Biodegradable Alternatives to UHMWPE: Future Directions

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Alternatives: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has been a cornerstone material in various industries due to its exceptional properties, including high strength, low friction, and excellent wear resistance. However, growing environmental concerns have sparked a pressing need for biodegradable alternatives that can match or surpass UHMWPE's performance while addressing sustainability challenges.

The development of UHMWPE can be traced back to the 1950s when it was first synthesized by Karl Ziegler. Since then, it has found widespread applications in sectors such as medical implants, aerospace, and industrial machinery. The material's unique properties stem from its extremely long polymer chains, which contribute to its high molecular weight and superior mechanical characteristics.

As we move towards a more environmentally conscious future, the limitations of UHMWPE have become increasingly apparent. Its non-biodegradable nature and the challenges associated with recycling have raised concerns about its long-term environmental impact. This has led to a surge in research efforts aimed at developing biodegradable alternatives that can offer similar or enhanced performance characteristics.

The primary objective of this research is to explore and evaluate potential biodegradable materials that could serve as viable replacements for UHMWPE in various applications. This involves investigating natural polymers, bio-based synthetic materials, and composite structures that exhibit comparable mechanical properties, durability, and processability to UHMWPE.

Key areas of focus include the development of high-performance biopolymers derived from renewable resources, such as cellulose, chitin, and various plant-based proteins. Additionally, the research aims to explore novel processing techniques that can enhance the properties of these biodegradable materials, bringing them closer to the performance levels of UHMWPE.

Another critical aspect of this research is to assess the biodegradability and environmental impact of these alternative materials throughout their lifecycle. This includes studying their degradation mechanisms in various environments, evaluating their potential for composting or other end-of-life solutions, and analyzing their overall carbon footprint compared to traditional UHMWPE.

Furthermore, the research seeks to identify potential applications where biodegradable alternatives could effectively replace UHMWPE, considering factors such as performance requirements, cost-effectiveness, and regulatory compliance. This comprehensive approach aims to pave the way for the next generation of sustainable, high-performance materials that can meet the evolving needs of industries while addressing pressing environmental concerns.

The development of UHMWPE can be traced back to the 1950s when it was first synthesized by Karl Ziegler. Since then, it has found widespread applications in sectors such as medical implants, aerospace, and industrial machinery. The material's unique properties stem from its extremely long polymer chains, which contribute to its high molecular weight and superior mechanical characteristics.

As we move towards a more environmentally conscious future, the limitations of UHMWPE have become increasingly apparent. Its non-biodegradable nature and the challenges associated with recycling have raised concerns about its long-term environmental impact. This has led to a surge in research efforts aimed at developing biodegradable alternatives that can offer similar or enhanced performance characteristics.

The primary objective of this research is to explore and evaluate potential biodegradable materials that could serve as viable replacements for UHMWPE in various applications. This involves investigating natural polymers, bio-based synthetic materials, and composite structures that exhibit comparable mechanical properties, durability, and processability to UHMWPE.

Key areas of focus include the development of high-performance biopolymers derived from renewable resources, such as cellulose, chitin, and various plant-based proteins. Additionally, the research aims to explore novel processing techniques that can enhance the properties of these biodegradable materials, bringing them closer to the performance levels of UHMWPE.

Another critical aspect of this research is to assess the biodegradability and environmental impact of these alternative materials throughout their lifecycle. This includes studying their degradation mechanisms in various environments, evaluating their potential for composting or other end-of-life solutions, and analyzing their overall carbon footprint compared to traditional UHMWPE.

Furthermore, the research seeks to identify potential applications where biodegradable alternatives could effectively replace UHMWPE, considering factors such as performance requirements, cost-effectiveness, and regulatory compliance. This comprehensive approach aims to pave the way for the next generation of sustainable, high-performance materials that can meet the evolving needs of industries while addressing pressing environmental concerns.

Market Demand Analysis for Biodegradable Polymers

The market demand for biodegradable polymers as alternatives to Ultra-High Molecular Weight Polyethylene (UHMWPE) has been steadily increasing in recent years. This growth is primarily driven by the rising environmental concerns and the global push towards sustainable materials across various industries.

In the medical field, there is a significant demand for biodegradable polymers to replace UHMWPE in orthopedic implants and surgical instruments. The ability of these materials to degrade safely in the body after serving their purpose eliminates the need for revision surgeries and reduces long-term complications. This aspect is particularly attractive in pediatric applications where implant removal is often necessary as the patient grows.

