Comparison of UHMWPE and PEEK in High-Tension Environments

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE and PEEK Overview

Ultra-high-molecular-weight polyethylene (UHMWPE) and polyetheretherketone (PEEK) are two advanced engineering polymers that have gained significant attention in high-tension environments due to their exceptional mechanical properties and chemical resistance. These materials have found widespread applications in various industries, including aerospace, automotive, medical, and industrial manufacturing.

UHMWPE is a linear polyethylene with an extremely high molecular weight, typically ranging from 3.5 to 7.5 million g/mol. This unique molecular structure imparts extraordinary properties to the material, such as high impact strength, excellent abrasion resistance, and low friction coefficient. UHMWPE also exhibits outstanding chemical resistance and biocompatibility, making it an ideal choice for medical implants and industrial applications where durability is crucial.

PEEK, on the other hand, is a semi-crystalline thermoplastic polymer belonging to the polyaryletherketone family. It is characterized by its high strength-to-weight ratio, excellent thermal stability, and superior chemical resistance. PEEK maintains its mechanical properties at elevated temperatures, making it suitable for demanding applications in aerospace and automotive industries. Additionally, its biocompatibility and radiolucency have led to its increasing use in medical implants and surgical instruments.

In high-tension environments, both UHMWPE and PEEK offer distinct advantages. UHMWPE's exceptional wear resistance and low friction properties make it an excellent choice for applications involving sliding or bearing surfaces under high loads. Its ability to withstand impact and absorb energy also contributes to its popularity in protective gear and high-performance textiles.

PEEK, with its high strength and stiffness, is particularly well-suited for structural components subjected to high mechanical stress. Its ability to maintain dimensional stability and mechanical properties at elevated temperatures gives it an edge in applications where thermal resistance is critical. PEEK's excellent fatigue resistance and creep performance further enhance its suitability for long-term use in high-tension environments.

Both materials exhibit remarkable chemical resistance, protecting them from degradation in harsh environments. This property is particularly valuable in industrial settings where exposure to corrosive chemicals is common. However, PEEK generally offers superior resistance to a broader range of chemicals compared to UHMWPE.

The choice between UHMWPE and PEEK in high-tension environments often depends on the specific requirements of the application. Factors such as operating temperature, mechanical load, chemical exposure, and cost considerations play crucial roles in material selection. While UHMWPE excels in applications requiring low friction and high wear resistance, PEEK is often preferred in scenarios demanding high strength, stiffness, and thermal stability.

UHMWPE is a linear polyethylene with an extremely high molecular weight, typically ranging from 3.5 to 7.5 million g/mol. This unique molecular structure imparts extraordinary properties to the material, such as high impact strength, excellent abrasion resistance, and low friction coefficient. UHMWPE also exhibits outstanding chemical resistance and biocompatibility, making it an ideal choice for medical implants and industrial applications where durability is crucial.

PEEK, on the other hand, is a semi-crystalline thermoplastic polymer belonging to the polyaryletherketone family. It is characterized by its high strength-to-weight ratio, excellent thermal stability, and superior chemical resistance. PEEK maintains its mechanical properties at elevated temperatures, making it suitable for demanding applications in aerospace and automotive industries. Additionally, its biocompatibility and radiolucency have led to its increasing use in medical implants and surgical instruments.

In high-tension environments, both UHMWPE and PEEK offer distinct advantages. UHMWPE's exceptional wear resistance and low friction properties make it an excellent choice for applications involving sliding or bearing surfaces under high loads. Its ability to withstand impact and absorb energy also contributes to its popularity in protective gear and high-performance textiles.

PEEK, with its high strength and stiffness, is particularly well-suited for structural components subjected to high mechanical stress. Its ability to maintain dimensional stability and mechanical properties at elevated temperatures gives it an edge in applications where thermal resistance is critical. PEEK's excellent fatigue resistance and creep performance further enhance its suitability for long-term use in high-tension environments.

