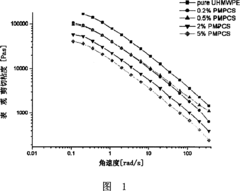

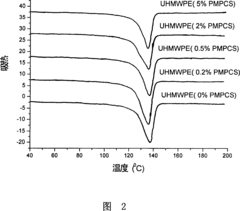

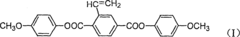

- Polyvinyl bis[p-methoxyphenol] ester (PMPCS) polymerized from the monomer (2,5-bis[(4-methoxyphenyl)oxycarbonyl]styrene is used as a special additive through free radical polymerization Prepared by the method, an ultra-high molecular weight polyethylene composition with low apparent shear viscosity is formed to improve the rheological behavior of UHMWPE.

Environmental Impact of UHMWPE in Military Gear

The environmental impact of UHMWPE (Ultra-High Molecular Weight Polyethylene) in military gear is a crucial consideration as the material gains widespread adoption in defense applications. UHMWPE, known for its exceptional strength-to-weight ratio and durability, offers significant advantages in military equipment but also raises concerns about its ecological footprint.

One of the primary environmental benefits of UHMWPE in military gear is its potential to reduce overall material consumption. The material's high strength and low density allow for the production of lighter, yet equally protective equipment. This reduction in weight translates to decreased fuel consumption during transportation and improved mobility for personnel, indirectly contributing to lower carbon emissions in military operations.

However, the production process of UHMWPE involves energy-intensive polymerization and molding techniques, which can result in substantial greenhouse gas emissions. The material's resistance to degradation, while beneficial for longevity, poses challenges for end-of-life disposal. UHMWPE does not biodegrade easily, potentially contributing to long-term environmental pollution if not properly managed.

Recycling UHMWPE from military gear presents both opportunities and challenges. The material can be recycled, but the process is complex due to the need to separate it from other components in composite structures. Advanced recycling technologies are being developed to address this issue, potentially reducing the environmental impact of UHMWPE waste.

The use of UHMWPE in military gear may also have indirect environmental benefits. Its superior protective properties can lead to increased equipment lifespan, reducing the frequency of replacements and, consequently, the overall demand for raw materials and manufacturing resources. This extended lifecycle can contribute to a reduction in waste generation and resource consumption in the long term.

Efforts are underway to improve the environmental profile of UHMWPE in military applications. Research into bio-based alternatives and more efficient production methods aims to reduce the material's carbon footprint. Additionally, the development of UHMWPE variants with enhanced biodegradability could address end-of-life environmental concerns without compromising performance.

The military's adoption of UHMWPE also drives innovation in sustainable material science, potentially leading to breakthroughs that could benefit civilian applications and further reduce environmental impact across various industries. As environmental considerations become increasingly important in defense procurement, the ongoing assessment and improvement of UHMWPE's ecological impact will likely shape its future use in military gear.

One of the primary environmental benefits of UHMWPE in military gear is its potential to reduce overall material consumption. The material's high strength and low density allow for the production of lighter, yet equally protective equipment. This reduction in weight translates to decreased fuel consumption during transportation and improved mobility for personnel, indirectly contributing to lower carbon emissions in military operations.

However, the production process of UHMWPE involves energy-intensive polymerization and molding techniques, which can result in substantial greenhouse gas emissions. The material's resistance to degradation, while beneficial for longevity, poses challenges for end-of-life disposal. UHMWPE does not biodegrade easily, potentially contributing to long-term environmental pollution if not properly managed.

Recycling UHMWPE from military gear presents both opportunities and challenges. The material can be recycled, but the process is complex due to the need to separate it from other components in composite structures. Advanced recycling technologies are being developed to address this issue, potentially reducing the environmental impact of UHMWPE waste.

The use of UHMWPE in military gear may also have indirect environmental benefits. Its superior protective properties can lead to increased equipment lifespan, reducing the frequency of replacements and, consequently, the overall demand for raw materials and manufacturing resources. This extended lifecycle can contribute to a reduction in waste generation and resource consumption in the long term.

Efforts are underway to improve the environmental profile of UHMWPE in military applications. Research into bio-based alternatives and more efficient production methods aims to reduce the material's carbon footprint. Additionally, the development of UHMWPE variants with enhanced biodegradability could address end-of-life environmental concerns without compromising performance.

