Nanotechnology Integration in UHMWPE for Improved Wear Resistance

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotech UHMWPE Wear Resistance: Background and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) has been a cornerstone material in various industries, particularly in orthopedic implants, due to its exceptional mechanical properties and biocompatibility. However, the wear resistance of UHMWPE has been a persistent challenge, limiting its longevity and performance in high-stress applications. The integration of nanotechnology into UHMWPE represents a promising frontier in materials science, aiming to address this critical limitation.

The evolution of UHMWPE technology can be traced back to the 1950s when it was first synthesized. Over the decades, various modifications have been attempted to enhance its properties, including cross-linking and the addition of antioxidants. However, these improvements have often come at the cost of other desirable characteristics, creating a need for more innovative solutions.

Nanotechnology, with its ability to manipulate materials at the molecular level, has emerged as a potential game-changer in the quest for improved wear resistance. The integration of nanoparticles into the UHMWPE matrix offers the possibility of enhancing wear resistance without significantly compromising other crucial properties such as mechanical strength and biocompatibility.

The primary objective of incorporating nanotechnology into UHMWPE is to create a composite material that exhibits superior wear resistance while maintaining or improving upon the existing beneficial properties of UHMWPE. This goal aligns with the broader trend in materials science towards multifunctional materials that can meet complex performance requirements in demanding applications.

Recent advancements in nanotechnology have opened up new avenues for achieving this objective. Various types of nanoparticles, including carbon nanotubes, graphene, and ceramic nanoparticles, have shown promise in preliminary studies. These nanoparticles can potentially reinforce the polymer matrix, create a more uniform stress distribution, and provide a barrier against wear mechanisms.

The technological trajectory in this field is moving towards optimizing the integration process, understanding the interactions between nanoparticles and the UHMWPE matrix, and developing scalable manufacturing techniques. Researchers are exploring different nanoparticle types, sizes, and concentrations to find the optimal combination that yields the most significant improvement in wear resistance without compromising other critical properties.

As we look towards the future, the successful integration of nanotechnology in UHMWPE could revolutionize fields such as orthopedic implants, industrial machinery, and aerospace applications. The potential for extended product lifespans, reduced failure rates, and improved performance in high-stress environments makes this an area of significant interest for both academic research and industrial development.

The evolution of UHMWPE technology can be traced back to the 1950s when it was first synthesized. Over the decades, various modifications have been attempted to enhance its properties, including cross-linking and the addition of antioxidants. However, these improvements have often come at the cost of other desirable characteristics, creating a need for more innovative solutions.

Nanotechnology, with its ability to manipulate materials at the molecular level, has emerged as a potential game-changer in the quest for improved wear resistance. The integration of nanoparticles into the UHMWPE matrix offers the possibility of enhancing wear resistance without significantly compromising other crucial properties such as mechanical strength and biocompatibility.

The primary objective of incorporating nanotechnology into UHMWPE is to create a composite material that exhibits superior wear resistance while maintaining or improving upon the existing beneficial properties of UHMWPE. This goal aligns with the broader trend in materials science towards multifunctional materials that can meet complex performance requirements in demanding applications.

Recent advancements in nanotechnology have opened up new avenues for achieving this objective. Various types of nanoparticles, including carbon nanotubes, graphene, and ceramic nanoparticles, have shown promise in preliminary studies. These nanoparticles can potentially reinforce the polymer matrix, create a more uniform stress distribution, and provide a barrier against wear mechanisms.

The technological trajectory in this field is moving towards optimizing the integration process, understanding the interactions between nanoparticles and the UHMWPE matrix, and developing scalable manufacturing techniques. Researchers are exploring different nanoparticle types, sizes, and concentrations to find the optimal combination that yields the most significant improvement in wear resistance without compromising other critical properties.

As we look towards the future, the successful integration of nanotechnology in UHMWPE could revolutionize fields such as orthopedic implants, industrial machinery, and aerospace applications. The potential for extended product lifespans, reduced failure rates, and improved performance in high-stress environments makes this an area of significant interest for both academic research and industrial development.

