UHMWPE's Contribution to Lightweight Aerospace Structures

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Aerospace: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the aerospace industry, offering exceptional strength-to-weight ratios and unique properties that make it ideal for lightweight structural applications. The development of UHMWPE can be traced back to the 1950s, but its potential in aerospace has only been fully recognized in recent decades.

The evolution of UHMWPE in aerospace applications has been driven by the industry's constant pursuit of lighter, stronger materials to improve fuel efficiency and payload capacity. As environmental concerns and cost pressures mount, the demand for innovative lightweight solutions has intensified, positioning UHMWPE as a key player in the future of aerospace engineering.

UHMWPE's journey in aerospace began with its use in non-structural components, gradually expanding to more critical applications as manufacturing techniques and material science advanced. The material's high specific strength, excellent impact resistance, and low density have made it an attractive alternative to traditional metals and composites in various aerospace structures.

The primary objective of incorporating UHMWPE into aerospace structures is to achieve significant weight reduction without compromising structural integrity. This aligns with the industry's broader goals of enhancing aircraft performance, reducing fuel consumption, and minimizing environmental impact. Additionally, UHMWPE's resistance to chemicals, UV radiation, and extreme temperatures makes it suitable for the harsh conditions encountered in aerospace operations.

Recent technological advancements have focused on improving UHMWPE's processability and its integration with other materials to create hybrid composites. These developments aim to overcome some of the material's limitations, such as its relatively low melting point and challenges in bonding with other substances.

Looking ahead, the aerospace industry is exploring new frontiers for UHMWPE applications, including its potential use in space exploration vehicles and satellite components. The material's ability to withstand micrometeoroid impacts and its low outgassing properties make it particularly attractive for space-based applications.

As research continues, the goal is to further enhance UHMWPE's properties and develop novel manufacturing techniques that will enable its wider adoption in critical aerospace structures. This includes improving its heat resistance, enhancing its compatibility with advanced composite systems, and developing more efficient production methods to reduce costs and increase scalability.

The evolution of UHMWPE in aerospace applications has been driven by the industry's constant pursuit of lighter, stronger materials to improve fuel efficiency and payload capacity. As environmental concerns and cost pressures mount, the demand for innovative lightweight solutions has intensified, positioning UHMWPE as a key player in the future of aerospace engineering.

UHMWPE's journey in aerospace began with its use in non-structural components, gradually expanding to more critical applications as manufacturing techniques and material science advanced. The material's high specific strength, excellent impact resistance, and low density have made it an attractive alternative to traditional metals and composites in various aerospace structures.

The primary objective of incorporating UHMWPE into aerospace structures is to achieve significant weight reduction without compromising structural integrity. This aligns with the industry's broader goals of enhancing aircraft performance, reducing fuel consumption, and minimizing environmental impact. Additionally, UHMWPE's resistance to chemicals, UV radiation, and extreme temperatures makes it suitable for the harsh conditions encountered in aerospace operations.

Recent technological advancements have focused on improving UHMWPE's processability and its integration with other materials to create hybrid composites. These developments aim to overcome some of the material's limitations, such as its relatively low melting point and challenges in bonding with other substances.

Looking ahead, the aerospace industry is exploring new frontiers for UHMWPE applications, including its potential use in space exploration vehicles and satellite components. The material's ability to withstand micrometeoroid impacts and its low outgassing properties make it particularly attractive for space-based applications.

As research continues, the goal is to further enhance UHMWPE's properties and develop novel manufacturing techniques that will enable its wider adoption in critical aerospace structures. This includes improving its heat resistance, enhancing its compatibility with advanced composite systems, and developing more efficient production methods to reduce costs and increase scalability.

Market Analysis for Lightweight Aerospace Materials

The aerospace industry has witnessed a growing demand for lightweight materials, driven by the need for improved fuel efficiency, increased payload capacity, and enhanced performance of aircraft and spacecraft. Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a promising material in this sector, offering exceptional strength-to-weight ratios and unique properties that make it suitable for various aerospace applications.

The global market for lightweight aerospace materials is projected to experience significant growth in the coming years. This expansion is fueled by the increasing production of commercial aircraft, the rising demand for fuel-efficient vehicles, and the growing emphasis on reducing carbon emissions in the aviation industry. UHMWPE, as a key player in this market, is expected to contribute substantially to this growth trajectory.

