UHMWPE's Role in Advanced Prosthetic Design

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Prosthetics: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the field of advanced prosthetic design, marking a significant milestone in the evolution of artificial limbs and joint replacements. The journey of UHMWPE in prosthetics began in the 1960s when it was first introduced as a bearing surface in total hip arthroplasty. Since then, its unique properties have propelled it to become a cornerstone material in modern prosthetic applications.

The development of UHMWPE for prosthetic use has been driven by the increasing demand for more durable, biocompatible, and high-performance materials in medical implants. As life expectancy increases globally, there is a growing need for prosthetic solutions that can withstand longer periods of use and provide improved quality of life for patients. This has led to continuous research and innovation in UHMWPE technology, focusing on enhancing its wear resistance, mechanical strength, and longevity.

One of the primary objectives in the advancement of UHMWPE for prosthetics is to address the limitations of traditional materials. Conventional prosthetic materials often suffer from issues such as wear debris generation, oxidative degradation, and limited lifespan. UHMWPE, with its exceptional wear resistance and low friction coefficient, offers a promising solution to these challenges. The goal is to develop prosthetic components that can maintain their structural integrity and performance over extended periods, reducing the need for revision surgeries and improving patient outcomes.

The evolution of UHMWPE in prosthetics has seen several key technological advancements. Cross-linked UHMWPE, introduced in the late 1990s, represented a significant leap forward in wear resistance. Subsequent innovations have focused on incorporating antioxidants, such as vitamin E, to combat oxidative degradation and further enhance the material's longevity. These developments align with the broader objective of creating "smart" prosthetics that can adapt to the user's needs and provide more natural functionality.

Looking ahead, the future of UHMWPE in prosthetic design is poised for further innovation. Research is ongoing to explore new manufacturing techniques, such as 3D printing of UHMWPE components, which could revolutionize the customization and production of prosthetic devices. Additionally, there is growing interest in developing UHMWPE composites that combine the material's inherent strengths with other advanced materials to create prosthetics with enhanced properties and functionalities.

The overarching goal in the development of UHMWPE for prosthetics is to bridge the gap between artificial and biological systems. This involves not only improving the mechanical properties of the material but also enhancing its biocompatibility and integration with the human body. As research progresses, the aim is to create prosthetic solutions that can more closely mimic natural human movement and function, ultimately leading to improved quality of life for individuals requiring prosthetic devices.

The development of UHMWPE for prosthetic use has been driven by the increasing demand for more durable, biocompatible, and high-performance materials in medical implants. As life expectancy increases globally, there is a growing need for prosthetic solutions that can withstand longer periods of use and provide improved quality of life for patients. This has led to continuous research and innovation in UHMWPE technology, focusing on enhancing its wear resistance, mechanical strength, and longevity.

One of the primary objectives in the advancement of UHMWPE for prosthetics is to address the limitations of traditional materials. Conventional prosthetic materials often suffer from issues such as wear debris generation, oxidative degradation, and limited lifespan. UHMWPE, with its exceptional wear resistance and low friction coefficient, offers a promising solution to these challenges. The goal is to develop prosthetic components that can maintain their structural integrity and performance over extended periods, reducing the need for revision surgeries and improving patient outcomes.

The evolution of UHMWPE in prosthetics has seen several key technological advancements. Cross-linked UHMWPE, introduced in the late 1990s, represented a significant leap forward in wear resistance. Subsequent innovations have focused on incorporating antioxidants, such as vitamin E, to combat oxidative degradation and further enhance the material's longevity. These developments align with the broader objective of creating "smart" prosthetics that can adapt to the user's needs and provide more natural functionality.

Looking ahead, the future of UHMWPE in prosthetic design is poised for further innovation. Research is ongoing to explore new manufacturing techniques, such as 3D printing of UHMWPE components, which could revolutionize the customization and production of prosthetic devices. Additionally, there is growing interest in developing UHMWPE composites that combine the material's inherent strengths with other advanced materials to create prosthetics with enhanced properties and functionalities.

