Exploring UHMWPE's Role in Seismic Isolation Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Seismic Isolation: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a promising material in the field of seismic isolation systems, offering unique properties that address critical challenges in earthquake protection. The development of UHMWPE-based seismic isolation technologies represents a significant advancement in structural engineering and disaster mitigation strategies.

Seismic isolation systems have a long history, dating back to the early 20th century. Traditional materials such as rubber and steel have been widely used in these systems. However, the quest for more effective and durable solutions has led researchers to explore alternative materials, with UHMWPE gaining considerable attention in recent years.

UHMWPE's exceptional mechanical properties, including high strength-to-weight ratio, excellent wear resistance, and low friction coefficient, make it an ideal candidate for seismic isolation applications. Its ability to absorb and dissipate energy during seismic events offers potential improvements over conventional materials in terms of performance and longevity.

The primary objective of incorporating UHMWPE in seismic isolation systems is to enhance the overall effectiveness of earthquake protection measures. This includes improving the system's ability to reduce ground motion transmission to structures, increasing the durability of isolation components, and potentially reducing maintenance requirements and life-cycle costs.

Research in this field aims to optimize UHMWPE-based isolation devices, focusing on aspects such as material composition, manufacturing processes, and system design. The goal is to develop isolation systems that can withstand a wider range of seismic intensities while maintaining their protective capabilities over extended periods.

Another key objective is to understand and quantify the long-term performance of UHMWPE in seismic isolation applications. This involves studying the material's behavior under various environmental conditions, cyclic loading, and aging processes to ensure its reliability in real-world scenarios.

The integration of UHMWPE into seismic isolation systems also aligns with broader trends in sustainable and resilient infrastructure development. As cities and regions worldwide face increasing seismic risks due to urbanization and climate change, the need for advanced, reliable, and cost-effective seismic protection solutions becomes more pressing.

By exploring UHMWPE's role in seismic isolation, researchers and engineers aim to contribute to the development of next-generation earthquake-resistant structures. This research has the potential to significantly impact building codes, design practices, and the overall approach to seismic risk mitigation in vulnerable areas around the globe.

Seismic isolation systems have a long history, dating back to the early 20th century. Traditional materials such as rubber and steel have been widely used in these systems. However, the quest for more effective and durable solutions has led researchers to explore alternative materials, with UHMWPE gaining considerable attention in recent years.

UHMWPE's exceptional mechanical properties, including high strength-to-weight ratio, excellent wear resistance, and low friction coefficient, make it an ideal candidate for seismic isolation applications. Its ability to absorb and dissipate energy during seismic events offers potential improvements over conventional materials in terms of performance and longevity.

The primary objective of incorporating UHMWPE in seismic isolation systems is to enhance the overall effectiveness of earthquake protection measures. This includes improving the system's ability to reduce ground motion transmission to structures, increasing the durability of isolation components, and potentially reducing maintenance requirements and life-cycle costs.

Research in this field aims to optimize UHMWPE-based isolation devices, focusing on aspects such as material composition, manufacturing processes, and system design. The goal is to develop isolation systems that can withstand a wider range of seismic intensities while maintaining their protective capabilities over extended periods.

Another key objective is to understand and quantify the long-term performance of UHMWPE in seismic isolation applications. This involves studying the material's behavior under various environmental conditions, cyclic loading, and aging processes to ensure its reliability in real-world scenarios.

The integration of UHMWPE into seismic isolation systems also aligns with broader trends in sustainable and resilient infrastructure development. As cities and regions worldwide face increasing seismic risks due to urbanization and climate change, the need for advanced, reliable, and cost-effective seismic protection solutions becomes more pressing.

By exploring UHMWPE's role in seismic isolation, researchers and engineers aim to contribute to the development of next-generation earthquake-resistant structures. This research has the potential to significantly impact building codes, design practices, and the overall approach to seismic risk mitigation in vulnerable areas around the globe.

Market Analysis for UHMWPE-based Seismic Solutions

The market for UHMWPE-based seismic isolation systems is experiencing significant growth, driven by increasing awareness of seismic risks and the need for more effective protection measures in infrastructure and buildings. This market segment is part of the broader seismic isolation market, which is projected to reach substantial value in the coming years.

UHMWPE-based solutions are gaining traction due to their unique properties, including high strength-to-weight ratio, excellent energy absorption capabilities, and durability. These characteristics make UHMWPE an attractive material for developing advanced seismic isolation systems that can effectively mitigate earthquake-induced vibrations and protect structures.