Both materials exhibit remarkable chemical resistance, protecting them from degradation in harsh environments. This property is particularly valuable in industrial settings where exposure to corrosive chemicals is common. However, PEEK generally offers superior resistance to a broader range of chemicals compared to UHMWPE.

The choice between UHMWPE and PEEK in high-tension environments often depends on the specific requirements of the application. Factors such as operating temperature, mechanical load, chemical exposure, and cost considerations play crucial roles in material selection. While UHMWPE excels in applications requiring low friction and high wear resistance, PEEK is often preferred in scenarios demanding high strength, stiffness, and thermal stability.

Market Demand Analysis

The market demand for high-performance polymers in high-tension environments has been steadily increasing across various industries. Both Ultra-High Molecular Weight Polyethylene (UHMWPE) and Polyether Ether Ketone (PEEK) have emerged as leading materials in this sector, each offering unique properties that cater to specific application needs.

In the aerospace industry, there is a growing demand for lightweight materials that can withstand extreme conditions. UHMWPE and PEEK are both being explored for their potential to replace traditional metals in aircraft components, reducing overall weight and improving fuel efficiency. The global aerospace plastics market, which includes these materials, is projected to experience significant growth in the coming years.

The medical device industry has also shown increased interest in these materials. UHMWPE has long been used in orthopedic implants due to its wear resistance and biocompatibility. PEEK, with its excellent mechanical properties and radiolucency, is gaining traction in spinal implants and other medical applications. The aging population and rise in orthopedic surgeries are driving factors for the demand of these materials in the medical sector.

In the oil and gas industry, both UHMWPE and PEEK are sought after for their resistance to harsh chemicals and high temperatures. As exploration moves into more challenging environments, such as deep-sea drilling, the demand for these high-performance polymers is expected to rise. The materials are used in various components, including seals, bearings, and pipeline linings.

The automotive sector is another key market for these materials. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, UHMWPE and PEEK are being considered for various applications, from gears to bearings. The shift towards electric vehicles may further boost demand, as these materials can contribute to overall weight reduction and improved battery range.

Sports and recreation equipment manufacturers are also driving demand for UHMWPE and PEEK. UHMWPE fibers are used in high-strength ropes and protective gear, while PEEK is finding applications in high-performance sporting goods. The growing interest in extreme sports and outdoor activities is expected to fuel this market segment.

While both materials show promising growth potential, challenges such as high production costs and competition from other advanced materials may impact market dynamics. However, ongoing research and development efforts aimed at improving material properties and reducing production costs are likely to address these challenges and further expand market opportunities for UHMWPE and PEEK in high-tension environments.

In the aerospace industry, there is a growing demand for lightweight materials that can withstand extreme conditions. UHMWPE and PEEK are both being explored for their potential to replace traditional metals in aircraft components, reducing overall weight and improving fuel efficiency. The global aerospace plastics market, which includes these materials, is projected to experience significant growth in the coming years.

The medical device industry has also shown increased interest in these materials. UHMWPE has long been used in orthopedic implants due to its wear resistance and biocompatibility. PEEK, with its excellent mechanical properties and radiolucency, is gaining traction in spinal implants and other medical applications. The aging population and rise in orthopedic surgeries are driving factors for the demand of these materials in the medical sector.

In the oil and gas industry, both UHMWPE and PEEK are sought after for their resistance to harsh chemicals and high temperatures. As exploration moves into more challenging environments, such as deep-sea drilling, the demand for these high-performance polymers is expected to rise. The materials are used in various components, including seals, bearings, and pipeline linings.

The automotive sector is another key market for these materials. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, UHMWPE and PEEK are being considered for various applications, from gears to bearings. The shift towards electric vehicles may further boost demand, as these materials can contribute to overall weight reduction and improved battery range.

Sports and recreation equipment manufacturers are also driving demand for UHMWPE and PEEK. UHMWPE fibers are used in high-strength ropes and protective gear, while PEEK is finding applications in high-performance sporting goods. The growing interest in extreme sports and outdoor activities is expected to fuel this market segment.