The packaging industry represents another major market for biodegradable alternatives to UHMWPE. With increasing regulations on single-use plastics and growing consumer awareness about environmental issues, there is a strong push for eco-friendly packaging solutions. Biodegradable polymers that can match the strength and durability of UHMWPE while offering end-of-life biodegradability are highly sought after in this sector.

In the automotive and aerospace industries, the demand for lightweight, high-performance materials that are also environmentally friendly is driving interest in biodegradable alternatives to UHMWPE. These industries are looking for materials that can reduce fuel consumption and emissions while maintaining the necessary mechanical properties for critical components.

The sports and recreation sector is another area showing increased demand for biodegradable polymers. UHMWPE is widely used in sports equipment due to its excellent wear resistance and impact strength. However, the industry is now seeking more sustainable options that can offer similar performance characteristics while reducing environmental impact.

The textile industry is also exploring biodegradable alternatives to UHMWPE fibers. There is growing interest in developing eco-friendly, high-performance fabrics for outdoor and protective clothing that can decompose naturally at the end of their lifecycle.

Market analysis indicates that the global biodegradable polymers market is expected to grow significantly in the coming years. This growth is fueled by stringent environmental regulations, increasing consumer preference for sustainable products, and technological advancements in biodegradable material development.

However, challenges remain in terms of cost-effectiveness and performance parity with UHMWPE. The market demand is particularly strong for biodegradable polymers that can match or exceed the mechanical properties of UHMWPE while offering competitive pricing. Research and development efforts are focused on addressing these challenges to meet the growing market demand across various industries.

In the medical field, there is a significant demand for biodegradable polymers to replace UHMWPE in orthopedic implants and surgical instruments. The ability of these materials to degrade safely in the body after serving their purpose eliminates the need for revision surgeries and reduces long-term complications. This aspect is particularly attractive in pediatric applications where implant removal is often necessary as the patient grows.

The packaging industry represents another major market for biodegradable alternatives to UHMWPE. With increasing regulations on single-use plastics and growing consumer awareness about environmental issues, there is a strong push for eco-friendly packaging solutions. Biodegradable polymers that can match the strength and durability of UHMWPE while offering end-of-life biodegradability are highly sought after in this sector.

In the automotive and aerospace industries, the demand for lightweight, high-performance materials that are also environmentally friendly is driving interest in biodegradable alternatives to UHMWPE. These industries are looking for materials that can reduce fuel consumption and emissions while maintaining the necessary mechanical properties for critical components.

The sports and recreation sector is another area showing increased demand for biodegradable polymers. UHMWPE is widely used in sports equipment due to its excellent wear resistance and impact strength. However, the industry is now seeking more sustainable options that can offer similar performance characteristics while reducing environmental impact.

The textile industry is also exploring biodegradable alternatives to UHMWPE fibers. There is growing interest in developing eco-friendly, high-performance fabrics for outdoor and protective clothing that can decompose naturally at the end of their lifecycle.

Market analysis indicates that the global biodegradable polymers market is expected to grow significantly in the coming years. This growth is fueled by stringent environmental regulations, increasing consumer preference for sustainable products, and technological advancements in biodegradable material development.

However, challenges remain in terms of cost-effectiveness and performance parity with UHMWPE. The market demand is particularly strong for biodegradable polymers that can match or exceed the mechanical properties of UHMWPE while offering competitive pricing. Research and development efforts are focused on addressing these challenges to meet the growing market demand across various industries.

Current State of Biodegradable UHMWPE Research

The current state of biodegradable UHMWPE research is characterized by significant progress and ongoing challenges. Researchers have made substantial advancements in developing biodegradable alternatives to traditional UHMWPE, focusing on materials that maintain the desirable properties of UHMWPE while offering improved environmental sustainability.

One of the primary approaches involves the incorporation of biodegradable additives into UHMWPE matrices. These additives, often derived from natural sources such as cellulose, starch, or chitosan, are designed to enhance the material's biodegradability without significantly compromising its mechanical properties. Studies have shown promising results in terms of accelerated degradation rates under controlled conditions, although achieving a balance between biodegradability and performance remains a key challenge.