The military's adoption of UHMWPE also drives innovation in sustainable material science, potentially leading to breakthroughs that could benefit civilian applications and further reduce environmental impact across various industries. As environmental considerations become increasingly important in defense procurement, the ongoing assessment and improvement of UHMWPE's ecological impact will likely shape its future use in military gear.

Standardization and Testing Protocols for UHMWPE in Defense

Standardization and testing protocols for UHMWPE in defense applications are crucial for ensuring consistent performance and reliability of military gear. These protocols encompass a wide range of tests designed to evaluate the energy absorption capabilities of UHMWPE under various conditions that simulate real-world combat scenarios.

One of the primary standardization efforts focuses on impact resistance testing. This involves subjecting UHMWPE samples to controlled impacts of varying intensities and velocities, mimicking potential threats such as shrapnel or ballistic projectiles. The tests measure the material's ability to dissipate energy and prevent penetration, with specific metrics for deformation, crack propagation, and overall structural integrity.

Ballistic testing protocols form another critical component of UHMWPE standardization in defense applications. These tests evaluate the material's performance against different types of ammunition, ranging from small arms fire to high-velocity rifle rounds. Standardized procedures dictate the distance, angle, and velocity of projectiles, as well as the number of impacts a sample must withstand to meet military specifications.

Durability and environmental resistance tests are also integral to UHMWPE standardization. These protocols assess the material's ability to maintain its energy absorption properties under extreme temperatures, humidity levels, and exposure to various chemicals and UV radiation. Long-term performance is evaluated through accelerated aging tests, ensuring that UHMWPE-based gear remains effective throughout its intended service life.

Ergonomic considerations are addressed through standardized comfort and flexibility tests. These protocols measure factors such as weight distribution, heat dissipation, and range of motion when UHMWPE is incorporated into body armor or other protective equipment. The goal is to balance maximum protection with optimal user comfort and mobility.

To ensure consistency across different manufacturers and batches, standardization efforts also include detailed specifications for raw material composition, processing methods, and quality control measures. This encompasses guidelines for fiber production, weaving techniques, and lamination processes used in creating UHMWPE-based protective gear.

Collaboration between military organizations, research institutions, and industry partners is essential in developing and refining these standardization and testing protocols. Regular reviews and updates to these standards ensure that they keep pace with advancements in UHMWPE technology and evolving threat landscapes, maintaining the highest level of protection for military personnel.

One of the primary standardization efforts focuses on impact resistance testing. This involves subjecting UHMWPE samples to controlled impacts of varying intensities and velocities, mimicking potential threats such as shrapnel or ballistic projectiles. The tests measure the material's ability to dissipate energy and prevent penetration, with specific metrics for deformation, crack propagation, and overall structural integrity.

Ballistic testing protocols form another critical component of UHMWPE standardization in defense applications. These tests evaluate the material's performance against different types of ammunition, ranging from small arms fire to high-velocity rifle rounds. Standardized procedures dictate the distance, angle, and velocity of projectiles, as well as the number of impacts a sample must withstand to meet military specifications.

Durability and environmental resistance tests are also integral to UHMWPE standardization. These protocols assess the material's ability to maintain its energy absorption properties under extreme temperatures, humidity levels, and exposure to various chemicals and UV radiation. Long-term performance is evaluated through accelerated aging tests, ensuring that UHMWPE-based gear remains effective throughout its intended service life.

Ergonomic considerations are addressed through standardized comfort and flexibility tests. These protocols measure factors such as weight distribution, heat dissipation, and range of motion when UHMWPE is incorporated into body armor or other protective equipment. The goal is to balance maximum protection with optimal user comfort and mobility.

To ensure consistency across different manufacturers and batches, standardization efforts also include detailed specifications for raw material composition, processing methods, and quality control measures. This encompasses guidelines for fiber production, weaving techniques, and lamination processes used in creating UHMWPE-based protective gear.

Collaboration between military organizations, research institutions, and industry partners is essential in developing and refining these standardization and testing protocols. Regular reviews and updates to these standards ensure that they keep pace with advancements in UHMWPE technology and evolving threat landscapes, maintaining the highest level of protection for military personnel.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!