While both materials show promising growth potential, challenges such as high production costs and competition from other advanced materials may impact market dynamics. However, ongoing research and development efforts aimed at improving material properties and reducing production costs are likely to address these challenges and further expand market opportunities for UHMWPE and PEEK in high-tension environments.

Technical Challenges

The comparison of Ultra-High Molecular Weight Polyethylene (UHMWPE) and Polyether Ether Ketone (PEEK) in high-tension environments presents several technical challenges. Both materials are known for their exceptional mechanical properties, but their performance under extreme conditions requires careful consideration.

One of the primary challenges is the long-term durability of these materials under constant high-tension loads. UHMWPE, while known for its excellent wear resistance and impact strength, may experience creep over time when subjected to continuous high stress. This can lead to dimensional changes and potential failure in critical applications. PEEK, on the other hand, exhibits better creep resistance but may be more susceptible to fatigue under cyclic loading conditions.

Temperature resistance poses another significant challenge. High-tension environments often involve elevated temperatures, which can affect the mechanical properties of both materials. UHMWPE has a lower melting point compared to PEEK, which limits its use in high-temperature applications. PEEK maintains its mechanical properties at higher temperatures, but its performance can still degrade in extreme heat conditions.

Chemical resistance is a crucial factor in many high-tension environments. While both materials offer good chemical resistance, they may react differently to specific chemicals or solvents. UHMWPE has excellent resistance to most chemicals but can be affected by strong oxidizing agents. PEEK demonstrates superior resistance to a wider range of chemicals but may be vulnerable to certain concentrated acids.

The manufacturing and processing of these materials for high-tension applications present their own set of challenges. UHMWPE, due to its high molecular weight, requires specialized processing techniques to achieve the desired shapes and properties. PEEK, while easier to process, demands high processing temperatures, which can be energy-intensive and require specialized equipment.

Joining and bonding these materials in complex assemblies can be problematic. UHMWPE's low surface energy makes it difficult to bond with adhesives or other materials. PEEK, while more amenable to bonding, still requires careful surface preparation and selection of compatible adhesives to ensure strong, durable joints in high-stress environments.

Lastly, the cost-effectiveness of using these high-performance materials in large-scale applications remains a challenge. Both UHMWPE and PEEK are significantly more expensive than conventional plastics, which can limit their adoption in cost-sensitive industries. Balancing the superior performance of these materials against their higher costs requires careful engineering and economic analysis.

One of the primary challenges is the long-term durability of these materials under constant high-tension loads. UHMWPE, while known for its excellent wear resistance and impact strength, may experience creep over time when subjected to continuous high stress. This can lead to dimensional changes and potential failure in critical applications. PEEK, on the other hand, exhibits better creep resistance but may be more susceptible to fatigue under cyclic loading conditions.

Temperature resistance poses another significant challenge. High-tension environments often involve elevated temperatures, which can affect the mechanical properties of both materials. UHMWPE has a lower melting point compared to PEEK, which limits its use in high-temperature applications. PEEK maintains its mechanical properties at higher temperatures, but its performance can still degrade in extreme heat conditions.

Chemical resistance is a crucial factor in many high-tension environments. While both materials offer good chemical resistance, they may react differently to specific chemicals or solvents. UHMWPE has excellent resistance to most chemicals but can be affected by strong oxidizing agents. PEEK demonstrates superior resistance to a wider range of chemicals but may be vulnerable to certain concentrated acids.

The manufacturing and processing of these materials for high-tension applications present their own set of challenges. UHMWPE, due to its high molecular weight, requires specialized processing techniques to achieve the desired shapes and properties. PEEK, while easier to process, demands high processing temperatures, which can be energy-intensive and require specialized equipment.

Joining and bonding these materials in complex assemblies can be problematic. UHMWPE's low surface energy makes it difficult to bond with adhesives or other materials. PEEK, while more amenable to bonding, still requires careful surface preparation and selection of compatible adhesives to ensure strong, durable joints in high-stress environments.

Lastly, the cost-effectiveness of using these high-performance materials in large-scale applications remains a challenge. Both UHMWPE and PEEK are significantly more expensive than conventional plastics, which can limit their adoption in cost-sensitive industries. Balancing the superior performance of these materials against their higher costs requires careful engineering and economic analysis.

