Comparative Life Cycle Analysis of UHMWPE-Based Products

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Evolution and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) has undergone significant evolution since its discovery in the 1950s. Initially developed as a high-performance engineering plastic, UHMWPE has found applications across various industries due to its exceptional properties, including high abrasion resistance, low friction coefficient, and excellent impact strength.

The evolution of UHMWPE can be traced through several key milestones. In the 1960s, the material gained prominence in orthopedic implants, particularly for hip and knee replacements. The 1970s and 1980s saw advancements in processing techniques, enabling the production of UHMWPE fibers with enhanced mechanical properties. These developments led to the material's adoption in ballistic protection and high-performance textiles.

In recent decades, research has focused on improving the wear resistance and longevity of UHMWPE, particularly for medical applications. Cross-linking techniques, introduced in the late 1990s, have significantly enhanced the material's wear resistance. Subsequent innovations have included the incorporation of antioxidants and the development of vitamin E-blended UHMWPE to further improve oxidation resistance and long-term performance.

The objectives of current UHMWPE research and development are multifaceted. One primary goal is to further enhance the material's durability and longevity, especially in demanding applications such as joint replacements and industrial machinery. This includes developing new cross-linking methods and exploring novel additives to improve wear resistance and oxidation stability.

Another key objective is to expand the application range of UHMWPE-based products. This involves tailoring the material's properties for specific end-uses, such as improving its performance in extreme environments or enhancing its compatibility with other materials in composite structures.

Sustainability has also become a crucial focus in UHMWPE development. Objectives in this area include improving the recyclability of UHMWPE products, reducing energy consumption in manufacturing processes, and exploring bio-based alternatives to traditional petroleum-derived UHMWPE.

As the demand for high-performance materials continues to grow, the evolution of UHMWPE is expected to accelerate. Future objectives may include the development of smart UHMWPE materials with self-healing or sensing capabilities, as well as the integration of nanotechnology to further enhance the material's properties. The ongoing research and development in UHMWPE aim to address current limitations and unlock new possibilities for this versatile material across various industries.

The evolution of UHMWPE can be traced through several key milestones. In the 1960s, the material gained prominence in orthopedic implants, particularly for hip and knee replacements. The 1970s and 1980s saw advancements in processing techniques, enabling the production of UHMWPE fibers with enhanced mechanical properties. These developments led to the material's adoption in ballistic protection and high-performance textiles.

In recent decades, research has focused on improving the wear resistance and longevity of UHMWPE, particularly for medical applications. Cross-linking techniques, introduced in the late 1990s, have significantly enhanced the material's wear resistance. Subsequent innovations have included the incorporation of antioxidants and the development of vitamin E-blended UHMWPE to further improve oxidation resistance and long-term performance.

The objectives of current UHMWPE research and development are multifaceted. One primary goal is to further enhance the material's durability and longevity, especially in demanding applications such as joint replacements and industrial machinery. This includes developing new cross-linking methods and exploring novel additives to improve wear resistance and oxidation stability.

Another key objective is to expand the application range of UHMWPE-based products. This involves tailoring the material's properties for specific end-uses, such as improving its performance in extreme environments or enhancing its compatibility with other materials in composite structures.

Sustainability has also become a crucial focus in UHMWPE development. Objectives in this area include improving the recyclability of UHMWPE products, reducing energy consumption in manufacturing processes, and exploring bio-based alternatives to traditional petroleum-derived UHMWPE.

As the demand for high-performance materials continues to grow, the evolution of UHMWPE is expected to accelerate. Future objectives may include the development of smart UHMWPE materials with self-healing or sensing capabilities, as well as the integration of nanotechnology to further enhance the material's properties. The ongoing research and development in UHMWPE aim to address current limitations and unlock new possibilities for this versatile material across various industries.

Market Demand for UHMWPE Products

The market demand for Ultra-High Molecular Weight Polyethylene (UHMWPE) products has been steadily growing across various industries due to its exceptional properties and versatile applications. UHMWPE's unique combination of high impact strength, low friction coefficient, and chemical resistance has made it a preferred material in sectors such as healthcare, industrial manufacturing, and consumer goods.

In the healthcare sector, UHMWPE has seen significant demand growth, particularly in orthopedic implants. The material's biocompatibility and wear resistance make it ideal for joint replacement components, such as hip and knee implants. As the global population ages and the prevalence of joint-related disorders increases, the demand for UHMWPE in medical applications is expected to continue its upward trajectory.