Market Analysis for Enhanced UHMWPE Applications

The market for enhanced Ultra-High Molecular Weight Polyethylene (UHMWPE) applications is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. UHMWPE, known for its exceptional wear resistance, low friction coefficient, and high impact strength, has found widespread use in orthopedic implants, industrial machinery, and aerospace components.

The integration of nanotechnology into UHMWPE to improve wear resistance has opened up new opportunities in the medical device market. The global orthopedic implants market, a key sector for enhanced UHMWPE applications, is projected to grow steadily over the next decade. This growth is primarily attributed to the rising prevalence of osteoarthritis, increasing geriatric population, and advancements in implant technologies.

In the industrial sector, the demand for wear-resistant materials in machinery and equipment is driving the adoption of nanotechnology-enhanced UHMWPE. Industries such as mining, material handling, and food processing are increasingly recognizing the benefits of improved wear resistance in reducing maintenance costs and extending equipment lifespan.

The aerospace industry represents another promising market for enhanced UHMWPE applications. The material's lightweight properties, combined with improved wear resistance, make it an attractive option for various aircraft components, including bearings, gears, and structural parts. As the aerospace industry continues to focus on fuel efficiency and performance optimization, the demand for advanced materials like nanotechnology-enhanced UHMWPE is expected to grow.

Geographically, North America and Europe currently dominate the market for enhanced UHMWPE applications, owing to their advanced healthcare infrastructure and strong presence of key industry players. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of advanced materials.

The market landscape is characterized by intense competition among key players, including Celanese Corporation, DSM, Braskem, and Mitsui Chemicals. These companies are investing heavily in research and development to enhance their product portfolios and gain a competitive edge in the market.

Despite the positive outlook, challenges such as high production costs and stringent regulatory requirements, particularly in the medical device sector, may hinder market growth. However, ongoing technological advancements and increasing collaborations between material scientists and end-users are expected to overcome these challenges and drive innovation in the field of nanotechnology-enhanced UHMWPE.

The integration of nanotechnology into UHMWPE to improve wear resistance has opened up new opportunities in the medical device market. The global orthopedic implants market, a key sector for enhanced UHMWPE applications, is projected to grow steadily over the next decade. This growth is primarily attributed to the rising prevalence of osteoarthritis, increasing geriatric population, and advancements in implant technologies.

In the industrial sector, the demand for wear-resistant materials in machinery and equipment is driving the adoption of nanotechnology-enhanced UHMWPE. Industries such as mining, material handling, and food processing are increasingly recognizing the benefits of improved wear resistance in reducing maintenance costs and extending equipment lifespan.

The aerospace industry represents another promising market for enhanced UHMWPE applications. The material's lightweight properties, combined with improved wear resistance, make it an attractive option for various aircraft components, including bearings, gears, and structural parts. As the aerospace industry continues to focus on fuel efficiency and performance optimization, the demand for advanced materials like nanotechnology-enhanced UHMWPE is expected to grow.

Geographically, North America and Europe currently dominate the market for enhanced UHMWPE applications, owing to their advanced healthcare infrastructure and strong presence of key industry players. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of advanced materials.

The market landscape is characterized by intense competition among key players, including Celanese Corporation, DSM, Braskem, and Mitsui Chemicals. These companies are investing heavily in research and development to enhance their product portfolios and gain a competitive edge in the market.

Despite the positive outlook, challenges such as high production costs and stringent regulatory requirements, particularly in the medical device sector, may hinder market growth. However, ongoing technological advancements and increasing collaborations between material scientists and end-users are expected to overcome these challenges and drive innovation in the field of nanotechnology-enhanced UHMWPE.

Current Challenges in UHMWPE Nanocomposite Development

The development of UHMWPE nanocomposites faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is achieving uniform dispersion of nanoparticles within the UHMWPE matrix. The high viscosity of UHMWPE and the tendency of nanoparticles to agglomerate make it difficult to attain homogeneous distribution, which is crucial for enhancing wear resistance and mechanical properties.

Another major challenge lies in maintaining the structural integrity of UHMWPE during nanocomposite processing. The high temperatures and shear forces involved in conventional melt-mixing techniques can lead to polymer degradation, compromising the material's long-term performance. This necessitates the development of novel processing methods that can effectively incorporate nanoparticles without damaging the polymer structure.

