Characterization of UHMWPE Surfaces for Improved Adhesion

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Surface Challenges

Ultra-high molecular weight polyethylene (UHMWPE) surfaces present significant challenges in achieving improved adhesion due to their inherent chemical and physical properties. The low surface energy and inert nature of UHMWPE result in poor wettability and limited chemical reactivity, making it difficult for adhesives or coatings to form strong bonds with the material.

One of the primary challenges is the lack of functional groups on the UHMWPE surface. The polymer chains consist mainly of carbon and hydrogen atoms, with no polar groups that could facilitate chemical bonding or interactions with adhesives. This absence of reactive sites severely limits the ability of adhesives to form covalent or strong secondary bonds with the surface.

The high molecular weight and crystalline structure of UHMWPE also contribute to its surface challenges. The long, entangled polymer chains create a dense, smooth surface with minimal surface roughness. This lack of mechanical interlocking opportunities further hinders adhesion, as there are few physical anchor points for adhesives to grip onto.

Surface contamination poses another significant challenge. UHMWPE's low surface energy makes it prone to accumulating contaminants such as oils, dust, and other particulates. These contaminants can form a weak boundary layer that interferes with adhesive bonding, even if surface modification techniques are applied.

The material's resistance to chemical etching and oxidation further complicates surface modification efforts. Traditional chemical treatments that work well for other polymers often have limited effectiveness on UHMWPE, requiring more aggressive or specialized approaches to alter the surface properties.

Temperature sensitivity is another factor to consider. UHMWPE has a relatively low melting point compared to other engineering plastics, which limits the range of thermal treatments that can be applied without compromising the bulk properties of the material. This constraint narrows the options for thermal surface modification techniques.

The dynamic nature of the UHMWPE surface adds another layer of complexity. Even when surface modifications are successfully applied, the polymer chains' mobility can lead to surface reorganization over time, potentially reversing or diminishing the effects of the treatment. This phenomenon, known as hydrophobic recovery, can reduce the long-term effectiveness of adhesion improvement efforts.

Lastly, the characterization of UHMWPE surfaces itself presents challenges. The material's low surface energy and chemical inertness can make it difficult to obtain accurate measurements using conventional surface analysis techniques. This complicates the process of quantifying surface modifications and understanding their impact on adhesion properties.

One of the primary challenges is the lack of functional groups on the UHMWPE surface. The polymer chains consist mainly of carbon and hydrogen atoms, with no polar groups that could facilitate chemical bonding or interactions with adhesives. This absence of reactive sites severely limits the ability of adhesives to form covalent or strong secondary bonds with the surface.

The high molecular weight and crystalline structure of UHMWPE also contribute to its surface challenges. The long, entangled polymer chains create a dense, smooth surface with minimal surface roughness. This lack of mechanical interlocking opportunities further hinders adhesion, as there are few physical anchor points for adhesives to grip onto.

Surface contamination poses another significant challenge. UHMWPE's low surface energy makes it prone to accumulating contaminants such as oils, dust, and other particulates. These contaminants can form a weak boundary layer that interferes with adhesive bonding, even if surface modification techniques are applied.

The material's resistance to chemical etching and oxidation further complicates surface modification efforts. Traditional chemical treatments that work well for other polymers often have limited effectiveness on UHMWPE, requiring more aggressive or specialized approaches to alter the surface properties.

Temperature sensitivity is another factor to consider. UHMWPE has a relatively low melting point compared to other engineering plastics, which limits the range of thermal treatments that can be applied without compromising the bulk properties of the material. This constraint narrows the options for thermal surface modification techniques.

The dynamic nature of the UHMWPE surface adds another layer of complexity. Even when surface modifications are successfully applied, the polymer chains' mobility can lead to surface reorganization over time, potentially reversing or diminishing the effects of the treatment. This phenomenon, known as hydrophobic recovery, can reduce the long-term effectiveness of adhesion improvement efforts.

Lastly, the characterization of UHMWPE surfaces itself presents challenges. The material's low surface energy and chemical inertness can make it difficult to obtain accurate measurements using conventional surface analysis techniques. This complicates the process of quantifying surface modifications and understanding their impact on adhesion properties.