The demand for UHMWPE-based seismic solutions is particularly strong in regions prone to seismic activities, such as the Pacific Ring of Fire, including countries like Japan, the United States, Chile, and New Zealand. Additionally, emerging economies with rapidly developing urban centers, such as China and India, are showing increased interest in adopting these advanced seismic protection technologies.

In the construction sector, there is a growing trend towards incorporating seismic isolation systems in both new buildings and retrofitting existing structures. This trend is driven by stricter building codes and regulations, as well as a heightened focus on resilience and safety in urban planning. UHMWPE-based solutions are well-positioned to capitalize on this trend due to their superior performance characteristics.

The infrastructure segment, including bridges, highways, and critical facilities like hospitals and power plants, represents another significant market opportunity for UHMWPE-based seismic isolation systems. Governments and private entities are increasingly investing in upgrading and protecting critical infrastructure against seismic events, creating a favorable environment for innovative solutions.

Market analysis indicates that while traditional materials like rubber and steel continue to dominate the seismic isolation market, UHMWPE-based solutions are carving out a niche. The unique properties of UHMWPE allow for the development of hybrid systems that combine the benefits of different materials, potentially offering superior performance and cost-effectiveness.

However, challenges remain in terms of market penetration. These include the need for extensive testing and certification to meet stringent building code requirements, as well as the relatively higher initial costs associated with UHMWPE-based systems. Overcoming these barriers will be crucial for wider adoption and market growth.

Looking ahead, the market for UHMWPE-based seismic solutions is expected to expand as research and development efforts continue to improve performance and reduce costs. The increasing focus on sustainable and resilient infrastructure is likely to further drive demand for innovative seismic protection technologies, positioning UHMWPE-based solutions for significant growth in the coming years.

UHMWPE-based solutions are gaining traction due to their unique properties, including high strength-to-weight ratio, excellent energy absorption capabilities, and durability. These characteristics make UHMWPE an attractive material for developing advanced seismic isolation systems that can effectively mitigate earthquake-induced vibrations and protect structures.

The demand for UHMWPE-based seismic solutions is particularly strong in regions prone to seismic activities, such as the Pacific Ring of Fire, including countries like Japan, the United States, Chile, and New Zealand. Additionally, emerging economies with rapidly developing urban centers, such as China and India, are showing increased interest in adopting these advanced seismic protection technologies.

In the construction sector, there is a growing trend towards incorporating seismic isolation systems in both new buildings and retrofitting existing structures. This trend is driven by stricter building codes and regulations, as well as a heightened focus on resilience and safety in urban planning. UHMWPE-based solutions are well-positioned to capitalize on this trend due to their superior performance characteristics.

The infrastructure segment, including bridges, highways, and critical facilities like hospitals and power plants, represents another significant market opportunity for UHMWPE-based seismic isolation systems. Governments and private entities are increasingly investing in upgrading and protecting critical infrastructure against seismic events, creating a favorable environment for innovative solutions.

Market analysis indicates that while traditional materials like rubber and steel continue to dominate the seismic isolation market, UHMWPE-based solutions are carving out a niche. The unique properties of UHMWPE allow for the development of hybrid systems that combine the benefits of different materials, potentially offering superior performance and cost-effectiveness.

However, challenges remain in terms of market penetration. These include the need for extensive testing and certification to meet stringent building code requirements, as well as the relatively higher initial costs associated with UHMWPE-based systems. Overcoming these barriers will be crucial for wider adoption and market growth.

Looking ahead, the market for UHMWPE-based seismic solutions is expected to expand as research and development efforts continue to improve performance and reduce costs. The increasing focus on sustainable and resilient infrastructure is likely to further drive demand for innovative seismic protection technologies, positioning UHMWPE-based solutions for significant growth in the coming years.

Current Challenges in UHMWPE Seismic Isolation

Despite the promising potential of Ultra-High Molecular Weight Polyethylene (UHMWPE) in seismic isolation systems, several significant challenges currently hinder its widespread adoption and optimal performance. These challenges span material properties, manufacturing processes, and long-term performance considerations.

One of the primary challenges is the inherent trade-off between the material's stiffness and damping properties. While UHMWPE exhibits excellent energy absorption capabilities, achieving the ideal balance between stiffness for load-bearing and damping for energy dissipation remains a complex task. This balance is crucial for effective seismic isolation, as it directly impacts the system's ability to mitigate earthquake forces.