The overarching goal in the development of UHMWPE for prosthetics is to bridge the gap between artificial and biological systems. This involves not only improving the mechanical properties of the material but also enhancing its biocompatibility and integration with the human body. As research progresses, the aim is to create prosthetic solutions that can more closely mimic natural human movement and function, ultimately leading to improved quality of life for individuals requiring prosthetic devices.

Market Analysis for Advanced Prosthetic Materials

The market for advanced prosthetic materials, particularly Ultra-High Molecular Weight Polyethylene (UHMWPE), has shown significant growth in recent years. This trend is driven by the increasing demand for high-performance, lightweight, and durable prosthetic components that can enhance the quality of life for amputees and individuals with limb differences.

UHMWPE has emerged as a key material in advanced prosthetic design due to its exceptional properties, including high strength-to-weight ratio, excellent wear resistance, and biocompatibility. These characteristics make it ideal for use in prosthetic joints, sockets, and structural components, contributing to improved comfort, mobility, and longevity of prosthetic devices.

The global prosthetics market, which includes materials like UHMWPE, is experiencing steady growth. Factors contributing to this expansion include the rising prevalence of diabetes and vascular diseases leading to amputations, an aging population, and increased awareness and acceptance of advanced prosthetic solutions. Additionally, technological advancements in prosthetic design and manufacturing processes have expanded the application scope of UHMWPE in this field.

Geographically, North America and Europe currently dominate the market for advanced prosthetic materials, including UHMWPE. This is primarily due to well-established healthcare infrastructure, higher healthcare spending, and greater adoption of cutting-edge medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access, rising disposable incomes, and increasing awareness of advanced prosthetic options.

The adoption of UHMWPE in prosthetics is also influenced by ongoing research and development efforts aimed at enhancing its properties and expanding its applications. Innovations such as cross-linked UHMWPE and vitamin E-infused UHMWPE are opening new possibilities for improved wear resistance and longevity in prosthetic components.

Despite the positive market outlook, challenges remain. The high cost of advanced prosthetic materials and devices can limit accessibility, particularly in developing regions. Additionally, reimbursement policies and insurance coverage for high-end prosthetics vary widely across different countries, impacting market growth potential.

Looking ahead, the market for UHMWPE in advanced prosthetic design is poised for continued growth. Factors such as increasing investment in research and development, growing demand for customized prosthetic solutions, and advancements in 3D printing technology for prosthetic manufacturing are expected to drive innovation and market expansion in the coming years.

UHMWPE has emerged as a key material in advanced prosthetic design due to its exceptional properties, including high strength-to-weight ratio, excellent wear resistance, and biocompatibility. These characteristics make it ideal for use in prosthetic joints, sockets, and structural components, contributing to improved comfort, mobility, and longevity of prosthetic devices.

The global prosthetics market, which includes materials like UHMWPE, is experiencing steady growth. Factors contributing to this expansion include the rising prevalence of diabetes and vascular diseases leading to amputations, an aging population, and increased awareness and acceptance of advanced prosthetic solutions. Additionally, technological advancements in prosthetic design and manufacturing processes have expanded the application scope of UHMWPE in this field.

Geographically, North America and Europe currently dominate the market for advanced prosthetic materials, including UHMWPE. This is primarily due to well-established healthcare infrastructure, higher healthcare spending, and greater adoption of cutting-edge medical technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access, rising disposable incomes, and increasing awareness of advanced prosthetic options.

The adoption of UHMWPE in prosthetics is also influenced by ongoing research and development efforts aimed at enhancing its properties and expanding its applications. Innovations such as cross-linked UHMWPE and vitamin E-infused UHMWPE are opening new possibilities for improved wear resistance and longevity in prosthetic components.

Despite the positive market outlook, challenges remain. The high cost of advanced prosthetic materials and devices can limit accessibility, particularly in developing regions. Additionally, reimbursement policies and insurance coverage for high-end prosthetics vary widely across different countries, impacting market growth potential.

