UV Resistance Mechanisms in Modified UHMWPE

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE UV Resistance Background and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) has been a cornerstone material in various industries due to its exceptional mechanical properties and chemical resistance. However, its susceptibility to ultraviolet (UV) radiation has long been a significant challenge, limiting its applications in outdoor environments. The evolution of UV resistance mechanisms in UHMWPE represents a critical area of research and development, with implications spanning from medical implants to aerospace components.

The journey of enhancing UHMWPE's UV resistance began in the late 1970s when researchers first recognized the detrimental effects of UV exposure on the polymer's structure. Initial efforts focused on understanding the photodegradation process, which involves chain scission and oxidation, leading to a deterioration of mechanical properties and surface integrity. This foundational knowledge set the stage for subsequent technological advancements in UV protection strategies.

As the demand for more durable and versatile UHMWPE grew, the research community intensified its efforts to develop effective UV resistance mechanisms. The 1990s saw a surge in studies exploring various additives and modification techniques aimed at mitigating UV-induced damage. These investigations laid the groundwork for modern approaches to UV stabilization in UHMWPE, including the incorporation of UV absorbers, hindered amine light stabilizers (HALS), and antioxidants.

The primary objective of current research in UV resistance mechanisms for modified UHMWPE is to achieve long-term stability without compromising the material's inherent properties. This goal encompasses several key aspects: enhancing UV absorption capacity, improving radical scavenging efficiency, and developing synergistic stabilization systems that address both UV and thermal degradation simultaneously.

Recent technological trends have shifted towards more sophisticated modification techniques, such as nanocomposite formulations and surface treatments. These approaches aim to create a multi-layered defense against UV radiation, offering protection that extends beyond the surface and into the bulk of the material. Additionally, there is growing interest in bio-based and environmentally friendly UV stabilizers, aligning with the broader trend towards sustainable materials.

The evolution of UV resistance mechanisms in UHMWPE is closely tied to advancements in analytical techniques and testing methodologies. Improved methods for characterizing UV-induced changes at the molecular level have enabled researchers to develop more targeted and effective protection strategies. This progress has been crucial in bridging the gap between laboratory findings and practical applications, allowing for the development of UHMWPE products with enhanced UV resistance for use in demanding environments.

The journey of enhancing UHMWPE's UV resistance began in the late 1970s when researchers first recognized the detrimental effects of UV exposure on the polymer's structure. Initial efforts focused on understanding the photodegradation process, which involves chain scission and oxidation, leading to a deterioration of mechanical properties and surface integrity. This foundational knowledge set the stage for subsequent technological advancements in UV protection strategies.

As the demand for more durable and versatile UHMWPE grew, the research community intensified its efforts to develop effective UV resistance mechanisms. The 1990s saw a surge in studies exploring various additives and modification techniques aimed at mitigating UV-induced damage. These investigations laid the groundwork for modern approaches to UV stabilization in UHMWPE, including the incorporation of UV absorbers, hindered amine light stabilizers (HALS), and antioxidants.

The primary objective of current research in UV resistance mechanisms for modified UHMWPE is to achieve long-term stability without compromising the material's inherent properties. This goal encompasses several key aspects: enhancing UV absorption capacity, improving radical scavenging efficiency, and developing synergistic stabilization systems that address both UV and thermal degradation simultaneously.

Recent technological trends have shifted towards more sophisticated modification techniques, such as nanocomposite formulations and surface treatments. These approaches aim to create a multi-layered defense against UV radiation, offering protection that extends beyond the surface and into the bulk of the material. Additionally, there is growing interest in bio-based and environmentally friendly UV stabilizers, aligning with the broader trend towards sustainable materials.

The evolution of UV resistance mechanisms in UHMWPE is closely tied to advancements in analytical techniques and testing methodologies. Improved methods for characterizing UV-induced changes at the molecular level have enabled researchers to develop more targeted and effective protection strategies. This progress has been crucial in bridging the gap between laboratory findings and practical applications, allowing for the development of UHMWPE products with enhanced UV resistance for use in demanding environments.