Market Demand Analysis

The market demand for improved adhesion of Ultra-High Molecular Weight Polyethylene (UHMWPE) surfaces has been steadily growing across various industries. This demand is primarily driven by the unique properties of UHMWPE, including its high impact strength, low friction coefficient, and excellent chemical resistance. However, the inherent low surface energy of UHMWPE poses significant challenges for adhesion, limiting its applications in many fields.

In the medical device industry, there is a pressing need for enhanced UHMWPE surface adhesion in orthopedic implants, particularly for hip and knee replacements. Improved adhesion can lead to better integration with bone cement and increased implant longevity. The global orthopedic implants market, where UHMWPE is extensively used, is projected to reach substantial growth in the coming years, further emphasizing the importance of adhesion improvements.

The aerospace sector also demonstrates a strong demand for UHMWPE with improved adhesion properties. UHMWPE composites are increasingly used in aircraft interiors and structural components due to their lightweight nature and high strength-to-weight ratio. Enhanced surface adhesion would enable better bonding with other materials, expanding the potential applications of UHMWPE in this high-value industry.

In the automotive industry, UHMWPE is gaining traction for use in wear-resistant components and lightweight structures. Improved adhesion capabilities would allow for more efficient integration of UHMWPE parts with other materials, potentially leading to weight reduction and enhanced fuel efficiency in vehicles.

The packaging industry represents another significant market for UHMWPE with improved adhesion. Better surface adhesion properties would enable the development of more effective multi-layer packaging materials, enhancing barrier properties and extending the shelf life of packaged goods.

The sports and recreation sector also shows growing interest in UHMWPE with enhanced adhesion. From protective gear to high-performance sporting equipment, improved bonding capabilities could lead to more durable and effective products.

Market analysis indicates that companies investing in research and development of UHMWPE surface modification techniques for improved adhesion are likely to gain a competitive edge. The potential for expanding UHMWPE applications into new markets and enhancing its performance in existing applications presents significant opportunities for growth and innovation.

As environmental concerns continue to rise, there is an increasing demand for sustainable and recyclable materials. Improving the adhesion properties of UHMWPE could potentially enhance its recyclability and expand its use in eco-friendly applications, aligning with global sustainability trends.

In the medical device industry, there is a pressing need for enhanced UHMWPE surface adhesion in orthopedic implants, particularly for hip and knee replacements. Improved adhesion can lead to better integration with bone cement and increased implant longevity. The global orthopedic implants market, where UHMWPE is extensively used, is projected to reach substantial growth in the coming years, further emphasizing the importance of adhesion improvements.

The aerospace sector also demonstrates a strong demand for UHMWPE with improved adhesion properties. UHMWPE composites are increasingly used in aircraft interiors and structural components due to their lightweight nature and high strength-to-weight ratio. Enhanced surface adhesion would enable better bonding with other materials, expanding the potential applications of UHMWPE in this high-value industry.

In the automotive industry, UHMWPE is gaining traction for use in wear-resistant components and lightweight structures. Improved adhesion capabilities would allow for more efficient integration of UHMWPE parts with other materials, potentially leading to weight reduction and enhanced fuel efficiency in vehicles.

The packaging industry represents another significant market for UHMWPE with improved adhesion. Better surface adhesion properties would enable the development of more effective multi-layer packaging materials, enhancing barrier properties and extending the shelf life of packaged goods.

The sports and recreation sector also shows growing interest in UHMWPE with enhanced adhesion. From protective gear to high-performance sporting equipment, improved bonding capabilities could lead to more durable and effective products.

Market analysis indicates that companies investing in research and development of UHMWPE surface modification techniques for improved adhesion are likely to gain a competitive edge. The potential for expanding UHMWPE applications into new markets and enhancing its performance in existing applications presents significant opportunities for growth and innovation.

As environmental concerns continue to rise, there is an increasing demand for sustainable and recyclable materials. Improving the adhesion properties of UHMWPE could potentially enhance its recyclability and expand its use in eco-friendly applications, aligning with global sustainability trends.

Current State of UHMWPE

Ultra-high molecular weight polyethylene (UHMWPE) is a high-performance polymer widely used in various industries due to its exceptional mechanical properties, chemical resistance, and low friction coefficient. However, its inherently low surface energy poses significant challenges for adhesion applications, limiting its use in certain fields.