Looking ahead, the market for UHMWPE in advanced prosthetic design is poised for continued growth. Factors such as increasing investment in research and development, growing demand for customized prosthetic solutions, and advancements in 3D printing technology for prosthetic manufacturing are expected to drive innovation and market expansion in the coming years.

Current Challenges in UHMWPE Prosthetic Applications

Despite the widespread use of Ultra-High Molecular Weight Polyethylene (UHMWPE) in prosthetic applications, several challenges persist in maximizing its potential. One of the primary concerns is the material's susceptibility to wear and oxidation, which can lead to reduced longevity of prosthetic components. This issue is particularly pronounced in high-stress applications such as knee and hip replacements, where the material undergoes continuous mechanical stress and exposure to bodily fluids.

Another significant challenge lies in balancing the mechanical properties of UHMWPE. While its high molecular weight contributes to excellent wear resistance and impact strength, it can also result in reduced processability and difficulty in achieving optimal surface finishes. This trade-off between performance and manufacturability poses a constant challenge for prosthetic designers and manufacturers.

The biocompatibility of UHMWPE, although generally good, still presents some concerns. Long-term implantation can lead to the release of microscopic wear particles, potentially triggering inflammatory responses in surrounding tissues. This phenomenon, known as osteolysis, can compromise the stability of prosthetic implants and necessitate revision surgeries.

Furthermore, the integration of UHMWPE with other materials in advanced prosthetic designs presents its own set of challenges. Achieving strong, durable bonds between UHMWPE and metals or ceramics often requires specialized surface treatments or bonding techniques, adding complexity to the manufacturing process.

The sterilization of UHMWPE components also remains a critical issue. Traditional methods such as gamma irradiation can induce cross-linking, which enhances wear resistance but may also lead to increased brittleness and oxidation susceptibility. Balancing sterilization efficacy with the preservation of desirable material properties continues to be a focus of ongoing research and development efforts.

Another challenge lies in the customization of UHMWPE for specific patient needs. While the material offers good overall performance, tailoring its properties to match individual patient characteristics, such as activity level, weight, and anatomy, remains difficult. This limitation can impact the overall effectiveness and longevity of prosthetic devices.

Lastly, the environmental impact of UHMWPE in prosthetics is an emerging concern. As a non-biodegradable polymer, the disposal and recycling of UHMWPE components at the end of their service life pose significant environmental challenges. Developing sustainable practices for the lifecycle management of UHMWPE prosthetics is becoming increasingly important in the context of global environmental consciousness.

Another significant challenge lies in balancing the mechanical properties of UHMWPE. While its high molecular weight contributes to excellent wear resistance and impact strength, it can also result in reduced processability and difficulty in achieving optimal surface finishes. This trade-off between performance and manufacturability poses a constant challenge for prosthetic designers and manufacturers.

The biocompatibility of UHMWPE, although generally good, still presents some concerns. Long-term implantation can lead to the release of microscopic wear particles, potentially triggering inflammatory responses in surrounding tissues. This phenomenon, known as osteolysis, can compromise the stability of prosthetic implants and necessitate revision surgeries.

Furthermore, the integration of UHMWPE with other materials in advanced prosthetic designs presents its own set of challenges. Achieving strong, durable bonds between UHMWPE and metals or ceramics often requires specialized surface treatments or bonding techniques, adding complexity to the manufacturing process.

The sterilization of UHMWPE components also remains a critical issue. Traditional methods such as gamma irradiation can induce cross-linking, which enhances wear resistance but may also lead to increased brittleness and oxidation susceptibility. Balancing sterilization efficacy with the preservation of desirable material properties continues to be a focus of ongoing research and development efforts.

Another challenge lies in the customization of UHMWPE for specific patient needs. While the material offers good overall performance, tailoring its properties to match individual patient characteristics, such as activity level, weight, and anatomy, remains difficult. This limitation can impact the overall effectiveness and longevity of prosthetic devices.

Lastly, the environmental impact of UHMWPE in prosthetics is an emerging concern. As a non-biodegradable polymer, the disposal and recycling of UHMWPE components at the end of their service life pose significant environmental challenges. Developing sustainable practices for the lifecycle management of UHMWPE prosthetics is becoming increasingly important in the context of global environmental consciousness.