The industrial sector represents another major market for UHMWPE products. The material's high abrasion resistance and low coefficient of friction make it valuable in applications such as conveyor belts, wear strips, and lining materials. Industries like mining, agriculture, and material handling have been driving the demand for UHMWPE components to improve equipment durability and reduce maintenance costs.

In the consumer goods market, UHMWPE has found applications in sporting equipment, outdoor gear, and protective wear. Its lightweight nature combined with high strength has made it popular in products such as climbing ropes, cut-resistant gloves, and high-performance fabrics. The growing interest in outdoor activities and personal protective equipment has contributed to increased demand in this sector.

The automotive industry has also shown increasing interest in UHMWPE-based products. The material's potential to reduce vehicle weight while maintaining strength aligns with the industry's focus on fuel efficiency and sustainability. Applications in automotive interiors, underbody shields, and battery components for electric vehicles are areas of growing demand.

Geographically, North America and Europe have been leading markets for UHMWPE products, driven by advanced healthcare systems and robust industrial sectors. However, the Asia-Pacific region is emerging as a significant growth market, fueled by rapid industrialization, increasing healthcare expenditure, and growing consumer awareness of high-performance materials.

The market demand for UHMWPE products is closely tied to technological advancements in processing and manufacturing. Innovations in fiber production, compression molding, and additive manufacturing techniques are expanding the potential applications of UHMWPE, thereby opening new market opportunities and driving demand growth across various sectors.

In the healthcare sector, UHMWPE has seen significant demand growth, particularly in orthopedic implants. The material's biocompatibility and wear resistance make it ideal for joint replacement components, such as hip and knee implants. As the global population ages and the prevalence of joint-related disorders increases, the demand for UHMWPE in medical applications is expected to continue its upward trajectory.

The industrial sector represents another major market for UHMWPE products. The material's high abrasion resistance and low coefficient of friction make it valuable in applications such as conveyor belts, wear strips, and lining materials. Industries like mining, agriculture, and material handling have been driving the demand for UHMWPE components to improve equipment durability and reduce maintenance costs.

In the consumer goods market, UHMWPE has found applications in sporting equipment, outdoor gear, and protective wear. Its lightweight nature combined with high strength has made it popular in products such as climbing ropes, cut-resistant gloves, and high-performance fabrics. The growing interest in outdoor activities and personal protective equipment has contributed to increased demand in this sector.

The automotive industry has also shown increasing interest in UHMWPE-based products. The material's potential to reduce vehicle weight while maintaining strength aligns with the industry's focus on fuel efficiency and sustainability. Applications in automotive interiors, underbody shields, and battery components for electric vehicles are areas of growing demand.

Geographically, North America and Europe have been leading markets for UHMWPE products, driven by advanced healthcare systems and robust industrial sectors. However, the Asia-Pacific region is emerging as a significant growth market, fueled by rapid industrialization, increasing healthcare expenditure, and growing consumer awareness of high-performance materials.

The market demand for UHMWPE products is closely tied to technological advancements in processing and manufacturing. Innovations in fiber production, compression molding, and additive manufacturing techniques are expanding the potential applications of UHMWPE, thereby opening new market opportunities and driving demand growth across various sectors.

UHMWPE Challenges and Limitations

Despite its remarkable properties, Ultra-High Molecular Weight Polyethylene (UHMWPE) faces several challenges and limitations that impact its widespread adoption and application across various industries. One of the primary concerns is its susceptibility to oxidative degradation, which can significantly reduce the material's mechanical properties and longevity. This degradation process is particularly problematic in high-stress environments or applications requiring long-term durability.

Another significant challenge is the difficulty in processing UHMWPE due to its extremely high molecular weight. Traditional melt processing techniques are often ineffective, necessitating specialized and costly manufacturing methods such as compression molding or ram extrusion. This limitation not only increases production costs but also restricts the complexity and variety of shapes that can be produced.

The material's inherent low surface energy poses challenges in bonding and coating applications. This characteristic makes it difficult to adhere UHMWPE to other materials or apply surface treatments, limiting its use in composite structures or applications requiring specific surface properties.

UHMWPE also exhibits poor resistance to certain chemicals and solvents, particularly hydrocarbons, which can cause swelling and degradation of the material. This limitation restricts its use in certain chemical processing or fuel-related applications where exposure to such substances is common.