The manufacturing process of UHMWPE for seismic isolation applications presents another set of challenges. Producing large-scale, uniform sheets or components with consistent properties throughout is technically demanding. Variations in molecular weight distribution and crystallinity can lead to inconsistencies in mechanical properties, potentially compromising the reliability of the isolation system.

Long-term durability and creep resistance pose significant concerns for UHMWPE in seismic applications. Under sustained loads, UHMWPE can experience creep deformation, which may alter the geometry and performance characteristics of the isolation system over time. This behavior necessitates careful design considerations and potentially more frequent maintenance or replacement schedules compared to traditional materials.

Environmental factors, such as temperature fluctuations and exposure to UV radiation, can affect the material's properties and long-term performance. Developing UHMWPE formulations that maintain stable properties across a wide range of environmental conditions remains a challenge for researchers and manufacturers.

The integration of UHMWPE into existing seismic isolation system designs presents engineering challenges. Adapting current designs or developing new ones to fully leverage UHMWPE's unique properties while ensuring compatibility with other system components requires extensive research and testing.

Cost considerations also play a role in the challenges facing UHMWPE adoption. While the material offers potential performance benefits, the overall cost of UHMWPE-based systems, including manufacturing, installation, and maintenance, must be competitive with traditional solutions to encourage widespread adoption in the construction industry.

Lastly, the lack of long-term performance data and standardized testing protocols specific to UHMWPE in seismic isolation applications creates uncertainty. This gap in knowledge makes it difficult for engineers and policymakers to confidently specify UHMWPE-based systems in critical infrastructure projects, highlighting the need for extensive field testing and data collection.

One of the primary challenges is the inherent trade-off between the material's stiffness and damping properties. While UHMWPE exhibits excellent energy absorption capabilities, achieving the ideal balance between stiffness for load-bearing and damping for energy dissipation remains a complex task. This balance is crucial for effective seismic isolation, as it directly impacts the system's ability to mitigate earthquake forces.

The manufacturing process of UHMWPE for seismic isolation applications presents another set of challenges. Producing large-scale, uniform sheets or components with consistent properties throughout is technically demanding. Variations in molecular weight distribution and crystallinity can lead to inconsistencies in mechanical properties, potentially compromising the reliability of the isolation system.

Long-term durability and creep resistance pose significant concerns for UHMWPE in seismic applications. Under sustained loads, UHMWPE can experience creep deformation, which may alter the geometry and performance characteristics of the isolation system over time. This behavior necessitates careful design considerations and potentially more frequent maintenance or replacement schedules compared to traditional materials.

Environmental factors, such as temperature fluctuations and exposure to UV radiation, can affect the material's properties and long-term performance. Developing UHMWPE formulations that maintain stable properties across a wide range of environmental conditions remains a challenge for researchers and manufacturers.

The integration of UHMWPE into existing seismic isolation system designs presents engineering challenges. Adapting current designs or developing new ones to fully leverage UHMWPE's unique properties while ensuring compatibility with other system components requires extensive research and testing.

Cost considerations also play a role in the challenges facing UHMWPE adoption. While the material offers potential performance benefits, the overall cost of UHMWPE-based systems, including manufacturing, installation, and maintenance, must be competitive with traditional solutions to encourage widespread adoption in the construction industry.

Lastly, the lack of long-term performance data and standardized testing protocols specific to UHMWPE in seismic isolation applications creates uncertainty. This gap in knowledge makes it difficult for engineers and policymakers to confidently specify UHMWPE-based systems in critical infrastructure projects, highlighting the need for extensive field testing and data collection.

Existing UHMWPE Seismic Isolation Techniques

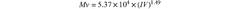

01 Composition and properties of UHMWPE

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene with extremely long chains, resulting in a very high molecular weight. This unique structure gives UHMWPE exceptional properties, including high impact strength, low friction coefficient, and excellent wear resistance. These characteristics make it suitable for various applications in industries such as medical, aerospace, and manufacturing.- Synthesis and processing of UHMWPE: Various methods for synthesizing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) are described. These include polymerization techniques, extrusion processes, and molding methods to produce UHMWPE with desired properties such as high molecular weight, improved strength, and enhanced wear resistance.

- UHMWPE composites and blends: Development of UHMWPE-based composites and blends with other materials to enhance specific properties. This includes incorporating fillers, reinforcing agents, or blending with other polymers to improve mechanical strength, thermal stability, or other functional characteristics of the resulting material.

