Comparing UHMWPE Fibers with Other High-Modulus Fibers in Textile Engineering

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Fiber Evolution

The evolution of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers represents a significant milestone in textile engineering. Initially developed in the 1960s, UHMWPE fibers have undergone substantial improvements in their properties and manufacturing processes over the past decades.

In the early stages, UHMWPE fibers were primarily produced through gel spinning, a technique that allowed for the creation of high-strength fibers. However, these early versions had limitations in terms of their modulus and thermal stability. The 1980s saw a breakthrough with the introduction of the gel-spinning process by DSM, which significantly enhanced the mechanical properties of UHMWPE fibers.

The 1990s marked a period of rapid advancement in UHMWPE fiber technology. Researchers focused on improving the fiber's molecular orientation and crystallinity, leading to substantial increases in tensile strength and modulus. This era also saw the development of surface treatment techniques to enhance the fiber's adhesion properties, crucial for its application in composites.

By the early 2000s, UHMWPE fibers had established themselves as a formidable competitor to other high-modulus fibers such as aramid and carbon fibers. The introduction of multi-stage drawing processes further improved the fiber's mechanical properties, pushing its strength-to-weight ratio to unprecedented levels.

Recent years have witnessed a focus on enhancing the thermal and chemical resistance of UHMWPE fibers. Innovations in polymer chemistry and processing techniques have led to fibers with improved performance at elevated temperatures, addressing one of the key limitations of earlier generations.

The evolution of UHMWPE fibers has also been characterized by a continuous effort to reduce production costs and increase scalability. Advanced manufacturing technologies, such as continuous gel spinning and high-speed drawing, have significantly improved production efficiency, making UHMWPE fibers more commercially viable for a wider range of applications.

In comparison to other high-modulus fibers, UHMWPE has shown remarkable progress in closing the performance gap, particularly in terms of specific strength and modulus. While aramid and carbon fibers still maintain advantages in certain areas, such as high-temperature performance, UHMWPE fibers have carved out a unique position in applications requiring exceptional strength-to-weight ratios and impact resistance.

Looking forward, the evolution of UHMWPE fibers is expected to continue, with research focusing on further enhancing their thermal stability, improving their interfacial properties for better composite performance, and exploring new applications in emerging fields such as wearable technology and advanced protective equipment.

In the early stages, UHMWPE fibers were primarily produced through gel spinning, a technique that allowed for the creation of high-strength fibers. However, these early versions had limitations in terms of their modulus and thermal stability. The 1980s saw a breakthrough with the introduction of the gel-spinning process by DSM, which significantly enhanced the mechanical properties of UHMWPE fibers.

The 1990s marked a period of rapid advancement in UHMWPE fiber technology. Researchers focused on improving the fiber's molecular orientation and crystallinity, leading to substantial increases in tensile strength and modulus. This era also saw the development of surface treatment techniques to enhance the fiber's adhesion properties, crucial for its application in composites.

By the early 2000s, UHMWPE fibers had established themselves as a formidable competitor to other high-modulus fibers such as aramid and carbon fibers. The introduction of multi-stage drawing processes further improved the fiber's mechanical properties, pushing its strength-to-weight ratio to unprecedented levels.

Recent years have witnessed a focus on enhancing the thermal and chemical resistance of UHMWPE fibers. Innovations in polymer chemistry and processing techniques have led to fibers with improved performance at elevated temperatures, addressing one of the key limitations of earlier generations.

The evolution of UHMWPE fibers has also been characterized by a continuous effort to reduce production costs and increase scalability. Advanced manufacturing technologies, such as continuous gel spinning and high-speed drawing, have significantly improved production efficiency, making UHMWPE fibers more commercially viable for a wider range of applications.

In comparison to other high-modulus fibers, UHMWPE has shown remarkable progress in closing the performance gap, particularly in terms of specific strength and modulus. While aramid and carbon fibers still maintain advantages in certain areas, such as high-temperature performance, UHMWPE fibers have carved out a unique position in applications requiring exceptional strength-to-weight ratios and impact resistance.