The interface between nanoparticles and the UHMWPE matrix presents another hurdle. Poor interfacial adhesion can result in nanoparticle detachment during wear, negating the intended reinforcement effects. Improving the compatibility and bonding between nanofillers and UHMWPE is essential for achieving sustained wear resistance improvements.

Scalability and cost-effectiveness of nanocomposite production pose significant challenges for industrial implementation. Current laboratory-scale methods for preparing UHMWPE nanocomposites often involve complex, multi-step processes that are difficult to scale up for mass production. Developing economically viable manufacturing techniques that can maintain nanoparticle dispersion and material properties at larger scales is crucial for commercial viability.

The long-term stability and performance of UHMWPE nanocomposites in real-world applications remain areas of concern. The potential for nanoparticle migration or leaching over time, especially in biomedical applications, raises safety and efficacy questions. Comprehensive long-term studies are needed to assess the durability of wear resistance improvements and potential biological impacts of nanocomposites.

Characterization and quality control of UHMWPE nanocomposites present technical challenges due to the complexity of these materials. Developing standardized testing methods and protocols for assessing nanoparticle dispersion, interfacial properties, and wear performance is essential for consistent product development and regulatory approval, particularly in medical applications.

Addressing these challenges requires interdisciplinary collaboration among materials scientists, polymer engineers, and manufacturing experts. Innovative approaches, such as surface functionalization of nanoparticles, novel processing techniques like supercritical fluid-assisted mixing, and the development of hybrid nanocomposite systems, are being explored to overcome these obstacles and realize the full potential of nanotechnology in enhancing UHMWPE wear resistance.

Another major challenge lies in maintaining the structural integrity of UHMWPE during nanocomposite processing. The high temperatures and shear forces involved in conventional melt-mixing techniques can lead to polymer degradation, compromising the material's long-term performance. This necessitates the development of novel processing methods that can effectively incorporate nanoparticles without damaging the polymer structure.

The interface between nanoparticles and the UHMWPE matrix presents another hurdle. Poor interfacial adhesion can result in nanoparticle detachment during wear, negating the intended reinforcement effects. Improving the compatibility and bonding between nanofillers and UHMWPE is essential for achieving sustained wear resistance improvements.

Scalability and cost-effectiveness of nanocomposite production pose significant challenges for industrial implementation. Current laboratory-scale methods for preparing UHMWPE nanocomposites often involve complex, multi-step processes that are difficult to scale up for mass production. Developing economically viable manufacturing techniques that can maintain nanoparticle dispersion and material properties at larger scales is crucial for commercial viability.

The long-term stability and performance of UHMWPE nanocomposites in real-world applications remain areas of concern. The potential for nanoparticle migration or leaching over time, especially in biomedical applications, raises safety and efficacy questions. Comprehensive long-term studies are needed to assess the durability of wear resistance improvements and potential biological impacts of nanocomposites.

Characterization and quality control of UHMWPE nanocomposites present technical challenges due to the complexity of these materials. Developing standardized testing methods and protocols for assessing nanoparticle dispersion, interfacial properties, and wear performance is essential for consistent product development and regulatory approval, particularly in medical applications.

Addressing these challenges requires interdisciplinary collaboration among materials scientists, polymer engineers, and manufacturing experts. Innovative approaches, such as surface functionalization of nanoparticles, novel processing techniques like supercritical fluid-assisted mixing, and the development of hybrid nanocomposite systems, are being explored to overcome these obstacles and realize the full potential of nanotechnology in enhancing UHMWPE wear resistance.