Current Application Methods

01 Composite materials combining UHMWPE and PEEK

Composite materials are developed by combining Ultra-High Molecular Weight Polyethylene (UHMWPE) and Polyether Ether Ketone (PEEK) to enhance mechanical properties, wear resistance, and biocompatibility. These composites find applications in various industries, including medical devices, aerospace, and industrial components.- Composite materials combining UHMWPE and PEEK: Composite materials are developed by combining Ultra-High Molecular Weight Polyethylene (UHMWPE) and Polyether Ether Ketone (PEEK) to enhance mechanical properties, wear resistance, and biocompatibility. These composites find applications in various industries, including medical implants, aerospace, and industrial components.

- Medical implants and prosthetics using UHMWPE and PEEK: UHMWPE and PEEK are utilized in the development of medical implants and prosthetics due to their excellent biocompatibility, wear resistance, and mechanical properties. These materials are used in orthopedic implants, spinal devices, and dental applications to improve patient outcomes and implant longevity.

- Surface modification and coating techniques for UHMWPE and PEEK: Various surface modification and coating techniques are applied to UHMWPE and PEEK to enhance their properties, such as wear resistance, biocompatibility, and adhesion. These techniques include plasma treatment, chemical etching, and the application of specialized coatings to improve the performance of components made from these materials.

- Processing methods for UHMWPE and PEEK components: Advanced processing methods are developed for manufacturing components from UHMWPE and PEEK, including injection molding, compression molding, and additive manufacturing techniques. These methods aim to optimize the mechanical properties, dimensional accuracy, and overall performance of the final products.

- Tribological studies and wear resistance improvements: Research focuses on improving the tribological properties and wear resistance of UHMWPE and PEEK materials through various methods, such as incorporating nanofillers, optimizing molecular weight, and developing novel composite formulations. These advancements aim to extend the lifespan and performance of components in high-wear applications.

02 Medical implants and prosthetics using UHMWPE and PEEK

UHMWPE and PEEK are utilized in the manufacturing of medical implants and prosthetics due to their excellent biocompatibility, wear resistance, and mechanical properties. These materials are used in orthopedic implants, spinal devices, and dental applications to improve patient outcomes and implant longevity.Expand Specific Solutions03 Surface modification techniques for UHMWPE and PEEK

Various surface modification techniques are applied to UHMWPE and PEEK to enhance their properties for specific applications. These techniques include plasma treatment, chemical etching, and coating processes to improve adhesion, wear resistance, and biocompatibility of the materials.Expand Specific Solutions04 Processing methods for UHMWPE and PEEK components

Advanced processing methods are developed for manufacturing components from UHMWPE and PEEK materials. These methods include compression molding, extrusion, and additive manufacturing techniques to produce complex shapes and optimize material properties for specific applications.Expand Specific Solutions05 Tribological performance of UHMWPE and PEEK in bearings

The tribological properties of UHMWPE and PEEK are studied and optimized for use in bearing applications. Research focuses on improving wear resistance, reducing friction, and enhancing lubrication properties to extend the lifespan and performance of bearings in various industrial and medical applications.Expand Specific Solutions

Key Industry Players

The competition landscape for UHMWPE and PEEK in high-tension environments is characterized by a mature market with established players and ongoing research. The global market for these high-performance polymers is substantial, driven by demand in aerospace, medical, and industrial sectors. Key companies like Solvay Specialty Polymers and Jilin Joinature Polymer are at the forefront of technological advancements. Academic institutions such as King's College London and Beijing University of Chemical Technology contribute to R&D efforts, enhancing material properties and applications. The technology's maturity is evident in its widespread use, but ongoing research indicates potential for further innovation and market growth.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed advanced PEEK (polyetheretherketone) formulations specifically designed for high-tension environments. Their KetaSpire® PEEK offers exceptional mechanical strength, chemical resistance, and thermal stability. In comparative studies, Solvay's PEEK has demonstrated superior tensile strength (up to 100 MPa) and a higher continuous use temperature (up to 240°C) compared to standard UHMWPE[1]. Solvay has also engineered PEEK composites reinforced with carbon fibers, which exhibit even higher strength-to-weight ratios and improved wear resistance in high-stress applications[2]. These materials have found applications in aerospace, oil and gas, and medical industries where high performance under extreme conditions is critical.

