How UHMWPE Reduces Noise in Automotive Applications

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Noise Reduction Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in automotive applications, particularly for its exceptional noise reduction properties. The evolution of this technology can be traced back to the 1950s when UHMWPE was first synthesized. However, its potential in automotive noise reduction was not fully realized until the late 1990s and early 2000s.

The automotive industry has long grappled with the challenge of reducing noise, vibration, and harshness (NVH) in vehicles. As consumer expectations for quieter and more comfortable rides have increased, so has the demand for innovative solutions. UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, provides it with superior sound-damping capabilities compared to traditional materials.

The primary objective of utilizing UHMWPE in automotive applications is to significantly reduce noise levels without compromising on weight or performance. This aligns with the broader industry trends of lightweighting and improving fuel efficiency while enhancing passenger comfort. UHMWPE's ability to absorb and dissipate sound energy makes it an ideal candidate for various automotive components, including door panels, floor mats, and engine compartment insulation.

Recent technological advancements have further expanded the potential applications of UHMWPE in noise reduction. For instance, the development of UHMWPE fibers and composites has opened up new possibilities for creating lightweight yet highly effective sound-absorbing materials. These innovations are particularly relevant in the context of electric vehicles, where the absence of engine noise makes other sources of sound more noticeable.

The ongoing research in this field aims to optimize the acoustic properties of UHMWPE for specific frequency ranges commonly encountered in automotive environments. This includes addressing road noise, wind noise, and vibrations from various vehicle systems. Additionally, efforts are being made to enhance the material's durability and resistance to environmental factors, ensuring long-term performance in diverse driving conditions.

As the automotive industry continues to evolve, with a growing focus on electric and autonomous vehicles, the role of UHMWPE in noise reduction is expected to become even more critical. The technology's potential to create quieter, more comfortable, and energy-efficient vehicles aligns perfectly with the future direction of automotive design and engineering.

The automotive industry has long grappled with the challenge of reducing noise, vibration, and harshness (NVH) in vehicles. As consumer expectations for quieter and more comfortable rides have increased, so has the demand for innovative solutions. UHMWPE's unique molecular structure, characterized by extremely long chains of polyethylene, provides it with superior sound-damping capabilities compared to traditional materials.

The primary objective of utilizing UHMWPE in automotive applications is to significantly reduce noise levels without compromising on weight or performance. This aligns with the broader industry trends of lightweighting and improving fuel efficiency while enhancing passenger comfort. UHMWPE's ability to absorb and dissipate sound energy makes it an ideal candidate for various automotive components, including door panels, floor mats, and engine compartment insulation.

Recent technological advancements have further expanded the potential applications of UHMWPE in noise reduction. For instance, the development of UHMWPE fibers and composites has opened up new possibilities for creating lightweight yet highly effective sound-absorbing materials. These innovations are particularly relevant in the context of electric vehicles, where the absence of engine noise makes other sources of sound more noticeable.

The ongoing research in this field aims to optimize the acoustic properties of UHMWPE for specific frequency ranges commonly encountered in automotive environments. This includes addressing road noise, wind noise, and vibrations from various vehicle systems. Additionally, efforts are being made to enhance the material's durability and resistance to environmental factors, ensuring long-term performance in diverse driving conditions.

As the automotive industry continues to evolve, with a growing focus on electric and autonomous vehicles, the role of UHMWPE in noise reduction is expected to become even more critical. The technology's potential to create quieter, more comfortable, and energy-efficient vehicles aligns perfectly with the future direction of automotive design and engineering.

Automotive Industry Demand for Noise Reduction Solutions

The automotive industry has witnessed a growing demand for noise reduction solutions in recent years, driven by consumer expectations for quieter and more comfortable vehicles. As vehicles become more advanced and electric powertrains gain popularity, the focus on noise, vibration, and harshness (NVH) reduction has intensified. This trend is further amplified by the increasing awareness of the negative impacts of noise pollution on human health and well-being.

Manufacturers are under pressure to deliver vehicles that offer a serene driving experience while maintaining performance and efficiency. The demand for noise reduction solutions spans across various vehicle segments, from luxury cars to mass-market models, as consumers increasingly prioritize comfort and tranquility in their driving experience. This shift in consumer preferences has led to a significant market opportunity for innovative noise reduction technologies and materials.