Existing Nanotech Solutions for UHMWPE Wear Resistance

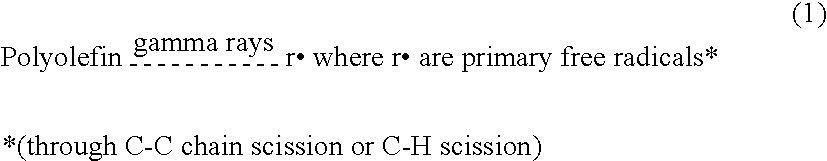

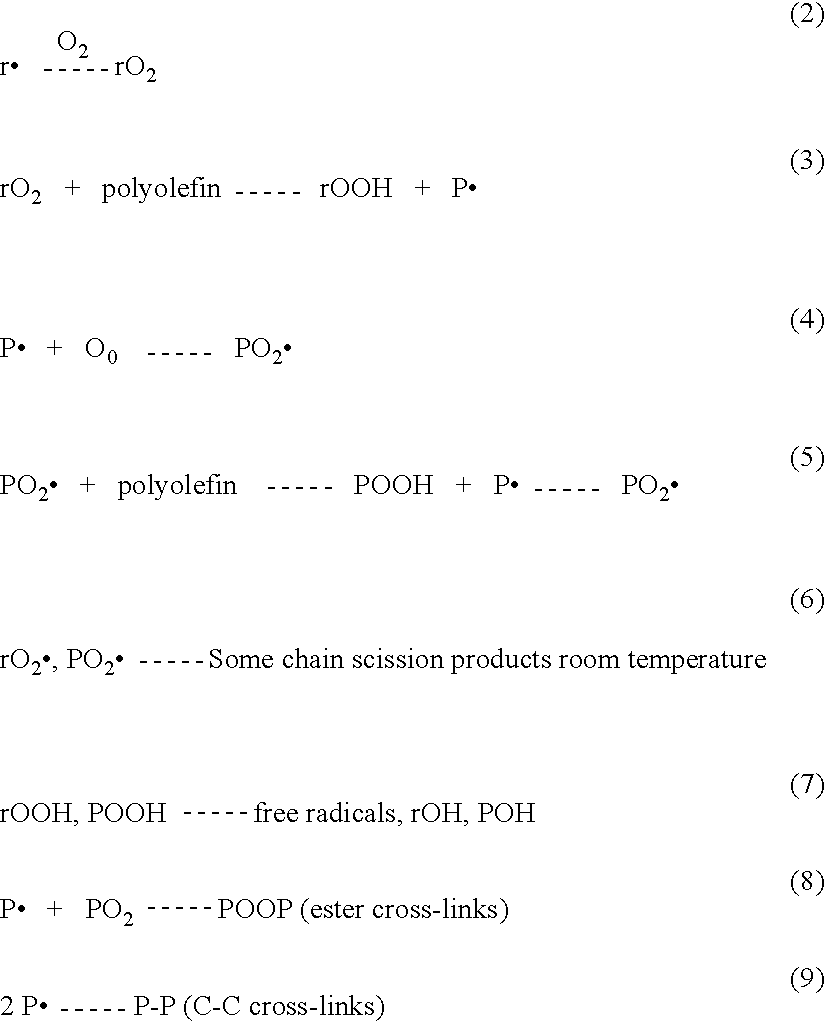

01 Crosslinking and irradiation techniques

Enhancing UHMWPE wear resistance through crosslinking and irradiation methods. These techniques involve exposing the material to radiation or chemical agents to create stronger bonds between polymer chains, resulting in improved mechanical properties and wear resistance.- Crosslinking of UHMWPE: Crosslinking UHMWPE through various methods, such as irradiation or chemical processes, can significantly improve its wear resistance. This process creates stronger bonds between polymer chains, resulting in a more durable material that can withstand higher levels of stress and friction.

- Incorporation of nanoparticles: Adding nanoparticles, such as carbon nanotubes, graphene, or ceramic particles, to UHMWPE can enhance its wear resistance. These nanoparticles can improve the material's mechanical properties and create a more robust composite structure that is less susceptible to wear and tear.

- Surface modification techniques: Applying various surface modification techniques to UHMWPE can improve its wear resistance. These methods may include plasma treatment, ion implantation, or surface coating with wear-resistant materials. Such modifications can create a harder, more durable surface layer that protects the underlying material from wear.

- Blending with other polymers: Blending UHMWPE with other polymers or additives can enhance its wear resistance properties. This approach can create a synergistic effect, combining the beneficial properties of multiple materials to produce a more wear-resistant composite. Careful selection of blend components can optimize the material's performance for specific applications.

- Heat treatment and processing methods: Employing specific heat treatment and processing methods during the manufacturing of UHMWPE products can improve their wear resistance. These techniques may include controlled cooling rates, annealing processes, or compression molding under specific conditions. Optimizing these parameters can result in a more uniform and durable material structure.