Looking forward, the evolution of UHMWPE fibers is expected to continue, with research focusing on further enhancing their thermal stability, improving their interfacial properties for better composite performance, and exploring new applications in emerging fields such as wearable technology and advanced protective equipment.

Market Demand Analysis

The market demand for high-modulus fibers, including Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers, has been steadily increasing across various industries. This growth is primarily driven by the exceptional properties these fibers offer, such as high strength-to-weight ratio, excellent chemical resistance, and superior durability.

In the textile engineering sector, UHMWPE fibers are gaining significant traction due to their unique combination of properties. The global market for high-performance fibers, which includes UHMWPE, is expected to continue its upward trajectory in the coming years. This growth is fueled by the rising demand for lightweight and high-strength materials in industries such as aerospace, defense, and sports equipment manufacturing.

When comparing UHMWPE fibers with other high-modulus fibers like aramid and carbon fibers, each has its specific advantages and applications. UHMWPE fibers are particularly valued for their exceptional strength-to-weight ratio and resistance to abrasion, making them ideal for applications requiring durability and lightweight properties.

The automotive industry has shown increasing interest in high-modulus fibers, including UHMWPE, for lightweighting vehicles to improve fuel efficiency and reduce emissions. This trend aligns with global efforts to combat climate change and meet stringent environmental regulations.

In the defense sector, the demand for high-modulus fibers, especially UHMWPE, has been growing steadily. These fibers are crucial in the production of advanced personal protective equipment, such as ballistic vests and helmets, offering enhanced protection while reducing overall weight.

The sports and outdoor equipment industry has also been a significant driver of demand for UHMWPE fibers. Their use in high-performance ropes, nets, and protective gear has increased due to their superior strength and lightweight characteristics.

The marine industry represents another growing market for UHMWPE fibers, particularly in the production of ropes and cables for offshore applications. The fiber's resistance to saltwater and UV radiation makes it an attractive option for marine environments.

As sustainability becomes increasingly important across industries, the recyclability and long lifespan of UHMWPE fibers are becoming key selling points. This aligns with the growing trend towards circular economy principles in manufacturing and product design.

While the market for high-modulus fibers, including UHMWPE, is expanding, it's important to note that each type of fiber has its specific niche based on its unique properties. The choice between UHMWPE and other high-modulus fibers often depends on the specific requirements of the application, including factors such as strength, weight, temperature resistance, and cost-effectiveness.

In the textile engineering sector, UHMWPE fibers are gaining significant traction due to their unique combination of properties. The global market for high-performance fibers, which includes UHMWPE, is expected to continue its upward trajectory in the coming years. This growth is fueled by the rising demand for lightweight and high-strength materials in industries such as aerospace, defense, and sports equipment manufacturing.

When comparing UHMWPE fibers with other high-modulus fibers like aramid and carbon fibers, each has its specific advantages and applications. UHMWPE fibers are particularly valued for their exceptional strength-to-weight ratio and resistance to abrasion, making them ideal for applications requiring durability and lightweight properties.

The automotive industry has shown increasing interest in high-modulus fibers, including UHMWPE, for lightweighting vehicles to improve fuel efficiency and reduce emissions. This trend aligns with global efforts to combat climate change and meet stringent environmental regulations.

In the defense sector, the demand for high-modulus fibers, especially UHMWPE, has been growing steadily. These fibers are crucial in the production of advanced personal protective equipment, such as ballistic vests and helmets, offering enhanced protection while reducing overall weight.

The sports and outdoor equipment industry has also been a significant driver of demand for UHMWPE fibers. Their use in high-performance ropes, nets, and protective gear has increased due to their superior strength and lightweight characteristics.

The marine industry represents another growing market for UHMWPE fibers, particularly in the production of ropes and cables for offshore applications. The fiber's resistance to saltwater and UV radiation makes it an attractive option for marine environments.

As sustainability becomes increasingly important across industries, the recyclability and long lifespan of UHMWPE fibers are becoming key selling points. This aligns with the growing trend towards circular economy principles in manufacturing and product design.