In the commercial aviation segment, major aircraft manufacturers are actively seeking lightweight solutions to improve fuel efficiency and reduce operating costs. UHMWPE composites have shown potential in replacing traditional materials in various aircraft components, including interior panels, cargo liners, and structural elements. The material's high impact resistance and low density make it particularly attractive for these applications.

The military aerospace sector also presents significant opportunities for UHMWPE. Defense organizations worldwide are investing in advanced materials to enhance the performance and survivability of military aircraft and spacecraft. UHMWPE's ballistic protection properties and resistance to extreme temperatures make it a valuable material for military aerospace applications, including armor systems and protective gear for personnel.

The space exploration industry is another key market for UHMWPE in aerospace applications. As space agencies and private companies focus on developing reusable launch vehicles and long-duration spacecraft, the demand for lightweight, durable materials continues to grow. UHMWPE's resistance to radiation and its ability to maintain its properties in extreme space environments position it as a promising material for spacecraft components and space habitats.

Geographically, North America and Europe are expected to dominate the lightweight aerospace materials market, with Asia-Pacific showing rapid growth potential. The presence of major aerospace manufacturers and ongoing research and development activities in these regions contribute to their market leadership. Emerging economies in Asia-Pacific, particularly China and India, are investing heavily in their aerospace industries, creating new opportunities for UHMWPE and other lightweight materials.

Despite the positive outlook, challenges remain in the widespread adoption of UHMWPE in aerospace structures. These include the need for advanced manufacturing techniques, concerns about long-term durability in certain applications, and the relatively higher cost compared to some traditional materials. Ongoing research and development efforts are focused on addressing these challenges and expanding the material's applications in the aerospace sector.

The global market for lightweight aerospace materials is projected to experience significant growth in the coming years. This expansion is fueled by the increasing production of commercial aircraft, the rising demand for fuel-efficient vehicles, and the growing emphasis on reducing carbon emissions in the aviation industry. UHMWPE, as a key player in this market, is expected to contribute substantially to this growth trajectory.

In the commercial aviation segment, major aircraft manufacturers are actively seeking lightweight solutions to improve fuel efficiency and reduce operating costs. UHMWPE composites have shown potential in replacing traditional materials in various aircraft components, including interior panels, cargo liners, and structural elements. The material's high impact resistance and low density make it particularly attractive for these applications.

The military aerospace sector also presents significant opportunities for UHMWPE. Defense organizations worldwide are investing in advanced materials to enhance the performance and survivability of military aircraft and spacecraft. UHMWPE's ballistic protection properties and resistance to extreme temperatures make it a valuable material for military aerospace applications, including armor systems and protective gear for personnel.

The space exploration industry is another key market for UHMWPE in aerospace applications. As space agencies and private companies focus on developing reusable launch vehicles and long-duration spacecraft, the demand for lightweight, durable materials continues to grow. UHMWPE's resistance to radiation and its ability to maintain its properties in extreme space environments position it as a promising material for spacecraft components and space habitats.

Geographically, North America and Europe are expected to dominate the lightweight aerospace materials market, with Asia-Pacific showing rapid growth potential. The presence of major aerospace manufacturers and ongoing research and development activities in these regions contribute to their market leadership. Emerging economies in Asia-Pacific, particularly China and India, are investing heavily in their aerospace industries, creating new opportunities for UHMWPE and other lightweight materials.

Despite the positive outlook, challenges remain in the widespread adoption of UHMWPE in aerospace structures. These include the need for advanced manufacturing techniques, concerns about long-term durability in certain applications, and the relatively higher cost compared to some traditional materials. Ongoing research and development efforts are focused on addressing these challenges and expanding the material's applications in the aerospace sector.

Current State and Challenges of UHMWPE in Aerospace

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a promising material in the aerospace industry due to its exceptional strength-to-weight ratio and unique properties. Currently, UHMWPE is being extensively researched and applied in various aerospace applications, particularly in lightweight structural components and protective gear.

In terms of structural applications, UHMWPE fibers and composites are being utilized in aircraft and spacecraft components where weight reduction is critical. These materials offer significant advantages over traditional metals and other composites, providing superior strength and stiffness while drastically reducing overall weight. This contributes to improved fuel efficiency and increased payload capacity in aerospace vehicles.

