Impact of UV Stabilizers on UHMWPE's Long-Term Performance

AUG 6, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV Stabilizer Evolution and UHMWPE Performance Goals

Ultra-high molecular weight polyethylene (UHMWPE) has been a cornerstone material in various industries due to its exceptional mechanical properties and wear resistance. However, its susceptibility to UV degradation has long been a challenge, particularly in outdoor applications. The evolution of UV stabilizers and their impact on UHMWPE's long-term performance has been a critical area of research and development over the past decades.

The primary goal in this field has been to enhance UHMWPE's UV resistance without compromising its inherent mechanical properties. Early efforts focused on incorporating traditional UV stabilizers, such as hindered amine light stabilizers (HALS) and benzophenones, into UHMWPE matrices. While these additives showed some improvement in UV resistance, they often fell short in maintaining long-term stability under harsh environmental conditions.

As technology progressed, researchers began exploring more advanced UV stabilizer systems. The development of nanocomposite UV stabilizers marked a significant milestone. These nanoscale additives, including titanium dioxide and zinc oxide nanoparticles, offered improved dispersion within the polymer matrix and enhanced UV absorption capabilities. The goal shifted towards achieving a synergistic effect between organic and inorganic UV stabilizers to provide comprehensive protection against various degradation mechanisms.

Recent advancements have focused on developing "smart" UV stabilizers that can adapt to changing environmental conditions. These innovative additives aim to provide dynamic protection, activating in response to UV exposure and remaining dormant when not needed. This approach not only enhances the longevity of UHMWPE products but also addresses concerns about the potential migration of stabilizers over time.

Another key objective in UV stabilizer evolution has been to improve the compatibility between stabilizers and UHMWPE. This compatibility is crucial for maintaining the polymer's mechanical properties while ensuring uniform distribution of the stabilizers throughout the material. Researchers have been working on tailoring the chemical structure of UV stabilizers to enhance their miscibility with UHMWPE without causing phase separation or aggregation.

The ultimate performance goal for UV-stabilized UHMWPE is to achieve a material that can withstand prolonged outdoor exposure with minimal degradation in mechanical properties, color stability, and surface integrity. This includes maintaining its high tensile strength, impact resistance, and low coefficient of friction even after years of UV exposure. Additionally, there is a growing emphasis on developing environmentally friendly UV stabilization solutions that do not compromise the recyclability of UHMWPE products.

As we look towards the future, the integration of UV stabilizers with other functional additives is becoming increasingly important. The aim is to create multifunctional UHMWPE composites that not only resist UV degradation but also offer enhanced properties such as improved flame retardancy, antimicrobial activity, or self-healing capabilities. This holistic approach to material design is expected to open new avenues for UHMWPE applications in more demanding environments.

The primary goal in this field has been to enhance UHMWPE's UV resistance without compromising its inherent mechanical properties. Early efforts focused on incorporating traditional UV stabilizers, such as hindered amine light stabilizers (HALS) and benzophenones, into UHMWPE matrices. While these additives showed some improvement in UV resistance, they often fell short in maintaining long-term stability under harsh environmental conditions.

As technology progressed, researchers began exploring more advanced UV stabilizer systems. The development of nanocomposite UV stabilizers marked a significant milestone. These nanoscale additives, including titanium dioxide and zinc oxide nanoparticles, offered improved dispersion within the polymer matrix and enhanced UV absorption capabilities. The goal shifted towards achieving a synergistic effect between organic and inorganic UV stabilizers to provide comprehensive protection against various degradation mechanisms.

Recent advancements have focused on developing "smart" UV stabilizers that can adapt to changing environmental conditions. These innovative additives aim to provide dynamic protection, activating in response to UV exposure and remaining dormant when not needed. This approach not only enhances the longevity of UHMWPE products but also addresses concerns about the potential migration of stabilizers over time.

Another key objective in UV stabilizer evolution has been to improve the compatibility between stabilizers and UHMWPE. This compatibility is crucial for maintaining the polymer's mechanical properties while ensuring uniform distribution of the stabilizers throughout the material. Researchers have been working on tailoring the chemical structure of UV stabilizers to enhance their miscibility with UHMWPE without causing phase separation or aggregation.