The current state of UHMWPE surfaces is characterized by their hydrophobic nature, resulting from the material's non-polar structure and lack of reactive functional groups. This hydrophobicity leads to poor wettability and weak adhesion to other materials, including adhesives, coatings, and biological substances. Consequently, untreated UHMWPE surfaces exhibit limited compatibility with many industrial and biomedical applications that require strong interfacial bonding.

Recent research has focused on developing various surface modification techniques to enhance the adhesion properties of UHMWPE. These methods aim to alter the surface chemistry and topography without compromising the bulk properties of the material. Common approaches include plasma treatment, chemical etching, UV irradiation, and grafting of functional groups.

Plasma treatment has emerged as a promising technique for improving UHMWPE surface characteristics. This method introduces oxygen-containing functional groups on the surface, increasing its surface energy and wettability. However, the effects of plasma treatment are often temporary, with surface properties reverting over time due to the polymer's tendency to recover its original state.

Chemical etching, typically using strong oxidizing agents, has been employed to create a more reactive surface by introducing polar groups and increasing surface roughness. While effective, this method can potentially degrade the material's bulk properties if not carefully controlled.

UV irradiation, often combined with photoinitiators or photosensitizers, has shown potential for creating reactive sites on the UHMWPE surface. This technique allows for subsequent grafting of functional molecules, enhancing adhesion properties. However, the depth of modification is limited, and the process can be time-consuming.

Grafting techniques, such as radiation-induced grafting and plasma-induced grafting, have been explored to covalently attach functional molecules to the UHMWPE surface. These methods offer more stable and long-lasting surface modifications but can be complex and costly to implement on a large scale.

Despite these advancements, challenges remain in achieving uniform, stable, and cost-effective surface modifications for UHMWPE. The development of scalable and industrially viable processes for enhancing UHMWPE surface adhesion properties continues to be an active area of research and development.

The current state of UHMWPE surfaces is characterized by their hydrophobic nature, resulting from the material's non-polar structure and lack of reactive functional groups. This hydrophobicity leads to poor wettability and weak adhesion to other materials, including adhesives, coatings, and biological substances. Consequently, untreated UHMWPE surfaces exhibit limited compatibility with many industrial and biomedical applications that require strong interfacial bonding.

Recent research has focused on developing various surface modification techniques to enhance the adhesion properties of UHMWPE. These methods aim to alter the surface chemistry and topography without compromising the bulk properties of the material. Common approaches include plasma treatment, chemical etching, UV irradiation, and grafting of functional groups.

Plasma treatment has emerged as a promising technique for improving UHMWPE surface characteristics. This method introduces oxygen-containing functional groups on the surface, increasing its surface energy and wettability. However, the effects of plasma treatment are often temporary, with surface properties reverting over time due to the polymer's tendency to recover its original state.

Chemical etching, typically using strong oxidizing agents, has been employed to create a more reactive surface by introducing polar groups and increasing surface roughness. While effective, this method can potentially degrade the material's bulk properties if not carefully controlled.

UV irradiation, often combined with photoinitiators or photosensitizers, has shown potential for creating reactive sites on the UHMWPE surface. This technique allows for subsequent grafting of functional molecules, enhancing adhesion properties. However, the depth of modification is limited, and the process can be time-consuming.

Grafting techniques, such as radiation-induced grafting and plasma-induced grafting, have been explored to covalently attach functional molecules to the UHMWPE surface. These methods offer more stable and long-lasting surface modifications but can be complex and costly to implement on a large scale.

Despite these advancements, challenges remain in achieving uniform, stable, and cost-effective surface modifications for UHMWPE. The development of scalable and industrially viable processes for enhancing UHMWPE surface adhesion properties continues to be an active area of research and development.

Existing Surface Solutions

01 Surface modification techniques for UHMWPE adhesion

Various surface modification techniques can be applied to improve the adhesion properties of UHMWPE surfaces. These methods may include plasma treatment, chemical etching, or the application of specific coatings to enhance the surface energy and promote better adhesion with other materials or substrates.- Surface modification techniques for UHMWPE adhesion: Various surface modification techniques can be applied to improve the adhesion properties of UHMWPE surfaces. These methods may include plasma treatment, chemical etching, or the application of specific coatings to enhance the surface energy and promote better adhesion with other materials or substrates.

