Advanced UHMWPE Coatings for Industrial Gear Durability

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Coating Evolution

The evolution of UHMWPE coatings for industrial gear durability has been marked by significant advancements over the past few decades. Initially, UHMWPE was primarily used in bulk form for various industrial applications due to its excellent wear resistance and low friction properties. However, the potential of UHMWPE as a coating material was recognized in the late 1980s, leading to extensive research and development efforts.

In the early 1990s, the first attempts to apply UHMWPE coatings on industrial gears were made using thermal spray techniques. These early coatings showed promise in reducing wear and improving lubrication, but they suffered from poor adhesion to metal substrates and limited thickness control. The mid-1990s saw the introduction of plasma spray techniques, which allowed for better coating adhesion and improved control over coating thickness and morphology.

A significant breakthrough came in the early 2000s with the development of cold spray deposition methods for UHMWPE. This technique enabled the creation of denser coatings with enhanced mechanical properties and better bonding to the substrate. Concurrently, research into surface modification techniques, such as plasma treatment and chemical etching, further improved the adhesion of UHMWPE coatings to metal surfaces.

The late 2000s and early 2010s witnessed the emergence of nanocomposite UHMWPE coatings. By incorporating nanoparticles such as carbon nanotubes, graphene, and ceramic nanoparticles into the UHMWPE matrix, researchers were able to significantly enhance the mechanical strength, wear resistance, and thermal stability of the coatings. This development opened up new possibilities for UHMWPE coatings in more demanding industrial gear applications.

Recent years have seen a focus on developing advanced deposition techniques and hybrid coating systems. Electrospray deposition and solution casting methods have been explored to create ultra-thin UHMWPE coatings with precise thickness control. Additionally, multilayer coating systems combining UHMWPE with other high-performance materials like DLC (Diamond-Like Carbon) have shown promising results in extreme operating conditions.

The current frontier in UHMWPE coating evolution involves the integration of smart materials and self-healing properties. Researchers are exploring the incorporation of shape memory polymers and self-healing agents into UHMWPE coatings to create adaptive surfaces that can respond to environmental changes and repair minor damage autonomously. These developments aim to further extend the lifespan and reliability of industrial gears in demanding applications.

In the early 1990s, the first attempts to apply UHMWPE coatings on industrial gears were made using thermal spray techniques. These early coatings showed promise in reducing wear and improving lubrication, but they suffered from poor adhesion to metal substrates and limited thickness control. The mid-1990s saw the introduction of plasma spray techniques, which allowed for better coating adhesion and improved control over coating thickness and morphology.

A significant breakthrough came in the early 2000s with the development of cold spray deposition methods for UHMWPE. This technique enabled the creation of denser coatings with enhanced mechanical properties and better bonding to the substrate. Concurrently, research into surface modification techniques, such as plasma treatment and chemical etching, further improved the adhesion of UHMWPE coatings to metal surfaces.

The late 2000s and early 2010s witnessed the emergence of nanocomposite UHMWPE coatings. By incorporating nanoparticles such as carbon nanotubes, graphene, and ceramic nanoparticles into the UHMWPE matrix, researchers were able to significantly enhance the mechanical strength, wear resistance, and thermal stability of the coatings. This development opened up new possibilities for UHMWPE coatings in more demanding industrial gear applications.

Recent years have seen a focus on developing advanced deposition techniques and hybrid coating systems. Electrospray deposition and solution casting methods have been explored to create ultra-thin UHMWPE coatings with precise thickness control. Additionally, multilayer coating systems combining UHMWPE with other high-performance materials like DLC (Diamond-Like Carbon) have shown promising results in extreme operating conditions.

The current frontier in UHMWPE coating evolution involves the integration of smart materials and self-healing properties. Researchers are exploring the incorporation of shape memory polymers and self-healing agents into UHMWPE coatings to create adaptive surfaces that can respond to environmental changes and repair minor damage autonomously. These developments aim to further extend the lifespan and reliability of industrial gears in demanding applications.

