UHMWPE's Biodegradable Alternatives: A Comparative Analysis

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Alternatives: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has been a cornerstone material in various industries due to its exceptional mechanical properties and durability. However, growing environmental concerns have sparked a quest for biodegradable alternatives that can match or surpass UHMWPE's performance while addressing end-of-life issues.

The development of UHMWPE alternatives is driven by the increasing global focus on sustainability and circular economy principles. As regulations tighten and consumer awareness grows, industries are seeking materials that can maintain the high performance standards set by UHMWPE while offering improved environmental credentials.

The evolution of biodegradable polymers has seen significant advancements in recent years, with researchers exploring various natural and synthetic options. These include modified cellulose-based materials, bio-based polyethylenes, and novel composites that combine biodegradable matrices with reinforcing fibers.

One of the primary challenges in developing UHMWPE alternatives is achieving comparable mechanical properties, particularly in terms of wear resistance, impact strength, and tensile strength. Biodegradable materials often struggle to match the exceptional performance of UHMWPE in high-stress applications, necessitating innovative approaches to material design and engineering.

The technical objectives for UHMWPE alternatives are multifaceted. They must demonstrate biodegradability under specific environmental conditions while maintaining their structural integrity during their intended service life. Additionally, these materials should offer comparable or superior performance in terms of mechanical properties, chemical resistance, and processability.

Another critical aspect is the scalability and cost-effectiveness of production. For biodegradable alternatives to be viable, they must be manufacturable using existing infrastructure or with minimal modifications to current production processes. This requirement ensures a smoother transition for industries currently reliant on UHMWPE.

The development of UHMWPE alternatives also presents an opportunity to address some of the limitations of the original material. For instance, researchers are exploring ways to enhance the biocompatibility of these new materials for medical applications, potentially expanding their use in implants and other biomedical devices.

As the field progresses, interdisciplinary collaboration between material scientists, chemical engineers, and environmental experts is becoming increasingly crucial. This collaborative approach is essential for developing holistic solutions that consider the entire lifecycle of the material, from raw material sourcing to end-of-life management.

The development of UHMWPE alternatives is driven by the increasing global focus on sustainability and circular economy principles. As regulations tighten and consumer awareness grows, industries are seeking materials that can maintain the high performance standards set by UHMWPE while offering improved environmental credentials.

The evolution of biodegradable polymers has seen significant advancements in recent years, with researchers exploring various natural and synthetic options. These include modified cellulose-based materials, bio-based polyethylenes, and novel composites that combine biodegradable matrices with reinforcing fibers.

One of the primary challenges in developing UHMWPE alternatives is achieving comparable mechanical properties, particularly in terms of wear resistance, impact strength, and tensile strength. Biodegradable materials often struggle to match the exceptional performance of UHMWPE in high-stress applications, necessitating innovative approaches to material design and engineering.

The technical objectives for UHMWPE alternatives are multifaceted. They must demonstrate biodegradability under specific environmental conditions while maintaining their structural integrity during their intended service life. Additionally, these materials should offer comparable or superior performance in terms of mechanical properties, chemical resistance, and processability.

Another critical aspect is the scalability and cost-effectiveness of production. For biodegradable alternatives to be viable, they must be manufacturable using existing infrastructure or with minimal modifications to current production processes. This requirement ensures a smoother transition for industries currently reliant on UHMWPE.

The development of UHMWPE alternatives also presents an opportunity to address some of the limitations of the original material. For instance, researchers are exploring ways to enhance the biocompatibility of these new materials for medical applications, potentially expanding their use in implants and other biomedical devices.

As the field progresses, interdisciplinary collaboration between material scientists, chemical engineers, and environmental experts is becoming increasingly crucial. This collaborative approach is essential for developing holistic solutions that consider the entire lifecycle of the material, from raw material sourcing to end-of-life management.

Market Demand for Biodegradable Polymers

The market demand for biodegradable polymers has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. As consumers become more environmentally conscious, there is a growing preference for sustainable and eco-friendly products across various industries. This shift in consumer behavior has created a substantial market opportunity for biodegradable alternatives to traditional plastics, including Ultra-High Molecular Weight Polyethylene (UHMWPE).