From a sustainability perspective, the high durability of UHMWPE presents a double-edged sword. While its longevity reduces the need for frequent replacements, it also poses challenges in terms of end-of-life management and recycling. The material's resistance to degradation makes it difficult to break down or recycle effectively, potentially contributing to long-term environmental concerns.

In medical applications, particularly in orthopedic implants, UHMWPE faces challenges related to wear particle generation. Although it has excellent wear resistance compared to many materials, the microscopic wear particles produced over time can lead to inflammatory responses in the body, potentially causing implant loosening or failure.

The thermal properties of UHMWPE also present limitations. Its relatively low melting point and poor heat conductivity restrict its use in high-temperature applications or environments where efficient heat dissipation is crucial.

Lastly, the comparative life cycle analysis of UHMWPE-based products reveals challenges in energy-intensive production processes and the material's fossil fuel-based origin. These factors contribute to a significant carbon footprint, which may conflict with increasingly stringent environmental regulations and sustainability goals in various industries.

Another significant challenge is the difficulty in processing UHMWPE due to its extremely high molecular weight. Traditional melt processing techniques are often ineffective, necessitating specialized and costly manufacturing methods such as compression molding or ram extrusion. This limitation not only increases production costs but also restricts the complexity and variety of shapes that can be produced.

The material's inherent low surface energy poses challenges in bonding and coating applications. This characteristic makes it difficult to adhere UHMWPE to other materials or apply surface treatments, limiting its use in composite structures or applications requiring specific surface properties.

UHMWPE also exhibits poor resistance to certain chemicals and solvents, particularly hydrocarbons, which can cause swelling and degradation of the material. This limitation restricts its use in certain chemical processing or fuel-related applications where exposure to such substances is common.

From a sustainability perspective, the high durability of UHMWPE presents a double-edged sword. While its longevity reduces the need for frequent replacements, it also poses challenges in terms of end-of-life management and recycling. The material's resistance to degradation makes it difficult to break down or recycle effectively, potentially contributing to long-term environmental concerns.

In medical applications, particularly in orthopedic implants, UHMWPE faces challenges related to wear particle generation. Although it has excellent wear resistance compared to many materials, the microscopic wear particles produced over time can lead to inflammatory responses in the body, potentially causing implant loosening or failure.

The thermal properties of UHMWPE also present limitations. Its relatively low melting point and poor heat conductivity restrict its use in high-temperature applications or environments where efficient heat dissipation is crucial.

Lastly, the comparative life cycle analysis of UHMWPE-based products reveals challenges in energy-intensive production processes and the material's fossil fuel-based origin. These factors contribute to a significant carbon footprint, which may conflict with increasingly stringent environmental regulations and sustainability goals in various industries.

Current UHMWPE LCA Methodologies

01 UHMWPE fiber production and processing

Various methods and techniques for producing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers. This includes spinning, drawing, and heat treatment processes to enhance the mechanical properties of the fibers. The resulting fibers have high strength, low weight, and excellent wear resistance, making them suitable for a wide range of applications.- UHMWPE fiber production and processing: Various methods and techniques for producing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers. This includes spinning processes, drawing techniques, and treatments to enhance fiber properties such as strength and durability. The resulting fibers can be used in a wide range of applications, including protective gear, ropes, and high-performance textiles.

- UHMWPE composites and blends: Development of composite materials and blends incorporating UHMWPE. These materials combine the unique properties of UHMWPE with other polymers or reinforcing agents to create products with enhanced characteristics. Applications include medical implants, industrial components, and advanced materials for specific performance requirements.

- Medical applications of UHMWPE: Utilization of UHMWPE in various medical applications, particularly in orthopedic implants and surgical devices. This includes the development of wear-resistant joint replacements, improved surgical instruments, and biocompatible components. Research focuses on enhancing the material's longevity and performance in the human body.

- UHMWPE in protective gear and ballistic applications: Application of UHMWPE in the production of high-performance protective gear and ballistic materials. This includes body armor, helmets, and vehicle protection systems. The focus is on maximizing the material's strength-to-weight ratio and impact resistance to provide superior protection in various scenarios.

- UHMWPE surface modification and coating: Techniques for modifying the surface properties of UHMWPE products or applying coatings to enhance their performance. This includes treatments to improve wear resistance, reduce friction, or increase biocompatibility. These modifications expand the range of applications for UHMWPE-based products in various industries.