Market Analysis for UV-Resistant UHMWPE

The market for UV-resistant Ultra-High Molecular Weight Polyethylene (UHMWPE) has shown significant growth potential in recent years, driven by increasing demand across various industries. This material's unique properties, including excellent wear resistance, high impact strength, and low friction coefficient, make it particularly valuable in applications where UV exposure is a concern.

In the medical sector, UV-resistant UHMWPE has found extensive use in orthopedic implants, particularly for joint replacements. The global orthopedic implants market, where UV-resistant UHMWPE plays a crucial role, is expected to grow steadily due to the rising prevalence of musculoskeletal disorders and an aging population. The material's ability to withstand UV radiation during sterilization processes has further enhanced its appeal in this sector.

The automotive industry represents another significant market for UV-resistant UHMWPE. As manufacturers increasingly focus on lightweight materials to improve fuel efficiency, UV-resistant UHMWPE has gained traction for use in exterior components, such as bumpers and trim parts. The material's durability under prolonged UV exposure makes it an attractive option for these applications.

In the renewable energy sector, particularly in solar panel installations, UV-resistant UHMWPE has emerged as a valuable material for cable protection and insulation. The growing adoption of solar energy worldwide is expected to drive demand for UV-resistant materials, including modified UHMWPE.

The packaging industry has also shown interest in UV-resistant UHMWPE, especially for applications involving outdoor storage or transportation of sensitive goods. The material's ability to maintain its properties under UV exposure while providing excellent barrier properties has led to its increased use in this sector.

Geographically, North America and Europe currently dominate the market for UV-resistant UHMWPE, owing to their advanced manufacturing capabilities and high adoption rates across various industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing automotive production.

Despite the positive market outlook, challenges remain. The relatively high cost of UV-resistant UHMWPE compared to conventional alternatives may limit its adoption in price-sensitive applications. Additionally, the development of competing materials with similar UV-resistant properties could potentially impact market growth.

Overall, the market for UV-resistant UHMWPE is poised for steady growth, supported by ongoing research and development efforts to enhance its properties and expand its applications. As industries continue to prioritize durability and performance under UV exposure, the demand for this modified material is expected to increase across various sectors.

In the medical sector, UV-resistant UHMWPE has found extensive use in orthopedic implants, particularly for joint replacements. The global orthopedic implants market, where UV-resistant UHMWPE plays a crucial role, is expected to grow steadily due to the rising prevalence of musculoskeletal disorders and an aging population. The material's ability to withstand UV radiation during sterilization processes has further enhanced its appeal in this sector.

The automotive industry represents another significant market for UV-resistant UHMWPE. As manufacturers increasingly focus on lightweight materials to improve fuel efficiency, UV-resistant UHMWPE has gained traction for use in exterior components, such as bumpers and trim parts. The material's durability under prolonged UV exposure makes it an attractive option for these applications.

In the renewable energy sector, particularly in solar panel installations, UV-resistant UHMWPE has emerged as a valuable material for cable protection and insulation. The growing adoption of solar energy worldwide is expected to drive demand for UV-resistant materials, including modified UHMWPE.

The packaging industry has also shown interest in UV-resistant UHMWPE, especially for applications involving outdoor storage or transportation of sensitive goods. The material's ability to maintain its properties under UV exposure while providing excellent barrier properties has led to its increased use in this sector.

Geographically, North America and Europe currently dominate the market for UV-resistant UHMWPE, owing to their advanced manufacturing capabilities and high adoption rates across various industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing automotive production.

Despite the positive market outlook, challenges remain. The relatively high cost of UV-resistant UHMWPE compared to conventional alternatives may limit its adoption in price-sensitive applications. Additionally, the development of competing materials with similar UV-resistant properties could potentially impact market growth.

Overall, the market for UV-resistant UHMWPE is poised for steady growth, supported by ongoing research and development efforts to enhance its properties and expand its applications. As industries continue to prioritize durability and performance under UV exposure, the demand for this modified material is expected to increase across various sectors.