Industrial Gear Market

The industrial gear market has been experiencing steady growth, driven by increasing demand across various sectors such as manufacturing, automotive, aerospace, and energy. This market segment is crucial for the efficient operation of machinery and equipment in industrial applications, where gears play a vital role in power transmission and motion control.

The global industrial gear market size was valued at approximately USD 70 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2028. This growth is attributed to the rising industrialization in emerging economies, technological advancements in gear manufacturing, and the increasing adoption of automation in various industries.

Key factors influencing the industrial gear market include the growing demand for energy-efficient gears, the expansion of the manufacturing sector in developing countries, and the increasing focus on reducing maintenance costs and improving operational efficiency. Additionally, the rising investments in infrastructure development and the growth of the renewable energy sector are creating new opportunities for industrial gear manufacturers.

The market is segmented based on gear type, including spur gears, helical gears, bevel gears, worm gears, and others. Among these, helical gears hold a significant market share due to their superior load-carrying capacity and smooth operation. The automotive industry remains one of the largest end-users of industrial gears, followed by the manufacturing and construction sectors.

Geographically, Asia Pacific dominates the industrial gear market, accounting for the largest share of global revenue. This can be attributed to the rapid industrialization in countries like China and India, coupled with the presence of major manufacturing hubs in the region. North America and Europe also hold substantial market shares, driven by technological advancements and the presence of established industrial sectors.

The industrial gear market is characterized by intense competition, with several key players vying for market share. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The increasing emphasis on durability and performance of industrial gears has led to a growing interest in advanced coating technologies, such as Ultra-High Molecular Weight Polyethylene (UHMWPE) coatings, which offer improved wear resistance and longevity.

As industries continue to evolve and demand more efficient and durable gear solutions, the market for advanced coatings like UHMWPE is expected to grow significantly. This trend aligns with the broader industry focus on enhancing gear performance, reducing maintenance costs, and extending the operational life of industrial equipment.

The global industrial gear market size was valued at approximately USD 70 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2028. This growth is attributed to the rising industrialization in emerging economies, technological advancements in gear manufacturing, and the increasing adoption of automation in various industries.

Key factors influencing the industrial gear market include the growing demand for energy-efficient gears, the expansion of the manufacturing sector in developing countries, and the increasing focus on reducing maintenance costs and improving operational efficiency. Additionally, the rising investments in infrastructure development and the growth of the renewable energy sector are creating new opportunities for industrial gear manufacturers.

The market is segmented based on gear type, including spur gears, helical gears, bevel gears, worm gears, and others. Among these, helical gears hold a significant market share due to their superior load-carrying capacity and smooth operation. The automotive industry remains one of the largest end-users of industrial gears, followed by the manufacturing and construction sectors.

Geographically, Asia Pacific dominates the industrial gear market, accounting for the largest share of global revenue. This can be attributed to the rapid industrialization in countries like China and India, coupled with the presence of major manufacturing hubs in the region. North America and Europe also hold substantial market shares, driven by technological advancements and the presence of established industrial sectors.

The industrial gear market is characterized by intense competition, with several key players vying for market share. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The increasing emphasis on durability and performance of industrial gears has led to a growing interest in advanced coating technologies, such as Ultra-High Molecular Weight Polyethylene (UHMWPE) coatings, which offer improved wear resistance and longevity.

As industries continue to evolve and demand more efficient and durable gear solutions, the market for advanced coatings like UHMWPE is expected to grow significantly. This trend aligns with the broader industry focus on enhancing gear performance, reducing maintenance costs, and extending the operational life of industrial equipment.

UHMWPE Coating Challenges

Ultra-high molecular weight polyethylene (UHMWPE) coatings have emerged as a promising solution for enhancing industrial gear durability. However, the application of these coatings faces several significant challenges that need to be addressed to fully realize their potential in industrial settings.