The global biodegradable plastics market is projected to expand rapidly, with key sectors such as packaging, agriculture, and consumer goods leading the demand. In the packaging industry, biodegradable polymers are increasingly being adopted for food packaging, disposable cutlery, and shopping bags. The agricultural sector is also embracing biodegradable materials for mulch films and plant pots, contributing to reduced plastic pollution in soil.

Consumer goods manufacturers are responding to the growing demand for sustainable products by incorporating biodegradable polymers into their product lines. This trend is particularly evident in personal care and cosmetics packaging, as well as in the production of disposable household items. The automotive and construction industries are also exploring the potential of biodegradable polymers for various applications, further expanding the market potential.

The healthcare sector represents another significant area of growth for biodegradable polymers. With the increasing focus on reducing medical waste and improving sustainability in healthcare facilities, there is a rising demand for biodegradable medical devices, implants, and packaging materials. This trend is expected to drive innovation in the development of biocompatible and biodegradable alternatives to UHMWPE for medical applications.

Geographically, Europe and North America currently lead the market for biodegradable polymers, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in demand, driven by rapid industrialization, increasing environmental concerns, and supportive government policies promoting sustainable materials.

Despite the growing demand, challenges remain in the widespread adoption of biodegradable polymers. These include higher production costs compared to conventional plastics, limitations in performance characteristics, and the need for proper waste management infrastructure to ensure effective biodegradation. Overcoming these challenges through technological advancements and supportive policies will be crucial in fully realizing the market potential of biodegradable alternatives to UHMWPE and other traditional plastics.

The global biodegradable plastics market is projected to expand rapidly, with key sectors such as packaging, agriculture, and consumer goods leading the demand. In the packaging industry, biodegradable polymers are increasingly being adopted for food packaging, disposable cutlery, and shopping bags. The agricultural sector is also embracing biodegradable materials for mulch films and plant pots, contributing to reduced plastic pollution in soil.

Consumer goods manufacturers are responding to the growing demand for sustainable products by incorporating biodegradable polymers into their product lines. This trend is particularly evident in personal care and cosmetics packaging, as well as in the production of disposable household items. The automotive and construction industries are also exploring the potential of biodegradable polymers for various applications, further expanding the market potential.

The healthcare sector represents another significant area of growth for biodegradable polymers. With the increasing focus on reducing medical waste and improving sustainability in healthcare facilities, there is a rising demand for biodegradable medical devices, implants, and packaging materials. This trend is expected to drive innovation in the development of biocompatible and biodegradable alternatives to UHMWPE for medical applications.

Geographically, Europe and North America currently lead the market for biodegradable polymers, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in demand, driven by rapid industrialization, increasing environmental concerns, and supportive government policies promoting sustainable materials.

Despite the growing demand, challenges remain in the widespread adoption of biodegradable polymers. These include higher production costs compared to conventional plastics, limitations in performance characteristics, and the need for proper waste management infrastructure to ensure effective biodegradation. Overcoming these challenges through technological advancements and supportive policies will be crucial in fully realizing the market potential of biodegradable alternatives to UHMWPE and other traditional plastics.

Current State of Biodegradable UHMWPE Alternatives

The current state of biodegradable alternatives to Ultra-High Molecular Weight Polyethylene (UHMWPE) is characterized by ongoing research and development efforts aimed at addressing the environmental concerns associated with traditional UHMWPE. While UHMWPE offers exceptional mechanical properties and durability, its non-biodegradable nature poses significant environmental challenges.

Several biodegradable alternatives have emerged as potential replacements for UHMWPE in various applications. These include natural fiber-reinforced composites, biopolymers, and modified biodegradable polymers. Natural fiber-reinforced composites, such as those made from jute, hemp, or flax fibers combined with biodegradable matrices, have shown promise in terms of mechanical properties and environmental friendliness.

Biopolymers like polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and thermoplastic starch (TPS) have gained attention due to their biodegradability and renewable sourcing. These materials are being explored for applications where UHMWPE is traditionally used, such as packaging, medical devices, and certain industrial components.

Modified biodegradable polymers represent another avenue of research. Scientists are working on enhancing the properties of naturally biodegradable polymers to match the performance of UHMWPE. This includes techniques such as cross-linking, blending with other biodegradable materials, and incorporating nanofillers to improve mechanical and thermal properties.