Current Challenges in UHMWPE UV Protection

Despite significant advancements in UHMWPE technology, UV protection remains a critical challenge for this versatile material. The primary issue stems from UHMWPE's inherent susceptibility to UV radiation, which can lead to degradation of its mechanical properties and overall performance. This vulnerability is particularly problematic in outdoor applications where prolonged exposure to sunlight is inevitable.

One of the main challenges in UHMWPE UV protection is achieving a balance between effective UV resistance and maintaining the material's desirable properties. Traditional UV stabilizers, while effective in other polymers, often struggle to provide long-term protection in UHMWPE due to its unique molecular structure and high crystallinity. This necessitates the development of specialized UV protection mechanisms tailored specifically for UHMWPE.

Another significant hurdle is the migration and leaching of UV stabilizers from the UHMWPE matrix over time. This phenomenon not only reduces the long-term effectiveness of UV protection but also raises concerns about environmental impact and potential contamination in sensitive applications, such as medical implants or food packaging.

The high molecular weight and low reactivity of UHMWPE pose challenges in incorporating UV-resistant additives uniformly throughout the material. Conventional mixing methods often result in uneven distribution, leading to inconsistent UV protection across the product. This issue is particularly pronounced in large-scale manufacturing processes, where achieving homogeneous dispersion of additives becomes increasingly difficult.

Furthermore, the development of UV-resistant UHMWPE that maintains its transparency is a complex task. Many UV stabilizers tend to impart a yellowish tint to the material, which can be undesirable in applications requiring optical clarity. Balancing UV protection with optical properties remains a significant challenge for researchers and manufacturers.

The durability of UV protection mechanisms in UHMWPE under extreme conditions is another area of concern. In applications involving high temperatures, mechanical stress, or chemical exposure, the effectiveness of UV stabilizers can be compromised, leading to accelerated degradation of the material. Developing robust UV protection systems that can withstand these harsh environments is crucial for expanding the application range of UHMWPE.

Lastly, the cost-effectiveness of UV protection solutions for UHMWPE is a persistent challenge. Advanced UV stabilizers and novel incorporation techniques often come with increased production costs, which can limit the commercial viability of UV-resistant UHMWPE in price-sensitive markets. Striking a balance between performance and affordability remains a key focus for industry stakeholders.

One of the main challenges in UHMWPE UV protection is achieving a balance between effective UV resistance and maintaining the material's desirable properties. Traditional UV stabilizers, while effective in other polymers, often struggle to provide long-term protection in UHMWPE due to its unique molecular structure and high crystallinity. This necessitates the development of specialized UV protection mechanisms tailored specifically for UHMWPE.

Another significant hurdle is the migration and leaching of UV stabilizers from the UHMWPE matrix over time. This phenomenon not only reduces the long-term effectiveness of UV protection but also raises concerns about environmental impact and potential contamination in sensitive applications, such as medical implants or food packaging.

The high molecular weight and low reactivity of UHMWPE pose challenges in incorporating UV-resistant additives uniformly throughout the material. Conventional mixing methods often result in uneven distribution, leading to inconsistent UV protection across the product. This issue is particularly pronounced in large-scale manufacturing processes, where achieving homogeneous dispersion of additives becomes increasingly difficult.

Furthermore, the development of UV-resistant UHMWPE that maintains its transparency is a complex task. Many UV stabilizers tend to impart a yellowish tint to the material, which can be undesirable in applications requiring optical clarity. Balancing UV protection with optical properties remains a significant challenge for researchers and manufacturers.

The durability of UV protection mechanisms in UHMWPE under extreme conditions is another area of concern. In applications involving high temperatures, mechanical stress, or chemical exposure, the effectiveness of UV stabilizers can be compromised, leading to accelerated degradation of the material. Developing robust UV protection systems that can withstand these harsh environments is crucial for expanding the application range of UHMWPE.

