UHMWPE Membranes in Filtration Technology: A Performance Study

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Membrane Evolution

The evolution of UHMWPE membranes in filtration technology represents a significant advancement in material science and separation processes. Initially developed in the 1950s, Ultra-High Molecular Weight Polyethylene (UHMWPE) has undergone substantial improvements in its application as a filtration membrane.

In the early stages, UHMWPE was primarily used in industrial applications due to its exceptional mechanical properties and chemical resistance. However, its potential in filtration was not fully realized until the late 1980s when researchers began exploring its microporous structure for separation processes.

The 1990s marked a turning point in UHMWPE membrane development. Scientists discovered methods to create controlled pore sizes and distributions, enhancing the material's filtration capabilities. This period saw the introduction of UHMWPE membranes in water treatment and pharmaceutical applications, where their durability and chemical inertness proved advantageous.

The early 2000s witnessed a surge in research focused on improving the hydrophilicity of UHMWPE membranes. This was crucial for expanding their use in aqueous filtration processes. Surface modification techniques, such as plasma treatment and grafting of hydrophilic polymers, were developed to enhance the membrane's wettability without compromising its structural integrity.

From 2010 onwards, nanotechnology began playing a significant role in UHMWPE membrane evolution. The incorporation of nanoparticles and the development of nanocomposite UHMWPE membranes led to enhanced filtration performance, including improved flux rates and selectivity.

Recent years have seen a focus on sustainability and environmental considerations in UHMWPE membrane production. Efforts have been made to develop more eco-friendly manufacturing processes and to explore the potential of recycled UHMWPE in membrane fabrication.

The latest advancements in UHMWPE membrane technology include the development of smart membranes with responsive properties. These membranes can adapt their filtration characteristics based on environmental stimuli, offering unprecedented control in separation processes.

Throughout its evolution, UHMWPE membranes have consistently demonstrated improvements in key performance metrics such as permeability, selectivity, and fouling resistance. This progression has expanded their application from simple mechanical filtration to complex molecular separations, positioning UHMWPE as a versatile and high-performance material in the field of filtration technology.

In the early stages, UHMWPE was primarily used in industrial applications due to its exceptional mechanical properties and chemical resistance. However, its potential in filtration was not fully realized until the late 1980s when researchers began exploring its microporous structure for separation processes.

The 1990s marked a turning point in UHMWPE membrane development. Scientists discovered methods to create controlled pore sizes and distributions, enhancing the material's filtration capabilities. This period saw the introduction of UHMWPE membranes in water treatment and pharmaceutical applications, where their durability and chemical inertness proved advantageous.

The early 2000s witnessed a surge in research focused on improving the hydrophilicity of UHMWPE membranes. This was crucial for expanding their use in aqueous filtration processes. Surface modification techniques, such as plasma treatment and grafting of hydrophilic polymers, were developed to enhance the membrane's wettability without compromising its structural integrity.

From 2010 onwards, nanotechnology began playing a significant role in UHMWPE membrane evolution. The incorporation of nanoparticles and the development of nanocomposite UHMWPE membranes led to enhanced filtration performance, including improved flux rates and selectivity.

Recent years have seen a focus on sustainability and environmental considerations in UHMWPE membrane production. Efforts have been made to develop more eco-friendly manufacturing processes and to explore the potential of recycled UHMWPE in membrane fabrication.

The latest advancements in UHMWPE membrane technology include the development of smart membranes with responsive properties. These membranes can adapt their filtration characteristics based on environmental stimuli, offering unprecedented control in separation processes.

Throughout its evolution, UHMWPE membranes have consistently demonstrated improvements in key performance metrics such as permeability, selectivity, and fouling resistance. This progression has expanded their application from simple mechanical filtration to complex molecular separations, positioning UHMWPE as a versatile and high-performance material in the field of filtration technology.

Filtration Market Analysis

The global filtration market has been experiencing significant growth, driven by increasing environmental concerns, stringent regulations, and the growing demand for clean water and air across various industries. The market for filtration technologies, including membranes, is expected to continue its upward trajectory in the coming years.

In the water treatment sector, the demand for advanced filtration solutions is particularly strong. Municipalities, industrial facilities, and households are seeking more efficient and cost-effective ways to purify water for consumption and industrial processes. This has led to a surge in the adoption of membrane-based filtration systems, with UHMWPE (Ultra-High Molecular Weight Polyethylene) membranes gaining attention due to their unique properties.