Despite these advancements, current biodegradable alternatives still face challenges in matching the full range of UHMWPE's performance characteristics. Mechanical strength, wear resistance, and chemical stability remain areas where biodegradable options often fall short of UHMWPE's capabilities. This gap is particularly evident in high-stress applications such as orthopedic implants and industrial machinery components.

The biodegradation rates and mechanisms of these alternatives are also subjects of ongoing study. Researchers are working to fine-tune the degradation profiles to ensure that the materials break down in a controlled manner without premature loss of properties during their intended use life.

Cost-effectiveness remains a significant hurdle for widespread adoption of biodegradable UHMWPE alternatives. The production processes for many of these materials are currently more expensive than those for traditional UHMWPE, limiting their commercial viability in price-sensitive markets.

Regulatory frameworks and standards for biodegradable materials are still evolving, which can impact the adoption and commercialization of these alternatives. Efforts are underway to establish clear guidelines for testing and certifying the biodegradability and environmental impact of these new materials.

Several biodegradable alternatives have emerged as potential replacements for UHMWPE in various applications. These include natural fiber-reinforced composites, biopolymers, and modified biodegradable polymers. Natural fiber-reinforced composites, such as those made from jute, hemp, or flax fibers combined with biodegradable matrices, have shown promise in terms of mechanical properties and environmental friendliness.

Biopolymers like polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and thermoplastic starch (TPS) have gained attention due to their biodegradability and renewable sourcing. These materials are being explored for applications where UHMWPE is traditionally used, such as packaging, medical devices, and certain industrial components.

Modified biodegradable polymers represent another avenue of research. Scientists are working on enhancing the properties of naturally biodegradable polymers to match the performance of UHMWPE. This includes techniques such as cross-linking, blending with other biodegradable materials, and incorporating nanofillers to improve mechanical and thermal properties.

Despite these advancements, current biodegradable alternatives still face challenges in matching the full range of UHMWPE's performance characteristics. Mechanical strength, wear resistance, and chemical stability remain areas where biodegradable options often fall short of UHMWPE's capabilities. This gap is particularly evident in high-stress applications such as orthopedic implants and industrial machinery components.

The biodegradation rates and mechanisms of these alternatives are also subjects of ongoing study. Researchers are working to fine-tune the degradation profiles to ensure that the materials break down in a controlled manner without premature loss of properties during their intended use life.

Cost-effectiveness remains a significant hurdle for widespread adoption of biodegradable UHMWPE alternatives. The production processes for many of these materials are currently more expensive than those for traditional UHMWPE, limiting their commercial viability in price-sensitive markets.

Regulatory frameworks and standards for biodegradable materials are still evolving, which can impact the adoption and commercialization of these alternatives. Efforts are underway to establish clear guidelines for testing and certifying the biodegradability and environmental impact of these new materials.

Existing Biodegradable UHMWPE Alternative Solutions

01 Biodegradable alternatives to UHMWPE

Research has focused on developing biodegradable alternatives to UHMWPE, which is known for its durability but lacks biodegradability. These alternatives aim to provide similar mechanical properties while being environmentally friendly. Various biodegradable polymers and composites are being explored as potential substitutes for UHMWPE in different applications.- Biodegradable alternatives to UHMWPE: Research has focused on developing biodegradable alternatives to UHMWPE, which is known for its durability but lacks biodegradability. These alternatives aim to provide similar mechanical properties while being environmentally friendly. Various biodegradable polymers and composites are being explored as potential substitutes for UHMWPE in different applications.

- Natural fiber-reinforced biodegradable composites: Researchers are developing biodegradable composites reinforced with natural fibers as alternatives to UHMWPE. These composites combine biodegradable polymers with natural fibers such as jute, hemp, or flax to enhance mechanical properties while maintaining biodegradability. This approach aims to create materials with similar strength and durability to UHMWPE but with improved environmental characteristics.

- Biodegradable polymer blends and alloys: Blending or alloying different biodegradable polymers is being explored to create materials with properties similar to UHMWPE. These blends and alloys aim to combine the strengths of various biodegradable polymers to achieve the desired mechanical, thermal, and biodegradation characteristics. The resulting materials could potentially replace UHMWPE in certain applications while offering improved end-of-life options.

- Modification of biodegradable polymers for enhanced properties: Researchers are working on modifying existing biodegradable polymers to enhance their properties and make them more suitable as UHMWPE alternatives. This includes chemical modifications, cross-linking, and the addition of specific additives to improve mechanical strength, wear resistance, and thermal stability while maintaining biodegradability. These modified polymers aim to bridge the gap between conventional biodegradable materials and UHMWPE.