The automotive industry's pursuit of lightweight materials to improve fuel efficiency and reduce emissions has created a unique challenge in noise reduction. Traditional sound-dampening materials often add weight to vehicles, conflicting with the goal of weight reduction. This has spurred the search for advanced materials that can effectively reduce noise without compromising the vehicle's overall weight and performance.

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a promising solution to address these conflicting demands. Its unique properties, including high strength-to-weight ratio, excellent vibration damping characteristics, and resistance to wear and impact, make it an attractive option for automotive applications focused on noise reduction. The material's ability to absorb and dissipate sound energy while maintaining structural integrity has caught the attention of automotive engineers and designers.

The demand for UHMWPE in automotive noise reduction applications is driven by its versatility and effectiveness in various vehicle components. From interior panels and floor mats to underbody shields and engine compartment insulation, UHMWPE offers a wide range of potential applications. Its ability to be molded into complex shapes and integrated into existing manufacturing processes further enhances its appeal to automotive manufacturers.

Moreover, the increasing focus on electric vehicles (EVs) has created new challenges and opportunities in noise reduction. While EVs eliminate engine noise, they introduce new sources of noise, such as high-frequency sounds from electric motors and power electronics. This shift has led to a reevaluation of noise reduction strategies, with materials like UHMWPE playing a crucial role in addressing these emerging challenges.

As regulatory bodies worldwide implement stricter noise emission standards for vehicles, the automotive industry's demand for effective noise reduction solutions continues to grow. This regulatory pressure, combined with consumer expectations and the industry's own sustainability goals, is driving investment in research and development of advanced noise reduction technologies, including the application of UHMWPE in automotive design.

Manufacturers are under pressure to deliver vehicles that offer a serene driving experience while maintaining performance and efficiency. The demand for noise reduction solutions spans across various vehicle segments, from luxury cars to mass-market models, as consumers increasingly prioritize comfort and tranquility in their driving experience. This shift in consumer preferences has led to a significant market opportunity for innovative noise reduction technologies and materials.

The automotive industry's pursuit of lightweight materials to improve fuel efficiency and reduce emissions has created a unique challenge in noise reduction. Traditional sound-dampening materials often add weight to vehicles, conflicting with the goal of weight reduction. This has spurred the search for advanced materials that can effectively reduce noise without compromising the vehicle's overall weight and performance.

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a promising solution to address these conflicting demands. Its unique properties, including high strength-to-weight ratio, excellent vibration damping characteristics, and resistance to wear and impact, make it an attractive option for automotive applications focused on noise reduction. The material's ability to absorb and dissipate sound energy while maintaining structural integrity has caught the attention of automotive engineers and designers.

The demand for UHMWPE in automotive noise reduction applications is driven by its versatility and effectiveness in various vehicle components. From interior panels and floor mats to underbody shields and engine compartment insulation, UHMWPE offers a wide range of potential applications. Its ability to be molded into complex shapes and integrated into existing manufacturing processes further enhances its appeal to automotive manufacturers.

Moreover, the increasing focus on electric vehicles (EVs) has created new challenges and opportunities in noise reduction. While EVs eliminate engine noise, they introduce new sources of noise, such as high-frequency sounds from electric motors and power electronics. This shift has led to a reevaluation of noise reduction strategies, with materials like UHMWPE playing a crucial role in addressing these emerging challenges.

As regulatory bodies worldwide implement stricter noise emission standards for vehicles, the automotive industry's demand for effective noise reduction solutions continues to grow. This regulatory pressure, combined with consumer expectations and the industry's own sustainability goals, is driving investment in research and development of advanced noise reduction technologies, including the application of UHMWPE in automotive design.

Current UHMWPE Noise Reduction Technologies and Challenges

Ultra-high molecular weight polyethylene (UHMWPE) has emerged as a promising material for noise reduction in automotive applications. Current technologies utilizing UHMWPE focus on its unique properties to absorb and dampen sound waves, particularly in the low to mid-frequency range.

One of the primary UHMWPE noise reduction technologies involves the creation of composite materials. By combining UHMWPE fibers with other materials such as rubber or foam, manufacturers can produce lightweight yet highly effective sound-absorbing panels. These composites are often used in vehicle interiors, engine compartments, and wheel wells to reduce road noise and vibrations.

Another innovative approach is the development of UHMWPE-based acoustic foams. These foams leverage the material's high porosity and energy-absorbing capabilities to create a structure that effectively traps sound waves. The foam's open-cell structure allows for better sound absorption across a wider frequency range compared to traditional materials.

