Development of UHMWPE Nanocomposites for Enhanced Mechanical Properties

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Nanocomposite Background and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) has been a subject of intense research and development in materials science due to its exceptional properties, including high impact strength, low friction coefficient, and excellent chemical resistance. The evolution of UHMWPE technology has been driven by the increasing demand for high-performance materials in various industries, such as aerospace, automotive, and medical devices.

The development of UHMWPE nanocomposites represents a significant advancement in polymer science, aiming to enhance the already impressive mechanical properties of UHMWPE. This technological progression is rooted in the understanding that incorporating nanoscale fillers into the polymer matrix can lead to substantial improvements in strength, stiffness, and wear resistance while maintaining the desirable characteristics of the base material.

The primary objective of developing UHMWPE nanocomposites is to overcome the limitations of conventional UHMWPE, particularly in applications requiring higher mechanical strength and improved wear resistance. By integrating nanoparticles such as carbon nanotubes, graphene, or ceramic nanoparticles into the UHMWPE matrix, researchers aim to create a new class of materials with superior performance characteristics.

The historical context of UHMWPE nanocomposite development can be traced back to the early 2000s when nanotechnology began to make significant inroads into materials science. Initial efforts focused on understanding the fundamental interactions between nanofillers and the UHMWPE matrix, as well as developing effective dispersion techniques to ensure uniform distribution of nanoparticles throughout the polymer.

As research in this field progressed, several key technological trends emerged. These include the exploration of various types of nanofillers, optimization of processing techniques to achieve better dispersion and interfacial bonding, and the development of novel characterization methods to assess the nanocomposite structure and properties at multiple scales.

The anticipated technological goals for UHMWPE nanocomposites include achieving significant enhancements in mechanical properties, such as tensile strength, Young's modulus, and impact resistance, without compromising the material's low density and chemical inertness. Additionally, researchers aim to improve the wear resistance and longevity of UHMWPE-based components, particularly for applications in joint replacements and industrial bearings.

Another critical objective is to develop scalable and cost-effective manufacturing processes for UHMWPE nanocomposites, enabling their widespread adoption in various industries. This involves overcoming challenges related to nanoparticle dispersion, polymer processing, and maintaining consistent quality in large-scale production.

The development of UHMWPE nanocomposites represents a significant advancement in polymer science, aiming to enhance the already impressive mechanical properties of UHMWPE. This technological progression is rooted in the understanding that incorporating nanoscale fillers into the polymer matrix can lead to substantial improvements in strength, stiffness, and wear resistance while maintaining the desirable characteristics of the base material.

The primary objective of developing UHMWPE nanocomposites is to overcome the limitations of conventional UHMWPE, particularly in applications requiring higher mechanical strength and improved wear resistance. By integrating nanoparticles such as carbon nanotubes, graphene, or ceramic nanoparticles into the UHMWPE matrix, researchers aim to create a new class of materials with superior performance characteristics.

The historical context of UHMWPE nanocomposite development can be traced back to the early 2000s when nanotechnology began to make significant inroads into materials science. Initial efforts focused on understanding the fundamental interactions between nanofillers and the UHMWPE matrix, as well as developing effective dispersion techniques to ensure uniform distribution of nanoparticles throughout the polymer.

As research in this field progressed, several key technological trends emerged. These include the exploration of various types of nanofillers, optimization of processing techniques to achieve better dispersion and interfacial bonding, and the development of novel characterization methods to assess the nanocomposite structure and properties at multiple scales.

The anticipated technological goals for UHMWPE nanocomposites include achieving significant enhancements in mechanical properties, such as tensile strength, Young's modulus, and impact resistance, without compromising the material's low density and chemical inertness. Additionally, researchers aim to improve the wear resistance and longevity of UHMWPE-based components, particularly for applications in joint replacements and industrial bearings.

Another critical objective is to develop scalable and cost-effective manufacturing processes for UHMWPE nanocomposites, enabling their widespread adoption in various industries. This involves overcoming challenges related to nanoparticle dispersion, polymer processing, and maintaining consistent quality in large-scale production.

Market Analysis for High-Performance Polymers

The high-performance polymer market, particularly for Ultra-High Molecular Weight Polyethylene (UHMWPE) nanocomposites, is experiencing significant growth driven by increasing demand across various industries. These advanced materials offer superior mechanical properties, making them attractive for applications in aerospace, automotive, defense, and medical sectors.