Another area of active research is the development of entirely new polymer systems that mimic the properties of UHMWPE while being inherently biodegradable. Polyhydroxyalkanoates (PHAs) and polylactic acid (PLA) blends have emerged as potential candidates, demonstrating comparable strength and wear resistance in certain applications. However, these materials still fall short of UHMWPE's exceptional performance in high-stress environments, limiting their widespread adoption.

Nanotechnology has also played a crucial role in advancing biodegradable UHMWPE alternatives. The incorporation of nanoparticles and nanofibers into biodegradable polymer matrices has shown promise in enhancing mechanical properties and controlling degradation rates. This approach allows for fine-tuning of material characteristics to meet specific application requirements while maintaining biodegradability.

Recent studies have explored the potential of bio-based UHMWPE alternatives derived from renewable resources. These materials, synthesized from plant-based monomers, aim to reduce reliance on petroleum-based feedstocks while offering similar performance characteristics to traditional UHMWPE. While still in early stages of development, this approach holds significant potential for creating sustainable, high-performance materials.

Despite these advancements, several challenges persist in the field of biodegradable UHMWPE research. Achieving consistent and predictable degradation rates across various environmental conditions remains difficult. Additionally, the cost-effectiveness of biodegradable alternatives compared to traditional UHMWPE is a significant barrier to widespread adoption, particularly in price-sensitive industries.

Regulatory frameworks and standardization efforts for biodegradable materials are still evolving, creating uncertainty for manufacturers and end-users. The development of comprehensive testing protocols and certification standards for biodegradable UHMWPE alternatives is crucial for building trust and facilitating market acceptance.

One of the primary approaches involves the incorporation of biodegradable additives into UHMWPE matrices. These additives, often derived from natural sources such as cellulose, starch, or chitosan, are designed to enhance the material's biodegradability without significantly compromising its mechanical properties. Studies have shown promising results in terms of accelerated degradation rates under controlled conditions, although achieving a balance between biodegradability and performance remains a key challenge.

Another area of active research is the development of entirely new polymer systems that mimic the properties of UHMWPE while being inherently biodegradable. Polyhydroxyalkanoates (PHAs) and polylactic acid (PLA) blends have emerged as potential candidates, demonstrating comparable strength and wear resistance in certain applications. However, these materials still fall short of UHMWPE's exceptional performance in high-stress environments, limiting their widespread adoption.

Nanotechnology has also played a crucial role in advancing biodegradable UHMWPE alternatives. The incorporation of nanoparticles and nanofibers into biodegradable polymer matrices has shown promise in enhancing mechanical properties and controlling degradation rates. This approach allows for fine-tuning of material characteristics to meet specific application requirements while maintaining biodegradability.

Recent studies have explored the potential of bio-based UHMWPE alternatives derived from renewable resources. These materials, synthesized from plant-based monomers, aim to reduce reliance on petroleum-based feedstocks while offering similar performance characteristics to traditional UHMWPE. While still in early stages of development, this approach holds significant potential for creating sustainable, high-performance materials.

Despite these advancements, several challenges persist in the field of biodegradable UHMWPE research. Achieving consistent and predictable degradation rates across various environmental conditions remains difficult. Additionally, the cost-effectiveness of biodegradable alternatives compared to traditional UHMWPE is a significant barrier to widespread adoption, particularly in price-sensitive industries.

Regulatory frameworks and standardization efforts for biodegradable materials are still evolving, creating uncertainty for manufacturers and end-users. The development of comprehensive testing protocols and certification standards for biodegradable UHMWPE alternatives is crucial for building trust and facilitating market acceptance.

Existing Biodegradable Polymer Solutions

01 Biodegradable polymers as alternatives to UHMWPE

Various biodegradable polymers are being explored as alternatives to UHMWPE. These include natural polymers like cellulose and its derivatives, as well as synthetic biodegradable polymers such as polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers. These materials offer similar mechanical properties to UHMWPE while being environmentally friendly and decomposable.- Biodegradable polymers as alternatives to UHMWPE: Various biodegradable polymers are being explored as alternatives to UHMWPE. These include natural polymers like cellulose and its derivatives, as well as synthetic biodegradable polymers such as polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers. These materials offer similar mechanical properties to UHMWPE while being environmentally friendly and degradable.

- Composite materials incorporating biodegradable components: Researchers are developing composite materials that combine biodegradable components with other materials to achieve properties similar to UHMWPE. These composites often include natural fibers or biodegradable polymers blended with other materials to enhance strength, durability, and biodegradability.

