UHMWPE's Application in High-Speed Train Components

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Rail Tech: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the field of high-speed rail technology. Its unique properties, including exceptional wear resistance, low friction coefficient, and high impact strength, have positioned it as a game-changing component in various train applications. The evolution of UHMWPE in rail technology can be traced back to the early 2000s when researchers began exploring its potential to address the limitations of traditional materials used in train components.

The primary objective of incorporating UHMWPE in high-speed train components is to enhance overall performance, safety, and efficiency. By leveraging its superior mechanical properties, engineers aim to reduce wear and tear, minimize maintenance requirements, and extend the lifespan of critical train parts. This aligns with the industry's broader goals of improving operational reliability and reducing lifecycle costs.

One of the key drivers behind the adoption of UHMWPE in rail technology is the increasing demand for faster and more efficient transportation systems. As train speeds continue to rise, the need for materials that can withstand higher stresses and maintain their integrity under extreme conditions becomes paramount. UHMWPE's ability to perform exceptionally well in high-speed, high-load environments makes it an ideal candidate for addressing these challenges.

The technical evolution of UHMWPE in rail applications has been marked by continuous improvements in material formulation and processing techniques. Early iterations focused on enhancing the basic properties of the polymer, while recent developments have explored advanced composites and hybrid materials that combine UHMWPE with other high-performance substances. These innovations have led to the creation of components with even greater durability, lower weight, and improved thermal stability.

In the context of high-speed train components, UHMWPE has found applications in various critical areas. These include bearings, gears, sliding plates, and wear pads, where its low friction and high wear resistance properties are particularly beneficial. Additionally, its use in noise-dampening components and energy-absorbing structures has contributed to improved passenger comfort and safety.

The ongoing research and development in UHMWPE technology for rail applications aim to push the boundaries of material performance even further. Current objectives include developing UHMWPE variants with enhanced heat resistance, improved dimensional stability, and better integration with other materials used in train construction. These advancements are expected to enable the design of next-generation high-speed trains that are faster, more reliable, and more energy-efficient than ever before.

The primary objective of incorporating UHMWPE in high-speed train components is to enhance overall performance, safety, and efficiency. By leveraging its superior mechanical properties, engineers aim to reduce wear and tear, minimize maintenance requirements, and extend the lifespan of critical train parts. This aligns with the industry's broader goals of improving operational reliability and reducing lifecycle costs.

One of the key drivers behind the adoption of UHMWPE in rail technology is the increasing demand for faster and more efficient transportation systems. As train speeds continue to rise, the need for materials that can withstand higher stresses and maintain their integrity under extreme conditions becomes paramount. UHMWPE's ability to perform exceptionally well in high-speed, high-load environments makes it an ideal candidate for addressing these challenges.

The technical evolution of UHMWPE in rail applications has been marked by continuous improvements in material formulation and processing techniques. Early iterations focused on enhancing the basic properties of the polymer, while recent developments have explored advanced composites and hybrid materials that combine UHMWPE with other high-performance substances. These innovations have led to the creation of components with even greater durability, lower weight, and improved thermal stability.

In the context of high-speed train components, UHMWPE has found applications in various critical areas. These include bearings, gears, sliding plates, and wear pads, where its low friction and high wear resistance properties are particularly beneficial. Additionally, its use in noise-dampening components and energy-absorbing structures has contributed to improved passenger comfort and safety.

The ongoing research and development in UHMWPE technology for rail applications aim to push the boundaries of material performance even further. Current objectives include developing UHMWPE variants with enhanced heat resistance, improved dimensional stability, and better integration with other materials used in train construction. These advancements are expected to enable the design of next-generation high-speed trains that are faster, more reliable, and more energy-efficient than ever before.

Market Analysis for UHMWPE in High-Speed Trains

The market for Ultra-High Molecular Weight Polyethylene (UHMWPE) in high-speed train components is experiencing significant growth, driven by the material's exceptional properties and the expanding global high-speed rail network. UHMWPE's unique combination of high strength, low weight, and excellent wear resistance makes it an ideal candidate for various applications in high-speed train systems.

The global high-speed rail market is projected to grow substantially in the coming years, with major infrastructure projects underway in countries such as China, Japan, France, and Germany. This expansion is creating a robust demand for advanced materials like UHMWPE that can enhance train performance, safety, and longevity.