Lastly, the cost-effectiveness of UV protection solutions for UHMWPE is a persistent challenge. Advanced UV stabilizers and novel incorporation techniques often come with increased production costs, which can limit the commercial viability of UV-resistant UHMWPE in price-sensitive markets. Striking a balance between performance and affordability remains a key focus for industry stakeholders.

Existing UV Resistance Solutions for UHMWPE

01 Incorporation of UV stabilizers

UV stabilizers are added to UHMWPE to enhance its resistance to ultraviolet radiation. These additives absorb or reflect UV light, preventing degradation of the polymer structure. Common UV stabilizers include hindered amine light stabilizers (HALS) and benzophenones. The incorporation of these stabilizers significantly improves the longevity and performance of UHMWPE products exposed to sunlight or other UV sources.- UV stabilizers and antioxidants: Incorporating UV stabilizers and antioxidants into UHMWPE can significantly enhance its resistance to UV radiation. These additives help prevent degradation of the polymer chains and maintain the material's mechanical properties when exposed to sunlight. Common UV stabilizers include hindered amine light stabilizers (HALS) and UV absorbers, while antioxidants such as phenolic compounds can further protect against oxidative degradation.

- Surface modification techniques: Various surface modification techniques can be applied to UHMWPE to improve its UV resistance. These methods include plasma treatment, corona discharge, and chemical grafting. Such treatments can alter the surface properties of UHMWPE, making it more resistant to UV degradation while potentially enhancing other characteristics like wettability and adhesion.

- Nanoparticle incorporation: Adding nanoparticles to UHMWPE can significantly improve its UV resistance. Nanoparticles such as titanium dioxide, zinc oxide, and carbon nanotubes can effectively absorb or scatter UV radiation, protecting the polymer matrix. These nanocomposites often exhibit enhanced mechanical properties and thermal stability in addition to improved UV resistance.

- Crosslinking and irradiation: Controlled crosslinking of UHMWPE, often achieved through irradiation techniques, can improve its UV resistance. This process creates a more stable polymer network that is less susceptible to UV-induced degradation. Irradiation methods may include gamma rays, electron beams, or UV light itself, sometimes combined with thermal treatments for optimized results.

- Blending with other polymers: Blending UHMWPE with other UV-resistant polymers or elastomers can enhance its overall UV resistance. This approach combines the beneficial properties of multiple materials, potentially resulting in a composite with improved UV stability, mechanical strength, and processability. Careful selection of compatible polymers and optimized blending ratios are crucial for achieving the desired performance.

02 Surface modification techniques

Various surface modification techniques are employed to improve the UV resistance of UHMWPE. These methods include plasma treatment, chemical grafting, and coating applications. Such modifications create a protective layer on the UHMWPE surface, enhancing its ability to withstand UV exposure. These techniques can also improve other properties like wettability and adhesion while maintaining the bulk properties of UHMWPE.Expand Specific Solutions03 Nanoparticle reinforcement

Incorporating nanoparticles into UHMWPE matrices enhances UV resistance. Nanoparticles such as titanium dioxide, zinc oxide, and carbon nanotubes are commonly used. These nanoparticles not only provide UV protection but also improve mechanical properties. The small size of nanoparticles allows for better dispersion within the polymer, resulting in more effective UV shielding and overall performance enhancement.Expand Specific Solutions04 Antioxidant addition

Antioxidants are incorporated into UHMWPE to prevent oxidative degradation caused by UV exposure. These additives neutralize free radicals generated during UV irradiation, protecting the polymer chains from breakdown. Common antioxidants used include phenolic compounds and phosphites. The addition of antioxidants not only improves UV resistance but also enhances the overall durability and lifespan of UHMWPE products.Expand Specific Solutions05 Copolymerization and blending

UHMWPE is modified through copolymerization with UV-resistant monomers or blending with other UV-resistant polymers. This approach combines the desirable properties of UHMWPE with the UV resistance of the added components. Copolymers or blends can be tailored to achieve specific UV resistance levels while maintaining other essential properties of UHMWPE, such as its high molecular weight and excellent mechanical characteristics.Expand Specific Solutions