One of the primary challenges is achieving strong adhesion between the UHMWPE coating and the substrate material of the gear. The non-polar nature of UHMWPE makes it inherently difficult to bond with most metal surfaces commonly used in gear manufacturing. This poor adhesion can lead to coating delamination under high stress and cyclic loading conditions, compromising the protective function of the coating.

Another critical issue is the thickness control of UHMWPE coatings. Industrial gears often require precise dimensional tolerances to maintain optimal performance. Applying UHMWPE coatings without compromising these tolerances can be challenging, as thicker coatings may alter gear geometry and affect meshing characteristics. Conversely, excessively thin coatings may not provide adequate protection against wear and corrosion.

The thermal stability of UHMWPE coatings presents another hurdle. Industrial gears frequently operate in high-temperature environments, which can cause thermal degradation of the polymer coating. This degradation can lead to a loss of mechanical properties and reduced wear resistance, limiting the coating's effectiveness in protecting the gear surface.

Wear resistance is a critical factor in gear durability, and while UHMWPE exhibits excellent wear properties in many applications, its performance under the extreme conditions experienced by industrial gears may be insufficient. The high loads, speeds, and potential presence of abrasive particles in industrial environments can accelerate wear rates beyond the coating's capabilities.

The processing of UHMWPE for coating applications also poses challenges. The high molecular weight of the polymer results in a very high melt viscosity, making traditional melt processing techniques difficult to apply. This limitation necessitates the development of specialized coating methods that can effectively deposit UHMWPE onto gear surfaces without compromising its unique properties.

Environmental concerns and regulatory compliance add another layer of complexity to UHMWPE coating development. As industrial sectors face increasing pressure to adopt more sustainable practices, the environmental impact of coating materials and processes must be carefully considered. This includes addressing issues related to the disposal of UHMWPE-coated components at the end of their lifecycle.

Lastly, the cost-effectiveness of UHMWPE coatings for industrial gears remains a significant challenge. While the potential benefits in terms of extended gear life and reduced maintenance are clear, the initial costs associated with developing and applying these advanced coatings must be justified against traditional gear protection methods. Balancing performance improvements with economic viability is crucial for widespread adoption in industrial applications.

One of the primary challenges is achieving strong adhesion between the UHMWPE coating and the substrate material of the gear. The non-polar nature of UHMWPE makes it inherently difficult to bond with most metal surfaces commonly used in gear manufacturing. This poor adhesion can lead to coating delamination under high stress and cyclic loading conditions, compromising the protective function of the coating.

Another critical issue is the thickness control of UHMWPE coatings. Industrial gears often require precise dimensional tolerances to maintain optimal performance. Applying UHMWPE coatings without compromising these tolerances can be challenging, as thicker coatings may alter gear geometry and affect meshing characteristics. Conversely, excessively thin coatings may not provide adequate protection against wear and corrosion.

The thermal stability of UHMWPE coatings presents another hurdle. Industrial gears frequently operate in high-temperature environments, which can cause thermal degradation of the polymer coating. This degradation can lead to a loss of mechanical properties and reduced wear resistance, limiting the coating's effectiveness in protecting the gear surface.

Wear resistance is a critical factor in gear durability, and while UHMWPE exhibits excellent wear properties in many applications, its performance under the extreme conditions experienced by industrial gears may be insufficient. The high loads, speeds, and potential presence of abrasive particles in industrial environments can accelerate wear rates beyond the coating's capabilities.

The processing of UHMWPE for coating applications also poses challenges. The high molecular weight of the polymer results in a very high melt viscosity, making traditional melt processing techniques difficult to apply. This limitation necessitates the development of specialized coating methods that can effectively deposit UHMWPE onto gear surfaces without compromising its unique properties.

Environmental concerns and regulatory compliance add another layer of complexity to UHMWPE coating development. As industrial sectors face increasing pressure to adopt more sustainable practices, the environmental impact of coating materials and processes must be carefully considered. This includes addressing issues related to the disposal of UHMWPE-coated components at the end of their lifecycle.