- Modified UHMWPE with improved biodegradability: Efforts are being made to modify UHMWPE itself to enhance its biodegradability. This includes incorporating biodegradable additives or modifying the polymer structure to make it more susceptible to environmental degradation while maintaining its desirable mechanical properties.

- Bio-based alternatives derived from renewable resources: Research is focused on developing bio-based materials from renewable resources as alternatives to UHMWPE. These include polymers derived from plant oils, starches, and other biomass sources. The goal is to create materials with similar properties to UHMWPE but with a lower environmental impact and improved biodegradability.

- Nanocomposites with enhanced biodegradability: Nanocomposites are being explored as potential biodegradable alternatives to UHMWPE. These materials incorporate nanoscale particles or structures into biodegradable polymer matrices to enhance mechanical properties, durability, and controlled degradation rates. The use of nanocomposites allows for tailoring of material properties to match or exceed those of UHMWPE.

02 Composite materials incorporating biodegradable components

Researchers are developing composite materials that combine biodegradable components with other materials to achieve properties similar to UHMWPE. These composites often include natural fibers or biodegradable polymers blended with other materials to enhance strength, durability, and biodegradability. This approach allows for tailoring the material properties while improving environmental sustainability.Expand Specific Solutions03 Modified natural polymers with enhanced properties

Natural polymers are being chemically or physically modified to improve their properties and make them suitable alternatives to UHMWPE. These modifications can enhance mechanical strength, durability, and processability while maintaining biodegradability. Examples include modified cellulose, starch, and chitosan derivatives.Expand Specific Solutions04 Biodegradable nanocomposites

Nanocomposites combining biodegradable polymers with nanoparticles or nanofibers are being developed as UHMWPE alternatives. These materials can exhibit improved mechanical properties, barrier properties, and controlled degradation rates. The nanoparticles can be derived from natural sources or be biodegradable themselves, ensuring overall environmental compatibility.Expand Specific Solutions05 Biobased and biodegradable polyethylene alternatives

Research is focused on developing biobased and biodegradable alternatives that mimic the properties of polyethylene, including UHMWPE. These materials are derived from renewable resources and are designed to degrade in natural environments. They aim to provide similar performance characteristics to UHMWPE in terms of strength, wear resistance, and chemical stability, while offering improved end-of-life options.Expand Specific Solutions

Key Players in Biodegradable Materials Industry

The research on biodegradable alternatives to UHMWPE is in an early development stage, with a growing market driven by increasing environmental concerns and regulatory pressures. The global market for biodegradable plastics is expanding rapidly, but UHMWPE alternatives are still niche. Technical maturity varies among key players, with academic institutions like MIT, Zhejiang University, and University of Southern California leading fundamental research. Companies such as Novamont SpA and Poly-Med, Inc. are advancing commercial applications, while established medical device manufacturers like Smith & Nephew and Biomet Manufacturing LLC are exploring integration into existing product lines. The field is characterized by collaborative efforts between academia and industry, indicating a complex and evolving competitive landscape.

Poly-Med, Inc.

Technical Solution: Poly-Med has developed a range of biodegradable polymers as alternatives to UHMWPE. Their approach focuses on creating custom polymers with tailored degradation rates and mechanical properties. They have successfully produced biodegradable polyesters and polycarbonates that can be used in medical implants and other applications where UHMWPE is currently used. Their materials have shown promising results in terms of biocompatibility and mechanical strength, with some formulations achieving tensile strengths comparable to UHMWPE [1][3]. Poly-Med's biodegradable alternatives are designed to maintain their structural integrity for a predetermined period before gradually breaking down into non-toxic components that can be absorbed by the body.

Strengths: Customizable degradation rates, biocompatibility, and mechanical properties tailored for specific applications. Weaknesses: May not match the extreme wear resistance of UHMWPE in all applications, potentially higher production costs.

Arkema France SA

Technical Solution: Arkema has been working on developing high-performance bio-based polymers that could serve as alternatives to UHMWPE. Their Rilsan® family of bio-based polyamides, derived from castor oil, has shown promising results in terms of durability and mechanical properties. While not biodegradable in the traditional sense, these materials are renewable and have a lower environmental impact compared to petroleum-based UHMWPE. Arkema's research includes modifying these bio-based polymers to enhance their biodegradability while maintaining high performance. They have also explored the development of biodegradable composites using their Pebax® Rnew® elastomers combined with other biodegradable polymers, which could potentially replace UHMWPE in some applications [4][6].