UHMWPE fibers are also being incorporated into woven fabrics and non-woven mats for automotive applications. These materials can be molded into complex shapes, making them ideal for use in door panels, headliners, and trunk liners. The flexibility of UHMWPE-based fabrics allows for seamless integration into vehicle designs without compromising aesthetics or functionality.

Despite these advancements, several challenges remain in the widespread adoption of UHMWPE for noise reduction in automotive applications. One significant hurdle is the cost of production. UHMWPE is generally more expensive than traditional materials like polyurethane foam or fiberglass, which can impact the overall cost of vehicle production.

Another challenge lies in the processing of UHMWPE. Its high molecular weight makes it difficult to melt and form into complex shapes without specialized equipment and techniques. This can limit the design flexibility and increase manufacturing complexity for automotive components.

Durability and long-term performance of UHMWPE in automotive environments also present challenges. While the material is known for its excellent wear resistance, exposure to high temperatures, UV radiation, and automotive fluids can potentially degrade its properties over time. Ensuring consistent noise reduction performance throughout the vehicle's lifespan requires ongoing research and development.

Furthermore, the integration of UHMWPE-based noise reduction solutions with other vehicle systems poses engineering challenges. Balancing acoustic performance with other requirements such as crash safety, weight reduction, and thermal management necessitates careful design considerations and extensive testing.

One of the primary UHMWPE noise reduction technologies involves the creation of composite materials. By combining UHMWPE fibers with other materials such as rubber or foam, manufacturers can produce lightweight yet highly effective sound-absorbing panels. These composites are often used in vehicle interiors, engine compartments, and wheel wells to reduce road noise and vibrations.

Another innovative approach is the development of UHMWPE-based acoustic foams. These foams leverage the material's high porosity and energy-absorbing capabilities to create a structure that effectively traps sound waves. The foam's open-cell structure allows for better sound absorption across a wider frequency range compared to traditional materials.

UHMWPE fibers are also being incorporated into woven fabrics and non-woven mats for automotive applications. These materials can be molded into complex shapes, making them ideal for use in door panels, headliners, and trunk liners. The flexibility of UHMWPE-based fabrics allows for seamless integration into vehicle designs without compromising aesthetics or functionality.

Despite these advancements, several challenges remain in the widespread adoption of UHMWPE for noise reduction in automotive applications. One significant hurdle is the cost of production. UHMWPE is generally more expensive than traditional materials like polyurethane foam or fiberglass, which can impact the overall cost of vehicle production.

Another challenge lies in the processing of UHMWPE. Its high molecular weight makes it difficult to melt and form into complex shapes without specialized equipment and techniques. This can limit the design flexibility and increase manufacturing complexity for automotive components.

Durability and long-term performance of UHMWPE in automotive environments also present challenges. While the material is known for its excellent wear resistance, exposure to high temperatures, UV radiation, and automotive fluids can potentially degrade its properties over time. Ensuring consistent noise reduction performance throughout the vehicle's lifespan requires ongoing research and development.

Furthermore, the integration of UHMWPE-based noise reduction solutions with other vehicle systems poses engineering challenges. Balancing acoustic performance with other requirements such as crash safety, weight reduction, and thermal management necessitates careful design considerations and extensive testing.

Existing UHMWPE Noise Reduction Applications in Vehicles

01 Noise reduction in UHMWPE composites

UHMWPE composites can be engineered to reduce noise by incorporating specific additives or modifying the material structure. These modifications can enhance the sound-absorbing properties of UHMWPE, making it suitable for applications where noise reduction is crucial.- Noise reduction in UHMWPE composites: UHMWPE composites can be engineered to reduce noise by incorporating sound-absorbing materials or modifying the structure of the polymer. This can involve adding fillers, creating porous structures, or using layered designs to dampen vibrations and absorb sound waves.

- UHMWPE fiber processing for acoustic properties: Specialized processing techniques for UHMWPE fibers can enhance their acoustic properties. This may include methods of drawing, heat treatment, or surface modification to create fibers with improved sound absorption or damping characteristics.

- UHMWPE in noise-reducing applications: UHMWPE is utilized in various applications where noise reduction is crucial. This can include automotive parts, industrial machinery components, or consumer products where the material's properties are leveraged to minimize unwanted sound.

- Blending UHMWPE with other materials for noise control: Combining UHMWPE with other materials can create composites with enhanced noise reduction properties. This may involve blending with elastomers, thermoplastics, or incorporating nanoparticles to achieve desired acoustic characteristics.