The global UHMWPE market size was valued at over $1.5 billion in 2020 and is projected to grow at a CAGR of 9.5% from 2021 to 2028. This growth is primarily attributed to the rising demand for lightweight and high-strength materials in automotive and aerospace industries, where fuel efficiency and performance are critical factors.

In the automotive sector, UHMWPE nanocomposites are increasingly being used in the production of lightweight components, contributing to improved fuel efficiency and reduced emissions. The aerospace industry is another key driver, with these materials finding applications in aircraft interiors, structural components, and protective gear due to their excellent strength-to-weight ratio.

The medical industry represents a significant market for UHMWPE nanocomposites, particularly in orthopedic implants. The global orthopedic implants market, valued at $45 billion in 2020, is expected to reach $64 billion by 2026, with UHMWPE-based implants playing a crucial role in this growth.

Geographically, North America and Europe dominate the UHMWPE nanocomposites market, owing to their advanced manufacturing capabilities and high adoption rates in key industries. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, increasing automotive production, and growing healthcare infrastructure.

The market is characterized by intense competition among key players such as Celanese Corporation, LyondellBasell Industries, and Braskem. These companies are investing heavily in research and development to enhance the mechanical properties of UHMWPE nanocomposites and expand their application areas.

Despite the positive outlook, challenges such as high production costs and complex manufacturing processes may hinder market growth. However, ongoing technological advancements and increasing focus on sustainable materials are expected to create new opportunities in the UHMWPE nanocomposites market.

In conclusion, the market for high-performance polymers, specifically UHMWPE nanocomposites, shows strong growth potential driven by diverse industrial applications and continuous technological innovations. The development of enhanced mechanical properties in these materials is likely to further expand their market reach and drive adoption across various sectors.

The global UHMWPE market size was valued at over $1.5 billion in 2020 and is projected to grow at a CAGR of 9.5% from 2021 to 2028. This growth is primarily attributed to the rising demand for lightweight and high-strength materials in automotive and aerospace industries, where fuel efficiency and performance are critical factors.

In the automotive sector, UHMWPE nanocomposites are increasingly being used in the production of lightweight components, contributing to improved fuel efficiency and reduced emissions. The aerospace industry is another key driver, with these materials finding applications in aircraft interiors, structural components, and protective gear due to their excellent strength-to-weight ratio.

The medical industry represents a significant market for UHMWPE nanocomposites, particularly in orthopedic implants. The global orthopedic implants market, valued at $45 billion in 2020, is expected to reach $64 billion by 2026, with UHMWPE-based implants playing a crucial role in this growth.

Geographically, North America and Europe dominate the UHMWPE nanocomposites market, owing to their advanced manufacturing capabilities and high adoption rates in key industries. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, increasing automotive production, and growing healthcare infrastructure.

The market is characterized by intense competition among key players such as Celanese Corporation, LyondellBasell Industries, and Braskem. These companies are investing heavily in research and development to enhance the mechanical properties of UHMWPE nanocomposites and expand their application areas.

Despite the positive outlook, challenges such as high production costs and complex manufacturing processes may hinder market growth. However, ongoing technological advancements and increasing focus on sustainable materials are expected to create new opportunities in the UHMWPE nanocomposites market.

In conclusion, the market for high-performance polymers, specifically UHMWPE nanocomposites, shows strong growth potential driven by diverse industrial applications and continuous technological innovations. The development of enhanced mechanical properties in these materials is likely to further expand their market reach and drive adoption across various sectors.

Current Challenges in UHMWPE Nanocomposite Development

The development of Ultra-High Molecular Weight Polyethylene (UHMWPE) nanocomposites for enhanced mechanical properties faces several significant challenges. One of the primary obstacles is achieving uniform dispersion of nanofillers within the UHMWPE matrix. The high viscosity and low surface energy of UHMWPE make it difficult to incorporate and distribute nanoparticles evenly, often resulting in agglomeration and poor interfacial adhesion.

Another major challenge lies in maintaining the unique properties of UHMWPE while incorporating nanofillers. The addition of nanoparticles can potentially disrupt the long-chain structure of UHMWPE, leading to a decrease in its inherent toughness and wear resistance. Striking a balance between enhancing certain mechanical properties and preserving the desirable characteristics of UHMWPE remains a complex task.