Existing UHMWPE Solutions in Prosthetics

01 Composition and manufacturing of UHMWPE

UHMWPE is a type of polyethylene with extremely long chains, resulting in a very high molecular weight. The manufacturing process typically involves polymerization of ethylene using specialized catalysts and controlled conditions. Various additives and processing techniques can be employed to enhance its properties, such as cross-linking or the incorporation of reinforcing materials.- Composition and manufacturing of UHMWPE: Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene with extremely long molecular chains. The manufacturing process involves specialized polymerization techniques to achieve the high molecular weight. Various additives and processing methods can be used to enhance its properties, such as improved wear resistance and mechanical strength.

- Applications of UHMWPE in medical devices: UHMWPE is widely used in medical applications due to its biocompatibility and excellent mechanical properties. It is commonly used in orthopedic implants, such as artificial joints, due to its low friction and high wear resistance. The material can be processed into various forms, including fibers and films, for use in medical devices and surgical applications.

- UHMWPE fiber reinforcement in composites: UHMWPE fibers are used as reinforcement in composite materials due to their high strength-to-weight ratio and excellent impact resistance. These composites find applications in various industries, including aerospace, automotive, and protective equipment. The fibers can be combined with different matrix materials to create composites with tailored properties.

- Surface modification and coating of UHMWPE: Various surface modification techniques and coatings are applied to UHMWPE to enhance its properties for specific applications. These modifications can improve wear resistance, reduce friction, or enhance bonding with other materials. Techniques such as plasma treatment, chemical grafting, and nanoparticle incorporation are used to modify the surface characteristics of UHMWPE.

- Recycling and sustainability of UHMWPE: Efforts are being made to develop recycling methods for UHMWPE products to improve sustainability. This includes mechanical recycling, chemical recycling, and the development of biodegradable additives. Research is also focused on creating more environmentally friendly production processes and exploring bio-based alternatives for UHMWPE.

02 Applications of UHMWPE in medical devices

UHMWPE is widely used in medical applications due to its biocompatibility, wear resistance, and low friction properties. It is commonly used in orthopedic implants, such as artificial joints, as well as in other medical devices like catheters and surgical instruments. Research focuses on improving its longevity and performance in these applications.Expand Specific Solutions03 UHMWPE fibers and composites

UHMWPE can be processed into high-strength fibers and used in composite materials. These fibers exhibit exceptional strength-to-weight ratios and are used in applications requiring high performance, such as ballistic protection, ropes, and sports equipment. Composite materials incorporating UHMWPE fibers can offer enhanced mechanical properties and impact resistance.Expand Specific Solutions04 Surface modification and coating of UHMWPE

Various surface modification techniques and coatings can be applied to UHMWPE to enhance its properties or compatibility with other materials. These modifications can improve wear resistance, reduce friction, or enhance bonding with other substances. Examples include plasma treatment, chemical grafting, and the application of specialized coatings.Expand Specific Solutions05 Recycling and sustainability of UHMWPE

As environmental concerns grow, research is being conducted on methods to recycle and reuse UHMWPE materials. This includes developing processes for breaking down and reprocessing UHMWPE products, as well as exploring bio-based alternatives or additives to improve the material's environmental profile. Efforts are also being made to enhance the material's longevity to reduce waste.Expand Specific Solutions

Key Players in UHMWPE Prosthetic Development

The market for UHMWPE in advanced prosthetic design is in a growth phase, driven by increasing demand for high-performance, lightweight materials in medical applications. The global market size for UHMWPE in orthopedic implants is expected to expand significantly in the coming years. Technologically, UHMWPE is mature but continues to evolve, with companies like Howmedica Osteonics Corp., Smith & Nephew Orthopaedics GmbH, and DePuy Synthes Products, Inc. leading innovations in wear resistance and longevity. Research institutions such as Massachusetts Institute of Technology and University of Southern California are contributing to advancements in UHMWPE formulations and processing techniques, further enhancing its properties for prosthetic applications.