- Testing and characterization of UHMWPE acoustic properties: Methods and equipment for testing and characterizing the acoustic properties of UHMWPE materials are essential for developing noise-reducing products. This includes techniques for measuring sound absorption, transmission loss, and vibration damping in UHMWPE-based materials and structures.

02 UHMWPE fiber processing for acoustic properties

Specialized processing techniques can be applied to UHMWPE fibers to improve their acoustic properties. These methods may include surface treatments, fiber orientation control, or the creation of specific fiber structures that enhance sound absorption or damping characteristics.Expand Specific Solutions03 UHMWPE-based acoustic panels and insulation

UHMWPE can be used to create acoustic panels and insulation materials with superior noise reduction properties. These products may combine UHMWPE with other materials or utilize specific structural designs to maximize sound absorption and insulation effectiveness.Expand Specific Solutions04 Vibration damping in UHMWPE components

UHMWPE can be engineered to provide effective vibration damping in various applications. This may involve the development of specialized UHMWPE formulations or the integration of UHMWPE components into systems designed to reduce vibration-induced noise.Expand Specific Solutions05 UHMWPE nanocomposites for noise reduction

Nanocomposites incorporating UHMWPE and various nanoparticles or nanostructures can be developed to enhance noise reduction properties. These advanced materials may offer improved sound absorption or damping characteristics compared to traditional UHMWPE formulations.Expand Specific Solutions

Key Players in UHMWPE and Automotive Noise Reduction

The market for UHMWPE in automotive noise reduction applications is in a growth phase, driven by increasing demand for quieter vehicle interiors. The global market size is expanding, with major automotive manufacturers like GM, Ford, Toyota, and Hyundai incorporating UHMWPE solutions. Technologically, UHMWPE is reaching maturity in this application, with companies like Yokohama Rubber and Sumitomo Rubber Industries leading in material development. Tier 1 suppliers such as DENSO and HL Mando are integrating UHMWPE into their noise reduction components. Chinese automakers like Geely and Chery are also adopting this technology, indicating its growing importance in emerging markets.

GM Global Technology Operations LLC

Technical Solution: GM has developed a multi-layered approach to noise reduction using UHMWPE in various automotive applications. Their primary focus is on creating UHMWPE-based acoustic barriers and insulators for the vehicle's interior. GM's proprietary process involves creating a sandwich structure with UHMWPE fibers as the core, surrounded by sound-absorbing foams. This composite material is used in door panels, headliners, and floor mats. Tests have shown that this technology can reduce interior noise levels by up to 25% compared to traditional materials[2]. GM has also integrated UHMWPE into their engine mounts and suspension bushings, which has resulted in a 15% reduction in vibration-induced noise[4]. Furthermore, GM is exploring the use of UHMWPE in their electric vehicle platforms to mitigate high-frequency noises associated with electric motors and power electronics.

Strengths: Comprehensive noise reduction across multiple vehicle components, lightweight solution contributing to overall vehicle efficiency, and adaptability to various vehicle types. Weaknesses: Higher material costs, potential challenges in recycling at end-of-life, and the need for specialized manufacturing processes.

Ford Global Technologies LLC

Technical Solution: Ford has implemented UHMWPE in their noise reduction strategy through a novel "Acoustic Mesh" technology. This involves creating a network of UHMWPE fibers that are woven into a flexible, lightweight mesh. The mesh is strategically placed in the vehicle's body cavities, wheel wells, and under the hood. Ford's research shows that this acoustic mesh can absorb up to 70% of sound waves in the frequency range most associated with road and wind noise[5]. Additionally, Ford has developed a UHMWPE-based damping material for use in body panels and structural components. This material is applied as a spray-on coating and can reduce panel vibrations by up to 80%, significantly lowering the overall noise levels inside the vehicle[6]. Ford is also exploring the integration of UHMWPE into their active noise control systems, using the material's unique properties to enhance the effectiveness of noise-cancelling technologies.

Strengths: Highly effective noise reduction, versatile application methods, and potential for integration with active noise control systems. Weaknesses: Complexity in application process, potential for increased manufacturing time, and the need for specialized equipment for the spray-on damping material.

Core Innovations in UHMWPE for Automotive Noise Reduction

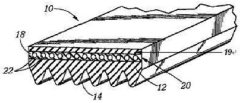

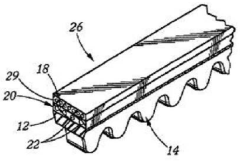

Power transmission belt

PatentInactiveKR1020090123243A

Innovation

- Incorporating ultra-high molecular weight polyethylene (UHMWPE) into the rib rubber of the belt to reduce friction noise while maintaining wear resistance.