02 Incorporation of nanoparticles or fillers

Adding nanoparticles or fillers to UHMWPE to enhance its wear resistance. These additives can include carbon nanotubes, graphene, or ceramic particles, which improve the material's mechanical strength and tribological properties.Expand Specific Solutions03 Surface modification techniques

Applying various surface treatments to UHMWPE to improve its wear resistance. These methods may include plasma treatment, ion implantation, or chemical etching to modify the surface properties and enhance the material's durability.Expand Specific Solutions04 Blending with other polymers or materials

Combining UHMWPE with other polymers or materials to create composites with enhanced wear resistance. This approach can involve blending UHMWPE with elastomers, thermoplastics, or other high-performance polymers to achieve desired properties.Expand Specific Solutions05 Optimization of processing parameters

Improving UHMWPE wear resistance through careful control of processing parameters during manufacturing. This includes optimizing molding conditions, compression techniques, and thermal treatments to enhance the material's microstructure and overall performance.Expand Specific Solutions

Key Players in UHMWPE and Nanocomposite Industry

The integration of nanotechnology in UHMWPE for improved wear resistance is in a growth phase, with increasing market potential due to rising demand for high-performance materials in orthopedic and industrial applications. The global market for nanocomposite UHMWPE is expanding, driven by advancements in medical implants and aerospace industries. Technologically, the field is progressing rapidly, with companies like Howmedica Osteonics Corp., Smith & Nephew Orthopaedics GmbH, and The General Hospital Corp. leading research and development efforts. Academic institutions such as the University of Southern California and Massachusetts Institute of Technology are also contributing significantly to the advancement of this technology, indicating a collaborative ecosystem between industry and academia.

Howmedica Osteonics Corp.

Technical Solution: Howmedica Osteonics, a subsidiary of Stryker Corporation, has developed a proprietary nanotechnology-enhanced UHMWPE called X3™ Advanced Bearing Technology. This technology utilizes a sequential irradiation and annealing process to create highly crosslinked UHMWPE with improved wear resistance [8]. The company has also incorporated antioxidants, such as vitamin E, into their UHMWPE formulations to enhance oxidation resistance and long-term stability. Howmedica's research has shown that their X3™ material can reduce wear by up to 97% compared to conventional polyethylene in hip implants [9]. Additionally, the company has explored the use of ceramic nanoparticles, such as hydroxyapatite and zirconia, to further enhance the mechanical properties and biocompatibility of UHMWPE for orthopedic applications [10].

Strengths: Strong research and development capabilities, extensive clinical experience, and established distribution networks. Weaknesses: Limited focus on non-medical applications of nanotechnology-enhanced UHMWPE.

Smith & Nephew Orthopaedics GmbH

Technical Solution: Smith & Nephew has developed a proprietary nanotechnology-enhanced UHMWPE called OXINIUM™ Oxidized Zirconium. This innovative material combines a ceramic surface with a metal core, providing exceptional wear resistance for orthopedic implants [2]. The company has also introduced a vitamin E-blended highly cross-linked polyethylene (XLPE) called VERILAST™ Technology. This technology incorporates antioxidant properties of vitamin E with nanosized UHMWPE particles, resulting in improved oxidation resistance and mechanical properties [4]. Smith & Nephew's research has shown that VERILAST™ Technology can reduce wear by up to 81% compared to conventional polyethylene in hip implants [6]. The company has also explored the use of carbon nanotubes (CNTs) as reinforcing agents in UHMWPE, demonstrating enhanced mechanical strength and wear resistance in laboratory studies [7].

Strengths: Established market presence, extensive clinical data, and FDA-approved products. Weaknesses: Higher cost compared to traditional materials and potential long-term effects of nanoparticles in the body.

Core Innovations in UHMWPE Nanocomposite Research

Polyethylene cross-linked with an anthocyanin

PatentActiveUS20100036491A1

Innovation

- The use of anthocyanin as an antioxidant to eliminate free radicals during irradiation, combined with a series of low-dose radiation and annealing processes, to create a cross-linked UHMWPE with enhanced oxidation resistance and wear properties, without employing additional chemical stabilizers or antioxidants that could have adverse effects in biomedical applications.