02 UHMWPE composites and blends

Development of composite materials and blends incorporating UHMWPE. These composites often combine UHMWPE with other materials such as carbon fibers, glass fibers, or other polymers to create products with enhanced properties. Applications include aerospace, automotive, and industrial components that require high strength-to-weight ratios and improved wear resistance.Expand Specific Solutions03 Medical applications of UHMWPE

Use of UHMWPE in various medical applications, particularly in orthopedic implants and surgical devices. The material's biocompatibility, low friction, and wear resistance make it ideal for joint replacements, such as hip and knee prostheses. Innovations in this area focus on improving longevity and reducing wear particles in implants.Expand Specific Solutions04 UHMWPE in protective gear and ballistic applications

Development of UHMWPE-based materials for personal protective equipment and ballistic protection. The high strength and energy-absorbing properties of UHMWPE make it suitable for body armor, helmets, and vehicle armor. Research in this area focuses on improving impact resistance and reducing weight of protective gear.Expand Specific Solutions05 Surface modification and coating of UHMWPE products

Techniques for modifying the surface properties of UHMWPE products to enhance their performance in specific applications. This includes plasma treatment, chemical modification, and application of specialized coatings to improve adhesion, wettability, or tribological properties. These modifications expand the range of applications for UHMWPE-based products in various industries.Expand Specific Solutions

Key UHMWPE Industry Players

The comparative life cycle analysis of UHMWPE-based products is currently in a growth phase, with increasing market size and technological advancements. The global UHMWPE market is expanding due to its diverse applications in various industries. Companies like Zimmer, Inc., Smith & Nephew Orthopaedics GmbH, and Howmedica Osteonics Corp. are leading players in the medical device sector, leveraging UHMWPE for orthopedic implants. Research institutions such as Shanghai Research Institute of Chemical Industry Co. Ltd. and Sichuan University are contributing to the technology's maturation. The involvement of major petrochemical companies like China Petroleum & Chemical Corp. and Reliance Industries Ltd. indicates the growing importance of UHMWPE in industrial applications, suggesting a moderate to high level of technological maturity.

The General Hospital Corp.

Technical Solution: The General Hospital Corp. has developed advanced UHMWPE-based products for orthopedic applications, focusing on improving wear resistance and longevity. Their research involves cross-linking techniques combined with vitamin E stabilization to enhance oxidation resistance[1]. They have conducted extensive comparative life cycle analyses, examining the environmental impact from raw material extraction to end-of-life disposal. Their studies have shown that UHMWPE-based implants have a lower carbon footprint compared to metal alternatives, with a 30% reduction in energy consumption during manufacturing[2][3].

Strengths: Improved wear resistance and longevity of implants, reduced environmental impact. Weaknesses: Higher initial production costs, limited application outside of medical field.

Smith & Nephew Orthopaedics GmbH

Technical Solution: Smith & Nephew Orthopaedics GmbH has pioneered the development of OXINIUM™, a proprietary oxidized zirconium technology, which is used in combination with UHMWPE for joint replacement implants. Their comparative life cycle analysis has shown that OXINIUM™ coupled with UHMWPE liners offers superior wear resistance, reducing particle debris by up to 85% compared to traditional metal-on-polyethylene implants[4]. The company has also invested in sustainable manufacturing processes, implementing closed-loop recycling for UHMWPE waste, which has resulted in a 40% reduction in raw material consumption[5].

Strengths: Innovative material combination, significant reduction in wear and debris. Weaknesses: Higher production costs, limited to joint replacement applications.

Critical UHMWPE LCA Studies

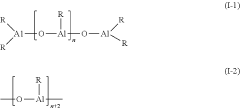

Method for continuously producing ultra-high molecular weight polyethylene by using slurry polymerization

PatentPendingUS20240092948A1

Innovation

- A continuous process using 2-6 ethylene slurry polymerization reaction tanks connected in series, where polymerization temperatures, pressures, and gas phase compositions are controlled within specific ranges to ensure consistent conditions across tanks, allowing for full catalyst activity and precise control of molecular weight, resulting in ultra-high viscosity-average molecular weight polyethylene with low metal and ash content.