Lastly, the cost-effectiveness of UHMWPE coatings for industrial gears remains a significant challenge. While the potential benefits in terms of extended gear life and reduced maintenance are clear, the initial costs associated with developing and applying these advanced coatings must be justified against traditional gear protection methods. Balancing performance improvements with economic viability is crucial for widespread adoption in industrial applications.

Current UHMWPE Solutions

01 Surface modification techniques for UHMWPE coatings

Various surface modification techniques can be applied to enhance the durability of UHMWPE coatings. These methods include plasma treatment, chemical etching, and grafting of functional groups onto the UHMWPE surface. Such modifications can improve adhesion to substrates, increase wear resistance, and enhance overall coating performance.- Surface modification techniques for UHMWPE coatings: Various surface modification techniques can be applied to enhance the durability of UHMWPE coatings. These may include plasma treatment, chemical etching, or the application of coupling agents to improve adhesion and wear resistance. Such modifications can alter the surface properties of UHMWPE, leading to improved bonding with substrates and increased overall durability of the coating.

- Incorporation of nanoparticles or reinforcing agents: The addition of nanoparticles or other reinforcing agents to UHMWPE coatings can significantly improve their durability. These additives can enhance mechanical properties, increase wear resistance, and improve the overall performance of the coating. Common reinforcing agents may include carbon nanotubes, graphene, or ceramic particles.

- Crosslinking methods for UHMWPE coatings: Crosslinking techniques can be employed to enhance the durability of UHMWPE coatings. Methods such as radiation-induced crosslinking or chemical crosslinking can improve the wear resistance, mechanical strength, and overall longevity of the coating. These processes create stronger bonds between polymer chains, resulting in a more durable coating.

- Optimization of coating application processes: The durability of UHMWPE coatings can be improved through optimization of the coating application process. This may involve adjusting parameters such as temperature, pressure, and curing time during the coating application. Advanced techniques like electrostatic spraying or powder coating can also be utilized to achieve more uniform and durable UHMWPE coatings.

- Development of hybrid or multi-layer coating systems: Creating hybrid or multi-layer coating systems that incorporate UHMWPE can enhance overall durability. This approach may involve combining UHMWPE with other materials or applying it as part of a multi-layer coating system. Such combinations can leverage the unique properties of UHMWPE while addressing its limitations, resulting in coatings with improved durability and performance.

02 Incorporation of nanoparticles in UHMWPE coatings

Adding nanoparticles to UHMWPE coatings can significantly improve their durability. Nanoparticles such as carbon nanotubes, graphene, or ceramic particles can enhance mechanical strength, wear resistance, and thermal stability of the coatings. This approach results in a more robust and long-lasting UHMWPE coating suitable for demanding applications.Expand Specific Solutions03 Crosslinking methods for UHMWPE coatings

Crosslinking techniques can be employed to improve the durability of UHMWPE coatings. Methods such as electron beam irradiation, gamma radiation, or chemical crosslinking agents can create a more tightly bound polymer network. This results in enhanced mechanical properties, increased wear resistance, and improved chemical stability of the UHMWPE coating.Expand Specific Solutions04 Multi-layer UHMWPE coating systems

Developing multi-layer coating systems that incorporate UHMWPE can enhance overall durability. These systems may include primer layers for improved adhesion, intermediate layers for specific functional properties, and a top UHMWPE layer for wear resistance and low friction. The combination of different materials in a layered structure can provide superior performance compared to single-layer UHMWPE coatings.Expand Specific Solutions05 Optimization of UHMWPE coating application methods

Improving the application methods for UHMWPE coatings can lead to enhanced durability. Techniques such as electrostatic spraying, powder coating, or thermal spraying can be optimized to achieve better coating uniformity, thickness control, and adhesion to substrates. These refined application methods result in more durable and longer-lasting UHMWPE coatings.Expand Specific Solutions

Key UHMWPE Manufacturers

The research on advanced UHMWPE coatings for industrial gear durability is in a growth phase, with increasing market demand driven by the need for improved gear performance and longevity. The global market for specialized industrial coatings is expanding, estimated to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with companies like Howmedica Osteonics Corp., DSM IP Assets BV, and Asahi Kasei Corp. leading innovation. These firms are developing proprietary UHMWPE formulations and coating techniques, pushing the boundaries of wear resistance and durability. Academic institutions such as the University of Southern California and Nanjing University of Science & Technology are also contributing to research advancements, fostering industry-academia collaborations to accelerate technological progress in this domain.