The industrial filtration segment is another key driver of market growth. Industries such as pharmaceuticals, food and beverage, and chemicals require high-performance filtration solutions to meet quality standards and regulatory requirements. UHMWPE membranes are finding applications in these sectors due to their excellent chemical resistance and durability.

In the healthcare sector, the filtration market is expanding rapidly, especially in the wake of the global pandemic. The need for effective air filtration in hospitals, clinics, and other healthcare facilities has intensified, creating new opportunities for advanced filtration technologies. UHMWPE membranes, with their potential for high particulate removal efficiency, are being explored for use in medical-grade air filtration systems.

The automotive industry is another significant consumer of filtration products. With the increasing focus on reducing emissions and improving air quality inside vehicles, there is a growing demand for high-performance cabin air filters. UHMWPE membranes are being investigated for their potential to enhance filtration efficiency in automotive applications.

Geographically, Asia-Pacific is emerging as a key market for filtration technologies. Rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India are driving the demand for advanced filtration solutions. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and adopting more sustainable filtration technologies.

The competitive landscape of the filtration market is characterized by the presence of both large multinational corporations and specialized niche players. Companies are investing heavily in research and development to innovate and improve filtration technologies, with a particular focus on enhancing membrane performance and durability. The potential of UHMWPE membranes in various filtration applications is attracting attention from both established players and startups in the industry.

In the water treatment sector, the demand for advanced filtration solutions is particularly strong. Municipalities, industrial facilities, and households are seeking more efficient and cost-effective ways to purify water for consumption and industrial processes. This has led to a surge in the adoption of membrane-based filtration systems, with UHMWPE (Ultra-High Molecular Weight Polyethylene) membranes gaining attention due to their unique properties.

The industrial filtration segment is another key driver of market growth. Industries such as pharmaceuticals, food and beverage, and chemicals require high-performance filtration solutions to meet quality standards and regulatory requirements. UHMWPE membranes are finding applications in these sectors due to their excellent chemical resistance and durability.

In the healthcare sector, the filtration market is expanding rapidly, especially in the wake of the global pandemic. The need for effective air filtration in hospitals, clinics, and other healthcare facilities has intensified, creating new opportunities for advanced filtration technologies. UHMWPE membranes, with their potential for high particulate removal efficiency, are being explored for use in medical-grade air filtration systems.

The automotive industry is another significant consumer of filtration products. With the increasing focus on reducing emissions and improving air quality inside vehicles, there is a growing demand for high-performance cabin air filters. UHMWPE membranes are being investigated for their potential to enhance filtration efficiency in automotive applications.

Geographically, Asia-Pacific is emerging as a key market for filtration technologies. Rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India are driving the demand for advanced filtration solutions. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and adopting more sustainable filtration technologies.

The competitive landscape of the filtration market is characterized by the presence of both large multinational corporations and specialized niche players. Companies are investing heavily in research and development to innovate and improve filtration technologies, with a particular focus on enhancing membrane performance and durability. The potential of UHMWPE membranes in various filtration applications is attracting attention from both established players and startups in the industry.

UHMWPE Membrane Challenges

Despite the promising potential of Ultra-High Molecular Weight Polyethylene (UHMWPE) membranes in filtration technology, several significant challenges hinder their widespread adoption and optimal performance. These challenges span across material properties, manufacturing processes, and application-specific requirements.

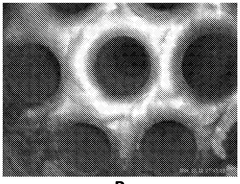

One of the primary obstacles is the inherent hydrophobicity of UHMWPE. This characteristic limits its effectiveness in aqueous filtration applications, as it can lead to membrane fouling and reduced flux rates. The hydrophobic nature of UHMWPE also makes it difficult to achieve uniform pore distribution and consistent membrane thickness, which are crucial for efficient filtration.

The high molecular weight of UHMWPE, while beneficial for its mechanical properties, poses challenges in membrane fabrication. Traditional melt processing techniques are often inadequate due to the material's high viscosity and thermal sensitivity. This necessitates the development of specialized manufacturing methods, which can be complex and costly, potentially limiting large-scale production.

Another significant challenge lies in achieving the desired pore size and distribution in UHMWPE membranes. The material's resistance to chemical etching and other conventional pore-forming techniques makes it difficult to create precise and uniform pore structures. This limitation affects the membrane's selectivity and overall filtration efficiency.