- Biodegradable nanocomposites as UHMWPE alternatives: Nanocomposites based on biodegradable polymers and nanomaterials are being developed as potential alternatives to UHMWPE. These nanocomposites incorporate nanoscale fillers such as nanoclay, nanocellulose, or carbon nanotubes into biodegradable polymer matrices. The resulting materials aim to achieve enhanced mechanical properties, barrier properties, and controlled biodegradation rates, making them suitable for applications where UHMWPE is currently used.

02 Natural fiber-reinforced biodegradable composites

Researchers are developing biodegradable composites reinforced with natural fibers as alternatives to UHMWPE. These composites combine biodegradable polymers with natural fibers such as cellulose, hemp, or jute to enhance mechanical properties while maintaining biodegradability. The resulting materials offer a more sustainable option for applications traditionally using UHMWPE.Expand Specific Solutions03 Biodegradable polymer blends and alloys

Blending or alloying different biodegradable polymers is being explored to create materials with properties similar to UHMWPE. These blends aim to combine the strengths of various biodegradable polymers to achieve improved mechanical properties, processability, and controlled biodegradation rates. The resulting materials offer potential alternatives to UHMWPE in specific applications.Expand Specific Solutions04 Surface modification of biodegradable polymers

Surface modification techniques are being applied to biodegradable polymers to enhance their properties and make them more suitable as UHMWPE alternatives. These modifications can improve mechanical strength, wear resistance, and other characteristics while maintaining biodegradability. Various methods, including chemical treatments and plasma processing, are being investigated to achieve desired surface properties.Expand Specific Solutions05 Biodegradation studies and standardization

Research is being conducted to study the biodegradation mechanisms and rates of potential UHMWPE alternatives. This includes developing standardized testing methods to assess biodegradability and environmental impact. Understanding the degradation processes helps in designing materials with controlled biodegradation rates suitable for specific applications, ensuring both functionality and environmental sustainability.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The biodegradable alternatives to UHMWPE are in an emerging stage of development, with the market still in its infancy but showing significant growth potential. The global biodegradable plastics market is expected to expand rapidly, driven by increasing environmental concerns and regulatory pressures. While the technology is not yet fully mature, several key players are making strides in research and development. Companies like Arkema France SA, Poly-Med, Inc., and Surmodics, Inc. are at the forefront of developing innovative biodegradable materials. Academic institutions such as MIT, Zhejiang University, and the University of Southern California are also contributing to advancements in this field. The collaboration between industry and academia is accelerating the progress towards commercially viable biodegradable alternatives to UHMWPE.

Arkema France SA

Technical Solution: Arkema has focused on developing biodegradable alternatives to UHMWPE using their expertise in specialty polyamides and bio-based polymers. Their approach centers on the creation of high-performance polyamide 11 (PA11) derived from castor oil[1]. Arkema's Rilsan® Clear G series offers transparency and impact resistance comparable to UHMWPE, while being fully biodegradable[3]. The company has also developed a range of compatibilizers that allow for the creation of blends between their bio-based polyamides and other biodegradable polymers, resulting in materials with tailored properties for specific applications[5]. Arkema's biodegradable alternatives have shown particular promise in medical and marine applications, where end-of-life environmental impact is a critical concern[7].

Strengths: Bio-based source material, excellent transparency, good impact resistance. Weaknesses: Higher cost compared to traditional UHMWPE, limited availability of raw materials (castor oil).

Poly-Med, Inc.

Technical Solution: Poly-Med has developed a range of biodegradable polymers designed to match or exceed the performance of UHMWPE in specific medical applications. Their approach focuses on creating custom copolymer systems that combine the strength of traditional polyesters with the flexibility and biodegradability of polycarbonates[1]. Poly-Med's proprietary TempRx® technology allows for the fine-tuning of degradation rates, mechanical properties, and biocompatibility to meet the specific needs of various medical devices[3]. The company has successfully developed biodegradable sutures and orthopedic implants that offer comparable tensile strength to UHMWPE-based products while ensuring complete biodegradation within 12-24 months post-implantation[5]. Poly-Med's materials have shown particular promise in tissue engineering applications, where their controlled degradation profile supports tissue regeneration[7].