- Adhesive formulations for UHMWPE bonding: Specialized adhesive formulations have been developed to effectively bond UHMWPE surfaces. These adhesives are designed to overcome the low surface energy of UHMWPE and may incorporate specific chemical compounds or additives to enhance adhesion strength and durability.

- Composite materials incorporating UHMWPE: UHMWPE can be incorporated into composite materials to improve their overall properties. The adhesion between UHMWPE and other components in these composites is crucial for maintaining structural integrity and performance. Various techniques and materials are used to enhance the interfacial adhesion in such composites.

- Nanotechnology approaches for UHMWPE surface adhesion: Nanotechnology-based approaches are being explored to enhance the adhesion properties of UHMWPE surfaces. These may include the use of nanoparticles, nanostructured coatings, or nanoscale surface modifications to improve the interaction between UHMWPE and other materials at the molecular level.

- Testing and characterization of UHMWPE surface adhesion: Various methods and techniques have been developed to test and characterize the adhesion properties of UHMWPE surfaces. These may include standardized adhesion tests, surface analysis techniques, and advanced imaging methods to evaluate the effectiveness of different adhesion enhancement strategies.

02 Adhesive formulations for UHMWPE bonding

Specialized adhesive formulations have been developed to effectively bond UHMWPE surfaces. These adhesives are designed to overcome the low surface energy of UHMWPE and may incorporate specific chemical compounds or additives to enhance adhesion strength and durability.Expand Specific Solutions03 UHMWPE composite materials for improved adhesion

Composite materials incorporating UHMWPE and other components have been developed to enhance adhesion properties. These composites may combine UHMWPE with other polymers, fibers, or nanoparticles to create surfaces with improved adhesion characteristics while maintaining the desirable properties of UHMWPE.Expand Specific Solutions04 Surface functionalization of UHMWPE for adhesion enhancement

Chemical functionalization of UHMWPE surfaces can be employed to introduce specific functional groups that promote adhesion. This approach may involve grafting techniques or the use of coupling agents to create reactive sites on the UHMWPE surface, facilitating stronger bonding with other materials.Expand Specific Solutions05 Mechanical surface treatments for UHMWPE adhesion

Mechanical surface treatments can be applied to UHMWPE to improve its adhesion properties. These methods may include abrasion, sandblasting, or other physical modifications that increase surface roughness and create more favorable conditions for adhesion with other materials or coatings.Expand Specific Solutions

Key Industry Players

The characterization of UHMWPE surfaces for improved adhesion is in a developing stage, with growing market potential due to its applications in various industries. The technology is advancing, but still requires further research and development. Key players like DuPont, Zimmer, and Nitto Denko are leading the field, leveraging their expertise in materials science and surface engineering. Academic institutions such as Donghua University and Tiangong University are contributing to fundamental research. The market is seeing increased interest from both established chemical companies and specialized materials firms, indicating a competitive landscape with opportunities for innovation and market expansion.

Donghua University

Technical Solution: Researchers at Donghua University have developed a novel approach to UHMWPE surface modification using a combination of plasma treatment and in-situ polymerization. Their method involves creating active sites on the UHMWPE surface through plasma activation, followed by the growth of polymer brushes directly from these sites[5]. This technique has shown to significantly improve the adhesion strength between UHMWPE and various adhesives, including epoxy resins. The university has also explored the use of atmospheric pressure plasma for continuous surface treatment of UHMWPE fibers, enhancing their compatibility with matrix materials in composites[6].

Strengths: Innovative research approaches, strong focus on fundamental understanding of surface chemistry. Weaknesses: May face challenges in scaling up laboratory techniques to industrial production levels.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has focused on developing surface modification techniques for UHMWPE in oil and gas applications. Their approach includes using chemical etching combined with nanoparticle coatings to improve the adhesion properties of UHMWPE pipes and linings. They have reported success in creating a hierarchical surface structure that significantly increases the surface area and mechanical interlocking with adhesives[2]. Sinopec has also explored the use of fluorination treatments to enhance the surface energy of UHMWPE, resulting in improved adhesion to metals and other polymers[4].

Strengths: Large-scale production capabilities, extensive experience in oil and gas industry applications. Weaknesses: May be more focused on industrial applications rather than broader consumer or medical uses of UHMWPE.