DSM IP Assets BV

Technical Solution: DSM IP Assets BV has developed advanced UHMWPE coatings for industrial gear durability using their proprietary Dyneema® fiber technology. Their approach involves creating a thin, highly wear-resistant layer of UHMWPE on gear surfaces. The coating is applied through a specialized thermal spray process, resulting in a uniform, strongly bonded layer typically 100-200 microns thick[1]. This coating significantly reduces friction and wear, with laboratory tests showing up to 80% reduction in wear rates compared to uncoated gears[3]. The company has also incorporated nano-additives into the UHMWPE matrix to further enhance its mechanical properties and thermal stability[5].

Strengths: Exceptional wear resistance, low friction, and high impact strength. The coating's thinness allows for minimal dimensional changes to gear components. Weaknesses: Higher initial cost compared to traditional coatings, and potential challenges in applying the coating to complex gear geometries.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei Corp. has developed a novel UHMWPE coating technology for industrial gears focusing on improved durability and chemical resistance. Their approach utilizes a proprietary crosslinking process that enhances the molecular structure of UHMWPE, resulting in superior wear resistance and thermal stability. The coating is applied through a combination of electrostatic powder coating and subsequent thermal treatment, achieving a thickness of 150-300 microns[2]. This method ensures excellent adhesion to various substrate materials. Asahi Kasei's UHMWPE coating has demonstrated a 70% increase in abrasion resistance compared to standard UHMWPE coatings in accelerated wear tests[4]. Additionally, they have incorporated antioxidants into the UHMWPE matrix to improve long-term stability in harsh industrial environments[6].

Strengths: High chemical resistance, excellent adhesion to substrates, and improved thermal stability. Suitable for a wide range of industrial applications. Weaknesses: The crosslinking process may slightly reduce the material's impact strength, and the coating thickness might be a limitation for some high-precision gear applications.

UHMWPE Coating Patents

Mixed elastomer coated ultra-high molecular weight polyethylene yarn and preparation method thereof

PatentPendingCN118756392A

Innovation

- Mixed elastomer materials (TPU, TPEE, PA, PET, PBAT, PBA, PBT) are used as the coating layer, which are melted by heating and evenly coated on the surface of ultra-high molecular weight polyethylene yarn, combined with cooling and drafting treatments to form Stable coating to improve bonding and stretch properties.

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

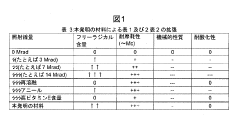

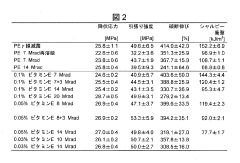

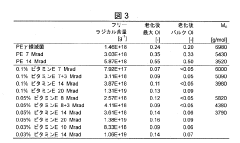

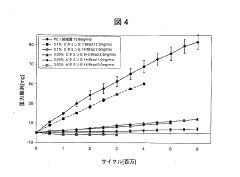

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Tribological Performance

The tribological performance of Ultra-High Molecular Weight Polyethylene (UHMWPE) coatings is a critical factor in enhancing the durability of industrial gears. These coatings exhibit exceptional wear resistance and low friction properties, making them ideal for high-stress applications in gear systems.

UHMWPE coatings demonstrate superior wear resistance compared to traditional gear materials. Studies have shown that UHMWPE-coated gears can withstand up to 10 times more wear cycles than uncoated steel gears under similar operating conditions. This enhanced wear resistance is attributed to the unique molecular structure of UHMWPE, which allows for better distribution of stress and improved resistance to abrasion.