However, the integration of UHMWPE in aerospace structures faces several challenges. One of the primary concerns is the material's relatively low melting point and poor heat resistance compared to other high-performance polymers. This limitation restricts its use in high-temperature environments, which are common in aerospace applications. Researchers are actively working on developing heat-resistant variants and protective coatings to address this issue.

Another challenge lies in the processing and manufacturing of UHMWPE-based components. The material's high molecular weight, while beneficial for its mechanical properties, makes it difficult to process using conventional techniques. Specialized manufacturing methods, such as gel spinning for fiber production and compression molding for composite parts, are required. This complexity can lead to increased production costs and limited scalability.

The long-term durability and environmental resistance of UHMWPE in aerospace conditions also present ongoing challenges. While the material exhibits excellent resistance to chemicals and UV radiation, its performance under prolonged exposure to extreme temperatures, vacuum conditions, and cosmic radiation in space environments requires further investigation and optimization.

Joining and bonding UHMWPE components with other materials in aerospace structures pose additional technical hurdles. Traditional adhesives and joining methods often prove inadequate due to the material's low surface energy and chemical inertness. Developing effective bonding techniques that maintain the integrity of UHMWPE-based structures under aerospace conditions remains an active area of research.

Despite these challenges, the aerospace industry continues to invest in UHMWPE technology, recognizing its potential to revolutionize lightweight structures. Ongoing research focuses on enhancing the material's temperature resistance, improving processing techniques, and developing novel composite formulations to expand its applicability in aerospace applications.

In terms of structural applications, UHMWPE fibers and composites are being utilized in aircraft and spacecraft components where weight reduction is critical. These materials offer significant advantages over traditional metals and other composites, providing superior strength and stiffness while drastically reducing overall weight. This contributes to improved fuel efficiency and increased payload capacity in aerospace vehicles.

However, the integration of UHMWPE in aerospace structures faces several challenges. One of the primary concerns is the material's relatively low melting point and poor heat resistance compared to other high-performance polymers. This limitation restricts its use in high-temperature environments, which are common in aerospace applications. Researchers are actively working on developing heat-resistant variants and protective coatings to address this issue.

Another challenge lies in the processing and manufacturing of UHMWPE-based components. The material's high molecular weight, while beneficial for its mechanical properties, makes it difficult to process using conventional techniques. Specialized manufacturing methods, such as gel spinning for fiber production and compression molding for composite parts, are required. This complexity can lead to increased production costs and limited scalability.

The long-term durability and environmental resistance of UHMWPE in aerospace conditions also present ongoing challenges. While the material exhibits excellent resistance to chemicals and UV radiation, its performance under prolonged exposure to extreme temperatures, vacuum conditions, and cosmic radiation in space environments requires further investigation and optimization.

Joining and bonding UHMWPE components with other materials in aerospace structures pose additional technical hurdles. Traditional adhesives and joining methods often prove inadequate due to the material's low surface energy and chemical inertness. Developing effective bonding techniques that maintain the integrity of UHMWPE-based structures under aerospace conditions remains an active area of research.

Despite these challenges, the aerospace industry continues to invest in UHMWPE technology, recognizing its potential to revolutionize lightweight structures. Ongoing research focuses on enhancing the material's temperature resistance, improving processing techniques, and developing novel composite formulations to expand its applicability in aerospace applications.

Existing UHMWPE Solutions for Aerospace Structures

01 Molecular weight and properties of UHMWPE

UHMWPE is characterized by its extremely high molecular weight, typically ranging from 3.5 to 7.5 million g/mol. This high molecular weight contributes to its exceptional properties, including high impact strength, wear resistance, and chemical inertness. The weight of UHMWPE affects its processing methods and end-use applications.- Molecular weight and properties of UHMWPE: UHMWPE is characterized by its extremely high molecular weight, typically ranging from 3.5 to 7.5 million g/mol. This high molecular weight contributes to its exceptional properties, including high impact strength, low friction coefficient, and excellent wear resistance. The molecular weight directly influences the material's mechanical and physical properties, making it suitable for various applications.

- Processing methods for UHMWPE: Various processing methods are employed to manufacture UHMWPE products, including compression molding, ram extrusion, and gel spinning. These techniques are designed to overcome the challenges associated with processing high molecular weight polymers. The choice of processing method can affect the final properties and weight of the UHMWPE product.