The ultimate performance goal for UV-stabilized UHMWPE is to achieve a material that can withstand prolonged outdoor exposure with minimal degradation in mechanical properties, color stability, and surface integrity. This includes maintaining its high tensile strength, impact resistance, and low coefficient of friction even after years of UV exposure. Additionally, there is a growing emphasis on developing environmentally friendly UV stabilization solutions that do not compromise the recyclability of UHMWPE products.

As we look towards the future, the integration of UV stabilizers with other functional additives is becoming increasingly important. The aim is to create multifunctional UHMWPE composites that not only resist UV degradation but also offer enhanced properties such as improved flame retardancy, antimicrobial activity, or self-healing capabilities. This holistic approach to material design is expected to open new avenues for UHMWPE applications in more demanding environments.

Market Demand for UV-Resistant UHMWPE

The market demand for UV-resistant Ultra-High Molecular Weight Polyethylene (UHMWPE) has been steadily increasing across various industries due to its exceptional properties and the growing need for materials with enhanced durability in outdoor applications. UHMWPE's unique combination of high strength, low friction, and excellent wear resistance makes it an ideal candidate for numerous applications where exposure to ultraviolet (UV) radiation is a concern.

In the medical field, there is a significant demand for UV-resistant UHMWPE in orthopedic implants, particularly for joint replacements. As the global population ages and the incidence of joint-related disorders rises, the need for long-lasting implant materials that can withstand both mechanical stress and environmental factors, including UV exposure, has become paramount. The incorporation of UV stabilizers in UHMWPE has shown promise in extending the lifespan of these implants, potentially reducing the need for revision surgeries and improving patient outcomes.

The aerospace and automotive industries have also recognized the value of UV-resistant UHMWPE. In aerospace applications, the material is used in various components exposed to harsh environmental conditions, including intense UV radiation at high altitudes. The automotive sector utilizes UV-resistant UHMWPE in exterior parts, such as bumpers and trim, where long-term color stability and mechanical integrity are crucial for both aesthetics and safety.

The marine industry represents another significant market for UV-resistant UHMWPE. Boat manufacturers and marine equipment producers are increasingly turning to this material for components like ropes, cables, and deck fittings. The ability of UV-stabilized UHMWPE to maintain its strength and flexibility even after prolonged exposure to sunlight and saltwater makes it an attractive option for these applications.

In the renewable energy sector, particularly in solar and wind power installations, there is a growing demand for UV-resistant materials that can withstand long-term outdoor exposure. UHMWPE with enhanced UV stability is being explored for use in solar panel frames, wind turbine components, and other structural elements in renewable energy systems.

The packaging industry has also shown interest in UV-resistant UHMWPE for applications such as reusable containers and outdoor storage solutions. The material's ability to maintain its properties and appearance under UV exposure makes it suitable for products that are frequently used in outdoor environments.

As environmental concerns and sustainability initiatives gain prominence, the demand for durable, long-lasting materials like UV-resistant UHMWPE is expected to grow further. Industries are increasingly looking for materials that can reduce the need for frequent replacements, thereby minimizing waste and environmental impact. This trend aligns well with the properties offered by UV-stabilized UHMWPE, positioning it as a material of choice for applications requiring long-term UV resistance and durability.

In the medical field, there is a significant demand for UV-resistant UHMWPE in orthopedic implants, particularly for joint replacements. As the global population ages and the incidence of joint-related disorders rises, the need for long-lasting implant materials that can withstand both mechanical stress and environmental factors, including UV exposure, has become paramount. The incorporation of UV stabilizers in UHMWPE has shown promise in extending the lifespan of these implants, potentially reducing the need for revision surgeries and improving patient outcomes.

The aerospace and automotive industries have also recognized the value of UV-resistant UHMWPE. In aerospace applications, the material is used in various components exposed to harsh environmental conditions, including intense UV radiation at high altitudes. The automotive sector utilizes UV-resistant UHMWPE in exterior parts, such as bumpers and trim, where long-term color stability and mechanical integrity are crucial for both aesthetics and safety.