In the high-speed train sector, UHMWPE finds applications in various components, including bearings, gears, sliding plates, and wear-resistant surfaces. The material's self-lubricating properties and resistance to abrasion contribute to reduced maintenance requirements and extended service life of train components, which are crucial factors in the cost-effective operation of high-speed rail systems.

The market for UHMWPE in high-speed trains is segmented by component type, with bearings and sliding parts representing the largest share. These components benefit from UHMWPE's low coefficient of friction and high impact strength, which are essential for the smooth operation of trains at high velocities.

Geographically, Asia-Pacific dominates the market for UHMWPE in high-speed train applications, with China being the largest consumer. The country's extensive high-speed rail network and ongoing expansion plans drive the demand for advanced materials. Europe follows as the second-largest market, with countries like France, Germany, and Spain investing heavily in high-speed rail infrastructure.

Key market trends include the development of UHMWPE composites that offer enhanced mechanical properties and the integration of nanotechnology to further improve the material's performance. These innovations are expected to expand the application scope of UHMWPE in high-speed train components, potentially replacing traditional materials in more critical parts of the train system.

The market is characterized by intense competition among major UHMWPE manufacturers, who are investing in research and development to create tailored solutions for the high-speed rail industry. Collaborations between material suppliers and train manufacturers are becoming more common, fostering innovation and ensuring that UHMWPE products meet the specific requirements of modern high-speed trains.

Despite the positive outlook, challenges such as the high initial cost of UHMWPE compared to conventional materials and the need for specialized processing techniques may hinder market growth. However, the long-term benefits of using UHMWPE, including reduced lifecycle costs and improved performance, are expected to outweigh these challenges, driving continued adoption in the high-speed train sector.

The global high-speed rail market is projected to grow substantially in the coming years, with major infrastructure projects underway in countries such as China, Japan, France, and Germany. This expansion is creating a robust demand for advanced materials like UHMWPE that can enhance train performance, safety, and longevity.

In the high-speed train sector, UHMWPE finds applications in various components, including bearings, gears, sliding plates, and wear-resistant surfaces. The material's self-lubricating properties and resistance to abrasion contribute to reduced maintenance requirements and extended service life of train components, which are crucial factors in the cost-effective operation of high-speed rail systems.

The market for UHMWPE in high-speed trains is segmented by component type, with bearings and sliding parts representing the largest share. These components benefit from UHMWPE's low coefficient of friction and high impact strength, which are essential for the smooth operation of trains at high velocities.

Geographically, Asia-Pacific dominates the market for UHMWPE in high-speed train applications, with China being the largest consumer. The country's extensive high-speed rail network and ongoing expansion plans drive the demand for advanced materials. Europe follows as the second-largest market, with countries like France, Germany, and Spain investing heavily in high-speed rail infrastructure.

Key market trends include the development of UHMWPE composites that offer enhanced mechanical properties and the integration of nanotechnology to further improve the material's performance. These innovations are expected to expand the application scope of UHMWPE in high-speed train components, potentially replacing traditional materials in more critical parts of the train system.

The market is characterized by intense competition among major UHMWPE manufacturers, who are investing in research and development to create tailored solutions for the high-speed rail industry. Collaborations between material suppliers and train manufacturers are becoming more common, fostering innovation and ensuring that UHMWPE products meet the specific requirements of modern high-speed trains.

Despite the positive outlook, challenges such as the high initial cost of UHMWPE compared to conventional materials and the need for specialized processing techniques may hinder market growth. However, the long-term benefits of using UHMWPE, including reduced lifecycle costs and improved performance, are expected to outweigh these challenges, driving continued adoption in the high-speed train sector.

UHMWPE: Current Status and Technical Challenges

Ultra-high molecular weight polyethylene (UHMWPE) has gained significant attention in the field of high-speed train components due to its exceptional properties. However, the current status and technical challenges associated with its application in this domain require careful examination.

UHMWPE's current status in high-speed train applications is characterized by its growing adoption in various components, particularly those requiring high wear resistance and low friction. The material's self-lubricating properties and ability to withstand high loads make it an attractive choice for bearings, gears, and sliding parts in train systems. Its use has been observed in bogies, pantographs, and other critical components where durability and performance are paramount.

Despite its promising attributes, UHMWPE faces several technical challenges in high-speed train applications. One of the primary concerns is its relatively low thermal stability compared to traditional metal components. As trains operate at increasingly higher speeds, the heat generated in critical parts can potentially compromise the structural integrity of UHMWPE components, limiting their long-term performance and reliability.