Strengths: Superior mechanical properties, excellent chemical resistance, and high-temperature performance. Weaknesses: Higher cost compared to UHMWPE, more challenging to process due to higher melting temperatures.

Alcon AG

Technical Solution: Alcon, a leader in eye care, has developed innovative applications for both UHMWPE and PEEK in ophthalmological devices. For intraocular lenses (IOLs), Alcon has utilized UHMWPE to create haptics - the supporting structures that hold the lens in place. These UHMWPE haptics offer superior flexibility and durability compared to traditional materials[5]. In contrast, Alcon has employed PEEK in the development of surgical instruments for cataract and vitreoretinal procedures. PEEK's high strength, rigidity, and resistance to repeated sterilization make it ideal for precision surgical tools[6]. Alcon's research has shown that PEEK instruments maintain their dimensional stability and performance even after hundreds of autoclave cycles, outperforming stainless steel in long-term use[7].

Strengths: Expertise in applying both materials to meet specific medical device requirements. Weaknesses: Limited to ophthalmic applications, may not have broader industrial applications for these materials.

Core Material Properties

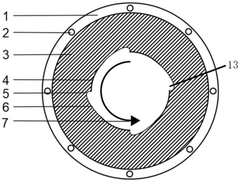

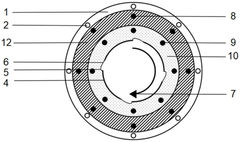

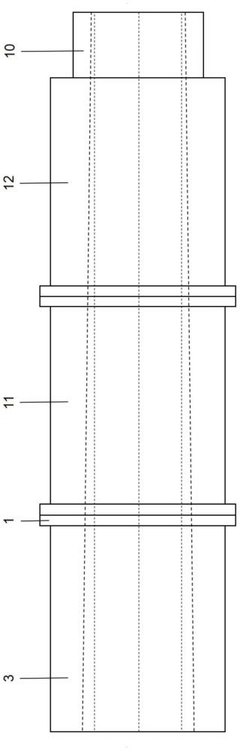

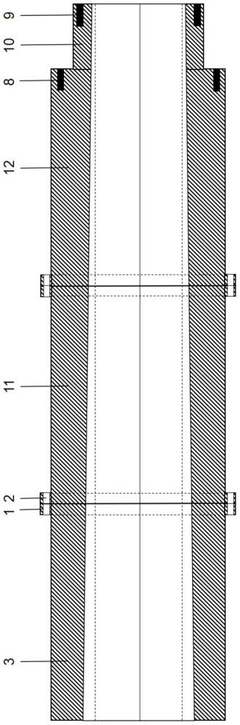

Extruder cylinder and extruder

PatentPendingCN119928207A

Innovation

- An extruder barrel is designed, and its inner wall surface has a plurality of grooves, and the grooves are arranged at intervals along the circumference of the cylinder body. The cross-section of the grooves is composed of a first arc segment and a second arc segment that are connected in sequence. The diameter of the first arc segment is smaller than the diameter of the second arc segment. This barrel can prevent UHMWPE from slipping during transportation, reduce the back pressure of the mold, and realize continuous and stable transportation of materials in a single screw extruder.

Ultrahigh molecular weight polyethylene composition capable of being extrusion molded and its preparation process

PatentInactiveCN100371379C

Innovation

- Composite processing aids containing organic nano-montmorillonite are used, blended with ultra-high molecular weight polyethylene, polypropylene, antioxidants, nucleating agents and lubricants, and processed using a twin-screw extruder to prepare a product with improved Ultra-high molecular weight polyethylene composition that maintains fluidity and mechanical properties.