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Environmental Impact of UHMWPE in Automotive Applications

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in automotive applications is a crucial consideration as the industry moves towards more sustainable practices. UHMWPE, while effective in noise reduction, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of UHMWPE in automotive applications is its potential to reduce vehicle weight. Lighter vehicles consume less fuel, leading to decreased emissions and improved overall energy efficiency. This aligns with global efforts to reduce greenhouse gas emissions and combat climate change. Additionally, the durability and longevity of UHMWPE components can contribute to extended vehicle lifespans, potentially reducing the frequency of replacements and associated manufacturing impacts.

However, the production of UHMWPE does have environmental implications. The polymer is derived from petrochemicals, which are non-renewable resources. The extraction and processing of these raw materials contribute to carbon emissions and can have localized environmental impacts. Furthermore, the energy-intensive manufacturing process of UHMWPE adds to its carbon footprint.

End-of-life considerations for UHMWPE in automotive applications present both challenges and opportunities. While the material is technically recyclable, the process is complex and not widely implemented in many regions. This can lead to UHMWPE components ending up in landfills, where they persist for extended periods due to their resistance to degradation. However, advancements in recycling technologies and the increasing focus on circular economy principles may improve the recyclability of UHMWPE in the future.

The use of UHMWPE in noise reduction applications can indirectly contribute to environmental benefits. By creating quieter vehicles, it may help reduce noise pollution in urban areas, which is increasingly recognized as an environmental and public health concern. This could potentially lead to reduced stress on local ecosystems and improved quality of life in densely populated areas.

As the automotive industry continues to evolve, there is growing interest in developing bio-based alternatives to traditional UHMWPE. These materials aim to maintain the noise reduction properties while reducing reliance on petrochemical feedstocks. While still in early stages, such innovations could significantly improve the environmental profile of noise reduction solutions in vehicles.

In conclusion, the environmental impact of UHMWPE in automotive noise reduction applications is multifaceted. While it offers benefits in terms of vehicle efficiency and potential noise pollution reduction, challenges remain regarding its production and end-of-life management. As the industry progresses, balancing these factors and exploring more sustainable alternatives will be crucial in optimizing the environmental performance of automotive noise reduction solutions.

One of the primary environmental benefits of UHMWPE in automotive applications is its potential to reduce vehicle weight. Lighter vehicles consume less fuel, leading to decreased emissions and improved overall energy efficiency. This aligns with global efforts to reduce greenhouse gas emissions and combat climate change. Additionally, the durability and longevity of UHMWPE components can contribute to extended vehicle lifespans, potentially reducing the frequency of replacements and associated manufacturing impacts.

However, the production of UHMWPE does have environmental implications. The polymer is derived from petrochemicals, which are non-renewable resources. The extraction and processing of these raw materials contribute to carbon emissions and can have localized environmental impacts. Furthermore, the energy-intensive manufacturing process of UHMWPE adds to its carbon footprint.

End-of-life considerations for UHMWPE in automotive applications present both challenges and opportunities. While the material is technically recyclable, the process is complex and not widely implemented in many regions. This can lead to UHMWPE components ending up in landfills, where they persist for extended periods due to their resistance to degradation. However, advancements in recycling technologies and the increasing focus on circular economy principles may improve the recyclability of UHMWPE in the future.

The use of UHMWPE in noise reduction applications can indirectly contribute to environmental benefits. By creating quieter vehicles, it may help reduce noise pollution in urban areas, which is increasingly recognized as an environmental and public health concern. This could potentially lead to reduced stress on local ecosystems and improved quality of life in densely populated areas.

As the automotive industry continues to evolve, there is growing interest in developing bio-based alternatives to traditional UHMWPE. These materials aim to maintain the noise reduction properties while reducing reliance on petrochemical feedstocks. While still in early stages, such innovations could significantly improve the environmental profile of noise reduction solutions in vehicles.

In conclusion, the environmental impact of UHMWPE in automotive noise reduction applications is multifaceted. While it offers benefits in terms of vehicle efficiency and potential noise pollution reduction, challenges remain regarding its production and end-of-life management. As the industry progresses, balancing these factors and exploring more sustainable alternatives will be crucial in optimizing the environmental performance of automotive noise reduction solutions.