The mechanical strength of UHMWPE membranes, while generally high, can be compromised under certain operating conditions. High-pressure filtration systems or applications involving aggressive chemical environments may lead to membrane deformation or degradation over time, affecting long-term performance and durability.

Surface modification of UHMWPE membranes presents another hurdle. Enhancing the membrane's surface properties, such as improving hydrophilicity or adding functional groups for specific separations, is challenging due to the material's chemical inertness. This limitation restricts the versatility of UHMWPE membranes in various filtration applications.

The thermal stability of UHMWPE membranes at elevated temperatures is also a concern. While the material exhibits excellent low-temperature properties, its performance can degrade significantly at higher temperatures, limiting its use in high-temperature filtration processes.

Lastly, the environmental impact and end-of-life management of UHMWPE membranes pose challenges. The material's resistance to degradation, while advantageous for durability, raises concerns about disposal and recycling. Developing sustainable practices for the production, use, and disposal of UHMWPE membranes is crucial for their long-term viability in filtration technology.

One of the primary obstacles is the inherent hydrophobicity of UHMWPE. This characteristic limits its effectiveness in aqueous filtration applications, as it can lead to membrane fouling and reduced flux rates. The hydrophobic nature of UHMWPE also makes it difficult to achieve uniform pore distribution and consistent membrane thickness, which are crucial for efficient filtration.

The high molecular weight of UHMWPE, while beneficial for its mechanical properties, poses challenges in membrane fabrication. Traditional melt processing techniques are often inadequate due to the material's high viscosity and thermal sensitivity. This necessitates the development of specialized manufacturing methods, which can be complex and costly, potentially limiting large-scale production.

Another significant challenge lies in achieving the desired pore size and distribution in UHMWPE membranes. The material's resistance to chemical etching and other conventional pore-forming techniques makes it difficult to create precise and uniform pore structures. This limitation affects the membrane's selectivity and overall filtration efficiency.

The mechanical strength of UHMWPE membranes, while generally high, can be compromised under certain operating conditions. High-pressure filtration systems or applications involving aggressive chemical environments may lead to membrane deformation or degradation over time, affecting long-term performance and durability.

Surface modification of UHMWPE membranes presents another hurdle. Enhancing the membrane's surface properties, such as improving hydrophilicity or adding functional groups for specific separations, is challenging due to the material's chemical inertness. This limitation restricts the versatility of UHMWPE membranes in various filtration applications.

The thermal stability of UHMWPE membranes at elevated temperatures is also a concern. While the material exhibits excellent low-temperature properties, its performance can degrade significantly at higher temperatures, limiting its use in high-temperature filtration processes.

Lastly, the environmental impact and end-of-life management of UHMWPE membranes pose challenges. The material's resistance to degradation, while advantageous for durability, raises concerns about disposal and recycling. Developing sustainable practices for the production, use, and disposal of UHMWPE membranes is crucial for their long-term viability in filtration technology.

Current UHMWPE Solutions

01 Improved mechanical properties of UHMWPE membranes

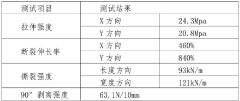

UHMWPE membranes can be engineered to have enhanced mechanical properties such as tensile strength, tear resistance, and durability. This is achieved through various processing techniques and the incorporation of additives or reinforcing materials. The improved mechanical properties make these membranes suitable for demanding applications in filtration, separation, and protective equipment.- Improved mechanical properties of UHMWPE membranes: UHMWPE membranes can be engineered to have enhanced mechanical properties, including increased tensile strength, tear resistance, and durability. This is achieved through various processing techniques and the incorporation of specific additives, resulting in membranes suitable for demanding applications.

- Enhanced filtration performance of UHMWPE membranes: UHMWPE membranes can be designed to exhibit superior filtration performance, including high flux rates and excellent selectivity. This is accomplished through precise control of pore size distribution, surface modifications, and optimization of membrane thickness, making them ideal for various separation processes.

- Chemical resistance and stability of UHMWPE membranes: UHMWPE membranes demonstrate exceptional chemical resistance and stability across a wide range of pH levels and in the presence of various solvents and aggressive chemicals. This property makes them suitable for use in harsh industrial environments and specialized applications.

- Thermal properties and heat resistance of UHMWPE membranes: UHMWPE membranes exhibit good thermal properties and heat resistance, maintaining their structural integrity and performance at elevated temperatures. This characteristic allows for their use in high-temperature filtration and separation processes.