The marine industry represents another significant market for UV-resistant UHMWPE. Boat manufacturers and marine equipment producers are increasingly turning to this material for components like ropes, cables, and deck fittings. The ability of UV-stabilized UHMWPE to maintain its strength and flexibility even after prolonged exposure to sunlight and saltwater makes it an attractive option for these applications.

In the renewable energy sector, particularly in solar and wind power installations, there is a growing demand for UV-resistant materials that can withstand long-term outdoor exposure. UHMWPE with enhanced UV stability is being explored for use in solar panel frames, wind turbine components, and other structural elements in renewable energy systems.

The packaging industry has also shown interest in UV-resistant UHMWPE for applications such as reusable containers and outdoor storage solutions. The material's ability to maintain its properties and appearance under UV exposure makes it suitable for products that are frequently used in outdoor environments.

As environmental concerns and sustainability initiatives gain prominence, the demand for durable, long-lasting materials like UV-resistant UHMWPE is expected to grow further. Industries are increasingly looking for materials that can reduce the need for frequent replacements, thereby minimizing waste and environmental impact. This trend aligns well with the properties offered by UV-stabilized UHMWPE, positioning it as a material of choice for applications requiring long-term UV resistance and durability.

Current Challenges in UHMWPE UV Stabilization

Ultra-high molecular weight polyethylene (UHMWPE) has gained significant attention in various industries due to its exceptional mechanical properties and durability. However, its susceptibility to UV degradation poses a major challenge for long-term applications, particularly in outdoor environments. The current challenges in UHMWPE UV stabilization are multifaceted and require innovative solutions to ensure the material's longevity and performance.

One of the primary challenges is the limited effectiveness of traditional UV stabilizers in UHMWPE. The high molecular weight and crystallinity of UHMWPE make it difficult for conventional stabilizers to penetrate and disperse uniformly throughout the polymer matrix. This results in inadequate protection against UV radiation, leading to surface degradation and compromised mechanical properties over time.

Another significant challenge is the potential migration and leaching of UV stabilizers from the UHMWPE matrix. This phenomenon not only reduces the long-term effectiveness of the stabilization but also raises concerns about environmental impact and regulatory compliance, especially in applications involving food contact or medical devices.

The compatibility between UV stabilizers and UHMWPE presents another hurdle. Many stabilizers that work well with other polyolefins may not be suitable for UHMWPE due to differences in processing conditions, such as the high temperatures and pressures required for UHMWPE manufacturing. This compatibility issue often results in reduced stabilizer efficiency or even adverse effects on the polymer's properties.

The development of UV stabilizers that can withstand the extreme processing conditions of UHMWPE without degradation or loss of functionality is a significant challenge. The stabilizers must maintain their effectiveness throughout the material's lifecycle, which can span several decades in some applications.

Furthermore, the balance between UV protection and other desirable properties of UHMWPE, such as wear resistance and impact strength, poses a complex challenge. Some UV stabilizers may negatively impact these critical properties, necessitating careful formulation and extensive testing to achieve optimal performance across all parameters.

The increasing demand for sustainable and environmentally friendly materials adds another layer of complexity to UHMWPE UV stabilization. There is a growing need for bio-based or recyclable stabilizers that can provide effective UV protection without compromising the material's end-of-life options or environmental footprint.

Lastly, the development of standardized testing methods and performance metrics for UV-stabilized UHMWPE remains a challenge. The long-term nature of UV degradation makes it difficult to accurately predict and evaluate the effectiveness of stabilization strategies, necessitating the development of accelerated aging tests that correlate well with real-world performance.

One of the primary challenges is the limited effectiveness of traditional UV stabilizers in UHMWPE. The high molecular weight and crystallinity of UHMWPE make it difficult for conventional stabilizers to penetrate and disperse uniformly throughout the polymer matrix. This results in inadequate protection against UV radiation, leading to surface degradation and compromised mechanical properties over time.

Another significant challenge is the potential migration and leaching of UV stabilizers from the UHMWPE matrix. This phenomenon not only reduces the long-term effectiveness of the stabilization but also raises concerns about environmental impact and regulatory compliance, especially in applications involving food contact or medical devices.