Howmedica Osteonics Corp.

Technical Solution: Howmedica Osteonics, now part of Stryker Corporation, has contributed significantly to UHMWPE advancements in prosthetic design. Their X3 Advanced Bearing Technology utilizes a sequential irradiation and annealing process to create a highly cross-linked UHMWPE with improved wear resistance and oxidation stability. This material has shown up to 96% reduction in wear compared to conventional UHMWPE in hip simulator studies[8]. Additionally, they have developed the Tritanium Advanced Fixation Technology, which combines a porous titanium structure with their advanced UHMWPE to enhance implant stability and promote bone ingrowth[9].

Strengths: Excellent wear resistance, maintained mechanical properties, and potential for enhanced implant fixation. Weaknesses: Increased production complexity and costs associated with advanced processing techniques.

Zimmer, Inc.

Technical Solution: Zimmer has made significant strides in UHMWPE technology for prosthetic applications with their Vivacit-E HXPE (Highly Cross-linked Polyethylene) material. This innovation incorporates vitamin E as an antioxidant directly into the UHMWPE resin before consolidation and irradiation. The process results in a material with improved oxidation resistance and mechanical properties, showing up to 97% less wear than conventional polyethylene in hip simulator studies[6]. Zimmer has also developed the Trabecular Metal Technology, which, when used in conjunction with their advanced UHMWPE, provides a unique porous structure that promotes bone ingrowth and stability in joint replacements[7].

Strengths: Enhanced wear resistance, oxidative stability, and potential for improved implant fixation. Weaknesses: Complex manufacturing process and higher material costs.

Innovations in UHMWPE for Prosthetic Use

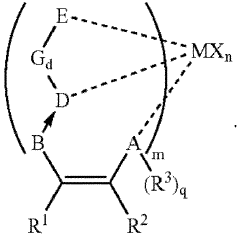

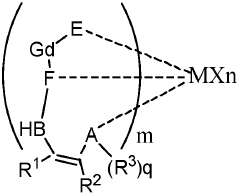

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

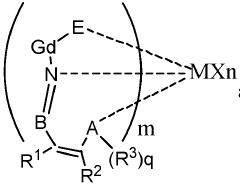

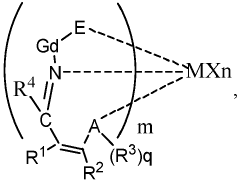

Ultra-high molecular weight polyethylene

PatentWO2011089017A1

Innovation

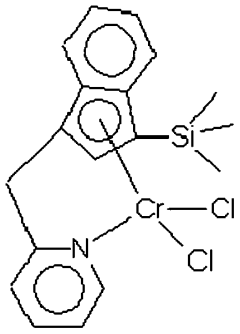

- The use of a blend of two metallocene-type catalysts, with Hafnium (Hf) and Chromium (Cr) as catalyst residues, to produce UHMW-PE with medium density and enhanced Charpy impact resistance, achieving a synergistic effect that improves both abrasion and impact resistance, and maintaining a suitable average grain size.

Biocompatibility and Safety Considerations

The biocompatibility and safety considerations of Ultra-High Molecular Weight Polyethylene (UHMWPE) in advanced prosthetic design are paramount to ensuring the long-term success and patient well-being in orthopedic applications. UHMWPE has been widely used in prosthetic components due to its excellent mechanical properties and wear resistance. However, its interaction with the human body requires careful evaluation and ongoing research.

One of the primary concerns in using UHMWPE for prosthetics is its potential to generate wear particles over time. These microscopic particles can lead to an inflammatory response in the surrounding tissues, potentially causing osteolysis and implant loosening. To address this issue, researchers have developed cross-linked UHMWPE, which exhibits improved wear resistance and reduced particle generation. Additionally, the incorporation of antioxidants, such as vitamin E, has shown promise in enhancing the material's long-term stability and reducing oxidative degradation.