Ultra highmolecular weight polyethylene compositions

PatentInactiveUS20180037726A1

Innovation

- Adding ultrahigh molecular weight silicone to UHMWPE during compounding enables processing by traditional injection molding and extrusion methods, enhancing wear resistance and allowing for the creation of various forms such as fibers, films, and sheets.

Environmental Impact of Nanotech-Enhanced UHMWPE

The integration of nanotechnology in Ultra-High Molecular Weight Polyethylene (UHMWPE) for improved wear resistance brings forth significant environmental considerations. While the enhanced durability of nanotech-enhanced UHMWPE promises extended product lifespans, potentially reducing waste and resource consumption, the environmental impact of its production and end-of-life management requires careful examination.

The manufacturing process of nanotech-enhanced UHMWPE may involve increased energy consumption and the use of specialized materials, potentially leading to a larger carbon footprint compared to traditional UHMWPE production. However, the long-term benefits of improved wear resistance could offset these initial environmental costs by reducing the frequency of replacements and associated manufacturing demands.

Nanoparticle release during the use phase of nanotech-enhanced UHMWPE products is a critical environmental concern. As these materials wear over time, there is a potential for nanoparticles to be released into the environment. The fate and behavior of these nanoparticles in ecosystems are not fully understood, raising questions about their potential impact on aquatic and terrestrial environments.

The end-of-life management of nanotech-enhanced UHMWPE presents both challenges and opportunities. While the material's enhanced durability may extend its useful life, it may also complicate recycling processes. Traditional recycling methods may not be suitable for separating or processing the nanomaterials, potentially leading to increased landfill disposal or the need for specialized recycling technologies.

On the positive side, the improved wear resistance of nanotech-enhanced UHMWPE could contribute to a reduction in microplastic pollution. By minimizing material degradation and particle shedding during use, these advanced materials may help mitigate the release of harmful microplastics into the environment, particularly in applications such as marine equipment or high-wear industrial components.

The potential for bioaccumulation of nanoparticles in the food chain is another environmental consideration. Research is ongoing to determine whether nanoparticles from UHMWPE can enter and accumulate in living organisms, potentially affecting ecosystem health and biodiversity. This aspect underscores the need for comprehensive life cycle assessments and long-term environmental monitoring of nanotech-enhanced materials.

As the adoption of nanotech-enhanced UHMWPE grows, regulatory frameworks and industry standards will need to evolve to address these environmental concerns. Developing guidelines for safe production, use, and disposal of these materials will be crucial in maximizing their benefits while minimizing potential environmental risks.

The manufacturing process of nanotech-enhanced UHMWPE may involve increased energy consumption and the use of specialized materials, potentially leading to a larger carbon footprint compared to traditional UHMWPE production. However, the long-term benefits of improved wear resistance could offset these initial environmental costs by reducing the frequency of replacements and associated manufacturing demands.

Nanoparticle release during the use phase of nanotech-enhanced UHMWPE products is a critical environmental concern. As these materials wear over time, there is a potential for nanoparticles to be released into the environment. The fate and behavior of these nanoparticles in ecosystems are not fully understood, raising questions about their potential impact on aquatic and terrestrial environments.

The end-of-life management of nanotech-enhanced UHMWPE presents both challenges and opportunities. While the material's enhanced durability may extend its useful life, it may also complicate recycling processes. Traditional recycling methods may not be suitable for separating or processing the nanomaterials, potentially leading to increased landfill disposal or the need for specialized recycling technologies.

On the positive side, the improved wear resistance of nanotech-enhanced UHMWPE could contribute to a reduction in microplastic pollution. By minimizing material degradation and particle shedding during use, these advanced materials may help mitigate the release of harmful microplastics into the environment, particularly in applications such as marine equipment or high-wear industrial components.

The potential for bioaccumulation of nanoparticles in the food chain is another environmental consideration. Research is ongoing to determine whether nanoparticles from UHMWPE can enter and accumulate in living organisms, potentially affecting ecosystem health and biodiversity. This aspect underscores the need for comprehensive life cycle assessments and long-term environmental monitoring of nanotech-enhanced materials.

As the adoption of nanotech-enhanced UHMWPE grows, regulatory frameworks and industry standards will need to evolve to address these environmental concerns. Developing guidelines for safe production, use, and disposal of these materials will be crucial in maximizing their benefits while minimizing potential environmental risks.