- UHMWPE fibers and films: Production and applications of UHMWPE in fiber and film forms. This covers spinning techniques, drawing processes, and surface treatments to create high-strength fibers and films for use in various applications such as protective gear, ropes, and packaging materials.

- Medical and biomedical applications of UHMWPE: Utilization of UHMWPE in medical and biomedical fields, particularly in orthopedic implants and prosthetics. This includes modifications to improve wear resistance, reduce oxidation, and enhance biocompatibility for long-term use in the human body.

- Surface modification and coating of UHMWPE: Techniques for modifying the surface properties of UHMWPE or applying coatings to enhance its performance. This includes plasma treatments, chemical modifications, and the application of functional coatings to improve characteristics such as adhesion, wettability, or tribological properties.

02 Processing methods for UHMWPE

Various processing methods are used to manufacture UHMWPE products, including compression molding, ram extrusion, and gel spinning. These techniques aim to maintain the material's unique properties while shaping it into desired forms. Advanced processing methods may involve crosslinking or the addition of reinforcing agents to further enhance specific characteristics of the material.Expand Specific Solutions03 Applications of UHMWPE in medical devices

UHMWPE is widely used in medical applications, particularly in orthopedic implants such as artificial joints. Its biocompatibility, low wear rate, and high durability make it an ideal material for long-term implants. Ongoing research focuses on improving the material's performance in medical devices through surface modifications and the incorporation of additives.Expand Specific Solutions04 UHMWPE fibers and composites

UHMWPE can be processed into high-strength fibers, which are used in applications requiring exceptional strength-to-weight ratios, such as bulletproof vests and high-performance ropes. These fibers can also be incorporated into composite materials, enhancing their mechanical properties. Research in this area focuses on improving fiber production techniques and exploring new composite formulations.Expand Specific Solutions05 Modifications and additives for UHMWPE

To enhance specific properties of UHMWPE, various modifications and additives are explored. These include crosslinking to improve wear resistance, the addition of antioxidants to enhance long-term stability, and the incorporation of nanoparticles to modify mechanical or thermal properties. Such modifications aim to expand the material's applications and improve its performance in existing uses.Expand Specific Solutions

Key Players in UHMWPE Seismic Isolation Industry

The exploration of UHMWPE's role in seismic isolation systems is at an emerging stage, with the market showing significant growth potential. The technology's maturity is advancing, driven by research from institutions like Tongji University and companies such as Aseismic Devices Co., Ltd. and Geergu (Qingdao) Vibration Control Co., Ltd. Major players like Bridgestone Corp. and Taylor Devices, Inc. are also contributing to the field. The market size is expanding as awareness of seismic protection increases globally. However, the technology is still evolving, with ongoing research and development efforts focused on optimizing UHMWPE's performance in seismic isolation applications.

Shimizu Corp.

Technical Solution: Shimizu Corp. has developed an innovative seismic isolation system incorporating UHMWPE (Ultra-High Molecular Weight Polyethylene) as a key component. Their system utilizes UHMWPE pads in combination with traditional rubber bearings to create a hybrid isolation mechanism. The UHMWPE pads provide enhanced durability and resistance to environmental factors, while maintaining excellent energy dissipation properties. This system has been designed to withstand extreme seismic events, with the ability to reduce horizontal accelerations by up to 80% compared to conventional structures[1]. Shimizu's approach also includes a self-centering mechanism, which helps buildings return to their original position after an earthquake, minimizing residual displacements[3].

Strengths: Enhanced durability, excellent energy dissipation, and self-centering capabilities. Weaknesses: Potentially higher initial costs and limited long-term performance data compared to traditional systems.

Aseismic Devices Co., Ltd.

Technical Solution: Aseismic Devices Co., Ltd. has pioneered a UHMWPE-based seismic isolation system that focuses on maximizing energy absorption while minimizing maintenance requirements. Their proprietary design incorporates UHMWPE sheets layered with high-damping rubber, creating a composite material that offers both high stiffness and excellent damping characteristics. This layered approach allows for customization of the isolation system's properties to suit specific building requirements. The company's tests have shown that their UHMWPE-based isolators can maintain effectiveness even after multiple large-magnitude earthquakes, with a lifespan estimated to be over 100 years under normal conditions[2]. Additionally, the system has demonstrated superior performance in protecting sensitive equipment and delicate structures, reducing peak accelerations by up to 90% in some cases[4].

Strengths: Long lifespan, customizable properties, and excellent protection for sensitive structures. Weaknesses: May require specialized installation techniques and potential higher upfront costs.