While the market for high-modulus fibers, including UHMWPE, is expanding, it's important to note that each type of fiber has its specific niche based on its unique properties. The choice between UHMWPE and other high-modulus fibers often depends on the specific requirements of the application, including factors such as strength, weight, temperature resistance, and cost-effectiveness.

Technical Challenges

The development of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers has revolutionized the field of high-performance textiles. However, several technical challenges persist when comparing UHMWPE fibers with other high-modulus fibers in textile engineering applications.

One of the primary challenges is the inherent trade-off between strength and modulus in UHMWPE fibers. While these fibers exhibit exceptional tensile strength, their modulus is generally lower than that of carbon fibers or aramid fibers. This limitation affects their performance in applications requiring high stiffness, such as aerospace composites or structural reinforcements.

The thermal stability of UHMWPE fibers presents another significant challenge. Unlike carbon fibers or ceramic fibers, UHMWPE fibers have a relatively low melting point (around 150°C) and begin to lose their mechanical properties at temperatures as low as 80-100°C. This thermal sensitivity restricts their use in high-temperature environments and limits their applicability in certain industrial processes.

Adhesion to matrices is a critical issue when incorporating UHMWPE fibers into composite materials. The chemical inertness of UHMWPE, while beneficial for its resistance to chemicals and moisture, makes it difficult to achieve strong interfacial bonding with polymer matrices. This poor adhesion can lead to reduced load transfer efficiency and compromised mechanical properties in composite structures.

The creep behavior of UHMWPE fibers under sustained loads poses challenges in long-term structural applications. Although these fibers exhibit high initial strength, they are prone to time-dependent deformation, which can affect the dimensional stability and long-term performance of textile products or composites incorporating UHMWPE fibers.

UV resistance is another area where UHMWPE fibers face limitations compared to some other high-modulus fibers. Prolonged exposure to ultraviolet radiation can cause degradation of the polymer chains, leading to a reduction in mechanical properties. This susceptibility to UV damage necessitates additional protective measures in outdoor applications.

The processing of UHMWPE fibers into textile structures presents unique challenges due to their high molecular weight and low friction coefficient. Traditional textile processing techniques may need to be adapted or modified to effectively handle these fibers, particularly in weaving, knitting, or braiding operations.

Lastly, the cost-effectiveness of UHMWPE fibers compared to other high-modulus fibers remains a challenge in certain applications. While their specific strength is exceptional, the overall cost-performance ratio may not always be favorable when compared to more established fibers like carbon or glass fibers in some engineering contexts.

Addressing these technical challenges requires ongoing research and development efforts in fiber modification, surface treatments, composite design, and processing technologies. Overcoming these limitations will be crucial for expanding the application range of UHMWPE fibers and enhancing their competitiveness against other high-modulus fibers in advanced textile engineering applications.

One of the primary challenges is the inherent trade-off between strength and modulus in UHMWPE fibers. While these fibers exhibit exceptional tensile strength, their modulus is generally lower than that of carbon fibers or aramid fibers. This limitation affects their performance in applications requiring high stiffness, such as aerospace composites or structural reinforcements.

The thermal stability of UHMWPE fibers presents another significant challenge. Unlike carbon fibers or ceramic fibers, UHMWPE fibers have a relatively low melting point (around 150°C) and begin to lose their mechanical properties at temperatures as low as 80-100°C. This thermal sensitivity restricts their use in high-temperature environments and limits their applicability in certain industrial processes.

Adhesion to matrices is a critical issue when incorporating UHMWPE fibers into composite materials. The chemical inertness of UHMWPE, while beneficial for its resistance to chemicals and moisture, makes it difficult to achieve strong interfacial bonding with polymer matrices. This poor adhesion can lead to reduced load transfer efficiency and compromised mechanical properties in composite structures.

The creep behavior of UHMWPE fibers under sustained loads poses challenges in long-term structural applications. Although these fibers exhibit high initial strength, they are prone to time-dependent deformation, which can affect the dimensional stability and long-term performance of textile products or composites incorporating UHMWPE fibers.