Scalability and Manufacturing Considerations

The integration of nanotechnology into Ultra-High Molecular Weight Polyethylene (UHMWPE) for improved wear resistance presents significant challenges in terms of scalability and manufacturing considerations. As the demand for enhanced UHMWPE products grows, particularly in medical and industrial applications, the need for efficient and cost-effective production methods becomes paramount.

One of the primary challenges in scaling up nanocomposite UHMWPE production is achieving uniform dispersion of nanoparticles throughout the polymer matrix. Traditional mixing methods often result in agglomeration of nanoparticles, leading to inconsistent material properties. Advanced techniques such as in-situ polymerization and melt compounding have shown promise in addressing this issue, but further optimization is required for large-scale implementation.

The selection of appropriate nanoparticles and their functionalization also play crucial roles in the manufacturing process. Carbon nanotubes, graphene, and ceramic nanoparticles are commonly used, each offering unique benefits and challenges. Ensuring consistent quality and purity of these nanoparticles at industrial scales is essential for maintaining the desired wear-resistant properties of the final product.

Another critical aspect of scalability is the development of continuous production processes. Batch processing, while suitable for small-scale production and research, may not be economically viable for large-scale manufacturing. Continuous extrusion and compression molding techniques are being explored to increase throughput and reduce production costs.

Quality control and characterization of nanocomposite UHMWPE products present additional challenges in a scaled-up manufacturing environment. Advanced analytical techniques, such as X-ray diffraction and electron microscopy, are crucial for ensuring consistent nanoparticle distribution and material properties. However, integrating these methods into high-volume production lines requires significant investment and process optimization.

Environmental and safety considerations also come into play when scaling up nanocomposite UHMWPE production. The handling of nanoparticles at industrial scales necessitates robust safety protocols and specialized equipment to prevent worker exposure and environmental contamination. Additionally, the potential for nanoparticle release during the product lifecycle must be carefully evaluated and mitigated.

As the technology advances, there is a growing focus on developing more sustainable manufacturing processes for nanocomposite UHMWPE. This includes exploring bio-based nanofillers, reducing energy consumption during production, and improving the recyclability of the final products. These efforts aim to address environmental concerns while maintaining the enhanced wear resistance properties of the material.

One of the primary challenges in scaling up nanocomposite UHMWPE production is achieving uniform dispersion of nanoparticles throughout the polymer matrix. Traditional mixing methods often result in agglomeration of nanoparticles, leading to inconsistent material properties. Advanced techniques such as in-situ polymerization and melt compounding have shown promise in addressing this issue, but further optimization is required for large-scale implementation.

The selection of appropriate nanoparticles and their functionalization also play crucial roles in the manufacturing process. Carbon nanotubes, graphene, and ceramic nanoparticles are commonly used, each offering unique benefits and challenges. Ensuring consistent quality and purity of these nanoparticles at industrial scales is essential for maintaining the desired wear-resistant properties of the final product.

Another critical aspect of scalability is the development of continuous production processes. Batch processing, while suitable for small-scale production and research, may not be economically viable for large-scale manufacturing. Continuous extrusion and compression molding techniques are being explored to increase throughput and reduce production costs.

Quality control and characterization of nanocomposite UHMWPE products present additional challenges in a scaled-up manufacturing environment. Advanced analytical techniques, such as X-ray diffraction and electron microscopy, are crucial for ensuring consistent nanoparticle distribution and material properties. However, integrating these methods into high-volume production lines requires significant investment and process optimization.

Environmental and safety considerations also come into play when scaling up nanocomposite UHMWPE production. The handling of nanoparticles at industrial scales necessitates robust safety protocols and specialized equipment to prevent worker exposure and environmental contamination. Additionally, the potential for nanoparticle release during the product lifecycle must be carefully evaluated and mitigated.

As the technology advances, there is a growing focus on developing more sustainable manufacturing processes for nanocomposite UHMWPE. This includes exploring bio-based nanofillers, reducing energy consumption during production, and improving the recyclability of the final products. These efforts aim to address environmental concerns while maintaining the enhanced wear resistance properties of the material.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!