The biocompatibility of UHMWPE has been extensively studied, with numerous in vitro and in vivo tests demonstrating its overall safety for use in prosthetic applications. However, the material's surface properties play a crucial role in its interaction with cells and tissues. Surface modifications, such as plasma treatment or the application of bioactive coatings, have been explored to enhance cell adhesion and promote better integration with the surrounding tissue.

Another important safety consideration is the potential for bacterial colonization on UHMWPE surfaces. While the material itself does not promote bacterial growth, the formation of biofilms on prosthetic components can lead to serious infections. To mitigate this risk, researchers are investigating antimicrobial surface treatments and coatings that can be applied to UHMWPE without compromising its mechanical properties or biocompatibility.

The sterilization process for UHMWPE components is also a critical factor in ensuring safety. Traditional methods, such as gamma irradiation, can induce oxidation and affect the material's long-term performance. Alternative sterilization techniques, including ethylene oxide treatment and gas plasma sterilization, have been developed to minimize these adverse effects while maintaining the material's integrity and biocompatibility.

As prosthetic designs continue to evolve, the integration of UHMWPE with other materials, such as metals and ceramics, presents new challenges in terms of biocompatibility and safety. The interface between different materials must be carefully engineered to prevent galvanic corrosion, material degradation, and the release of potentially harmful ions or particles. Ongoing research in this area focuses on developing novel surface treatments and interface designs to ensure the long-term stability and safety of multi-material prosthetic components.

One of the primary concerns in using UHMWPE for prosthetics is its potential to generate wear particles over time. These microscopic particles can lead to an inflammatory response in the surrounding tissues, potentially causing osteolysis and implant loosening. To address this issue, researchers have developed cross-linked UHMWPE, which exhibits improved wear resistance and reduced particle generation. Additionally, the incorporation of antioxidants, such as vitamin E, has shown promise in enhancing the material's long-term stability and reducing oxidative degradation.

The biocompatibility of UHMWPE has been extensively studied, with numerous in vitro and in vivo tests demonstrating its overall safety for use in prosthetic applications. However, the material's surface properties play a crucial role in its interaction with cells and tissues. Surface modifications, such as plasma treatment or the application of bioactive coatings, have been explored to enhance cell adhesion and promote better integration with the surrounding tissue.

Another important safety consideration is the potential for bacterial colonization on UHMWPE surfaces. While the material itself does not promote bacterial growth, the formation of biofilms on prosthetic components can lead to serious infections. To mitigate this risk, researchers are investigating antimicrobial surface treatments and coatings that can be applied to UHMWPE without compromising its mechanical properties or biocompatibility.

The sterilization process for UHMWPE components is also a critical factor in ensuring safety. Traditional methods, such as gamma irradiation, can induce oxidation and affect the material's long-term performance. Alternative sterilization techniques, including ethylene oxide treatment and gas plasma sterilization, have been developed to minimize these adverse effects while maintaining the material's integrity and biocompatibility.

As prosthetic designs continue to evolve, the integration of UHMWPE with other materials, such as metals and ceramics, presents new challenges in terms of biocompatibility and safety. The interface between different materials must be carefully engineered to prevent galvanic corrosion, material degradation, and the release of potentially harmful ions or particles. Ongoing research in this area focuses on developing novel surface treatments and interface designs to ensure the long-term stability and safety of multi-material prosthetic components.

Cost-Effectiveness Analysis of UHMWPE Prosthetics

The cost-effectiveness analysis of UHMWPE prosthetics reveals significant advantages in both economic and functional aspects. UHMWPE, or Ultra-High Molecular Weight Polyethylene, has emerged as a game-changing material in advanced prosthetic design due to its unique properties and cost-efficient production methods.

From a manufacturing standpoint, UHMWPE offers substantial cost savings compared to traditional materials such as titanium or carbon fiber composites. The raw material costs are considerably lower, and the production process is less energy-intensive, resulting in reduced overall manufacturing expenses. Additionally, the ease of molding and shaping UHMWPE allows for more efficient production lines, further decreasing costs associated with prosthetic fabrication.