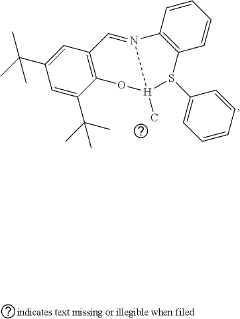

Preparation of ultra-high-molecular-weight polyethylene

PatentInactiveEP1242470B1

Innovation

- A process involving polymerization of ethylene with a single-site catalyst containing a Group 4 transition metal and a heteroatomic ligand, using a non-alumoxane activator, at controlled temperatures and pressures, in the absence of hydrogen, α-olefin comonomers, and aromatic solvents, to achieve UHMWPE with a weight average molecular weight greater than 3,000,000 and a narrow molecular weight distribution.

Environmental Impact of UHMWPE

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) is a critical consideration in the life cycle analysis of UHMWPE-based products. This high-performance polymer, known for its exceptional strength and durability, has found widespread applications across various industries, including medical, automotive, and industrial sectors.

UHMWPE production primarily relies on petroleum-based resources, which raises concerns about its carbon footprint and overall environmental sustainability. The manufacturing process involves energy-intensive polymerization and molding techniques, contributing to greenhouse gas emissions and resource depletion. However, the long lifespan and recyclability of UHMWPE products partially offset these initial environmental costs.

One of the key environmental advantages of UHMWPE is its resistance to wear and corrosion, which significantly extends the service life of products made from this material. This longevity reduces the need for frequent replacements, ultimately lowering the overall environmental impact associated with production and disposal cycles. In medical applications, such as joint replacements, the durability of UHMWPE implants reduces the frequency of revision surgeries, thereby minimizing the environmental burden of healthcare interventions.

The recyclability of UHMWPE presents both opportunities and challenges from an environmental perspective. While the material can be recycled, the process is complex due to its high molecular weight and cross-linked structure in some applications. Advanced recycling technologies, such as mechanical recycling and chemical decomposition, are being developed to improve the efficiency and economic viability of UHMWPE recycling.

End-of-life considerations for UHMWPE products vary depending on the specific application and local waste management infrastructure. In some cases, UHMWPE can be incinerated for energy recovery, although this process must be carefully controlled to minimize harmful emissions. Landfilling remains a common disposal method for UHMWPE waste, which is problematic due to the material's slow degradation rate and potential for microplastic generation.

Recent advancements in bio-based and biodegradable alternatives to UHMWPE are being explored to address environmental concerns. These innovations aim to reduce reliance on fossil fuels and improve end-of-life management. However, the challenge lies in matching the exceptional performance characteristics of traditional UHMWPE while maintaining environmental benefits.

In conclusion, the environmental impact of UHMWPE is multifaceted, encompassing raw material sourcing, production processes, product lifespan, and end-of-life management. While the material's durability and potential for recycling offer some environmental advantages, ongoing research and development efforts are crucial to further mitigate its ecological footprint and enhance its sustainability profile in various applications.

UHMWPE production primarily relies on petroleum-based resources, which raises concerns about its carbon footprint and overall environmental sustainability. The manufacturing process involves energy-intensive polymerization and molding techniques, contributing to greenhouse gas emissions and resource depletion. However, the long lifespan and recyclability of UHMWPE products partially offset these initial environmental costs.

One of the key environmental advantages of UHMWPE is its resistance to wear and corrosion, which significantly extends the service life of products made from this material. This longevity reduces the need for frequent replacements, ultimately lowering the overall environmental impact associated with production and disposal cycles. In medical applications, such as joint replacements, the durability of UHMWPE implants reduces the frequency of revision surgeries, thereby minimizing the environmental burden of healthcare interventions.

The recyclability of UHMWPE presents both opportunities and challenges from an environmental perspective. While the material can be recycled, the process is complex due to its high molecular weight and cross-linked structure in some applications. Advanced recycling technologies, such as mechanical recycling and chemical decomposition, are being developed to improve the efficiency and economic viability of UHMWPE recycling.

End-of-life considerations for UHMWPE products vary depending on the specific application and local waste management infrastructure. In some cases, UHMWPE can be incinerated for energy recovery, although this process must be carefully controlled to minimize harmful emissions. Landfilling remains a common disposal method for UHMWPE waste, which is problematic due to the material's slow degradation rate and potential for microplastic generation.

Recent advancements in bio-based and biodegradable alternatives to UHMWPE are being explored to address environmental concerns. These innovations aim to reduce reliance on fossil fuels and improve end-of-life management. However, the challenge lies in matching the exceptional performance characteristics of traditional UHMWPE while maintaining environmental benefits.