UV resistance is another area where UHMWPE fibers face limitations compared to some other high-modulus fibers. Prolonged exposure to ultraviolet radiation can cause degradation of the polymer chains, leading to a reduction in mechanical properties. This susceptibility to UV damage necessitates additional protective measures in outdoor applications.

The processing of UHMWPE fibers into textile structures presents unique challenges due to their high molecular weight and low friction coefficient. Traditional textile processing techniques may need to be adapted or modified to effectively handle these fibers, particularly in weaving, knitting, or braiding operations.

Lastly, the cost-effectiveness of UHMWPE fibers compared to other high-modulus fibers remains a challenge in certain applications. While their specific strength is exceptional, the overall cost-performance ratio may not always be favorable when compared to more established fibers like carbon or glass fibers in some engineering contexts.

Addressing these technical challenges requires ongoing research and development efforts in fiber modification, surface treatments, composite design, and processing technologies. Overcoming these limitations will be crucial for expanding the application range of UHMWPE fibers and enhancing their competitiveness against other high-modulus fibers in advanced textile engineering applications.

Current UHMWPE Solutions

01 Manufacturing processes for UHMWPE fibers

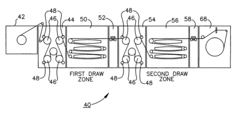

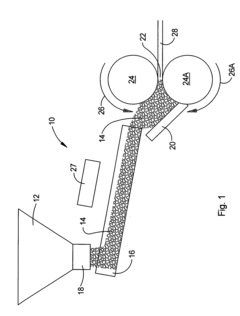

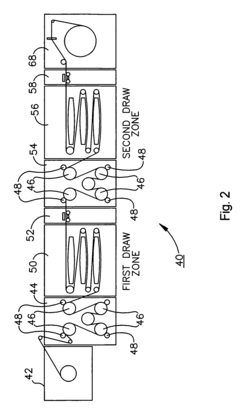

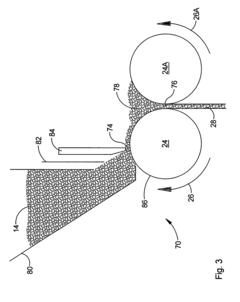

Various manufacturing processes are employed to produce UHMWPE fibers, including gel spinning, solution spinning, and melt spinning techniques. These processes involve dissolving or melting the polymer, extruding it through spinnerets, and drawing the resulting fibers to achieve high molecular orientation and strength.- Manufacturing processes for UHMWPE fibers: Various manufacturing processes are employed to produce UHMWPE fibers, including gel spinning, solution spinning, and melt spinning techniques. These processes involve dissolving or melting the polymer, extruding it through spinnerets, and drawing the resulting fibers to achieve high molecular orientation and strength.

- Composition and additives for UHMWPE fibers: UHMWPE fibers can be enhanced by incorporating various additives and modifying their composition. This may include the addition of stabilizers, colorants, or other polymers to improve specific properties such as UV resistance, thermal stability, or processability.

- Applications of UHMWPE fibers: UHMWPE fibers find applications in various fields due to their high strength-to-weight ratio and excellent properties. They are used in protective gear, ropes and cables, composites for aerospace and automotive industries, and medical devices such as surgical sutures.

- Surface treatment and modification of UHMWPE fibers: Surface treatments and modifications are applied to UHMWPE fibers to enhance their properties or compatibility with other materials. These treatments may include plasma treatment, chemical etching, or the application of coatings to improve adhesion, wettability, or other surface characteristics.

- Characterization and testing of UHMWPE fibers: Various methods and techniques are used to characterize and test UHMWPE fibers, including mechanical testing for tensile strength and modulus, thermal analysis, microscopy for structural analysis, and spectroscopic methods for chemical composition determination. These tests help ensure the quality and performance of the fibers for specific applications.