- UHMWPE composites and blends: UHMWPE is often combined with other materials to create composites or blends with enhanced properties. These combinations can alter the weight and performance characteristics of the final product. Common additives include carbon fibers, glass fibers, and other polymers, which can improve strength, stiffness, or specific functional properties while maintaining a relatively low weight.

- Weight reduction techniques for UHMWPE: Researchers and manufacturers are exploring various techniques to reduce the weight of UHMWPE products without compromising their performance. These methods include foaming, creating porous structures, and developing ultra-thin UHMWPE fibers. Such techniques aim to expand the application range of UHMWPE, particularly in industries where weight reduction is crucial.

- Applications leveraging UHMWPE's weight-to-strength ratio: UHMWPE's unique combination of low weight and high strength makes it ideal for various applications. It is widely used in aerospace, medical devices, sports equipment, and protective gear. The material's ability to provide high performance at a relatively low weight is particularly valuable in these fields, where weight reduction can lead to significant improvements in efficiency and functionality.

02 Processing techniques for UHMWPE

Various processing techniques are employed to manufacture UHMWPE products, including compression molding, ram extrusion, and gel spinning. These methods are adapted to handle the high molecular weight of the polymer, which can be challenging to process due to its high melt viscosity and limited flowability.Expand Specific Solutions03 UHMWPE composites and blends

UHMWPE is often combined with other materials to create composites or blends with enhanced properties. These can include reinforcing fibers, nanoparticles, or other polymers. The weight ratio of UHMWPE to other components in these composites affects the final properties of the material.Expand Specific Solutions04 Applications of UHMWPE based on weight

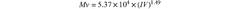

The weight of UHMWPE influences its suitability for various applications. Heavier grades are often used in high-performance applications such as orthopedic implants, industrial machinery parts, and ballistic protection. Lighter grades find use in applications like fibers for textiles and ropes.Expand Specific Solutions05 Measurement and characterization of UHMWPE weight

Accurate measurement and characterization of UHMWPE weight are crucial for quality control and research purposes. Techniques such as gel permeation chromatography (GPC) and viscometry are used to determine the molecular weight distribution and average molecular weight of UHMWPE samples.Expand Specific Solutions

Key Players in UHMWPE and Aerospace Industries

The UHMWPE lightweight aerospace structures market is in a growth phase, driven by increasing demand for high-performance materials in the aerospace industry. The market size is expanding, with a projected CAGR of 8-10% over the next five years. Technologically, UHMWPE applications are advancing rapidly, with companies like The Boeing Co. and Airbus Espana SL leading innovation in aerospace applications. Other key players, such as DSM and Honeywell, are developing specialized UHMWPE fibers for aerospace use. Research institutions like Massachusetts Institute of Technology and South China University of Technology are contributing to material advancements, indicating a collaborative ecosystem driving technological maturity in this field.

The Boeing Co.

Technical Solution: Boeing has developed advanced UHMWPE-based composites for aerospace applications, focusing on their high strength-to-weight ratio. They have implemented a proprietary manufacturing process that involves hot compaction and subsequent cooling of UHMWPE fibers, resulting in a material with exceptional tensile strength (up to 3.5 GPa) and low density (0.97 g/cm³) [1]. Boeing's UHMWPE composites are used in various aircraft components, including fuselage panels and interior structures, contributing to a significant weight reduction of up to 20% compared to traditional materials [3]. The company has also explored hybrid composites, combining UHMWPE with carbon fibers to achieve an optimal balance of strength, stiffness, and impact resistance for specific aerospace applications [5].

Strengths: Significant weight reduction, high strength-to-weight ratio, and improved impact resistance. Weaknesses: Higher material costs and potential challenges in joining and bonding with other materials.

Bucher Leichtbau AG

Technical Solution: Bucher Leichtbau AG has focused on developing UHMWPE-based solutions for interior aerospace structures. They have created a range of lightweight panels and components using UHMWPE fibers in combination with advanced core materials. Their proprietary manufacturing process involves the use of thermoplastic matrices, allowing for easier recycling and reduced environmental impact. Bucher's UHMWPE composites have been implemented in aircraft galleys, lavatories, and other interior structures, offering weight savings of up to 30% compared to traditional materials [7]. The company has also developed fire-resistant UHMWPE composites that meet stringent aerospace safety standards, addressing one of the key challenges in using polymer-based materials in aircraft interiors [8].