The processing of UHMWPE nanocomposites presents additional hurdles. Traditional melt-processing techniques are often ineffective due to the extremely high molecular weight and melt viscosity of UHMWPE. Alternative methods such as solution blending or in-situ polymerization face scalability issues and may introduce unwanted impurities or residual solvents.

Compatibility between UHMWPE and various nanofillers is another critical challenge. The non-polar nature of UHMWPE makes it inherently incompatible with many polar nanofillers, necessitating surface modifications or the use of compatibilizers. However, these modifications can introduce additional complexities and potentially alter the desired properties of the nanocomposites.

Characterization and testing of UHMWPE nanocomposites pose unique difficulties. The high molecular weight and crystallinity of UHMWPE can interfere with standard characterization techniques, making it challenging to accurately assess the dispersion of nanofillers and the resulting property enhancements. Developing reliable and reproducible testing methods specific to UHMWPE nanocomposites is crucial for advancing the field.

Long-term stability and performance of UHMWPE nanocomposites under various environmental conditions and mechanical stresses remain areas of concern. The potential for nanoparticle migration, degradation, or changes in the composite structure over time could impact the longevity and reliability of products made from these materials.

Lastly, the cost-effectiveness of producing UHMWPE nanocomposites on an industrial scale presents a significant challenge. The high cost of nanofillers, coupled with the complexities in processing and quality control, may limit the widespread adoption of these advanced materials in commercial applications. Overcoming these economic barriers while maintaining the enhanced properties is essential for the successful implementation of UHMWPE nanocomposites in various industries.

Another major challenge lies in maintaining the unique properties of UHMWPE while incorporating nanofillers. The addition of nanoparticles can potentially disrupt the long-chain structure of UHMWPE, leading to a decrease in its inherent toughness and wear resistance. Striking a balance between enhancing certain mechanical properties and preserving the desirable characteristics of UHMWPE remains a complex task.

The processing of UHMWPE nanocomposites presents additional hurdles. Traditional melt-processing techniques are often ineffective due to the extremely high molecular weight and melt viscosity of UHMWPE. Alternative methods such as solution blending or in-situ polymerization face scalability issues and may introduce unwanted impurities or residual solvents.

Compatibility between UHMWPE and various nanofillers is another critical challenge. The non-polar nature of UHMWPE makes it inherently incompatible with many polar nanofillers, necessitating surface modifications or the use of compatibilizers. However, these modifications can introduce additional complexities and potentially alter the desired properties of the nanocomposites.

Characterization and testing of UHMWPE nanocomposites pose unique difficulties. The high molecular weight and crystallinity of UHMWPE can interfere with standard characterization techniques, making it challenging to accurately assess the dispersion of nanofillers and the resulting property enhancements. Developing reliable and reproducible testing methods specific to UHMWPE nanocomposites is crucial for advancing the field.

Long-term stability and performance of UHMWPE nanocomposites under various environmental conditions and mechanical stresses remain areas of concern. The potential for nanoparticle migration, degradation, or changes in the composite structure over time could impact the longevity and reliability of products made from these materials.

Lastly, the cost-effectiveness of producing UHMWPE nanocomposites on an industrial scale presents a significant challenge. The high cost of nanofillers, coupled with the complexities in processing and quality control, may limit the widespread adoption of these advanced materials in commercial applications. Overcoming these economic barriers while maintaining the enhanced properties is essential for the successful implementation of UHMWPE nanocomposites in various industries.

Existing UHMWPE Nanocomposite Fabrication Methods

01 Incorporation of nanofillers in UHMWPE

Nanofillers such as carbon nanotubes, graphene, or nanoparticles are incorporated into UHMWPE to enhance its mechanical properties. These nanofillers can significantly improve the strength, stiffness, and wear resistance of the resulting nanocomposites.- Incorporation of nanofillers in UHMWPE: Nanofillers such as carbon nanotubes, graphene, or nanoparticles are incorporated into UHMWPE to enhance its mechanical properties. These nanofillers can significantly improve the strength, stiffness, and wear resistance of the resulting nanocomposites.

- Processing techniques for UHMWPE nanocomposites: Various processing techniques are employed to fabricate UHMWPE nanocomposites, including melt blending, solution mixing, and in-situ polymerization. These methods aim to achieve uniform dispersion of nanofillers and optimize the interfacial interaction between the filler and the polymer matrix.

- Surface modification of nanofillers: Surface modification of nanofillers is performed to improve their compatibility with the UHMWPE matrix. This enhances the interfacial adhesion between the filler and the polymer, leading to better mechanical properties of the nanocomposites.