Core Surface Innovations

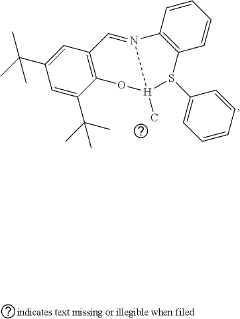

Ultra-high molecular weight polyethylene through plasma surface treatment

PatentActiveKR1020240110326A

Innovation

- Plasma surface treatment is applied to UHMWPE with specific conditions (200-240 VAC, 50/60 Hz, 1,000 Watt, 8-12 kVolt, 30-60 KHz, 0.4-0.6 MPa, 25-80 LPM) to improve adhesive properties.

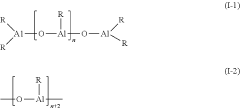

Method for continuously producing ultra-high molecular weight polyethylene by using slurry polymerization

PatentPendingUS20240092948A1

Innovation

- A continuous process using 2-6 ethylene slurry polymerization reaction tanks connected in series, where polymerization temperatures, pressures, and gas phase compositions are controlled within specific ranges to ensure consistent conditions across tanks, allowing for full catalyst activity and precise control of molecular weight, resulting in ultra-high viscosity-average molecular weight polyethylene with low metal and ash content.

Environmental Impact

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) surface characterization and adhesion improvement processes is a critical consideration in the development and application of this material. UHMWPE, known for its exceptional mechanical properties and chemical resistance, has found widespread use in various industries, including medical, automotive, and aerospace. However, the processes involved in surface modification and characterization can have significant environmental implications.

Surface treatment methods for UHMWPE, such as plasma treatment, chemical etching, and UV irradiation, often involve the use of chemicals and energy-intensive processes. These treatments can generate hazardous waste and emissions, potentially contributing to air and water pollution if not properly managed. For instance, plasma treatments may release ozone and other reactive species, while chemical etching processes can produce toxic byproducts that require careful disposal.

The production of UHMWPE itself has environmental considerations. The polymer is derived from non-renewable petroleum resources, and its manufacturing process consumes significant energy. While UHMWPE is highly durable and long-lasting, which can reduce the need for frequent replacements, its end-of-life disposal presents challenges due to its resistance to degradation.

Adhesion improvement techniques may introduce additional materials, such as primers or adhesives, which can complicate recycling efforts and increase the overall environmental footprint of UHMWPE products. The use of these additional materials may also introduce volatile organic compounds (VOCs) during application or curing processes, potentially impacting air quality and worker health.

On the positive side, improved adhesion of UHMWPE can lead to more durable and longer-lasting products, potentially reducing waste and the need for frequent replacements. This longevity can offset some of the environmental impacts associated with production and surface modification processes. Additionally, advancements in surface characterization techniques, such as non-destructive testing methods, can reduce material waste during quality control processes.

Research into more environmentally friendly surface modification techniques is ongoing. Bio-based treatments, such as those using enzymes or plant-derived compounds, show promise in reducing the reliance on harsh chemicals. Similarly, the development of water-based adhesives and low-VOC primers can mitigate some of the environmental concerns associated with traditional adhesion improvement methods.

Life cycle assessments (LCAs) of UHMWPE products, including their surface modification and adhesion improvement processes, are crucial for understanding and minimizing environmental impacts. These assessments can guide the development of more sustainable practices throughout the material's lifecycle, from production to disposal or recycling.

Surface treatment methods for UHMWPE, such as plasma treatment, chemical etching, and UV irradiation, often involve the use of chemicals and energy-intensive processes. These treatments can generate hazardous waste and emissions, potentially contributing to air and water pollution if not properly managed. For instance, plasma treatments may release ozone and other reactive species, while chemical etching processes can produce toxic byproducts that require careful disposal.

The production of UHMWPE itself has environmental considerations. The polymer is derived from non-renewable petroleum resources, and its manufacturing process consumes significant energy. While UHMWPE is highly durable and long-lasting, which can reduce the need for frequent replacements, its end-of-life disposal presents challenges due to its resistance to degradation.

Adhesion improvement techniques may introduce additional materials, such as primers or adhesives, which can complicate recycling efforts and increase the overall environmental footprint of UHMWPE products. The use of these additional materials may also introduce volatile organic compounds (VOCs) during application or curing processes, potentially impacting air quality and worker health.