Another significant challenge is the material's susceptibility to creep under sustained loads. This property can lead to dimensional changes over time, potentially affecting the precision and alignment of train components. Engineers must carefully consider this factor when designing UHMWPE parts for high-speed train applications, often necessitating innovative design solutions or hybrid material approaches.

The processing and manufacturing of UHMWPE components for high-speed trains also present technical hurdles. The material's high molecular weight, while beneficial for its mechanical properties, makes it challenging to process using conventional methods. Specialized techniques such as ram extrusion or compression molding are often required, which can increase production costs and limit the complexity of part geometries.

Furthermore, the integration of UHMWPE components with existing metal structures in train systems poses challenges in terms of joining and fastening. Traditional welding or adhesive bonding methods may not be suitable, necessitating the development of novel joining techniques or the use of mechanical fastening systems that can accommodate the material's unique properties.

The long-term performance and aging characteristics of UHMWPE in the harsh operating environment of high-speed trains remain areas of ongoing research. Factors such as UV radiation, moisture absorption, and exposure to various chemicals can potentially affect the material's properties over time. Developing accurate predictive models for the long-term behavior of UHMWPE components in these conditions is crucial for ensuring their reliability and safety throughout the service life of high-speed trains.

UHMWPE's current status in high-speed train applications is characterized by its growing adoption in various components, particularly those requiring high wear resistance and low friction. The material's self-lubricating properties and ability to withstand high loads make it an attractive choice for bearings, gears, and sliding parts in train systems. Its use has been observed in bogies, pantographs, and other critical components where durability and performance are paramount.

Despite its promising attributes, UHMWPE faces several technical challenges in high-speed train applications. One of the primary concerns is its relatively low thermal stability compared to traditional metal components. As trains operate at increasingly higher speeds, the heat generated in critical parts can potentially compromise the structural integrity of UHMWPE components, limiting their long-term performance and reliability.

Another significant challenge is the material's susceptibility to creep under sustained loads. This property can lead to dimensional changes over time, potentially affecting the precision and alignment of train components. Engineers must carefully consider this factor when designing UHMWPE parts for high-speed train applications, often necessitating innovative design solutions or hybrid material approaches.

The processing and manufacturing of UHMWPE components for high-speed trains also present technical hurdles. The material's high molecular weight, while beneficial for its mechanical properties, makes it challenging to process using conventional methods. Specialized techniques such as ram extrusion or compression molding are often required, which can increase production costs and limit the complexity of part geometries.

Furthermore, the integration of UHMWPE components with existing metal structures in train systems poses challenges in terms of joining and fastening. Traditional welding or adhesive bonding methods may not be suitable, necessitating the development of novel joining techniques or the use of mechanical fastening systems that can accommodate the material's unique properties.

The long-term performance and aging characteristics of UHMWPE in the harsh operating environment of high-speed trains remain areas of ongoing research. Factors such as UV radiation, moisture absorption, and exposure to various chemicals can potentially affect the material's properties over time. Developing accurate predictive models for the long-term behavior of UHMWPE components in these conditions is crucial for ensuring their reliability and safety throughout the service life of high-speed trains.

Current UHMWPE Solutions for Train Components

01 Synthesis and processing of UHMWPE

Various methods for synthesizing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) are explored. These include polymerization techniques, extrusion processes, and molding methods to produce UHMWPE with desired properties. The focus is on improving the molecular weight, crystallinity, and overall performance of the material.- Synthesis and processing of UHMWPE: Various methods for synthesizing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) are explored. These include polymerization techniques, extrusion processes, and molding methods to produce UHMWPE with desired properties. The focus is on improving the molecular weight, crystallinity, and overall performance of the material.

- UHMWPE composites and blends: Development of UHMWPE-based composites and blends to enhance specific properties. This includes incorporating additives, reinforcing materials, or blending with other polymers to improve mechanical strength, wear resistance, or other functional characteristics. The aim is to create tailored materials for specific applications.

- Surface modification of UHMWPE: Techniques for modifying the surface properties of UHMWPE are investigated. This includes chemical treatments, plasma processing, or grafting methods to alter surface characteristics such as adhesion, wettability, or biocompatibility. The goal is to expand the range of applications for UHMWPE in various industries.

- UHMWPE in medical applications: Utilization of UHMWPE in medical and biomedical fields, particularly for orthopedic implants and prosthetics. Research focuses on improving wear resistance, reducing oxidation, and enhancing long-term performance of UHMWPE in the human body. This includes development of cross-linked UHMWPE and vitamin E-infused variants.