Key Players in Modified UHMWPE Industry

The UV resistance mechanisms in modified UHMWPE represent a competitive field in advanced materials, currently in a growth phase. The market size is expanding due to increasing demand in medical, industrial, and consumer applications. Technologically, the field is progressing rapidly but still evolving. Companies like Howmedica Osteonics Corp., Zimmer, Inc., and Cambridge Polymer Group, Inc. are at the forefront, leveraging their expertise in polymer science and medical applications. Academic institutions such as MIT and Louisiana State University contribute significantly to research advancements. The involvement of diverse players, from specialized polymer companies to large petrochemical corporations like China Petroleum & Chemical Corp., indicates the broad potential and growing maturity of this technology.

Howmedica Osteonics Corp.

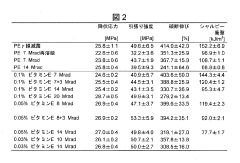

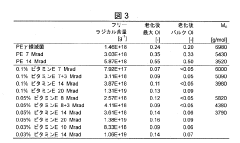

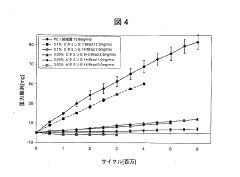

Technical Solution: Howmedica Osteonics Corp. has developed a proprietary UV resistance mechanism for modified UHMWPE used in orthopedic implants. Their approach involves incorporating antioxidants, particularly vitamin E, into the UHMWPE matrix during the manufacturing process. This method, known as E1 technology, creates a highly crosslinked UHMWPE with improved oxidation resistance and mechanical properties[1]. The company utilizes a unique irradiation and annealing process to optimize the crosslinking while maintaining the material's wear resistance. Additionally, they have implemented a surface modification technique that enhances the UV resistance of the outermost layer of the UHMWPE components[2].

Strengths: Enhanced oxidation resistance, improved mechanical properties, and long-term stability of implants. Weaknesses: Potential for reduced mechanical strength due to crosslinking, and the need for specialized manufacturing processes.

Zimmer, Inc.

Technical Solution: Zimmer, Inc. has developed a multi-faceted approach to UV resistance in modified UHMWPE for their orthopedic implants. Their technology, known as Vivacit-E, combines highly crosslinked UHMWPE with a proprietary antioxidant blend. The process involves infusing the UHMWPE with vitamin E and other synergistic antioxidants before radiation crosslinking[3]. This method creates a uniform distribution of antioxidants throughout the material, providing long-term oxidation resistance. Zimmer has also implemented a post-irradiation annealing process to further enhance the material's mechanical properties and UV resistance. Their latest innovation includes a surface treatment that creates a gradient of crosslinking density, with the highest density at the surface for improved wear resistance and UV protection[4].

Strengths: Uniform antioxidant distribution, enhanced long-term stability, and improved wear resistance. Weaknesses: Complex manufacturing process and potential for reduced mechanical properties in highly crosslinked regions.

Core Innovations in UHMWPE UV Stabilization

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

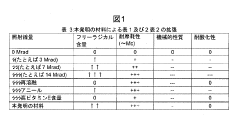

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

A process for preparing a disentangled uhmwpe product

PatentWO2015140681A1

Innovation

- A process involving a positive mold preheated in a compression molding machine, where disentangled UHMWPE is compacted below its melt temperature with stepwise pressure and temperature variations to achieve a density of at least 1 g/cc, followed by cooling and stretching to enhance crystallinity and mechanical properties.

Environmental Impact of UV-Resistant UHMWPE

The environmental impact of UV-resistant UHMWPE is a critical consideration in the development and application of this advanced material. As the demand for durable, long-lasting plastics increases, it is essential to evaluate the ecological consequences of their production, use, and disposal.