- Characterization of UHMWPE nanocomposite properties: Various characterization techniques are used to evaluate the mechanical properties of UHMWPE nanocomposites, including tensile testing, impact testing, and wear resistance measurements. These tests help quantify the improvements in strength, modulus, and toughness achieved through nanocomposite formulation.

- Applications of UHMWPE nanocomposites: UHMWPE nanocomposites with enhanced mechanical properties find applications in various fields, including orthopedic implants, aerospace components, and high-performance fibers. The improved strength and wear resistance of these materials make them suitable for demanding applications.

02 Processing techniques for UHMWPE nanocomposites

Various processing techniques are employed to fabricate UHMWPE nanocomposites, including melt blending, solution mixing, and in-situ polymerization. These methods aim to achieve uniform dispersion of nanofillers and optimize the interfacial interaction between the filler and the polymer matrix.Expand Specific Solutions03 Surface modification of nanofillers

Surface modification of nanofillers is performed to improve their compatibility with the UHMWPE matrix. This enhances the interfacial adhesion between the filler and the polymer, leading to better mechanical properties of the nanocomposites.Expand Specific Solutions04 Characterization of UHMWPE nanocomposite properties

Various characterization techniques are used to evaluate the mechanical properties of UHMWPE nanocomposites, including tensile testing, impact testing, and wear resistance measurements. These methods help in understanding the influence of nanofillers on the overall performance of the composites.Expand Specific Solutions05 Applications of UHMWPE nanocomposites

UHMWPE nanocomposites with enhanced mechanical properties find applications in various fields such as orthopedic implants, aerospace components, and high-performance fibers. The improved strength, stiffness, and wear resistance make these materials suitable for demanding applications.Expand Specific Solutions

Key Players in UHMWPE Nanocomposite Industry

The development of UHMWPE nanocomposites for enhanced mechanical properties is in a growth phase, with increasing market demand and technological advancements. The global market for these materials is expanding, driven by applications in aerospace, automotive, and medical industries. Technologically, the field is progressing rapidly, with companies like Shanghai Research Institute of Chemical Industry and Sichuan University leading research efforts. PetroChina and China Petroleum & Chemical Corp. are leveraging their petrochemical expertise to develop advanced UHMWPE formulations. International players such as Vale SA and Teijin Twaron BV are also contributing to the field's maturation. While the technology is advancing, there's still room for innovation in nanocomposite synthesis and property enhancement, indicating a moderate level of technological maturity.

Shanghai Research Institute of Chemical Industry Co. Ltd.

Technical Solution: Shanghai Research Institute of Chemical Industry Co. Ltd. has developed a novel approach to enhance the mechanical properties of UHMWPE nanocomposites. Their method involves the incorporation of graphene oxide (GO) nanosheets into the UHMWPE matrix through a solution mixing process followed by hot pressing[1]. This technique results in a significant improvement in tensile strength and Young's modulus of the nanocomposites. The researchers have optimized the GO content to achieve a balance between enhanced mechanical properties and processability. Additionally, they have implemented a surface modification technique for the GO nanosheets to improve their dispersion and interfacial adhesion with the UHMWPE matrix[3].

Strengths: Improved tensile strength and modulus, enhanced dispersion of nanofillers, and optimized processing conditions. Weaknesses: Potential challenges in scaling up the production process and maintaining uniform dispersion in large-scale manufacturing.

Sichuan University

Technical Solution: Sichuan University has pioneered a unique approach to developing UHMWPE nanocomposites with enhanced mechanical properties. Their method involves the use of a novel in-situ polymerization technique combined with a specially designed catalyst system[2]. This process allows for the uniform dispersion of nanofillers, such as carbon nanotubes or nanoclays, within the UHMWPE matrix at the molecular level. The researchers have also developed a post-processing treatment that involves controlled thermal annealing to further improve the crystallinity and orientation of the polymer chains[4]. This comprehensive approach has resulted in nanocomposites with significantly improved tensile strength, impact resistance, and wear properties compared to conventional UHMWPE.

Strengths: Excellent dispersion of nanofillers, improved crystallinity, and enhanced overall mechanical properties. Weaknesses: Complex synthesis process may increase production costs and time.