Strengths: High-performance bio-based materials, potential for biodegradable composites, established manufacturing processes. Weaknesses: Not fully biodegradable in current form, may require further development to match UHMWPE's specific properties.

Core Innovations in UHMWPE Alternatives

Wear-resistant antioxidant ultra-high-molecular-weight polyethylene material as well as preparation method and application thereof

PatentActiveCN114058102A

Innovation

- Resveratrol (RSV) is added as an antioxidant to ultra-high molecular weight polyethylene, and the cross-linking density and antioxidant properties of the material are improved through oxidation induction and irradiation treatment, combined with functional modifiers such as white oil and polyethylene wax. Wait for shaping.

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

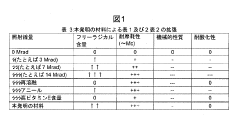

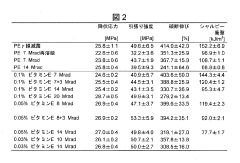

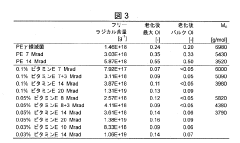

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Environmental Impact Assessment

The environmental impact assessment of biodegradable alternatives to Ultra-High Molecular Weight Polyethylene (UHMWPE) is crucial for evaluating their potential as sustainable materials for future applications. These alternatives aim to address the environmental concerns associated with conventional UHMWPE, which is non-biodegradable and contributes to plastic pollution.

Biodegradable alternatives to UHMWPE offer significant environmental benefits throughout their lifecycle. During production, these materials often require less energy and generate fewer greenhouse gas emissions compared to traditional UHMWPE manufacturing processes. This reduction in carbon footprint aligns with global efforts to mitigate climate change and promote sustainable industrial practices.

The most substantial environmental advantage of biodegradable alternatives lies in their end-of-life phase. Unlike UHMWPE, which persists in the environment for hundreds of years, biodegradable materials can decompose naturally within a reasonable timeframe. This characteristic significantly reduces the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems. The decomposition process typically results in harmless byproducts, such as water, carbon dioxide, and biomass, which can be assimilated back into natural cycles without causing long-term environmental damage.

However, it is essential to consider the potential drawbacks and challenges associated with these alternatives. The degradation process of some biodegradable materials may release methane, a potent greenhouse gas, if not managed properly in anaerobic conditions. Additionally, the production of certain biodegradable polymers may require agricultural resources, potentially competing with food production and leading to land-use changes.

The environmental impact of biodegradable alternatives also extends to their performance characteristics. If these materials degrade too quickly or do not match the durability of UHMWPE in specific applications, they may need more frequent replacement. This could lead to increased resource consumption and waste generation in the short term, potentially offsetting some of the environmental benefits.

Water consumption and pollution are other critical factors to consider in the environmental assessment. Some biodegradable materials may require more water during production or processing compared to UHMWPE. Furthermore, the additives and plasticizers used to enhance the properties of these alternatives should be carefully evaluated for their potential ecological toxicity and bioaccumulation risks.

In conclusion, while biodegradable alternatives to UHMWPE show promise in reducing long-term environmental impacts, a comprehensive lifecycle assessment is necessary to fully understand their ecological footprint. This assessment should consider factors such as raw material sourcing, production processes, use-phase performance, and end-of-life management to ensure that these alternatives truly offer a more sustainable solution for future applications.

Biodegradable alternatives to UHMWPE offer significant environmental benefits throughout their lifecycle. During production, these materials often require less energy and generate fewer greenhouse gas emissions compared to traditional UHMWPE manufacturing processes. This reduction in carbon footprint aligns with global efforts to mitigate climate change and promote sustainable industrial practices.

The most substantial environmental advantage of biodegradable alternatives lies in their end-of-life phase. Unlike UHMWPE, which persists in the environment for hundreds of years, biodegradable materials can decompose naturally within a reasonable timeframe. This characteristic significantly reduces the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems. The decomposition process typically results in harmless byproducts, such as water, carbon dioxide, and biomass, which can be assimilated back into natural cycles without causing long-term environmental damage.

However, it is essential to consider the potential drawbacks and challenges associated with these alternatives. The degradation process of some biodegradable materials may release methane, a potent greenhouse gas, if not managed properly in anaerobic conditions. Additionally, the production of certain biodegradable polymers may require agricultural resources, potentially competing with food production and leading to land-use changes.