The compatibility between UV stabilizers and UHMWPE presents another hurdle. Many stabilizers that work well with other polyolefins may not be suitable for UHMWPE due to differences in processing conditions, such as the high temperatures and pressures required for UHMWPE manufacturing. This compatibility issue often results in reduced stabilizer efficiency or even adverse effects on the polymer's properties.

The development of UV stabilizers that can withstand the extreme processing conditions of UHMWPE without degradation or loss of functionality is a significant challenge. The stabilizers must maintain their effectiveness throughout the material's lifecycle, which can span several decades in some applications.

Furthermore, the balance between UV protection and other desirable properties of UHMWPE, such as wear resistance and impact strength, poses a complex challenge. Some UV stabilizers may negatively impact these critical properties, necessitating careful formulation and extensive testing to achieve optimal performance across all parameters.

The increasing demand for sustainable and environmentally friendly materials adds another layer of complexity to UHMWPE UV stabilization. There is a growing need for bio-based or recyclable stabilizers that can provide effective UV protection without compromising the material's end-of-life options or environmental footprint.

Lastly, the development of standardized testing methods and performance metrics for UV-stabilized UHMWPE remains a challenge. The long-term nature of UV degradation makes it difficult to accurately predict and evaluate the effectiveness of stabilization strategies, necessitating the development of accelerated aging tests that correlate well with real-world performance.

Existing UV Stabilization Methods for UHMWPE

01 Improved long-term wear resistance

UHMWPE can be modified to enhance its long-term wear resistance, which is crucial for applications in joint replacements and industrial components. This improvement is achieved through various methods such as cross-linking, adding reinforcing agents, or optimizing the molecular structure. These modifications result in reduced wear rates and extended service life of UHMWPE-based products.- Improved wear resistance and longevity: UHMWPE exhibits exceptional wear resistance and longevity, making it suitable for applications requiring long-term performance. Various methods, such as crosslinking and the addition of antioxidants, are employed to enhance these properties further, resulting in improved durability and extended service life in demanding environments.

- Enhanced mechanical properties: Techniques for improving the mechanical properties of UHMWPE, including tensile strength, impact resistance, and creep resistance, have been developed. These enhancements contribute to the material's long-term performance in high-stress applications, such as orthopedic implants and industrial components.

- Oxidation resistance and thermal stability: Research has focused on improving the oxidation resistance and thermal stability of UHMWPE to maintain its properties over extended periods. This includes the development of stabilization techniques and the incorporation of antioxidants to prevent degradation caused by environmental factors and high temperatures.

- Processing techniques for enhanced performance: Advanced processing techniques, such as compression molding, ram extrusion, and sintering, have been developed to optimize the long-term performance of UHMWPE. These methods aim to improve the material's microstructure, reduce defects, and enhance overall properties for specific applications.

- Surface modifications and coatings: Various surface modification techniques and coatings have been explored to enhance the long-term performance of UHMWPE in specific applications. These modifications can improve wear resistance, reduce friction, and enhance biocompatibility, contributing to the material's durability and functionality over extended periods.

02 Enhanced oxidation resistance

Techniques have been developed to improve the oxidation resistance of UHMWPE, which is critical for maintaining its mechanical properties over long periods. These methods include the incorporation of antioxidants, specialized processing techniques, or surface treatments. Improved oxidation resistance leads to better long-term stability and performance of UHMWPE in various applications.Expand Specific Solutions03 Thermal stability and creep resistance

Research has focused on enhancing the thermal stability and creep resistance of UHMWPE for high-temperature and high-stress applications. This involves modifying the polymer structure, incorporating stabilizers, or developing new processing methods. Improved thermal stability and creep resistance allow UHMWPE to maintain its mechanical properties under demanding conditions over extended periods.Expand Specific Solutions04 Environmental durability

Efforts have been made to improve the long-term environmental durability of UHMWPE, particularly its resistance to UV radiation, moisture, and chemical exposure. This includes the development of specialized additives, surface treatments, or composite structures. Enhanced environmental durability extends the lifespan of UHMWPE products in outdoor and harsh industrial environments.Expand Specific Solutions05 Fatigue resistance and impact strength