Core Innovations in UHMWPE Nanocomposite Research

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Method to produce ultra-high molecular weight polyethylene

PatentInactiveUS20150274937A1

Innovation

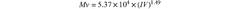

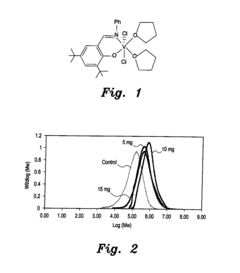

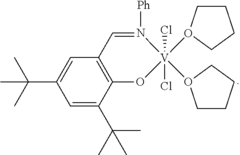

- Incorporating tungsten-doped titania (TiO2/W) nanofillers during the ethylene polymerization process using a vanadium (III) complex catalyst with bidentate salicylaldiminato ligands and a methyl aluminum dichloride co-catalyst, allowing for improved control over molecular weight, crystallinity, and thermal properties of UHMWPE.

Environmental Impact of UHMWPE Nanocomposites

The development of Ultra-High Molecular Weight Polyethylene (UHMWPE) nanocomposites for enhanced mechanical properties has significant environmental implications that warrant careful consideration. These advanced materials offer potential benefits in terms of durability and performance, which could lead to reduced material consumption and waste generation in various applications.

One of the primary environmental advantages of UHMWPE nanocomposites is their potential for extended product lifespans. By enhancing the mechanical properties of UHMWPE, these nanocomposites can create more durable and wear-resistant materials. This increased longevity can result in reduced replacement frequency and, consequently, lower overall material consumption and waste production over time.

However, the production of UHMWPE nanocomposites also raises environmental concerns. The manufacturing process may involve energy-intensive steps and the use of potentially harmful chemicals or nanoparticles. The environmental impact of these production methods needs to be carefully assessed and balanced against the benefits of the final product.

The disposal and end-of-life management of UHMWPE nanocomposites present another environmental challenge. While UHMWPE itself is recyclable, the addition of nanoparticles may complicate recycling processes. There is a need for research into effective recycling methods for these composite materials to ensure they do not contribute to long-term environmental pollution.

The potential release of nanoparticles from UHMWPE nanocomposites during use or disposal is an area of environmental concern that requires further investigation. The impact of these nanoparticles on ecosystems and human health is not yet fully understood, and precautionary measures may be necessary to mitigate any potential risks.

On the positive side, UHMWPE nanocomposites could contribute to energy efficiency in certain applications. For instance, in automotive or aerospace industries, the use of lighter yet stronger materials could lead to improved fuel efficiency and reduced emissions over the lifecycle of vehicles or aircraft.

The development of bio-based or biodegradable nanoparticles for use in UHMWPE composites is an emerging area of research that could potentially address some of the environmental concerns. Such innovations could lead to more environmentally friendly nanocomposites that maintain enhanced mechanical properties while reducing the ecological footprint.

In conclusion, while UHMWPE nanocomposites offer promising mechanical enhancements, their environmental impact is complex and multifaceted. A comprehensive life cycle assessment is crucial to fully understand and optimize the environmental performance of these materials. Balancing the benefits of improved mechanical properties against potential environmental risks will be key to the sustainable development and application of UHMWPE nanocomposites.

One of the primary environmental advantages of UHMWPE nanocomposites is their potential for extended product lifespans. By enhancing the mechanical properties of UHMWPE, these nanocomposites can create more durable and wear-resistant materials. This increased longevity can result in reduced replacement frequency and, consequently, lower overall material consumption and waste production over time.

However, the production of UHMWPE nanocomposites also raises environmental concerns. The manufacturing process may involve energy-intensive steps and the use of potentially harmful chemicals or nanoparticles. The environmental impact of these production methods needs to be carefully assessed and balanced against the benefits of the final product.

The disposal and end-of-life management of UHMWPE nanocomposites present another environmental challenge. While UHMWPE itself is recyclable, the addition of nanoparticles may complicate recycling processes. There is a need for research into effective recycling methods for these composite materials to ensure they do not contribute to long-term environmental pollution.

The potential release of nanoparticles from UHMWPE nanocomposites during use or disposal is an area of environmental concern that requires further investigation. The impact of these nanoparticles on ecosystems and human health is not yet fully understood, and precautionary measures may be necessary to mitigate any potential risks.

On the positive side, UHMWPE nanocomposites could contribute to energy efficiency in certain applications. For instance, in automotive or aerospace industries, the use of lighter yet stronger materials could lead to improved fuel efficiency and reduced emissions over the lifecycle of vehicles or aircraft.