The durability of UHMWPE prosthetics translates into long-term cost benefits for both healthcare systems and patients. These prosthetics exhibit exceptional wear resistance and mechanical strength, leading to extended lifespans and reduced frequency of replacements. This longevity not only minimizes the financial burden on healthcare providers and insurance companies but also reduces the physical and emotional stress on patients who would otherwise require more frequent prosthetic replacements.

In terms of functionality, UHMWPE prosthetics offer a superior cost-to-performance ratio. The material's lightweight nature enhances mobility and reduces energy expenditure for users, potentially leading to improved quality of life and decreased associated healthcare costs. The biocompatibility of UHMWPE also minimizes the risk of adverse reactions, thereby reducing potential medical complications and their associated expenses.

Maintenance costs for UHMWPE prosthetics are notably lower compared to alternatives. The material's resistance to chemicals, moisture, and abrasion means less frequent need for repairs or adjustments. This reduced maintenance requirement not only saves money but also minimizes disruption to the user's daily life.

When considering the entire lifecycle of prosthetic devices, UHMWPE demonstrates impressive cost-effectiveness. The initial investment in UHMWPE prosthetics, while potentially higher than some basic alternatives, is offset by their extended lifespan and reduced need for replacements. This long-term view reveals significant savings for healthcare systems and individuals alike.

The scalability of UHMWPE production also contributes to its cost-effectiveness. As demand for these advanced prosthetics grows, economies of scale in manufacturing are likely to further reduce costs, making high-quality prosthetics more accessible to a broader population.

In conclusion, the cost-effectiveness analysis of UHMWPE prosthetics demonstrates a compelling case for their adoption in advanced prosthetic design. The combination of lower production costs, extended durability, reduced maintenance needs, and improved functionality positions UHMWPE as an economically viable and technologically superior choice in the field of prosthetics.

From a manufacturing standpoint, UHMWPE offers substantial cost savings compared to traditional materials such as titanium or carbon fiber composites. The raw material costs are considerably lower, and the production process is less energy-intensive, resulting in reduced overall manufacturing expenses. Additionally, the ease of molding and shaping UHMWPE allows for more efficient production lines, further decreasing costs associated with prosthetic fabrication.

The durability of UHMWPE prosthetics translates into long-term cost benefits for both healthcare systems and patients. These prosthetics exhibit exceptional wear resistance and mechanical strength, leading to extended lifespans and reduced frequency of replacements. This longevity not only minimizes the financial burden on healthcare providers and insurance companies but also reduces the physical and emotional stress on patients who would otherwise require more frequent prosthetic replacements.

In terms of functionality, UHMWPE prosthetics offer a superior cost-to-performance ratio. The material's lightweight nature enhances mobility and reduces energy expenditure for users, potentially leading to improved quality of life and decreased associated healthcare costs. The biocompatibility of UHMWPE also minimizes the risk of adverse reactions, thereby reducing potential medical complications and their associated expenses.

Maintenance costs for UHMWPE prosthetics are notably lower compared to alternatives. The material's resistance to chemicals, moisture, and abrasion means less frequent need for repairs or adjustments. This reduced maintenance requirement not only saves money but also minimizes disruption to the user's daily life.

When considering the entire lifecycle of prosthetic devices, UHMWPE demonstrates impressive cost-effectiveness. The initial investment in UHMWPE prosthetics, while potentially higher than some basic alternatives, is offset by their extended lifespan and reduced need for replacements. This long-term view reveals significant savings for healthcare systems and individuals alike.

The scalability of UHMWPE production also contributes to its cost-effectiveness. As demand for these advanced prosthetics grows, economies of scale in manufacturing are likely to further reduce costs, making high-quality prosthetics more accessible to a broader population.

In conclusion, the cost-effectiveness analysis of UHMWPE prosthetics demonstrates a compelling case for their adoption in advanced prosthetic design. The combination of lower production costs, extended durability, reduced maintenance needs, and improved functionality positions UHMWPE as an economically viable and technologically superior choice in the field of prosthetics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!