02 Composition and additives for UHMWPE fibers

UHMWPE fibers can be enhanced by incorporating various additives and modifying their composition. This may include the addition of stabilizers, colorants, or other polymers to improve specific properties such as UV resistance, thermal stability, or processability.Expand Specific Solutions03 Applications of UHMWPE fibers

UHMWPE fibers find applications in various fields due to their high strength-to-weight ratio and excellent properties. They are used in ballistic protection, cut-resistant gloves, marine ropes, and high-performance textiles. The fibers can also be incorporated into composites for aerospace and automotive industries.Expand Specific Solutions04 Surface treatment and modification of UHMWPE fibers

Surface treatments and modifications are applied to UHMWPE fibers to enhance their properties or compatibility with other materials. These treatments may include plasma treatment, chemical etching, or the application of coatings to improve adhesion, wettability, or other surface characteristics.Expand Specific Solutions05 Characterization and testing of UHMWPE fibers

Various methods and techniques are used to characterize and test UHMWPE fibers. These include mechanical testing for tensile strength and modulus, thermal analysis, microscopy for structural analysis, and spectroscopic techniques to assess chemical composition and molecular orientation.Expand Specific Solutions

Key Industry Players

The competition landscape for UHMWPE fibers in textile engineering is characterized by a mature market with significant growth potential. The industry is in a consolidation phase, with established players like DSM and Honeywell dominating, alongside emerging Chinese manufacturers such as Beijing Tongyizhong and Shandong ICD. The global market size for high-performance fibers, including UHMWPE, is projected to reach $14 billion by 2026. Technologically, UHMWPE fibers are well-developed, with ongoing research focused on enhancing properties and expanding applications. Companies like Donghua University and Jiangsu Hanvo are actively contributing to technological advancements, indicating a competitive and innovation-driven environment.

Donghua University

Technical Solution: Donghua University has been at the forefront of research in UHMWPE fiber technology, developing innovative spinning and post-treatment processes to enhance fiber properties. Their approach involves a gel-spinning method followed by ultra-drawing, which results in UHMWPE fibers with exceptional tensile strength and modulus[1]. The university has also explored surface modification techniques to improve the fiber's interfacial adhesion with matrix materials, enhancing its performance in composite applications[2]. Additionally, they have investigated the incorporation of nanoparticles during the spinning process to further improve the mechanical and thermal properties of UHMWPE fibers[3].

Strengths: Advanced research facilities and expertise in fiber technology, strong industry collaborations. Weaknesses: Limited commercial production capabilities, potential challenges in scaling up laboratory processes.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary UHMWPE fiber production technology that utilizes their expertise in polymer science and chemical engineering. Their process involves a specialized catalytic system for polymerization, followed by a multi-stage drawing process to achieve high molecular orientation[4]. Sinopec's UHMWPE fibers boast a tensile strength of over 3.5 GPa and a modulus exceeding 120 GPa, making them competitive with other high-performance fibers[5]. The company has also focused on improving the fiber's resistance to creep and UV degradation, addressing some of the traditional limitations of UHMWPE fibers[6].

Strengths: Large-scale production capabilities, vertically integrated supply chain, strong R&D resources. Weaknesses: Potential higher production costs compared to some competitors, less specialization in textile applications.

Core UHMWPE Innovations

High modulus ultra high molecular weight polyethylene tape

PatentActiveUS8206810B1

Innovation

- A direct roll process that eliminates the compaction step and uses UHMWPE powder directly fed into heated calender rolls to produce a coherent, high-density sheet, which is then drawn to achieve a high tenacity and high modulus tape with an aspect ratio of 1600 to 2500 grams per denier, without the use of solvents and with simpler, less capital-intensive equipment.

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

Environmental Impact

The environmental impact of textile fibers is a critical consideration in the modern textile industry, particularly when comparing high-performance materials like Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers with other high-modulus fibers. UHMWPE fibers, known for their exceptional strength-to-weight ratio and durability, present a unique environmental profile that warrants careful examination.

In terms of production, UHMWPE fibers generally require less energy to manufacture compared to some other high-modulus fibers like aramid or carbon fibers. This lower energy requirement translates to reduced carbon emissions during the production phase, contributing to a smaller carbon footprint. Additionally, the production process for UHMWPE fibers typically involves fewer toxic chemicals and solvents, further minimizing environmental hazards associated with manufacturing.