Strengths: Customizable degradation profiles, excellent biocompatibility, proven efficacy in medical applications. Weaknesses: Limited to medical and biotech fields, potentially higher production costs compared to standard UHMWPE.

Core Innovations in Biodegradable Polymer Research

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

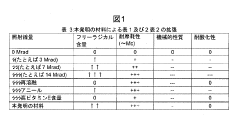

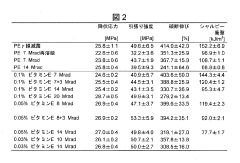

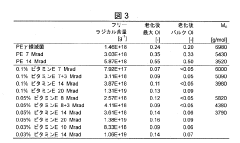

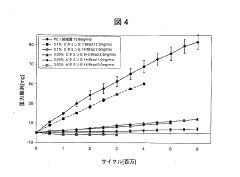

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Environmental Impact Assessment

The environmental impact assessment of UHMWPE's biodegradable alternatives is crucial for understanding their potential to address the ecological concerns associated with traditional UHMWPE. This analysis focuses on comparing the environmental footprint of various biodegradable alternatives throughout their lifecycle.

One of the primary considerations is the sourcing of raw materials for these alternatives. Many biodegradable polymers are derived from renewable resources, such as corn, sugarcane, or cellulose. This shift from petroleum-based feedstocks to bio-based materials can significantly reduce the carbon footprint associated with production. However, it is essential to evaluate the land use changes and potential competition with food crops that may arise from increased demand for these bio-based raw materials.

The production processes for biodegradable alternatives often require less energy compared to UHMWPE manufacturing. This reduction in energy consumption translates to lower greenhouse gas emissions during the production phase. Additionally, many biodegradable polymers can be processed at lower temperatures, further reducing the energy requirements and associated environmental impacts.

During the use phase, biodegradable alternatives may exhibit different performance characteristics compared to UHMWPE. While they may not match UHMWPE's exceptional wear resistance and durability in all applications, their shorter lifespan can be advantageous in certain scenarios where temporary use is desired. This can lead to reduced material accumulation in the environment over time.

The end-of-life stage is where biodegradable alternatives demonstrate their most significant environmental advantages. Unlike UHMWPE, which persists in the environment for centuries, these materials can break down into natural components under specific conditions. This biodegradation process reduces the long-term environmental burden and mitigates issues related to microplastic pollution.

However, it is crucial to consider the specific conditions required for biodegradation. Some alternatives may only degrade efficiently in industrial composting facilities, which are not universally available. The potential for incomplete degradation in natural environments and the formation of intermediate compounds must also be carefully evaluated to ensure that these materials do not introduce new environmental challenges.

Water consumption and pollution are additional factors to consider in the environmental impact assessment. The production of some biodegradable alternatives may require more water compared to UHMWPE manufacturing. Conversely, the reduced persistence of these materials in aquatic environments can lead to lower long-term water pollution risks.

In conclusion, while biodegradable alternatives to UHMWPE offer promising environmental benefits, particularly in terms of end-of-life management and reduced persistence in ecosystems, a comprehensive lifecycle assessment is necessary to fully understand their environmental impact. Factors such as raw material sourcing, production efficiency, use-phase performance, and degradation conditions must be carefully balanced to ensure that these alternatives truly represent a more sustainable option compared to traditional UHMWPE.

One of the primary considerations is the sourcing of raw materials for these alternatives. Many biodegradable polymers are derived from renewable resources, such as corn, sugarcane, or cellulose. This shift from petroleum-based feedstocks to bio-based materials can significantly reduce the carbon footprint associated with production. However, it is essential to evaluate the land use changes and potential competition with food crops that may arise from increased demand for these bio-based raw materials.

The production processes for biodegradable alternatives often require less energy compared to UHMWPE manufacturing. This reduction in energy consumption translates to lower greenhouse gas emissions during the production phase. Additionally, many biodegradable polymers can be processed at lower temperatures, further reducing the energy requirements and associated environmental impacts.

During the use phase, biodegradable alternatives may exhibit different performance characteristics compared to UHMWPE. While they may not match UHMWPE's exceptional wear resistance and durability in all applications, their shorter lifespan can be advantageous in certain scenarios where temporary use is desired. This can lead to reduced material accumulation in the environment over time.