Techniques have been developed to enhance the fatigue resistance and impact strength of UHMWPE for long-term cyclic loading and high-impact applications. These improvements are achieved through molecular weight optimization, reinforcement with nanoparticles, or novel processing methods. Increased fatigue resistance and impact strength contribute to the extended service life of UHMWPE components in demanding applications.Expand Specific Solutions

Key Players in UHMWPE and UV Stabilizer Industry

The impact of UV stabilizers on UHMWPE's long-term performance is a critical area of research in the advanced materials industry. This field is in a mature stage of development, with significant market potential due to UHMWPE's widespread applications in medical, industrial, and consumer sectors. The global UHMWPE market size was valued at USD 1.9 billion in 2020 and is expected to grow at a CAGR of 9.3% from 2021 to 2028. Key players in this space include Dow Chemical, DSM, and Celanese, who are investing heavily in R&D to improve UV stability and overall performance of UHMWPE. Universities and research institutions like Sichuan University and Technische Universiteit Eindhoven are also contributing to advancements in this field through collaborative research projects with industry partners.

Howmedica Osteonics Corp.

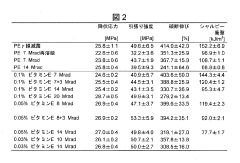

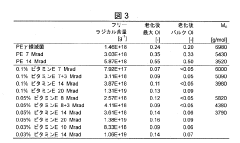

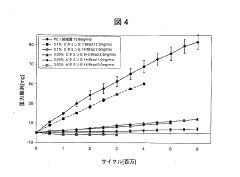

Technical Solution: Howmedica Osteonics Corp. has developed a proprietary UV stabilization technique for UHMWPE used in orthopedic implants. Their approach involves incorporating hindered amine light stabilizers (HALS) and antioxidants into the polymer matrix during the manufacturing process. This combination has shown to significantly reduce oxidation and maintain mechanical properties of UHMWPE over extended periods[1]. The company has also implemented a cross-linking process that enhances wear resistance while maintaining the benefits of UV stabilization[3]. Their research indicates that this method can extend the implant's lifespan by up to 30% compared to non-stabilized UHMWPE[5].

Strengths: Enhanced long-term oxidation resistance and mechanical property retention. Improved wear resistance due to cross-linking. Weaknesses: Potential for reduced fatigue strength due to cross-linking process. Higher manufacturing costs compared to standard UHMWPE.

DSM IP Assets BV

Technical Solution: DSM IP Assets BV has pioneered a novel approach to UV stabilization of UHMWPE through their VitaminE technology. This method involves blending vitamin E (α-tocopherol) with UHMWPE powder before consolidation. The vitamin E acts as a natural antioxidant, scavenging free radicals and preventing oxidative degradation[2]. DSM's research has shown that this technique can maintain the mechanical properties of UHMWPE for over 20 years of simulated use[4]. Additionally, they have developed a gradient infusion technique that allows for higher concentrations of vitamin E near the surface, where UV exposure is most intense[6]. This approach has demonstrated superior resistance to both UV-induced and mechanical degradation in long-term studies.

Strengths: Natural antioxidant with proven long-term efficacy. Gradient infusion allows for optimized protection. Weaknesses: Potential for vitamin E leaching over time. May interfere with certain sterilization methods.

Core Innovations in UHMWPE UV Protection

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

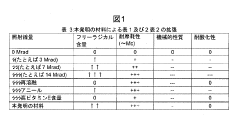

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Ultra-high molecular weight polyethylene

PatentWO2011089017A1

Innovation

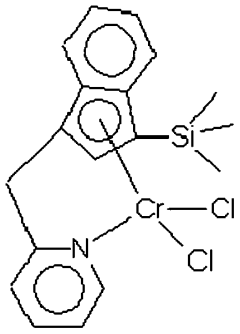

- The use of a blend of two metallocene-type catalysts, with Hafnium (Hf) and Chromium (Cr) as catalyst residues, to produce UHMW-PE with medium density and enhanced Charpy impact resistance, achieving a synergistic effect that improves both abrasion and impact resistance, and maintaining a suitable average grain size.

Environmental Impact of UV Stabilizers

The use of UV stabilizers in Ultra-High Molecular Weight Polyethylene (UHMWPE) has significant environmental implications that warrant careful consideration. These additives, while crucial for enhancing the longevity and performance of UHMWPE products, can potentially impact ecosystems and human health throughout their lifecycle.