Strengths: Significant weight reduction in interior structures, improved recyclability, and enhanced fire resistance. Weaknesses: Limited application in primary structural components and potential higher costs compared to traditional interior materials.

Core Innovations in UHMWPE for Aerospace Use

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Ultra-high molecular weight polyethylene

PatentWO2011089017A1

Innovation

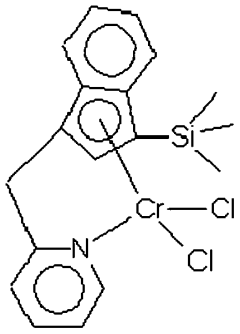

- The use of a blend of two metallocene-type catalysts, with Hafnium (Hf) and Chromium (Cr) as catalyst residues, to produce UHMW-PE with medium density and enhanced Charpy impact resistance, achieving a synergistic effect that improves both abrasion and impact resistance, and maintaining a suitable average grain size.

Environmental Impact of UHMWPE in Aerospace

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in aerospace applications is a critical consideration as the industry moves towards more sustainable practices. UHMWPE's lightweight properties contribute significantly to fuel efficiency in aircraft, potentially reducing overall carbon emissions during operation. However, the production process of UHMWPE involves energy-intensive methods and petrochemical feedstocks, which can have negative environmental implications.

The lifecycle assessment of UHMWPE in aerospace structures reveals both positive and negative environmental aspects. On the positive side, the material's durability and resistance to wear and tear mean that components made from UHMWPE have longer lifespans, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal. Additionally, the lightweight nature of UHMWPE contributes to reduced fuel consumption in aircraft, leading to lower greenhouse gas emissions over the operational life of the aerospace vehicle.

However, the production of UHMWPE requires significant energy input and relies on non-renewable resources. The polymerization process and subsequent treatment to achieve the desired properties for aerospace applications can result in substantial carbon dioxide emissions. Furthermore, the use of catalysts and solvents in the manufacturing process may lead to the release of volatile organic compounds (VOCs) and other pollutants if not properly managed.

End-of-life considerations for UHMWPE in aerospace structures present both challenges and opportunities. While the material is theoretically recyclable, the complex nature of aerospace components often makes recycling difficult in practice. The high purity requirements for aerospace-grade UHMWPE also limit the use of recycled content in new components, potentially leading to increased waste generation.

Efforts are underway to improve the environmental profile of UHMWPE in aerospace applications. Research into bio-based alternatives and more efficient production methods aims to reduce the reliance on fossil fuels and decrease the carbon footprint of UHMWPE manufacturing. Additionally, advancements in recycling technologies specific to aerospace materials are being explored to create closed-loop systems and minimize waste.

The aerospace industry is also investigating the potential for UHMWPE to contribute to the development of more environmentally friendly aircraft designs. By enabling lighter structures, UHMWPE could play a role in the creation of electric and hybrid-electric aircraft, which have the potential to significantly reduce aviation's environmental impact. However, this potential must be balanced against the material's current limitations in terms of recyclability and end-of-life management.

The lifecycle assessment of UHMWPE in aerospace structures reveals both positive and negative environmental aspects. On the positive side, the material's durability and resistance to wear and tear mean that components made from UHMWPE have longer lifespans, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal. Additionally, the lightweight nature of UHMWPE contributes to reduced fuel consumption in aircraft, leading to lower greenhouse gas emissions over the operational life of the aerospace vehicle.

However, the production of UHMWPE requires significant energy input and relies on non-renewable resources. The polymerization process and subsequent treatment to achieve the desired properties for aerospace applications can result in substantial carbon dioxide emissions. Furthermore, the use of catalysts and solvents in the manufacturing process may lead to the release of volatile organic compounds (VOCs) and other pollutants if not properly managed.

End-of-life considerations for UHMWPE in aerospace structures present both challenges and opportunities. While the material is theoretically recyclable, the complex nature of aerospace components often makes recycling difficult in practice. The high purity requirements for aerospace-grade UHMWPE also limit the use of recycled content in new components, potentially leading to increased waste generation.

Efforts are underway to improve the environmental profile of UHMWPE in aerospace applications. Research into bio-based alternatives and more efficient production methods aims to reduce the reliance on fossil fuels and decrease the carbon footprint of UHMWPE manufacturing. Additionally, advancements in recycling technologies specific to aerospace materials are being explored to create closed-loop systems and minimize waste.