- Surface modification techniques for UHMWPE membranes: Various surface modification techniques can be applied to UHMWPE membranes to enhance their performance, including improved hydrophilicity, reduced fouling, and increased biocompatibility. These modifications expand the range of applications for UHMWPE membranes in fields such as water treatment and biomedical devices.

02 Enhanced filtration performance of UHMWPE membranes

UHMWPE membranes can be designed to exhibit superior filtration performance, including high flux rates, excellent particle retention, and low fouling tendency. This is achieved through careful control of pore size distribution, surface modifications, and optimization of membrane thickness. These membranes find applications in water treatment, pharmaceutical processing, and industrial separations.Expand Specific Solutions03 Chemical resistance and stability of UHMWPE membranes

UHMWPE membranes demonstrate excellent chemical resistance and stability across a wide range of pH levels and in the presence of various solvents and aggressive chemicals. This property makes them suitable for use in harsh chemical environments, such as in the production of specialty chemicals, electrochemical applications, and in corrosive media filtration.Expand Specific Solutions04 Thermal and electrical properties of UHMWPE membranes

UHMWPE membranes can be engineered to possess specific thermal and electrical properties. This includes tailoring their heat resistance, thermal conductivity, and electrical insulation characteristics. These properties make them suitable for applications in battery separators, fuel cells, and thermal management systems.Expand Specific Solutions05 Surface modification techniques for UHMWPE membranes

Various surface modification techniques can be applied to UHMWPE membranes to enhance their performance. These include plasma treatment, grafting, and coating with functional materials. Such modifications can improve hydrophilicity, biocompatibility, antifouling properties, and selectivity of the membranes, expanding their potential applications in biomedical devices, water treatment, and gas separation.Expand Specific Solutions

Key Filtration Innovators

The UHMWPE membrane filtration technology market is in a growth phase, driven by increasing demand for high-performance filtration solutions across various industries. The market size is expanding, with significant potential in water treatment, chemical processing, and biomedical applications. Technologically, UHMWPE membranes are advancing rapidly, with companies like W. L. Gore & Associates and Pall Corporation leading innovation. Academic institutions such as the Hong Kong University of Science & Technology and National University of Singapore are contributing to research and development. The technology's maturity is progressing, with established players like 3M and emerging companies like Hangzhou Cobetter Filtration Equipment Co., Ltd. actively developing new applications and improving membrane performance.

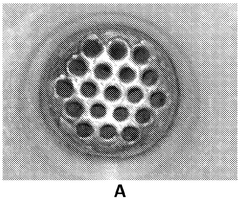

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced UHMWPE membrane technology for filtration applications. Their approach involves creating a microporous structure with high porosity and uniform pore size distribution[1]. The company utilizes a unique stretching process to create a network of interconnected fibrils, resulting in membranes with excellent filtration efficiency and high flow rates[2]. Gore's UHMWPE membranes are engineered to provide superior chemical resistance and mechanical strength, making them suitable for demanding industrial and pharmaceutical filtration processes[3]. The company has also implemented surface modification techniques to enhance the membrane's hydrophilicity and fouling resistance, addressing common challenges in membrane filtration[4].

Strengths: Superior chemical resistance, high mechanical strength, and excellent filtration efficiency. Weaknesses: Potentially higher production costs due to specialized manufacturing processes.

Pall Corp.

Technical Solution: Pall Corporation has developed innovative UHMWPE membrane technology for advanced filtration applications. Their approach focuses on creating asymmetric membrane structures with a thin, highly selective top layer supported by a more porous sublayer[1]. This design optimizes both selectivity and permeability. Pall's UHMWPE membranes are manufactured using a proprietary phase inversion process, which allows for precise control over pore size and distribution[2]. The company has also implemented surface modification techniques to enhance the membrane's fouling resistance and compatibility with various process fluids[3]. Pall's UHMWPE membranes are particularly well-suited for applications in the biopharmaceutical and food and beverage industries, where high purity and low extractables are critical[4].

Strengths: High selectivity combined with good permeability, low extractables, and excellent compatibility with sensitive processes. Weaknesses: May have limitations in extremely high-temperature applications.