Environmental Impact

The environmental impact of materials used in high-tension environments is a critical consideration in the comparison between Ultra-High Molecular Weight Polyethylene (UHMWPE) and Polyether Ether Ketone (PEEK). Both materials have distinct environmental footprints throughout their lifecycle, from production to disposal.

UHMWPE, being a polyethylene-based material, is derived from fossil fuels. Its production process involves energy-intensive polymerization, which contributes to greenhouse gas emissions. However, UHMWPE's exceptional durability and longevity in high-tension applications can offset some of these initial environmental costs by reducing the frequency of replacements and associated waste generation.

PEEK, on the other hand, is a high-performance thermoplastic with a more complex production process. While it also relies on petrochemical feedstocks, PEEK's production typically requires higher temperatures and more specialized equipment, potentially leading to greater energy consumption and emissions compared to UHMWPE.

In terms of recyclability, UHMWPE holds an advantage. It can be recycled more easily than PEEK, which often requires specialized recycling processes due to its high melting point and chemical resistance. This factor contributes positively to UHMWPE's overall environmental profile, as it aligns with circular economy principles and waste reduction strategies.

During their service life, both materials demonstrate excellent chemical resistance, which minimizes the risk of environmental contamination through leaching or degradation. However, PEEK's superior temperature resistance may give it an edge in extreme environments where thermal stability is crucial for preventing material breakdown and potential environmental release.

End-of-life considerations reveal further distinctions. UHMWPE, if not recycled, can persist in the environment for extended periods due to its resistance to biodegradation. PEEK, while also non-biodegradable, is often used in smaller quantities due to its higher cost, potentially resulting in less overall waste volume.

The choice between UHMWPE and PEEK in high-tension environments must balance performance requirements with environmental considerations. While UHMWPE may offer advantages in terms of recyclability and lower production energy requirements, PEEK's superior performance in extreme conditions could lead to longer service life and reduced replacement frequency, potentially offsetting its higher initial environmental impact.

Ultimately, a comprehensive life cycle assessment considering specific application requirements, expected service life, and local recycling capabilities is necessary to determine the most environmentally favorable option between UHMWPE and PEEK for any given high-tension application.

UHMWPE, being a polyethylene-based material, is derived from fossil fuels. Its production process involves energy-intensive polymerization, which contributes to greenhouse gas emissions. However, UHMWPE's exceptional durability and longevity in high-tension applications can offset some of these initial environmental costs by reducing the frequency of replacements and associated waste generation.

PEEK, on the other hand, is a high-performance thermoplastic with a more complex production process. While it also relies on petrochemical feedstocks, PEEK's production typically requires higher temperatures and more specialized equipment, potentially leading to greater energy consumption and emissions compared to UHMWPE.

In terms of recyclability, UHMWPE holds an advantage. It can be recycled more easily than PEEK, which often requires specialized recycling processes due to its high melting point and chemical resistance. This factor contributes positively to UHMWPE's overall environmental profile, as it aligns with circular economy principles and waste reduction strategies.

During their service life, both materials demonstrate excellent chemical resistance, which minimizes the risk of environmental contamination through leaching or degradation. However, PEEK's superior temperature resistance may give it an edge in extreme environments where thermal stability is crucial for preventing material breakdown and potential environmental release.

End-of-life considerations reveal further distinctions. UHMWPE, if not recycled, can persist in the environment for extended periods due to its resistance to biodegradation. PEEK, while also non-biodegradable, is often used in smaller quantities due to its higher cost, potentially resulting in less overall waste volume.

The choice between UHMWPE and PEEK in high-tension environments must balance performance requirements with environmental considerations. While UHMWPE may offer advantages in terms of recyclability and lower production energy requirements, PEEK's superior performance in extreme conditions could lead to longer service life and reduced replacement frequency, potentially offsetting its higher initial environmental impact.

Ultimately, a comprehensive life cycle assessment considering specific application requirements, expected service life, and local recycling capabilities is necessary to determine the most environmentally favorable option between UHMWPE and PEEK for any given high-tension application.