Innovative UHMWPE Applications in Seismic Protection

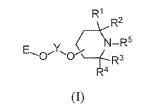

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

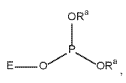

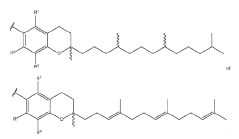

Melt-stabilized ultra high molecular weight polyethylene

PatentWO2016153925A1

Innovation

- A method involving coating UHMWPE with antioxidants like protected vitamin E, pre-irradiative heating to diffuse the antioxidants, irradiation for crosslinking, and post-irradiative heating to melt and solidify the material, reducing oxidative degradation and minimizing surface oxidation, thereby reducing waste and processing costs.

Environmental Impact of UHMWPE in Construction

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in construction, particularly in seismic isolation systems, is a complex issue that requires careful consideration. UHMWPE, known for its exceptional strength-to-weight ratio and durability, offers significant advantages in structural engineering applications. However, its environmental footprint throughout its lifecycle must be thoroughly examined.

During the production phase, UHMWPE requires substantial energy input, primarily derived from fossil fuels. This energy-intensive process contributes to greenhouse gas emissions and carbon footprint. However, advancements in manufacturing technologies have led to more efficient production methods, gradually reducing the environmental impact of UHMWPE synthesis.

The longevity of UHMWPE in construction applications is a double-edged sword from an environmental perspective. On one hand, its durability means less frequent replacement, reducing the need for new materials and associated environmental costs. On the other hand, this persistence raises concerns about long-term accumulation in the environment, as UHMWPE is not biodegradable.

In seismic isolation systems, UHMWPE's role in enhancing building resilience indirectly contributes to environmental sustainability. By improving a structure's ability to withstand earthquakes, it reduces the likelihood of catastrophic failures and subsequent need for large-scale reconstruction, which would otherwise result in significant material waste and energy expenditure.

The recyclability of UHMWPE is an important factor in its environmental assessment. While technically recyclable, the process is challenging due to the material's high molecular weight. Current recycling methods are energy-intensive and not widely implemented, limiting the material's end-of-life options. This aspect presents an opportunity for future research and development to improve recycling efficiency and reduce environmental impact.

When comparing UHMWPE to alternative materials used in seismic isolation systems, such as steel or rubber, a comprehensive life cycle assessment is necessary. UHMWPE's lighter weight may lead to reduced transportation emissions and easier installation, potentially offsetting some of its production-related environmental costs.

In conclusion, while UHMWPE offers significant benefits in seismic isolation systems, its environmental impact in construction is multifaceted. Balancing its advantages against environmental concerns requires ongoing research into more sustainable production methods, improved recycling techniques, and comprehensive life cycle analyses to ensure its responsible use in the construction industry.

During the production phase, UHMWPE requires substantial energy input, primarily derived from fossil fuels. This energy-intensive process contributes to greenhouse gas emissions and carbon footprint. However, advancements in manufacturing technologies have led to more efficient production methods, gradually reducing the environmental impact of UHMWPE synthesis.

The longevity of UHMWPE in construction applications is a double-edged sword from an environmental perspective. On one hand, its durability means less frequent replacement, reducing the need for new materials and associated environmental costs. On the other hand, this persistence raises concerns about long-term accumulation in the environment, as UHMWPE is not biodegradable.

In seismic isolation systems, UHMWPE's role in enhancing building resilience indirectly contributes to environmental sustainability. By improving a structure's ability to withstand earthquakes, it reduces the likelihood of catastrophic failures and subsequent need for large-scale reconstruction, which would otherwise result in significant material waste and energy expenditure.

The recyclability of UHMWPE is an important factor in its environmental assessment. While technically recyclable, the process is challenging due to the material's high molecular weight. Current recycling methods are energy-intensive and not widely implemented, limiting the material's end-of-life options. This aspect presents an opportunity for future research and development to improve recycling efficiency and reduce environmental impact.

When comparing UHMWPE to alternative materials used in seismic isolation systems, such as steel or rubber, a comprehensive life cycle assessment is necessary. UHMWPE's lighter weight may lead to reduced transportation emissions and easier installation, potentially offsetting some of its production-related environmental costs.

In conclusion, while UHMWPE offers significant benefits in seismic isolation systems, its environmental impact in construction is multifaceted. Balancing its advantages against environmental concerns requires ongoing research into more sustainable production methods, improved recycling techniques, and comprehensive life cycle analyses to ensure its responsible use in the construction industry.