UHMWPE Patent Landscape

Ultra-high molecular weight polyethylene wet-process composite membrane and preparation process thereof

PatentPendingCN117549627A

Innovation

- Ultra-high molecular weight polyethylene composite films are prepared using a two-step process of wet granulation and dry melt extrusion. Through thermally induced phase separation and melt blending technology, the molecular weight is controlled to be stable, melt fracture and molecular weight attenuation are reduced, and dilute lubricants are used. and cross-linking agents to improve processing properties.

Process for polymerization of ethylene using a cooling system with a slurry-free heat exchanger

PatentWO2024220786A1

Innovation

- A process utilizing a slurry-free heat exchanger in the cooling system, which reduces fouling by using a light hydrocarbon diluent and condensing vapor streams, thereby minimizing the need for external heat exchangers and antistatic agents, and improving catalytic activity.

Environmental Impact

The environmental impact of UHMWPE membranes in filtration technology is a critical aspect to consider when evaluating their performance and potential for widespread adoption. These membranes offer several environmental benefits, primarily due to their exceptional durability and efficiency in filtration processes.

UHMWPE membranes demonstrate superior resistance to chemical degradation and mechanical wear, resulting in extended operational lifespans compared to conventional filtration materials. This longevity translates to reduced waste generation and less frequent replacement of filtration systems, thereby minimizing the environmental footprint associated with manufacturing and disposal of filtration components.

The high efficiency of UHMWPE membranes in removing contaminants from various liquids and gases contributes to improved water and air quality. In water treatment applications, these membranes can effectively remove microplastics, bacteria, and other pollutants, helping to preserve aquatic ecosystems and reduce the burden on downstream water treatment facilities.

Furthermore, the energy efficiency of UHMWPE membrane-based filtration systems is noteworthy. The membranes' low surface friction and high porosity allow for reduced pumping energy requirements, leading to decreased energy consumption and associated greenhouse gas emissions in industrial and municipal filtration processes.

However, it is essential to consider the potential environmental drawbacks of UHMWPE membranes. The production of UHMWPE involves energy-intensive processes and the use of petrochemical feedstocks, which can contribute to carbon emissions and resource depletion. Additionally, while UHMWPE is recyclable, the complex nature of membrane structures may pose challenges for end-of-life recycling and disposal.

Research into bio-based alternatives and sustainable production methods for UHMWPE membranes is ongoing, aiming to further reduce their environmental impact. Innovations in membrane design, such as incorporating biodegradable components or developing more efficient recycling techniques, could enhance the overall sustainability profile of UHMWPE membrane technology.

In conclusion, while UHMWPE membranes offer significant environmental benefits through their performance and longevity in filtration applications, a comprehensive life cycle assessment is necessary to fully understand and optimize their environmental impact. Continued research and development efforts focused on sustainable production and end-of-life management will be crucial in maximizing the positive environmental contributions of this promising filtration technology.

UHMWPE membranes demonstrate superior resistance to chemical degradation and mechanical wear, resulting in extended operational lifespans compared to conventional filtration materials. This longevity translates to reduced waste generation and less frequent replacement of filtration systems, thereby minimizing the environmental footprint associated with manufacturing and disposal of filtration components.

The high efficiency of UHMWPE membranes in removing contaminants from various liquids and gases contributes to improved water and air quality. In water treatment applications, these membranes can effectively remove microplastics, bacteria, and other pollutants, helping to preserve aquatic ecosystems and reduce the burden on downstream water treatment facilities.

Furthermore, the energy efficiency of UHMWPE membrane-based filtration systems is noteworthy. The membranes' low surface friction and high porosity allow for reduced pumping energy requirements, leading to decreased energy consumption and associated greenhouse gas emissions in industrial and municipal filtration processes.

However, it is essential to consider the potential environmental drawbacks of UHMWPE membranes. The production of UHMWPE involves energy-intensive processes and the use of petrochemical feedstocks, which can contribute to carbon emissions and resource depletion. Additionally, while UHMWPE is recyclable, the complex nature of membrane structures may pose challenges for end-of-life recycling and disposal.

Research into bio-based alternatives and sustainable production methods for UHMWPE membranes is ongoing, aiming to further reduce their environmental impact. Innovations in membrane design, such as incorporating biodegradable components or developing more efficient recycling techniques, could enhance the overall sustainability profile of UHMWPE membrane technology.

In conclusion, while UHMWPE membranes offer significant environmental benefits through their performance and longevity in filtration applications, a comprehensive life cycle assessment is necessary to fully understand and optimize their environmental impact. Continued research and development efforts focused on sustainable production and end-of-life management will be crucial in maximizing the positive environmental contributions of this promising filtration technology.