The development of bio-based or biodegradable nanoparticles for use in UHMWPE composites is an emerging area of research that could potentially address some of the environmental concerns. Such innovations could lead to more environmentally friendly nanocomposites that maintain enhanced mechanical properties while reducing the ecological footprint.

In conclusion, while UHMWPE nanocomposites offer promising mechanical enhancements, their environmental impact is complex and multifaceted. A comprehensive life cycle assessment is crucial to fully understand and optimize the environmental performance of these materials. Balancing the benefits of improved mechanical properties against potential environmental risks will be key to the sustainable development and application of UHMWPE nanocomposites.

Scalability and Cost Analysis

The scalability and cost analysis of UHMWPE nanocomposites production is crucial for their widespread adoption in industrial applications. Current manufacturing processes for these advanced materials face significant challenges in scaling up from laboratory to commercial production levels. The primary obstacle lies in maintaining uniform dispersion of nanofillers within the UHMWPE matrix during large-scale processing, which is essential for achieving enhanced mechanical properties.

Traditional melt-mixing techniques, while suitable for small-scale production, encounter difficulties in ensuring homogeneous distribution of nanoparticles when scaled up. This can lead to inconsistent mechanical properties across the final product, potentially negating the benefits of nanocomposite technology. Alternative methods, such as in-situ polymerization or solution mixing, show promise for better dispersion but present their own scalability issues, including increased processing time and solvent recovery costs.

From a cost perspective, the production of UHMWPE nanocomposites involves several factors that impact economic viability. The raw material costs, particularly for high-quality nanofillers such as carbon nanotubes or graphene, remain a significant portion of the overall expenses. As production scales increase, there is potential for cost reduction through bulk purchasing and improved supply chain efficiencies. However, this must be balanced against the increased capital investment required for specialized processing equipment capable of handling larger volumes while maintaining quality.

Energy consumption during production is another critical cost factor. The high viscosity of UHMWPE necessitates substantial energy input for processing, which scales non-linearly with production volume. Innovations in energy-efficient mixing and molding technologies are essential for reducing operational costs at industrial scales. Additionally, the potential need for specialized handling and safety measures when working with nanoparticles at large scales may introduce additional overhead.

Quality control and consistency become increasingly challenging and costly as production scales up. Implementing robust quality assurance processes, including advanced characterization techniques, is necessary to ensure that the enhanced mechanical properties are consistently achieved across large production runs. This may require significant investment in testing equipment and skilled personnel.

In conclusion, while the development of UHMWPE nanocomposites shows great promise for enhancing mechanical properties, the path to large-scale, cost-effective production remains complex. Advancements in processing technologies, coupled with strategic cost management and quality control measures, will be key to overcoming these challenges and realizing the full potential of these materials in industrial applications.

Traditional melt-mixing techniques, while suitable for small-scale production, encounter difficulties in ensuring homogeneous distribution of nanoparticles when scaled up. This can lead to inconsistent mechanical properties across the final product, potentially negating the benefits of nanocomposite technology. Alternative methods, such as in-situ polymerization or solution mixing, show promise for better dispersion but present their own scalability issues, including increased processing time and solvent recovery costs.

From a cost perspective, the production of UHMWPE nanocomposites involves several factors that impact economic viability. The raw material costs, particularly for high-quality nanofillers such as carbon nanotubes or graphene, remain a significant portion of the overall expenses. As production scales increase, there is potential for cost reduction through bulk purchasing and improved supply chain efficiencies. However, this must be balanced against the increased capital investment required for specialized processing equipment capable of handling larger volumes while maintaining quality.

Energy consumption during production is another critical cost factor. The high viscosity of UHMWPE necessitates substantial energy input for processing, which scales non-linearly with production volume. Innovations in energy-efficient mixing and molding technologies are essential for reducing operational costs at industrial scales. Additionally, the potential need for specialized handling and safety measures when working with nanoparticles at large scales may introduce additional overhead.

Quality control and consistency become increasingly challenging and costly as production scales up. Implementing robust quality assurance processes, including advanced characterization techniques, is necessary to ensure that the enhanced mechanical properties are consistently achieved across large production runs. This may require significant investment in testing equipment and skilled personnel.

In conclusion, while the development of UHMWPE nanocomposites shows great promise for enhancing mechanical properties, the path to large-scale, cost-effective production remains complex. Advancements in processing technologies, coupled with strategic cost management and quality control measures, will be key to overcoming these challenges and realizing the full potential of these materials in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!