- UHMWPE fibers and films: Production and application of UHMWPE in fiber and film forms. This includes gel spinning techniques for high-strength fibers, as well as methods for creating thin films with exceptional properties. Applications range from ballistic protection to high-performance textiles and packaging materials.

02 UHMWPE composites and blends

Development of UHMWPE-based composites and blends to enhance specific properties. This involves combining UHMWPE with other materials such as fibers, nanoparticles, or other polymers to create materials with improved strength, wear resistance, or other desirable characteristics for various applications.Expand Specific Solutions03 Surface modification of UHMWPE

Techniques for modifying the surface of UHMWPE to improve its properties or compatibility with other materials. This may include chemical treatments, plasma treatments, or grafting processes to enhance adhesion, wettability, or other surface-dependent properties of UHMWPE.Expand Specific Solutions04 UHMWPE in medical applications

Utilization of UHMWPE in various medical applications, particularly in orthopedic implants and prosthetics. This includes developing UHMWPE formulations with improved wear resistance, biocompatibility, and longevity for use in joint replacements and other medical devices.Expand Specific Solutions05 UHMWPE fibers and films

Production and application of UHMWPE in fiber and film forms. This involves specialized processing techniques to create high-strength fibers or thin films for use in applications such as protective gear, ropes, or packaging materials. The focus is on maximizing the material's strength-to-weight ratio and other unique properties in these forms.Expand Specific Solutions

Key Players in UHMWPE and Rail Industry

The application of UHMWPE in high-speed train components represents an emerging market with significant growth potential. The industry is in its early growth stage, characterized by increasing adoption and technological advancements. The market size is expanding rapidly, driven by the global demand for high-performance materials in the transportation sector. Technologically, UHMWPE applications are progressing from experimental to commercial stages. Companies like China Petroleum & Chemical Corp., Zhuzhou Times New Materials Technology Co., Ltd., and DSM IP Assets BV are at the forefront of developing and implementing UHMWPE solutions for high-speed trains, leveraging their expertise in materials science and engineering to enhance performance and durability in critical components.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced UHMWPE materials specifically tailored for high-speed train components. Their proprietary manufacturing process involves reactor granule technology and compression molding, resulting in UHMWPE with enhanced mechanical properties[1]. The company's UHMWPE exhibits a tensile strength of over 40 MPa and an impact strength exceeding 170 kJ/m², making it ideal for high-stress applications in train bogies and suspension systems[2]. Sinopec has also implemented a unique crosslinking technique that improves the material's wear resistance by up to 30%, crucial for components subject to constant friction[3]. Additionally, they have developed a surface treatment method that enhances the material's adhesion properties, allowing for better integration with other train components[4].

Strengths: Superior mechanical properties, excellent wear resistance, and improved adhesion capabilities. Weaknesses: Potentially higher production costs due to specialized manufacturing processes and limited high-temperature performance compared to some metal alternatives.

Maurer Engineering GmbH

Technical Solution: Maurer Engineering GmbH has pioneered the use of UHMWPE in high-speed train bearings and sliding surfaces. Their proprietary MAURER Sliding Material MSM® is a specially formulated UHMWPE composite designed for extreme loads and velocities in railway applications[1]. The material exhibits a dynamic coefficient of friction as low as 0.03, significantly reducing energy loss and wear in train components[2]. Maurer's UHMWPE solutions incorporate nanotechnology to enhance thermal stability, allowing the material to maintain its properties at temperatures up to 80°C, which is crucial for high-speed train operations[3]. The company has also developed a unique surface texturing process that improves the material's load distribution capabilities, enabling it to withstand pressures of up to 180 N/mm² in sliding bearings[4]. Maurer's UHMWPE components have been successfully implemented in several high-speed rail projects across Europe, demonstrating a lifespan of over 25 years in some applications[5].

Strengths: Extremely low friction coefficient, high load-bearing capacity, and proven long-term durability. Weaknesses: Limited to specific component applications and potentially higher initial costs compared to traditional materials.