However, the environmental advantages of UHMWPE fibers are somewhat offset by their non-biodegradable nature. Like many synthetic fibers, UHMWPE does not break down naturally in the environment, potentially contributing to long-term plastic pollution if not properly managed at the end of its lifecycle. This characteristic stands in contrast to some natural high-performance fibers, such as certain types of regenerated cellulose fibers, which offer better biodegradability.

Water consumption and pollution are also important factors to consider. UHMWPE fiber production generally requires less water compared to natural fibers like cotton or even some synthetic fibers. Moreover, the process produces minimal water pollution, as it does not involve extensive dyeing or chemical treatments that are common in other textile manufacturing processes.

In terms of longevity and recyclability, UHMWPE fibers excel. Their high durability means products made from these fibers have extended lifespans, reducing the need for frequent replacements and thereby lowering overall resource consumption. Furthermore, UHMWPE fibers can be recycled, although the recycling process is not as straightforward as with some other materials due to their high melting point and resistance to solvents.

When considering the entire lifecycle of textile products, UHMWPE fibers demonstrate potential advantages in terms of energy efficiency during use. For instance, in applications like protective gear or high-performance clothing, their lightweight nature can contribute to reduced energy consumption in transportation or improved energy efficiency for the end-user.

In conclusion, while UHMWPE fibers offer several environmental benefits, particularly in terms of production efficiency and product longevity, their non-biodegradable nature remains a significant environmental concern. As the textile industry continues to evolve, balancing these factors against the performance characteristics of UHMWPE and other high-modulus fibers will be crucial in developing sustainable textile solutions for the future.

In terms of production, UHMWPE fibers generally require less energy to manufacture compared to some other high-modulus fibers like aramid or carbon fibers. This lower energy requirement translates to reduced carbon emissions during the production phase, contributing to a smaller carbon footprint. Additionally, the production process for UHMWPE fibers typically involves fewer toxic chemicals and solvents, further minimizing environmental hazards associated with manufacturing.

However, the environmental advantages of UHMWPE fibers are somewhat offset by their non-biodegradable nature. Like many synthetic fibers, UHMWPE does not break down naturally in the environment, potentially contributing to long-term plastic pollution if not properly managed at the end of its lifecycle. This characteristic stands in contrast to some natural high-performance fibers, such as certain types of regenerated cellulose fibers, which offer better biodegradability.

Water consumption and pollution are also important factors to consider. UHMWPE fiber production generally requires less water compared to natural fibers like cotton or even some synthetic fibers. Moreover, the process produces minimal water pollution, as it does not involve extensive dyeing or chemical treatments that are common in other textile manufacturing processes.

In terms of longevity and recyclability, UHMWPE fibers excel. Their high durability means products made from these fibers have extended lifespans, reducing the need for frequent replacements and thereby lowering overall resource consumption. Furthermore, UHMWPE fibers can be recycled, although the recycling process is not as straightforward as with some other materials due to their high melting point and resistance to solvents.

When considering the entire lifecycle of textile products, UHMWPE fibers demonstrate potential advantages in terms of energy efficiency during use. For instance, in applications like protective gear or high-performance clothing, their lightweight nature can contribute to reduced energy consumption in transportation or improved energy efficiency for the end-user.

In conclusion, while UHMWPE fibers offer several environmental benefits, particularly in terms of production efficiency and product longevity, their non-biodegradable nature remains a significant environmental concern. As the textile industry continues to evolve, balancing these factors against the performance characteristics of UHMWPE and other high-modulus fibers will be crucial in developing sustainable textile solutions for the future.

Cost-Benefit Analysis

When comparing UHMWPE fibers with other high-modulus fibers in textile engineering, a comprehensive cost-benefit analysis is crucial for determining their economic viability and practical applications. The production costs of UHMWPE fibers are generally higher than those of traditional fibers due to the complex manufacturing process and specialized equipment required. However, their exceptional strength-to-weight ratio and durability often justify the initial investment.