The low coefficient of friction of UHMWPE coatings contributes significantly to their tribological performance. Typical friction coefficients for UHMWPE coatings range from 0.05 to 0.10, which is considerably lower than that of steel-on-steel contact (0.5-0.8). This reduction in friction leads to decreased energy losses, reduced heat generation, and improved overall efficiency of gear systems.

UHMWPE coatings also exhibit excellent resistance to chemical degradation, maintaining their tribological properties even in harsh industrial environments. This characteristic ensures consistent performance over extended periods, reducing the need for frequent maintenance and replacement of gear components.

The load-bearing capacity of UHMWPE coatings is another crucial aspect of their tribological performance. Advanced UHMWPE coatings can withstand pressures up to 20 MPa without significant deformation or loss of tribological properties. This high load-bearing capacity makes them suitable for use in heavy-duty industrial gear applications.

Recent advancements in UHMWPE coating technology have focused on improving their adhesion to metal substrates. Techniques such as plasma treatment and the use of coupling agents have shown promising results in enhancing the bonding strength between the coating and the gear surface, further improving the overall tribological performance.

The self-lubricating properties of UHMWPE coatings contribute to their exceptional tribological performance. These coatings can operate effectively even in conditions with limited external lubrication, reducing the risk of gear failure due to lubricant starvation.

In conclusion, the tribological performance of advanced UHMWPE coatings offers significant advantages for industrial gear durability. Their combination of high wear resistance, low friction, chemical stability, and load-bearing capacity makes them an attractive solution for improving the longevity and efficiency of industrial gear systems.

UHMWPE coatings demonstrate superior wear resistance compared to traditional gear materials. Studies have shown that UHMWPE-coated gears can withstand up to 10 times more wear cycles than uncoated steel gears under similar operating conditions. This enhanced wear resistance is attributed to the unique molecular structure of UHMWPE, which allows for better distribution of stress and improved resistance to abrasion.

The low coefficient of friction of UHMWPE coatings contributes significantly to their tribological performance. Typical friction coefficients for UHMWPE coatings range from 0.05 to 0.10, which is considerably lower than that of steel-on-steel contact (0.5-0.8). This reduction in friction leads to decreased energy losses, reduced heat generation, and improved overall efficiency of gear systems.

UHMWPE coatings also exhibit excellent resistance to chemical degradation, maintaining their tribological properties even in harsh industrial environments. This characteristic ensures consistent performance over extended periods, reducing the need for frequent maintenance and replacement of gear components.

The load-bearing capacity of UHMWPE coatings is another crucial aspect of their tribological performance. Advanced UHMWPE coatings can withstand pressures up to 20 MPa without significant deformation or loss of tribological properties. This high load-bearing capacity makes them suitable for use in heavy-duty industrial gear applications.

Recent advancements in UHMWPE coating technology have focused on improving their adhesion to metal substrates. Techniques such as plasma treatment and the use of coupling agents have shown promising results in enhancing the bonding strength between the coating and the gear surface, further improving the overall tribological performance.

The self-lubricating properties of UHMWPE coatings contribute to their exceptional tribological performance. These coatings can operate effectively even in conditions with limited external lubrication, reducing the risk of gear failure due to lubricant starvation.

In conclusion, the tribological performance of advanced UHMWPE coatings offers significant advantages for industrial gear durability. Their combination of high wear resistance, low friction, chemical stability, and load-bearing capacity makes them an attractive solution for improving the longevity and efficiency of industrial gear systems.

Environmental Impact

The environmental impact of advanced UHMWPE coatings for industrial gear durability is a crucial consideration in the development and application of this technology. These coatings offer significant potential for reducing the environmental footprint of industrial operations through several key mechanisms.