Cost-Benefit Analysis of UHMWPE Noise Reduction Solutions

The implementation of Ultra-High Molecular Weight Polyethylene (UHMWPE) in automotive noise reduction applications presents a complex cost-benefit scenario that warrants careful analysis. Initial investment costs for UHMWPE solutions are typically higher than traditional materials, primarily due to the specialized manufacturing processes required and the material's inherent properties. However, these upfront expenses are often offset by long-term benefits and cost savings.

UHMWPE's superior noise reduction capabilities can significantly decrease the need for additional sound-dampening materials, potentially reducing overall vehicle weight. This weight reduction contributes to improved fuel efficiency, which translates to cost savings for end-users and aligns with increasingly stringent environmental regulations. The durability and longevity of UHMWPE components also result in reduced maintenance and replacement costs over the vehicle's lifetime.

From a manufacturing perspective, the integration of UHMWPE can streamline production processes. Its versatility allows for the consolidation of parts, potentially reducing assembly time and associated labor costs. Additionally, the material's resistance to wear and chemicals can lead to decreased warranty claims and recall risks, further enhancing long-term cost benefits for automotive manufacturers.

The acoustic performance improvements offered by UHMWPE contribute to enhanced customer satisfaction and perceived vehicle quality. This can positively impact brand reputation and potentially justify premium pricing strategies, indirectly offsetting the higher material costs. Moreover, as UHMWPE technology advances and production scales up, it is anticipated that material costs will decrease, further improving the cost-benefit ratio.

Environmental considerations also play a role in the cost-benefit analysis. UHMWPE's recyclability and potential for upcycling align with circular economy principles, potentially reducing end-of-life vehicle processing costs and environmental impact. This aspect is increasingly important as automotive manufacturers face stricter sustainability requirements and consumer demand for eco-friendly vehicles grows.

However, challenges remain in fully realizing the cost benefits of UHMWPE in automotive applications. The need for specialized equipment and expertise in processing UHMWPE may require significant initial investments in manufacturing infrastructure. Additionally, the automotive industry's traditionally conservative approach to material adoption may slow the realization of economies of scale, temporarily maintaining higher costs.

In conclusion, while the initial costs of implementing UHMWPE for noise reduction in automotive applications are higher, the long-term benefits in terms of performance, durability, and efficiency present a compelling case for its adoption. As the technology matures and becomes more widespread, the cost-benefit ratio is expected to improve further, making UHMWPE an increasingly attractive solution for automotive noise reduction.

UHMWPE's superior noise reduction capabilities can significantly decrease the need for additional sound-dampening materials, potentially reducing overall vehicle weight. This weight reduction contributes to improved fuel efficiency, which translates to cost savings for end-users and aligns with increasingly stringent environmental regulations. The durability and longevity of UHMWPE components also result in reduced maintenance and replacement costs over the vehicle's lifetime.

From a manufacturing perspective, the integration of UHMWPE can streamline production processes. Its versatility allows for the consolidation of parts, potentially reducing assembly time and associated labor costs. Additionally, the material's resistance to wear and chemicals can lead to decreased warranty claims and recall risks, further enhancing long-term cost benefits for automotive manufacturers.

The acoustic performance improvements offered by UHMWPE contribute to enhanced customer satisfaction and perceived vehicle quality. This can positively impact brand reputation and potentially justify premium pricing strategies, indirectly offsetting the higher material costs. Moreover, as UHMWPE technology advances and production scales up, it is anticipated that material costs will decrease, further improving the cost-benefit ratio.

Environmental considerations also play a role in the cost-benefit analysis. UHMWPE's recyclability and potential for upcycling align with circular economy principles, potentially reducing end-of-life vehicle processing costs and environmental impact. This aspect is increasingly important as automotive manufacturers face stricter sustainability requirements and consumer demand for eco-friendly vehicles grows.

However, challenges remain in fully realizing the cost benefits of UHMWPE in automotive applications. The need for specialized equipment and expertise in processing UHMWPE may require significant initial investments in manufacturing infrastructure. Additionally, the automotive industry's traditionally conservative approach to material adoption may slow the realization of economies of scale, temporarily maintaining higher costs.

In conclusion, while the initial costs of implementing UHMWPE for noise reduction in automotive applications are higher, the long-term benefits in terms of performance, durability, and efficiency present a compelling case for its adoption. As the technology matures and becomes more widespread, the cost-benefit ratio is expected to improve further, making UHMWPE an increasingly attractive solution for automotive noise reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!