In terms of raw material costs, UHMWPE fibers are more expensive than conventional fibers like polyester or nylon. The polyethylene used in UHMWPE production undergoes extensive processing to achieve its ultra-high molecular weight, contributing to higher material costs. Despite this, the long-term benefits of UHMWPE fibers can offset the initial expense.

The manufacturing process for UHMWPE fibers is energy-intensive, which adds to the overall production costs. However, advancements in production techniques have led to improved efficiency, gradually reducing energy consumption and associated expenses. This trend is expected to continue, potentially narrowing the cost gap between UHMWPE and other high-modulus fibers.

When considering the benefits, UHMWPE fibers offer superior performance characteristics that can lead to significant cost savings in various applications. Their exceptional strength allows for the use of less material in many products, potentially reducing overall material costs. Additionally, their resistance to chemicals, UV radiation, and abrasion translates to longer product lifespans and reduced maintenance costs.

In high-performance textiles, such as protective gear and aerospace applications, the use of UHMWPE fibers can result in substantial weight savings. This weight reduction can lead to improved fuel efficiency in transportation applications or enhanced mobility for personal protective equipment, providing long-term cost benefits that may outweigh the initial higher material costs.

The durability of UHMWPE fibers also contributes to their cost-effectiveness. Products made with these fibers often have extended service lives, reducing the frequency of replacements and associated costs. This is particularly valuable in demanding environments where frequent replacements of less durable materials would otherwise be necessary.

When comparing UHMWPE fibers to other high-modulus fibers like aramid or carbon fibers, each has its own cost-benefit profile. While aramid fibers may have a lower initial cost, UHMWPE fibers often outperform them in terms of specific strength and chemical resistance. Carbon fibers, on the other hand, offer superior stiffness but at a significantly higher cost than UHMWPE.

In conclusion, while the upfront costs of UHMWPE fibers are higher, their unique properties and performance characteristics often result in long-term cost savings and improved product performance. The cost-benefit analysis must consider not only the initial material and production costs but also the lifecycle costs, performance benefits, and potential for innovation in various applications.

In terms of raw material costs, UHMWPE fibers are more expensive than conventional fibers like polyester or nylon. The polyethylene used in UHMWPE production undergoes extensive processing to achieve its ultra-high molecular weight, contributing to higher material costs. Despite this, the long-term benefits of UHMWPE fibers can offset the initial expense.

The manufacturing process for UHMWPE fibers is energy-intensive, which adds to the overall production costs. However, advancements in production techniques have led to improved efficiency, gradually reducing energy consumption and associated expenses. This trend is expected to continue, potentially narrowing the cost gap between UHMWPE and other high-modulus fibers.

When considering the benefits, UHMWPE fibers offer superior performance characteristics that can lead to significant cost savings in various applications. Their exceptional strength allows for the use of less material in many products, potentially reducing overall material costs. Additionally, their resistance to chemicals, UV radiation, and abrasion translates to longer product lifespans and reduced maintenance costs.

In high-performance textiles, such as protective gear and aerospace applications, the use of UHMWPE fibers can result in substantial weight savings. This weight reduction can lead to improved fuel efficiency in transportation applications or enhanced mobility for personal protective equipment, providing long-term cost benefits that may outweigh the initial higher material costs.

The durability of UHMWPE fibers also contributes to their cost-effectiveness. Products made with these fibers often have extended service lives, reducing the frequency of replacements and associated costs. This is particularly valuable in demanding environments where frequent replacements of less durable materials would otherwise be necessary.

When comparing UHMWPE fibers to other high-modulus fibers like aramid or carbon fibers, each has its own cost-benefit profile. While aramid fibers may have a lower initial cost, UHMWPE fibers often outperform them in terms of specific strength and chemical resistance. Carbon fibers, on the other hand, offer superior stiffness but at a significantly higher cost than UHMWPE.

In conclusion, while the upfront costs of UHMWPE fibers are higher, their unique properties and performance characteristics often result in long-term cost savings and improved product performance. The cost-benefit analysis must consider not only the initial material and production costs but also the lifecycle costs, performance benefits, and potential for innovation in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!