During the production phase, the synthesis of UV stabilizers often involves complex chemical processes that may generate hazardous by-products. These manufacturing processes can contribute to air and water pollution if not properly managed. Additionally, the energy-intensive nature of UV stabilizer production contributes to increased carbon emissions, further exacerbating environmental concerns.

In the application stage, UV stabilizers incorporated into UHMWPE products can leach into the environment over time. This leaching process is particularly concerning in aquatic environments, where these chemicals can accumulate in sediments and bioaccumulate in marine organisms. Studies have shown that certain UV stabilizers exhibit endocrine-disrupting properties, potentially affecting the reproductive systems of aquatic life and disrupting ecosystem balance.

The persistence of UV stabilizers in the environment is another critical issue. Many of these compounds are designed to resist degradation, which inadvertently leads to their long-term presence in ecosystems. This persistence can result in prolonged exposure for wildlife and humans, raising concerns about chronic toxicity and potential long-term health effects.

At the end of a product's life cycle, the presence of UV stabilizers complicates recycling processes. These additives can interfere with traditional recycling methods, potentially reducing the quality of recycled materials or necessitating more energy-intensive recycling techniques. In cases where UHMWPE products are not properly recycled, UV stabilizers may contribute to microplastic pollution, a growing environmental concern.

However, it's important to note that the environmental impact of UV stabilizers is not uniformly negative. By extending the lifespan of UHMWPE products, these additives can reduce the overall demand for raw materials and energy required for replacement products. This longevity can lead to a net positive environmental impact, particularly in applications where frequent replacement would otherwise be necessary.

Recent research has focused on developing more environmentally friendly UV stabilizers, including bio-based alternatives and compounds designed for easier biodegradation. These innovations aim to mitigate the environmental concerns associated with traditional UV stabilizers while maintaining their protective properties. Additionally, improved manufacturing processes and stricter regulations on chemical use and disposal are being implemented to reduce the environmental footprint of UV stabilizer production and application.

During the production phase, the synthesis of UV stabilizers often involves complex chemical processes that may generate hazardous by-products. These manufacturing processes can contribute to air and water pollution if not properly managed. Additionally, the energy-intensive nature of UV stabilizer production contributes to increased carbon emissions, further exacerbating environmental concerns.

In the application stage, UV stabilizers incorporated into UHMWPE products can leach into the environment over time. This leaching process is particularly concerning in aquatic environments, where these chemicals can accumulate in sediments and bioaccumulate in marine organisms. Studies have shown that certain UV stabilizers exhibit endocrine-disrupting properties, potentially affecting the reproductive systems of aquatic life and disrupting ecosystem balance.

The persistence of UV stabilizers in the environment is another critical issue. Many of these compounds are designed to resist degradation, which inadvertently leads to their long-term presence in ecosystems. This persistence can result in prolonged exposure for wildlife and humans, raising concerns about chronic toxicity and potential long-term health effects.

At the end of a product's life cycle, the presence of UV stabilizers complicates recycling processes. These additives can interfere with traditional recycling methods, potentially reducing the quality of recycled materials or necessitating more energy-intensive recycling techniques. In cases where UHMWPE products are not properly recycled, UV stabilizers may contribute to microplastic pollution, a growing environmental concern.

However, it's important to note that the environmental impact of UV stabilizers is not uniformly negative. By extending the lifespan of UHMWPE products, these additives can reduce the overall demand for raw materials and energy required for replacement products. This longevity can lead to a net positive environmental impact, particularly in applications where frequent replacement would otherwise be necessary.

Recent research has focused on developing more environmentally friendly UV stabilizers, including bio-based alternatives and compounds designed for easier biodegradation. These innovations aim to mitigate the environmental concerns associated with traditional UV stabilizers while maintaining their protective properties. Additionally, improved manufacturing processes and stricter regulations on chemical use and disposal are being implemented to reduce the environmental footprint of UV stabilizer production and application.