Cost-Benefit Analysis

The cost-benefit analysis of UHMWPE membranes in filtration technology reveals a complex interplay of economic factors and performance advantages. Initial investment in UHMWPE membrane systems tends to be higher compared to conventional filtration methods, primarily due to the advanced manufacturing processes and specialized materials required. However, this upfront cost is often offset by long-term operational benefits.

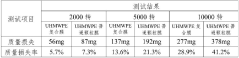

UHMWPE membranes demonstrate superior durability and chemical resistance, leading to extended operational lifespans. This longevity translates to reduced frequency of membrane replacement, resulting in significant cost savings over time. Additionally, the high mechanical strength of UHMWPE membranes allows for operation under higher pressures, potentially increasing throughput and efficiency in industrial applications.

The exceptional fouling resistance of UHMWPE membranes contributes to lower maintenance costs and reduced downtime for cleaning procedures. This characteristic is particularly valuable in industries dealing with challenging feed streams, where membrane fouling is a persistent issue. The improved flux rates and selectivity of UHMWPE membranes also lead to enhanced product quality and potentially higher market value for filtered products.

Energy consumption is another critical factor in the cost-benefit equation. UHMWPE membranes often exhibit lower energy requirements for operation due to their high permeability and ability to maintain performance under various conditions. This energy efficiency can result in substantial cost savings, especially in large-scale industrial applications where energy expenses constitute a significant portion of operational costs.

From an environmental perspective, the use of UHMWPE membranes can lead to reduced chemical consumption for cleaning and maintenance, aligning with increasingly stringent environmental regulations. This not only lowers operational costs but also enhances the sustainability profile of filtration processes, potentially opening up new market opportunities and improving corporate image.

However, the cost-benefit analysis must also consider potential drawbacks. The specialized nature of UHMWPE membranes may require additional training for operators and maintenance personnel, incurring short-term costs. Furthermore, the integration of UHMWPE membrane systems into existing filtration setups may necessitate modifications to infrastructure, adding to the initial investment.

In conclusion, while the upfront costs of implementing UHMWPE membrane filtration technology can be substantial, the long-term benefits in terms of operational efficiency, reduced maintenance, and improved product quality often justify the investment. The specific cost-benefit ratio will vary depending on the application, scale of operation, and local economic factors, necessitating a case-by-case analysis for optimal decision-making.

UHMWPE membranes demonstrate superior durability and chemical resistance, leading to extended operational lifespans. This longevity translates to reduced frequency of membrane replacement, resulting in significant cost savings over time. Additionally, the high mechanical strength of UHMWPE membranes allows for operation under higher pressures, potentially increasing throughput and efficiency in industrial applications.

The exceptional fouling resistance of UHMWPE membranes contributes to lower maintenance costs and reduced downtime for cleaning procedures. This characteristic is particularly valuable in industries dealing with challenging feed streams, where membrane fouling is a persistent issue. The improved flux rates and selectivity of UHMWPE membranes also lead to enhanced product quality and potentially higher market value for filtered products.

Energy consumption is another critical factor in the cost-benefit equation. UHMWPE membranes often exhibit lower energy requirements for operation due to their high permeability and ability to maintain performance under various conditions. This energy efficiency can result in substantial cost savings, especially in large-scale industrial applications where energy expenses constitute a significant portion of operational costs.

From an environmental perspective, the use of UHMWPE membranes can lead to reduced chemical consumption for cleaning and maintenance, aligning with increasingly stringent environmental regulations. This not only lowers operational costs but also enhances the sustainability profile of filtration processes, potentially opening up new market opportunities and improving corporate image.

However, the cost-benefit analysis must also consider potential drawbacks. The specialized nature of UHMWPE membranes may require additional training for operators and maintenance personnel, incurring short-term costs. Furthermore, the integration of UHMWPE membrane systems into existing filtration setups may necessitate modifications to infrastructure, adding to the initial investment.

In conclusion, while the upfront costs of implementing UHMWPE membrane filtration technology can be substantial, the long-term benefits in terms of operational efficiency, reduced maintenance, and improved product quality often justify the investment. The specific cost-benefit ratio will vary depending on the application, scale of operation, and local economic factors, necessitating a case-by-case analysis for optimal decision-making.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!