UV-resistant UHMWPE offers significant advantages in terms of longevity and performance, potentially reducing the need for frequent replacements and thereby minimizing waste generation. This extended lifespan can lead to a decrease in the overall environmental footprint associated with product manufacturing and disposal cycles.

However, the production of UV-resistant UHMWPE may involve additional chemical processes or additives, which could potentially increase the environmental burden during manufacturing. The use of UV stabilizers or other modifying agents may introduce new compounds into the material, raising concerns about their long-term environmental fate and potential toxicity.

During the use phase, UV-resistant UHMWPE demonstrates excellent stability and resistance to degradation, which can be both beneficial and problematic from an environmental perspective. While this stability prevents the release of microplastics due to UV-induced breakdown, it also means that the material persists in the environment for extended periods if not properly managed at the end of its life cycle.

The end-of-life management of UV-resistant UHMWPE presents unique challenges. Its enhanced durability may complicate recycling processes, potentially requiring specialized techniques or equipment to effectively recycle the material. This could lead to increased energy consumption and associated environmental impacts in the recycling phase.

Furthermore, the presence of UV stabilizers and other additives in the UHMWPE matrix may affect the material's biodegradability, potentially prolonging its persistence in landfills or natural environments. This raises concerns about long-term accumulation and the potential for these materials to interact with ecosystems over extended periods.

On the other hand, the improved UV resistance of UHMWPE may contribute to reduced environmental contamination by preventing the release of degradation products and microplastics that could otherwise result from UV-induced breakdown of conventional plastics. This aspect highlights the potential positive environmental impact of UV-resistant UHMWPE in certain applications, particularly in outdoor or high-exposure settings.

In conclusion, the environmental impact of UV-resistant UHMWPE is multifaceted, encompassing both potential benefits and challenges. As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate any negative environmental consequences while maximizing the material's positive contributions to sustainability and resource efficiency.

UV-resistant UHMWPE offers significant advantages in terms of longevity and performance, potentially reducing the need for frequent replacements and thereby minimizing waste generation. This extended lifespan can lead to a decrease in the overall environmental footprint associated with product manufacturing and disposal cycles.

However, the production of UV-resistant UHMWPE may involve additional chemical processes or additives, which could potentially increase the environmental burden during manufacturing. The use of UV stabilizers or other modifying agents may introduce new compounds into the material, raising concerns about their long-term environmental fate and potential toxicity.

During the use phase, UV-resistant UHMWPE demonstrates excellent stability and resistance to degradation, which can be both beneficial and problematic from an environmental perspective. While this stability prevents the release of microplastics due to UV-induced breakdown, it also means that the material persists in the environment for extended periods if not properly managed at the end of its life cycle.

The end-of-life management of UV-resistant UHMWPE presents unique challenges. Its enhanced durability may complicate recycling processes, potentially requiring specialized techniques or equipment to effectively recycle the material. This could lead to increased energy consumption and associated environmental impacts in the recycling phase.

Furthermore, the presence of UV stabilizers and other additives in the UHMWPE matrix may affect the material's biodegradability, potentially prolonging its persistence in landfills or natural environments. This raises concerns about long-term accumulation and the potential for these materials to interact with ecosystems over extended periods.

On the other hand, the improved UV resistance of UHMWPE may contribute to reduced environmental contamination by preventing the release of degradation products and microplastics that could otherwise result from UV-induced breakdown of conventional plastics. This aspect highlights the potential positive environmental impact of UV-resistant UHMWPE in certain applications, particularly in outdoor or high-exposure settings.

In conclusion, the environmental impact of UV-resistant UHMWPE is multifaceted, encompassing both potential benefits and challenges. As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments to fully understand and mitigate any negative environmental consequences while maximizing the material's positive contributions to sustainability and resource efficiency.

Standardization and Testing Protocols

Standardization and testing protocols play a crucial role in ensuring the reliability and comparability of UV resistance mechanisms in modified UHMWPE. These protocols provide a framework for consistent evaluation and benchmarking of materials across different manufacturers and research institutions.