In conclusion, the environmental impact of UHMWPE is multifaceted, encompassing raw material sourcing, production processes, product lifespan, and end-of-life management. While the material's durability and potential for recycling offer some environmental advantages, ongoing research and development efforts are crucial to further mitigate its ecological footprint and enhance its sustainability profile in various applications.

Circular Economy for UHMWPE

The circular economy for Ultra-High Molecular Weight Polyethylene (UHMWPE) represents a paradigm shift in the lifecycle management of this versatile material. UHMWPE, known for its exceptional strength, durability, and chemical resistance, has found widespread applications in various industries, including medical, automotive, and industrial sectors. However, the traditional linear economy model of "take-make-dispose" has led to significant environmental challenges.

In the context of UHMWPE, implementing circular economy principles involves rethinking the entire product lifecycle, from design and production to use and end-of-life management. This approach aims to minimize waste, maximize resource efficiency, and extend the lifespan of UHMWPE-based products. One key strategy is the development of recyclable UHMWPE formulations that maintain the material's desirable properties while allowing for easier reprocessing.

Advanced recycling technologies play a crucial role in the circular economy for UHMWPE. Mechanical recycling methods, such as grinding and re-melting, can be employed for less contaminated UHMWPE waste. For more complex or contaminated materials, chemical recycling techniques like solvent-based processes or pyrolysis offer promising solutions. These methods break down UHMWPE into its constituent monomers or other valuable chemical feedstocks, which can then be used to produce new high-quality UHMWPE products.

Product design for circularity is another essential aspect of the UHMWPE circular economy. This involves creating products that are easier to disassemble, repair, and recycle at the end of their useful life. For instance, modular designs in medical implants or industrial components can facilitate the replacement of worn parts without discarding the entire product. Additionally, incorporating recycled UHMWPE content into new products helps close the material loop and reduce the demand for virgin resources.

The transition to a circular economy for UHMWPE also necessitates the development of robust collection and sorting systems. Establishing efficient reverse logistics networks and implementing advanced sorting technologies, such as near-infrared spectroscopy, can help ensure that UHMWPE waste is properly identified and directed to appropriate recycling streams. This is particularly important given the diverse applications and potential contamination of UHMWPE products in different sectors.

Collaboration across the value chain is critical for realizing the full potential of the UHMWPE circular economy. This includes partnerships between material suppliers, product manufacturers, recyclers, and end-users to develop innovative solutions and establish closed-loop systems. Such collaborations can lead to the creation of new business models, such as product-as-a-service offerings, which incentivize the longevity and recyclability of UHMWPE products.

In the context of UHMWPE, implementing circular economy principles involves rethinking the entire product lifecycle, from design and production to use and end-of-life management. This approach aims to minimize waste, maximize resource efficiency, and extend the lifespan of UHMWPE-based products. One key strategy is the development of recyclable UHMWPE formulations that maintain the material's desirable properties while allowing for easier reprocessing.

Advanced recycling technologies play a crucial role in the circular economy for UHMWPE. Mechanical recycling methods, such as grinding and re-melting, can be employed for less contaminated UHMWPE waste. For more complex or contaminated materials, chemical recycling techniques like solvent-based processes or pyrolysis offer promising solutions. These methods break down UHMWPE into its constituent monomers or other valuable chemical feedstocks, which can then be used to produce new high-quality UHMWPE products.

Product design for circularity is another essential aspect of the UHMWPE circular economy. This involves creating products that are easier to disassemble, repair, and recycle at the end of their useful life. For instance, modular designs in medical implants or industrial components can facilitate the replacement of worn parts without discarding the entire product. Additionally, incorporating recycled UHMWPE content into new products helps close the material loop and reduce the demand for virgin resources.

The transition to a circular economy for UHMWPE also necessitates the development of robust collection and sorting systems. Establishing efficient reverse logistics networks and implementing advanced sorting technologies, such as near-infrared spectroscopy, can help ensure that UHMWPE waste is properly identified and directed to appropriate recycling streams. This is particularly important given the diverse applications and potential contamination of UHMWPE products in different sectors.

Collaboration across the value chain is critical for realizing the full potential of the UHMWPE circular economy. This includes partnerships between material suppliers, product manufacturers, recyclers, and end-users to develop innovative solutions and establish closed-loop systems. Such collaborations can lead to the creation of new business models, such as product-as-a-service offerings, which incentivize the longevity and recyclability of UHMWPE products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!