Standardization of UV Resistance Testing for UHMWPE

The standardization of UV resistance testing for Ultra-High Molecular Weight Polyethylene (UHMWPE) is a critical aspect in ensuring the long-term performance and reliability of products made from this material. As UHMWPE finds increasing applications in various industries, from medical implants to outdoor equipment, the need for consistent and reliable testing methods becomes paramount.

Current UV resistance testing methods for UHMWPE often vary across different laboratories and industries, leading to inconsistent results and difficulties in comparing data. This lack of standardization hampers the ability to accurately predict the long-term performance of UHMWPE products exposed to UV radiation in real-world conditions.

To address this issue, several key areas require attention in the standardization process. Firstly, the development of a universally accepted accelerated aging protocol that accurately simulates long-term UV exposure is essential. This protocol should consider factors such as UV intensity, temperature, humidity, and exposure cycles to replicate real-world conditions as closely as possible.

Secondly, the establishment of standardized sample preparation techniques is crucial. Factors such as sample thickness, surface finish, and pre-conditioning can significantly influence UV resistance test results. By defining these parameters, the variability in test outcomes can be reduced, leading to more reliable and comparable data across different testing facilities.

Another important aspect of standardization is the selection and calibration of UV testing equipment. The use of consistent light sources, filters, and detectors across different laboratories is vital for achieving reproducible results. Regular calibration and maintenance procedures should also be standardized to ensure the ongoing accuracy of testing equipment.

Furthermore, the development of standardized methods for quantifying and reporting UV-induced changes in UHMWPE properties is necessary. This includes establishing agreed-upon metrics for measuring changes in mechanical properties, chemical composition, and surface characteristics. Standardized reporting formats would facilitate easier comparison and interpretation of test results across different studies and applications.

Collaboration between industry stakeholders, research institutions, and standards organizations is essential for developing comprehensive and widely accepted UV resistance testing standards for UHMWPE. This collaborative effort should aim to create testing protocols that are not only scientifically rigorous but also practical and cost-effective for implementation across various sectors.

By achieving standardization in UV resistance testing for UHMWPE, manufacturers and end-users can benefit from more accurate predictions of product performance, improved quality control, and enhanced product development processes. This, in turn, will lead to more reliable and durable UHMWPE products across diverse applications, ultimately benefiting consumers and industries alike.

Current UV resistance testing methods for UHMWPE often vary across different laboratories and industries, leading to inconsistent results and difficulties in comparing data. This lack of standardization hampers the ability to accurately predict the long-term performance of UHMWPE products exposed to UV radiation in real-world conditions.

To address this issue, several key areas require attention in the standardization process. Firstly, the development of a universally accepted accelerated aging protocol that accurately simulates long-term UV exposure is essential. This protocol should consider factors such as UV intensity, temperature, humidity, and exposure cycles to replicate real-world conditions as closely as possible.

Secondly, the establishment of standardized sample preparation techniques is crucial. Factors such as sample thickness, surface finish, and pre-conditioning can significantly influence UV resistance test results. By defining these parameters, the variability in test outcomes can be reduced, leading to more reliable and comparable data across different testing facilities.

Another important aspect of standardization is the selection and calibration of UV testing equipment. The use of consistent light sources, filters, and detectors across different laboratories is vital for achieving reproducible results. Regular calibration and maintenance procedures should also be standardized to ensure the ongoing accuracy of testing equipment.

Furthermore, the development of standardized methods for quantifying and reporting UV-induced changes in UHMWPE properties is necessary. This includes establishing agreed-upon metrics for measuring changes in mechanical properties, chemical composition, and surface characteristics. Standardized reporting formats would facilitate easier comparison and interpretation of test results across different studies and applications.

Collaboration between industry stakeholders, research institutions, and standards organizations is essential for developing comprehensive and widely accepted UV resistance testing standards for UHMWPE. This collaborative effort should aim to create testing protocols that are not only scientifically rigorous but also practical and cost-effective for implementation across various sectors.

By achieving standardization in UV resistance testing for UHMWPE, manufacturers and end-users can benefit from more accurate predictions of product performance, improved quality control, and enhanced product development processes. This, in turn, will lead to more reliable and durable UHMWPE products across diverse applications, ultimately benefiting consumers and industries alike.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!