Core Innovations in UHMWPE for Rail Applications

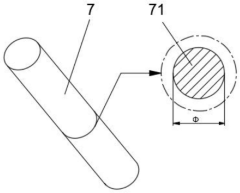

Continuous forming method of ultra-high molecular weight polyethylene bar

PatentPendingCN117484897A

Innovation

- The UHMWPE powder is plasticized and continuously extruded by a single screw extruder through the circumference uniform rotation of the screw in a reciprocating angular velocity rotation method. Combined with cooling and pneumatic cutting, ultra-high weight of up to 6.5 million is prepared. Net UHMWPE bar.

Ultra highmolecular weight polyethylene compositions

PatentInactiveUS20180037726A1

Innovation

- Adding ultrahigh molecular weight silicone to UHMWPE during compounding enables processing by traditional injection molding and extrusion methods, enhancing wear resistance and allowing for the creation of various forms such as fibers, films, and sheets.

Safety Standards for UHMWPE in Rail Transport

The implementation of safety standards for UHMWPE in rail transport is crucial to ensure the reliability and performance of high-speed train components. These standards encompass various aspects, including material properties, manufacturing processes, and testing protocols.

UHMWPE used in rail transport applications must meet specific mechanical and thermal requirements. The material should exhibit high tensile strength, excellent wear resistance, and low friction coefficients. Safety standards typically specify minimum values for these properties, which are determined through standardized testing methods.

Durability and long-term performance are key considerations in safety standards. UHMWPE components must maintain their structural integrity and functional properties over extended periods of use, withstanding the harsh conditions encountered in rail transport. Accelerated aging tests and fatigue resistance evaluations are often mandated to assess the material's long-term behavior.

Fire safety is another critical aspect addressed in UHMWPE safety standards for rail transport. The material must meet stringent fire resistance requirements, including low flame spread rates and minimal smoke generation. Specific fire testing protocols, such as the cone calorimeter test and the radiant panel test, are typically prescribed to evaluate the material's fire performance.

Environmental factors also play a role in safety standards. UHMWPE components must demonstrate resistance to UV radiation, moisture, and temperature fluctuations. Standards may require weathering tests and environmental cycling to ensure the material's stability under various conditions encountered during rail transport operations.

Quality control measures are an integral part of safety standards for UHMWPE in rail transport. These include specifications for raw material sourcing, manufacturing processes, and final product inspection. Traceability requirements ensure that the origin and processing history of UHMWPE components can be tracked throughout their lifecycle.

Compatibility with other materials used in high-speed train construction is another important consideration. Safety standards may include guidelines for assessing the interaction between UHMWPE and other components, such as metal fasteners or composite structures, to prevent potential degradation or failure modes.

Regular inspection and maintenance procedures for UHMWPE components are often outlined in safety standards. These may include non-destructive testing methods, such as ultrasonic inspection or thermography, to detect potential defects or degradation over time.

Compliance with these safety standards is typically verified through a combination of laboratory testing, field trials, and certification processes. Third-party testing and certification bodies may be involved in assessing and validating the conformity of UHMWPE components to the relevant safety standards for rail transport applications.

UHMWPE used in rail transport applications must meet specific mechanical and thermal requirements. The material should exhibit high tensile strength, excellent wear resistance, and low friction coefficients. Safety standards typically specify minimum values for these properties, which are determined through standardized testing methods.

Durability and long-term performance are key considerations in safety standards. UHMWPE components must maintain their structural integrity and functional properties over extended periods of use, withstanding the harsh conditions encountered in rail transport. Accelerated aging tests and fatigue resistance evaluations are often mandated to assess the material's long-term behavior.

Fire safety is another critical aspect addressed in UHMWPE safety standards for rail transport. The material must meet stringent fire resistance requirements, including low flame spread rates and minimal smoke generation. Specific fire testing protocols, such as the cone calorimeter test and the radiant panel test, are typically prescribed to evaluate the material's fire performance.

Environmental factors also play a role in safety standards. UHMWPE components must demonstrate resistance to UV radiation, moisture, and temperature fluctuations. Standards may require weathering tests and environmental cycling to ensure the material's stability under various conditions encountered during rail transport operations.

Quality control measures are an integral part of safety standards for UHMWPE in rail transport. These include specifications for raw material sourcing, manufacturing processes, and final product inspection. Traceability requirements ensure that the origin and processing history of UHMWPE components can be tracked throughout their lifecycle.

Compatibility with other materials used in high-speed train construction is another important consideration. Safety standards may include guidelines for assessing the interaction between UHMWPE and other components, such as metal fasteners or composite structures, to prevent potential degradation or failure modes.