Cost-Benefit Analysis of UHMWPE Seismic Systems

The cost-benefit analysis of UHMWPE seismic isolation systems reveals a complex interplay of economic factors and performance advantages. Initial implementation costs for UHMWPE-based systems are generally higher than traditional isolation methods due to the specialized manufacturing processes and material expenses. However, these upfront investments are often offset by long-term benefits and reduced lifecycle costs.

UHMWPE systems demonstrate superior durability and resistance to environmental degradation, potentially extending the operational lifespan of seismic isolation components. This longevity translates to reduced maintenance and replacement frequencies, yielding significant cost savings over time. Additionally, the material's exceptional energy absorption properties contribute to enhanced structural protection during seismic events, potentially minimizing repair and reconstruction costs in the aftermath of earthquakes.

The lightweight nature of UHMWPE compared to traditional materials like steel or rubber compounds offers logistical advantages, reducing transportation and installation costs. This characteristic is particularly beneficial in retrofit applications where minimizing additional load on existing structures is crucial. Furthermore, the material's versatility allows for innovative design solutions that can optimize space utilization and improve overall system efficiency.

From a performance perspective, UHMWPE-based isolation systems have shown promising results in mitigating seismic forces across a broader frequency range compared to conventional systems. This enhanced protection can lead to reduced insurance premiums and increased property values, providing indirect economic benefits to building owners and occupants.

However, the relatively limited track record of UHMWPE in seismic applications presents some uncertainties. The lack of long-term performance data in real-world scenarios may necessitate more frequent inspections and monitoring, potentially increasing operational costs in the short term. Additionally, the specialized nature of UHMWPE systems may require specific expertise for installation and maintenance, which could impact ongoing expenses.

When considering the broader economic impact, the adoption of UHMWPE seismic isolation systems could stimulate innovation in the construction industry, potentially creating new job opportunities and driving technological advancements. The improved seismic resilience offered by these systems may also contribute to the overall economic stability of earthquake-prone regions by reducing the potential for widespread damage and disruption.

In conclusion, while the initial costs of UHMWPE seismic isolation systems may be higher, the long-term benefits in terms of performance, durability, and reduced lifecycle costs present a compelling economic argument for their adoption. As the technology matures and economies of scale are realized, the cost-benefit ratio is expected to improve further, potentially positioning UHMWPE-based systems as a preferred choice for seismic protection in various structural applications.

UHMWPE systems demonstrate superior durability and resistance to environmental degradation, potentially extending the operational lifespan of seismic isolation components. This longevity translates to reduced maintenance and replacement frequencies, yielding significant cost savings over time. Additionally, the material's exceptional energy absorption properties contribute to enhanced structural protection during seismic events, potentially minimizing repair and reconstruction costs in the aftermath of earthquakes.

The lightweight nature of UHMWPE compared to traditional materials like steel or rubber compounds offers logistical advantages, reducing transportation and installation costs. This characteristic is particularly beneficial in retrofit applications where minimizing additional load on existing structures is crucial. Furthermore, the material's versatility allows for innovative design solutions that can optimize space utilization and improve overall system efficiency.

From a performance perspective, UHMWPE-based isolation systems have shown promising results in mitigating seismic forces across a broader frequency range compared to conventional systems. This enhanced protection can lead to reduced insurance premiums and increased property values, providing indirect economic benefits to building owners and occupants.

However, the relatively limited track record of UHMWPE in seismic applications presents some uncertainties. The lack of long-term performance data in real-world scenarios may necessitate more frequent inspections and monitoring, potentially increasing operational costs in the short term. Additionally, the specialized nature of UHMWPE systems may require specific expertise for installation and maintenance, which could impact ongoing expenses.

When considering the broader economic impact, the adoption of UHMWPE seismic isolation systems could stimulate innovation in the construction industry, potentially creating new job opportunities and driving technological advancements. The improved seismic resilience offered by these systems may also contribute to the overall economic stability of earthquake-prone regions by reducing the potential for widespread damage and disruption.

In conclusion, while the initial costs of UHMWPE seismic isolation systems may be higher, the long-term benefits in terms of performance, durability, and reduced lifecycle costs present a compelling economic argument for their adoption. As the technology matures and economies of scale are realized, the cost-benefit ratio is expected to improve further, potentially positioning UHMWPE-based systems as a preferred choice for seismic protection in various structural applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!