Firstly, the enhanced durability provided by UHMWPE coatings leads to a substantial increase in the lifespan of industrial gears. This longevity directly translates to a reduction in the frequency of gear replacements, consequently minimizing the demand for raw materials and energy required for manufacturing new components. The decreased production of replacement parts results in lower carbon emissions and reduced strain on natural resources.

Moreover, the improved wear resistance of UHMWPE-coated gears contributes to a reduction in particulate matter generation during operation. Traditional gear systems often produce metal particles as a result of wear and tear, which can contaminate lubricants and potentially enter the environment. UHMWPE coatings significantly mitigate this issue, leading to cleaner operations and reduced environmental pollution.

The application of UHMWPE coatings also enables the use of less toxic lubricants in gear systems. The superior lubricity of these coatings allows for the utilization of more environmentally friendly lubricants, reducing the risk of harmful chemical leakage into ecosystems. This shift towards greener lubricants aligns with increasingly stringent environmental regulations and corporate sustainability goals.

Furthermore, the energy efficiency gains achieved through UHMWPE coatings contribute to a reduction in overall power consumption in industrial processes. The lower friction coefficients of these coatings result in decreased energy losses, translating to lower electricity usage and, consequently, reduced greenhouse gas emissions from power generation.

From a lifecycle perspective, UHMWPE coatings present a favorable environmental profile. While the production of these coatings does require energy and resources, the net environmental benefit over the extended lifetime of the coated gears is substantial. The reduction in material waste, energy consumption, and pollution throughout the operational life of the gears outweighs the initial environmental investment in coating production.

In conclusion, the adoption of advanced UHMWPE coatings for industrial gear durability offers a promising pathway for enhancing the environmental sustainability of industrial operations. By extending component lifespans, reducing waste generation, enabling the use of greener lubricants, and improving energy efficiency, these coatings contribute significantly to minimizing the ecological footprint of industrial gear systems. As environmental concerns continue to shape industrial practices, the role of such innovative coating technologies in promoting sustainable manufacturing processes becomes increasingly vital.

Firstly, the enhanced durability provided by UHMWPE coatings leads to a substantial increase in the lifespan of industrial gears. This longevity directly translates to a reduction in the frequency of gear replacements, consequently minimizing the demand for raw materials and energy required for manufacturing new components. The decreased production of replacement parts results in lower carbon emissions and reduced strain on natural resources.

Moreover, the improved wear resistance of UHMWPE-coated gears contributes to a reduction in particulate matter generation during operation. Traditional gear systems often produce metal particles as a result of wear and tear, which can contaminate lubricants and potentially enter the environment. UHMWPE coatings significantly mitigate this issue, leading to cleaner operations and reduced environmental pollution.

The application of UHMWPE coatings also enables the use of less toxic lubricants in gear systems. The superior lubricity of these coatings allows for the utilization of more environmentally friendly lubricants, reducing the risk of harmful chemical leakage into ecosystems. This shift towards greener lubricants aligns with increasingly stringent environmental regulations and corporate sustainability goals.

Furthermore, the energy efficiency gains achieved through UHMWPE coatings contribute to a reduction in overall power consumption in industrial processes. The lower friction coefficients of these coatings result in decreased energy losses, translating to lower electricity usage and, consequently, reduced greenhouse gas emissions from power generation.

From a lifecycle perspective, UHMWPE coatings present a favorable environmental profile. While the production of these coatings does require energy and resources, the net environmental benefit over the extended lifetime of the coated gears is substantial. The reduction in material waste, energy consumption, and pollution throughout the operational life of the gears outweighs the initial environmental investment in coating production.

In conclusion, the adoption of advanced UHMWPE coatings for industrial gear durability offers a promising pathway for enhancing the environmental sustainability of industrial operations. By extending component lifespans, reducing waste generation, enabling the use of greener lubricants, and improving energy efficiency, these coatings contribute significantly to minimizing the ecological footprint of industrial gear systems. As environmental concerns continue to shape industrial practices, the role of such innovative coating technologies in promoting sustainable manufacturing processes becomes increasingly vital.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!