Regular inspection and maintenance procedures for UHMWPE components are often outlined in safety standards. These may include non-destructive testing methods, such as ultrasonic inspection or thermography, to detect potential defects or degradation over time.

Compliance with these safety standards is typically verified through a combination of laboratory testing, field trials, and certification processes. Third-party testing and certification bodies may be involved in assessing and validating the conformity of UHMWPE components to the relevant safety standards for rail transport applications.

Environmental Impact of UHMWPE in Train Manufacturing

The environmental impact of UHMWPE (Ultra-High Molecular Weight Polyethylene) in train manufacturing is a crucial consideration as the railway industry strives for sustainability. UHMWPE, known for its exceptional strength-to-weight ratio and wear resistance, offers significant advantages in high-speed train components. However, its production and use also present environmental challenges that must be carefully evaluated.

The manufacturing process of UHMWPE involves energy-intensive polymerization and molding techniques, contributing to greenhouse gas emissions. The raw materials used in UHMWPE production are primarily derived from fossil fuels, raising concerns about resource depletion and carbon footprint. However, compared to traditional materials like steel or aluminum, UHMWPE's lightweight properties can lead to reduced fuel consumption and lower emissions during train operation, potentially offsetting some of the initial environmental costs.

Durability is a key environmental benefit of UHMWPE in train components. Its resistance to wear, corrosion, and fatigue means that parts made from this material have a longer lifespan, reducing the frequency of replacements and associated waste. This longevity contributes to resource conservation and minimizes the environmental impact of maintenance activities over the train's operational life.

End-of-life considerations for UHMWPE components present both challenges and opportunities. While the material is technically recyclable, the process is complex and not widely implemented in the railway industry. Developing efficient recycling methods for UHMWPE train components could significantly reduce waste and promote a circular economy approach in train manufacturing.

The use of UHMWPE in train components also impacts noise pollution. Its vibration-damping properties can contribute to quieter train operations, potentially reducing noise pollution in urban areas and along railway corridors. This acoustic benefit indirectly contributes to environmental quality and public health in communities near railway lines.

Water pollution risks associated with UHMWPE in train manufacturing are relatively low compared to some other materials. The material's chemical inertness means it doesn't leach harmful substances into the environment during use. However, proper disposal and recycling practices are essential to prevent UHMWPE particles from entering waterways and contributing to microplastic pollution.

As the railway industry continues to adopt UHMWPE in high-speed train components, ongoing research into bio-based alternatives and improved recycling technologies is crucial. These advancements could further enhance the environmental profile of UHMWPE in train manufacturing, aligning with global sustainability goals and the increasing demand for eco-friendly transportation solutions.

The manufacturing process of UHMWPE involves energy-intensive polymerization and molding techniques, contributing to greenhouse gas emissions. The raw materials used in UHMWPE production are primarily derived from fossil fuels, raising concerns about resource depletion and carbon footprint. However, compared to traditional materials like steel or aluminum, UHMWPE's lightweight properties can lead to reduced fuel consumption and lower emissions during train operation, potentially offsetting some of the initial environmental costs.

Durability is a key environmental benefit of UHMWPE in train components. Its resistance to wear, corrosion, and fatigue means that parts made from this material have a longer lifespan, reducing the frequency of replacements and associated waste. This longevity contributes to resource conservation and minimizes the environmental impact of maintenance activities over the train's operational life.

End-of-life considerations for UHMWPE components present both challenges and opportunities. While the material is technically recyclable, the process is complex and not widely implemented in the railway industry. Developing efficient recycling methods for UHMWPE train components could significantly reduce waste and promote a circular economy approach in train manufacturing.

The use of UHMWPE in train components also impacts noise pollution. Its vibration-damping properties can contribute to quieter train operations, potentially reducing noise pollution in urban areas and along railway corridors. This acoustic benefit indirectly contributes to environmental quality and public health in communities near railway lines.

Water pollution risks associated with UHMWPE in train manufacturing are relatively low compared to some other materials. The material's chemical inertness means it doesn't leach harmful substances into the environment during use. However, proper disposal and recycling practices are essential to prevent UHMWPE particles from entering waterways and contributing to microplastic pollution.

As the railway industry continues to adopt UHMWPE in high-speed train components, ongoing research into bio-based alternatives and improved recycling technologies is crucial. These advancements could further enhance the environmental profile of UHMWPE in train manufacturing, aligning with global sustainability goals and the increasing demand for eco-friendly transportation solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!