The end-of-life stage is where biodegradable alternatives demonstrate their most significant environmental advantages. Unlike UHMWPE, which persists in the environment for centuries, these materials can break down into natural components under specific conditions. This biodegradation process reduces the long-term environmental burden and mitigates issues related to microplastic pollution.

However, it is crucial to consider the specific conditions required for biodegradation. Some alternatives may only degrade efficiently in industrial composting facilities, which are not universally available. The potential for incomplete degradation in natural environments and the formation of intermediate compounds must also be carefully evaluated to ensure that these materials do not introduce new environmental challenges.

Water consumption and pollution are additional factors to consider in the environmental impact assessment. The production of some biodegradable alternatives may require more water compared to UHMWPE manufacturing. Conversely, the reduced persistence of these materials in aquatic environments can lead to lower long-term water pollution risks.

In conclusion, while biodegradable alternatives to UHMWPE offer promising environmental benefits, particularly in terms of end-of-life management and reduced persistence in ecosystems, a comprehensive lifecycle assessment is necessary to fully understand their environmental impact. Factors such as raw material sourcing, production efficiency, use-phase performance, and degradation conditions must be carefully balanced to ensure that these alternatives truly represent a more sustainable option compared to traditional UHMWPE.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in shaping the development, production, and market adoption of alternatives to Ultra-High Molecular Weight Polyethylene (UHMWPE). As the global focus on sustainability intensifies, governments and international organizations have established comprehensive guidelines and standards to ensure the safety, efficacy, and environmental impact of biodegradable materials.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) are the primary regulatory bodies overseeing biodegradable materials. The EPA's Safer Choice program promotes the use of environmentally preferable chemicals, including biodegradable alternatives. The FDA, on the other hand, regulates biodegradable materials used in food packaging and medical devices, ensuring they meet stringent safety and performance standards.

The European Union has implemented the European Standard EN 13432, which specifies requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and serves as a benchmark for many countries worldwide. Additionally, the EU's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the development and use of biodegradable materials by requiring thorough safety assessments.

International standards, such as those developed by the International Organization for Standardization (ISO), provide a global framework for assessing biodegradability. ISO 14851 and ISO 14852, for instance, outline methods for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards ensure consistency in testing and certification across different countries and industries.

Many countries have implemented their own biodegradability standards and certification systems. Japan's GreenPla certification and Australia's AS 4736-2006 standard are examples of nation-specific approaches to regulating biodegradable materials. These localized standards often complement international frameworks while addressing unique regional environmental concerns.

The regulatory landscape for biodegradable materials is dynamic, with ongoing efforts to harmonize standards globally. The development of new biodegradable alternatives to UHMWPE must navigate this complex regulatory environment, ensuring compliance with various regional and international requirements. This regulatory framework not only ensures the safety and efficacy of biodegradable materials but also drives innovation in the field, pushing manufacturers to develop more sustainable and environmentally friendly alternatives.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) are the primary regulatory bodies overseeing biodegradable materials. The EPA's Safer Choice program promotes the use of environmentally preferable chemicals, including biodegradable alternatives. The FDA, on the other hand, regulates biodegradable materials used in food packaging and medical devices, ensuring they meet stringent safety and performance standards.

The European Union has implemented the European Standard EN 13432, which specifies requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and serves as a benchmark for many countries worldwide. Additionally, the EU's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the development and use of biodegradable materials by requiring thorough safety assessments.

International standards, such as those developed by the International Organization for Standardization (ISO), provide a global framework for assessing biodegradability. ISO 14851 and ISO 14852, for instance, outline methods for determining the aerobic biodegradability of plastic materials in an aqueous medium. These standards ensure consistency in testing and certification across different countries and industries.

Many countries have implemented their own biodegradability standards and certification systems. Japan's GreenPla certification and Australia's AS 4736-2006 standard are examples of nation-specific approaches to regulating biodegradable materials. These localized standards often complement international frameworks while addressing unique regional environmental concerns.

The regulatory landscape for biodegradable materials is dynamic, with ongoing efforts to harmonize standards globally. The development of new biodegradable alternatives to UHMWPE must navigate this complex regulatory environment, ensuring compliance with various regional and international requirements. This regulatory framework not only ensures the safety and efficacy of biodegradable materials but also drives innovation in the field, pushing manufacturers to develop more sustainable and environmentally friendly alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!