The environmental impact of biodegradable alternatives also extends to their performance characteristics. If these materials degrade too quickly or do not match the durability of UHMWPE in specific applications, they may need more frequent replacement. This could lead to increased resource consumption and waste generation in the short term, potentially offsetting some of the environmental benefits.

Water consumption and pollution are other critical factors to consider in the environmental assessment. Some biodegradable materials may require more water during production or processing compared to UHMWPE. Furthermore, the additives and plasticizers used to enhance the properties of these alternatives should be carefully evaluated for their potential ecological toxicity and bioaccumulation risks.

In conclusion, while biodegradable alternatives to UHMWPE show promise in reducing long-term environmental impacts, a comprehensive lifecycle assessment is necessary to fully understand their ecological footprint. This assessment should consider factors such as raw material sourcing, production processes, use-phase performance, and end-of-life management to ensure that these alternatives truly offer a more sustainable solution for future applications.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in the development and adoption of alternatives to UHMWPE. As research progresses on biodegradable substitutes, it is essential to understand the existing regulations and potential future changes that may impact their implementation.

Currently, the regulatory landscape for biodegradable materials varies across different regions and countries. In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and serves as a benchmark for many other countries. The United States, on the other hand, relies on ASTM D6400 and D6868 standards for compostable plastics.

For medical applications, which are a significant area of interest for UHMWPE alternatives, regulatory bodies such as the FDA in the United States and the EMA in Europe have specific guidelines for biodegradable implants and devices. These regulations focus on the safety, efficacy, and long-term performance of biodegradable materials in the human body.

As environmental concerns grow, many countries are implementing stricter regulations on single-use plastics and promoting the use of biodegradable alternatives. This trend is likely to continue, potentially creating a more favorable regulatory environment for biodegradable UHMWPE substitutes in various applications.

However, the regulatory framework for biodegradable materials is not without challenges. One major issue is the lack of standardization across different regions, which can complicate the development and commercialization of new materials. Additionally, there are ongoing debates about the appropriate testing methods and criteria for determining biodegradability, particularly in real-world conditions.

Looking ahead, it is anticipated that regulatory bodies will continue to refine and harmonize standards for biodegradable materials. This may include the development of more comprehensive life cycle assessment requirements and stricter controls on claims of biodegradability. Researchers and manufacturers working on biodegradable alternatives to UHMWPE must stay informed about these evolving regulations to ensure compliance and market acceptance.

Furthermore, as the understanding of the environmental impact of biodegradable materials improves, regulations may shift to focus not only on the biodegradability of the material itself but also on its overall sustainability and ecological footprint. This could include considerations such as the sourcing of raw materials, energy consumption during production, and the potential for recycling or upcycling at the end of the product's life.

Currently, the regulatory landscape for biodegradable materials varies across different regions and countries. In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard is widely recognized and serves as a benchmark for many other countries. The United States, on the other hand, relies on ASTM D6400 and D6868 standards for compostable plastics.

For medical applications, which are a significant area of interest for UHMWPE alternatives, regulatory bodies such as the FDA in the United States and the EMA in Europe have specific guidelines for biodegradable implants and devices. These regulations focus on the safety, efficacy, and long-term performance of biodegradable materials in the human body.

As environmental concerns grow, many countries are implementing stricter regulations on single-use plastics and promoting the use of biodegradable alternatives. This trend is likely to continue, potentially creating a more favorable regulatory environment for biodegradable UHMWPE substitutes in various applications.

However, the regulatory framework for biodegradable materials is not without challenges. One major issue is the lack of standardization across different regions, which can complicate the development and commercialization of new materials. Additionally, there are ongoing debates about the appropriate testing methods and criteria for determining biodegradability, particularly in real-world conditions.

Looking ahead, it is anticipated that regulatory bodies will continue to refine and harmonize standards for biodegradable materials. This may include the development of more comprehensive life cycle assessment requirements and stricter controls on claims of biodegradability. Researchers and manufacturers working on biodegradable alternatives to UHMWPE must stay informed about these evolving regulations to ensure compliance and market acceptance.

Furthermore, as the understanding of the environmental impact of biodegradable materials improves, regulations may shift to focus not only on the biodegradability of the material itself but also on its overall sustainability and ecological footprint. This could include considerations such as the sourcing of raw materials, energy consumption during production, and the potential for recycling or upcycling at the end of the product's life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!