The aerospace industry is also investigating the potential for UHMWPE to contribute to the development of more environmentally friendly aircraft designs. By enabling lighter structures, UHMWPE could play a role in the creation of electric and hybrid-electric aircraft, which have the potential to significantly reduce aviation's environmental impact. However, this potential must be balanced against the material's current limitations in terms of recyclability and end-of-life management.

Cost-Benefit Analysis of UHMWPE in Aerospace

The cost-benefit analysis of Ultra-High Molecular Weight Polyethylene (UHMWPE) in aerospace applications reveals a complex interplay of advantages and challenges. UHMWPE offers significant weight reduction potential, a critical factor in aerospace design where every gram saved translates to fuel efficiency and increased payload capacity. The material's exceptional strength-to-weight ratio surpasses many traditional aerospace materials, including certain grades of aluminum and titanium alloys.

From a cost perspective, the initial investment in UHMWPE for aerospace structures may be higher compared to conventional materials. However, the long-term benefits often outweigh these upfront costs. The reduced weight leads to lower fuel consumption over the lifespan of an aircraft, potentially resulting in substantial operational cost savings. Additionally, UHMWPE's resistance to fatigue and wear can extend the service life of components, reducing maintenance frequency and associated costs.

The material's unique properties, such as high impact resistance and self-lubricating characteristics, contribute to enhanced durability and reliability of aerospace structures. This translates to fewer replacements and repairs, further offsetting the initial higher material costs. Moreover, UHMWPE's excellent chemical resistance protects against corrosion and degradation, minimizing the need for protective coatings and treatments often required for metal components.

However, challenges exist in the widespread adoption of UHMWPE in aerospace. The material's relatively low melting point and thermal stability limitations restrict its use in high-temperature applications, necessitating careful design considerations and potentially hybrid material solutions. The manufacturing processes for UHMWPE aerospace components, including advanced forming and joining techniques, may require significant investment in new equipment and training.

Environmental factors also play a role in the cost-benefit analysis. While UHMWPE's lightweight properties contribute to reduced emissions through improved fuel efficiency, concerns about end-of-life recycling and disposal need to be addressed. The aerospace industry's stringent certification processes for new materials can also add to the overall cost and time required for UHMWPE integration.

In conclusion, the cost-benefit analysis of UHMWPE in aerospace applications indicates a promising potential for long-term value creation. The material's ability to significantly reduce weight while maintaining or improving performance characteristics offers compelling advantages. However, a comprehensive approach considering initial costs, lifecycle benefits, manufacturing challenges, and environmental impact is essential for aerospace manufacturers to make informed decisions about UHMWPE adoption in their structural designs.

From a cost perspective, the initial investment in UHMWPE for aerospace structures may be higher compared to conventional materials. However, the long-term benefits often outweigh these upfront costs. The reduced weight leads to lower fuel consumption over the lifespan of an aircraft, potentially resulting in substantial operational cost savings. Additionally, UHMWPE's resistance to fatigue and wear can extend the service life of components, reducing maintenance frequency and associated costs.

The material's unique properties, such as high impact resistance and self-lubricating characteristics, contribute to enhanced durability and reliability of aerospace structures. This translates to fewer replacements and repairs, further offsetting the initial higher material costs. Moreover, UHMWPE's excellent chemical resistance protects against corrosion and degradation, minimizing the need for protective coatings and treatments often required for metal components.

However, challenges exist in the widespread adoption of UHMWPE in aerospace. The material's relatively low melting point and thermal stability limitations restrict its use in high-temperature applications, necessitating careful design considerations and potentially hybrid material solutions. The manufacturing processes for UHMWPE aerospace components, including advanced forming and joining techniques, may require significant investment in new equipment and training.

Environmental factors also play a role in the cost-benefit analysis. While UHMWPE's lightweight properties contribute to reduced emissions through improved fuel efficiency, concerns about end-of-life recycling and disposal need to be addressed. The aerospace industry's stringent certification processes for new materials can also add to the overall cost and time required for UHMWPE integration.

In conclusion, the cost-benefit analysis of UHMWPE in aerospace applications indicates a promising potential for long-term value creation. The material's ability to significantly reduce weight while maintaining or improving performance characteristics offers compelling advantages. However, a comprehensive approach considering initial costs, lifecycle benefits, manufacturing challenges, and environmental impact is essential for aerospace manufacturers to make informed decisions about UHMWPE adoption in their structural designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!