On the positive side, improved adhesion of UHMWPE can lead to more durable and longer-lasting products, potentially reducing waste and the need for frequent replacements. This longevity can offset some of the environmental impacts associated with production and surface modification processes. Additionally, advancements in surface characterization techniques, such as non-destructive testing methods, can reduce material waste during quality control processes.

Research into more environmentally friendly surface modification techniques is ongoing. Bio-based treatments, such as those using enzymes or plant-derived compounds, show promise in reducing the reliance on harsh chemicals. Similarly, the development of water-based adhesives and low-VOC primers can mitigate some of the environmental concerns associated with traditional adhesion improvement methods.

Life cycle assessments (LCAs) of UHMWPE products, including their surface modification and adhesion improvement processes, are crucial for understanding and minimizing environmental impacts. These assessments can guide the development of more sustainable practices throughout the material's lifecycle, from production to disposal or recycling.

Regulatory Considerations

The regulatory landscape surrounding the characterization and improvement of Ultra-High Molecular Weight Polyethylene (UHMWPE) surfaces for enhanced adhesion is complex and multifaceted. Manufacturers and researchers must navigate a web of standards and guidelines to ensure compliance and product safety.

In the medical device industry, where UHMWPE is commonly used, the U.S. Food and Drug Administration (FDA) plays a crucial role. The FDA's guidance on the use of UHMWPE in orthopedic devices outlines specific requirements for material characterization, including surface properties. Manufacturers must demonstrate that any surface modifications to improve adhesion do not compromise the material's biocompatibility or mechanical properties.

The International Organization for Standardization (ISO) has established several standards relevant to UHMWPE characterization. ISO 5834-2 specifies requirements for ultra-high molecular weight polyethylene powder and fabricated forms for surgical implants. This standard includes guidelines for surface analysis and modification techniques that may be applicable to adhesion improvement efforts.

European regulations, particularly the Medical Device Regulation (MDR), impose stringent requirements on materials used in medical devices. Manufacturers seeking to improve UHMWPE surface adhesion must ensure that their processes comply with these regulations, which emphasize risk management and clinical evaluation.

In the aerospace and automotive industries, where UHMWPE is also utilized, different regulatory bodies come into play. The Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have specific requirements for materials used in aircraft components. Any surface modification techniques must be validated to meet these agencies' safety standards.

Environmental regulations also impact the development of surface characterization and modification techniques for UHMWPE. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to assess and manage the risks associated with chemicals used in surface treatments.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, must be considered when developing and implementing surface characterization and modification processes. These regulations ensure the safety of workers involved in the manufacturing and research processes.

As research progresses in the field of UHMWPE surface characterization and adhesion improvement, regulatory bodies are likely to update their guidelines. Manufacturers and researchers must stay informed about these changes and adapt their processes accordingly to maintain compliance and ensure product safety.

In the medical device industry, where UHMWPE is commonly used, the U.S. Food and Drug Administration (FDA) plays a crucial role. The FDA's guidance on the use of UHMWPE in orthopedic devices outlines specific requirements for material characterization, including surface properties. Manufacturers must demonstrate that any surface modifications to improve adhesion do not compromise the material's biocompatibility or mechanical properties.

The International Organization for Standardization (ISO) has established several standards relevant to UHMWPE characterization. ISO 5834-2 specifies requirements for ultra-high molecular weight polyethylene powder and fabricated forms for surgical implants. This standard includes guidelines for surface analysis and modification techniques that may be applicable to adhesion improvement efforts.

European regulations, particularly the Medical Device Regulation (MDR), impose stringent requirements on materials used in medical devices. Manufacturers seeking to improve UHMWPE surface adhesion must ensure that their processes comply with these regulations, which emphasize risk management and clinical evaluation.

In the aerospace and automotive industries, where UHMWPE is also utilized, different regulatory bodies come into play. The Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have specific requirements for materials used in aircraft components. Any surface modification techniques must be validated to meet these agencies' safety standards.

Environmental regulations also impact the development of surface characterization and modification techniques for UHMWPE. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to assess and manage the risks associated with chemicals used in surface treatments.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, must be considered when developing and implementing surface characterization and modification processes. These regulations ensure the safety of workers involved in the manufacturing and research processes.

As research progresses in the field of UHMWPE surface characterization and adhesion improvement, regulatory bodies are likely to update their guidelines. Manufacturers and researchers must stay informed about these changes and adapt their processes accordingly to maintain compliance and ensure product safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!