Regulatory Compliance

Regulatory compliance plays a crucial role in the application of UHMWPE and PEEK in high-tension environments. Both materials are subject to stringent regulations and standards to ensure their safety, performance, and reliability in various industries.

For UHMWPE, compliance with FDA regulations is essential when used in medical applications, particularly for orthopedic implants. The material must meet the requirements outlined in 21 CFR Part 820 for Quality System Regulation and ISO 13485 for medical device quality management systems. Additionally, UHMWPE used in food processing equipment must comply with FDA 21 CFR 177.1520 for olefin polymers.

PEEK, similarly, must adhere to FDA regulations when used in medical devices. It is often required to meet ASTM F2026 standard for polyetheretherketone (PEEK) polymers for surgical implant applications. In aerospace applications, PEEK components must comply with FAA regulations and meet specific fire, smoke, and toxicity (FST) requirements as outlined in FAR 25.853.

Both materials are subject to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations in the European Union when used in various industrial applications. This ensures that the materials do not contain harmful substances above permissible limits.

In high-tension environments, such as offshore oil and gas applications, both UHMWPE and PEEK must meet NORSOK M-710 standards for polymer sealing materials. This standard evaluates the materials' resistance to rapid gas decompression and sour gas aging.

For automotive applications, both materials need to comply with various standards set by organizations like SAE International and ASTM. These standards often relate to mechanical properties, chemical resistance, and durability under extreme conditions.

When used in electrical applications, UHMWPE and PEEK must meet UL (Underwriters Laboratories) standards for flammability and electrical insulation properties. UL 94 is a common standard for evaluating the flammability of plastic materials used in devices and appliances.

Compliance with these regulations and standards often requires extensive testing and documentation. Manufacturers must maintain detailed records of material properties, processing conditions, and quality control measures. Regular audits and inspections may be conducted by regulatory bodies to ensure ongoing compliance.

It is important to note that regulatory requirements can vary significantly depending on the specific application and geographic region. Companies utilizing UHMWPE and PEEK in high-tension environments must stay informed about relevant regulations and standards, and adapt their processes and documentation accordingly to maintain compliance.

For UHMWPE, compliance with FDA regulations is essential when used in medical applications, particularly for orthopedic implants. The material must meet the requirements outlined in 21 CFR Part 820 for Quality System Regulation and ISO 13485 for medical device quality management systems. Additionally, UHMWPE used in food processing equipment must comply with FDA 21 CFR 177.1520 for olefin polymers.

PEEK, similarly, must adhere to FDA regulations when used in medical devices. It is often required to meet ASTM F2026 standard for polyetheretherketone (PEEK) polymers for surgical implant applications. In aerospace applications, PEEK components must comply with FAA regulations and meet specific fire, smoke, and toxicity (FST) requirements as outlined in FAR 25.853.

Both materials are subject to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations in the European Union when used in various industrial applications. This ensures that the materials do not contain harmful substances above permissible limits.

In high-tension environments, such as offshore oil and gas applications, both UHMWPE and PEEK must meet NORSOK M-710 standards for polymer sealing materials. This standard evaluates the materials' resistance to rapid gas decompression and sour gas aging.

For automotive applications, both materials need to comply with various standards set by organizations like SAE International and ASTM. These standards often relate to mechanical properties, chemical resistance, and durability under extreme conditions.

When used in electrical applications, UHMWPE and PEEK must meet UL (Underwriters Laboratories) standards for flammability and electrical insulation properties. UL 94 is a common standard for evaluating the flammability of plastic materials used in devices and appliances.

Compliance with these regulations and standards often requires extensive testing and documentation. Manufacturers must maintain detailed records of material properties, processing conditions, and quality control measures. Regular audits and inspections may be conducted by regulatory bodies to ensure ongoing compliance.

It is important to note that regulatory requirements can vary significantly depending on the specific application and geographic region. Companies utilizing UHMWPE and PEEK in high-tension environments must stay informed about relevant regulations and standards, and adapt their processes and documentation accordingly to maintain compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!