One of the primary standardization bodies for UHMWPE testing is the American Society for Testing and Materials (ASTM). ASTM has developed several standards specifically for UHMWPE, including ASTM F2003 for accelerated aging of UHMWPE and ASTM F2565 for wear testing of polymeric materials used in total joint prostheses. These standards outline specific procedures for sample preparation, testing conditions, and data analysis.

For UV resistance testing, ASTM G154 is commonly used, which provides guidelines for operating fluorescent ultraviolet lamps for exposure of nonmetallic materials. This standard helps in simulating outdoor weathering conditions in a controlled laboratory environment. Additionally, ISO 4892-3 offers a similar framework for artificial weathering tests using fluorescent UV lamps.

The testing protocols typically involve exposing modified UHMWPE samples to UV radiation for specified periods, often in cycles that alternate between UV exposure and condensation to simulate real-world conditions. Key parameters monitored during these tests include color change, surface degradation, mechanical properties, and oxidation levels.

Mechanical property testing is another critical aspect of evaluating UV resistance in modified UHMWPE. Standards such as ASTM D638 for tensile properties and ASTM D790 for flexural properties are commonly employed to assess the impact of UV exposure on the material's strength and durability.

Oxidation measurement is particularly important in assessing UV resistance, as it is a primary mechanism of degradation. ASTM F2102 provides a standard for measuring oxidation in UHMWPE using Fourier Transform Infrared Spectroscopy (FTIR). This method allows for quantitative analysis of oxidation levels before and after UV exposure.

To ensure the relevance of these tests to real-world applications, many researchers and manufacturers also conduct field testing. This involves exposing samples to natural sunlight in various geographic locations and climates, providing valuable data on long-term performance under actual use conditions.

As the field of UV-resistant UHMWPE continues to evolve, there is an ongoing need to refine and develop new testing protocols. Current efforts focus on improving the correlation between accelerated laboratory tests and real-world performance, as well as developing standards for emerging modification techniques and additives used to enhance UV resistance.

One of the primary standardization bodies for UHMWPE testing is the American Society for Testing and Materials (ASTM). ASTM has developed several standards specifically for UHMWPE, including ASTM F2003 for accelerated aging of UHMWPE and ASTM F2565 for wear testing of polymeric materials used in total joint prostheses. These standards outline specific procedures for sample preparation, testing conditions, and data analysis.

For UV resistance testing, ASTM G154 is commonly used, which provides guidelines for operating fluorescent ultraviolet lamps for exposure of nonmetallic materials. This standard helps in simulating outdoor weathering conditions in a controlled laboratory environment. Additionally, ISO 4892-3 offers a similar framework for artificial weathering tests using fluorescent UV lamps.

The testing protocols typically involve exposing modified UHMWPE samples to UV radiation for specified periods, often in cycles that alternate between UV exposure and condensation to simulate real-world conditions. Key parameters monitored during these tests include color change, surface degradation, mechanical properties, and oxidation levels.

Mechanical property testing is another critical aspect of evaluating UV resistance in modified UHMWPE. Standards such as ASTM D638 for tensile properties and ASTM D790 for flexural properties are commonly employed to assess the impact of UV exposure on the material's strength and durability.

Oxidation measurement is particularly important in assessing UV resistance, as it is a primary mechanism of degradation. ASTM F2102 provides a standard for measuring oxidation in UHMWPE using Fourier Transform Infrared Spectroscopy (FTIR). This method allows for quantitative analysis of oxidation levels before and after UV exposure.

To ensure the relevance of these tests to real-world applications, many researchers and manufacturers also conduct field testing. This involves exposing samples to natural sunlight in various geographic locations and climates, providing valuable data on long-term performance under actual use conditions.

As the field of UV-resistant UHMWPE continues to evolve, there is an ongoing need to refine and develop new testing protocols. Current efforts focus on improving the correlation between accelerated laboratory tests and real-world performance, as well as developing standards for emerging modification techniques and additives used to enhance UV resistance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!