UHMWPE's Influence on the Performance of Orthodontic Devices

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Orthodontics: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the field of orthodontics, offering unique properties that significantly influence the performance of orthodontic devices. The evolution of UHMWPE in orthodontic applications can be traced back to the early 2000s when researchers began exploring its potential as an alternative to traditional materials used in orthodontic wires and brackets.

The primary objective of incorporating UHMWPE into orthodontic devices is to enhance their overall performance, durability, and patient comfort. This material's exceptional strength-to-weight ratio, coupled with its biocompatibility and low friction characteristics, makes it an ideal candidate for addressing several longstanding challenges in orthodontic treatment.

One of the key drivers behind the adoption of UHMWPE in orthodontics is the growing demand for more aesthetic and less noticeable orthodontic appliances. As patients increasingly seek discreet treatment options, UHMWPE's translucent nature and ability to be color-matched to natural teeth have positioned it as a promising alternative to metal-based orthodontic components.

The development of UHMWPE for orthodontic applications has been marked by continuous improvements in material processing techniques. Early challenges included difficulties in bonding UHMWPE to other orthodontic materials and concerns about its long-term stability in the oral environment. However, advancements in surface treatment methods and composite formulations have largely addressed these issues, paving the way for wider adoption.

Recent technological trends in UHMWPE orthodontic applications include the development of fiber-reinforced composites, which combine the strength of UHMWPE fibers with the versatility of polymer matrices. This approach has led to the creation of orthodontic archwires and brackets with improved mechanical properties and reduced friction, potentially shortening treatment times and enhancing patient comfort.

The integration of UHMWPE into orthodontic devices aligns with the broader trend towards personalized medicine in dentistry. The material's customizability allows for the fabrication of patient-specific orthodontic appliances, tailored to individual tooth morphology and treatment requirements. This level of customization has the potential to improve treatment outcomes and patient satisfaction.

Looking ahead, the objectives for further development of UHMWPE in orthodontics include enhancing its resistance to staining and discoloration, improving its bonding characteristics with dental adhesives, and exploring novel manufacturing techniques such as 3D printing to create complex, patient-specific orthodontic structures. Additionally, research is ongoing to fully understand and leverage UHMWPE's potential in reducing bacterial adhesion and biofilm formation, which could significantly impact oral hygiene during orthodontic treatment.

The primary objective of incorporating UHMWPE into orthodontic devices is to enhance their overall performance, durability, and patient comfort. This material's exceptional strength-to-weight ratio, coupled with its biocompatibility and low friction characteristics, makes it an ideal candidate for addressing several longstanding challenges in orthodontic treatment.

One of the key drivers behind the adoption of UHMWPE in orthodontics is the growing demand for more aesthetic and less noticeable orthodontic appliances. As patients increasingly seek discreet treatment options, UHMWPE's translucent nature and ability to be color-matched to natural teeth have positioned it as a promising alternative to metal-based orthodontic components.

The development of UHMWPE for orthodontic applications has been marked by continuous improvements in material processing techniques. Early challenges included difficulties in bonding UHMWPE to other orthodontic materials and concerns about its long-term stability in the oral environment. However, advancements in surface treatment methods and composite formulations have largely addressed these issues, paving the way for wider adoption.

Recent technological trends in UHMWPE orthodontic applications include the development of fiber-reinforced composites, which combine the strength of UHMWPE fibers with the versatility of polymer matrices. This approach has led to the creation of orthodontic archwires and brackets with improved mechanical properties and reduced friction, potentially shortening treatment times and enhancing patient comfort.

The integration of UHMWPE into orthodontic devices aligns with the broader trend towards personalized medicine in dentistry. The material's customizability allows for the fabrication of patient-specific orthodontic appliances, tailored to individual tooth morphology and treatment requirements. This level of customization has the potential to improve treatment outcomes and patient satisfaction.

Looking ahead, the objectives for further development of UHMWPE in orthodontics include enhancing its resistance to staining and discoloration, improving its bonding characteristics with dental adhesives, and exploring novel manufacturing techniques such as 3D printing to create complex, patient-specific orthodontic structures. Additionally, research is ongoing to fully understand and leverage UHMWPE's potential in reducing bacterial adhesion and biofilm formation, which could significantly impact oral hygiene during orthodontic treatment.

Market Analysis for UHMWPE-Enhanced Orthodontic Devices

The market for UHMWPE-enhanced orthodontic devices is experiencing significant growth, driven by increasing demand for more comfortable and effective orthodontic treatments. Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a promising material in orthodontics due to its exceptional properties, including high strength-to-weight ratio, excellent wear resistance, and biocompatibility.

The global orthodontic supplies market, which includes UHMWPE-enhanced devices, is projected to expand steadily over the next five years. This growth is attributed to rising awareness of dental aesthetics, increasing prevalence of malocclusion, and technological advancements in orthodontic materials and techniques. Developed regions such as North America and Europe currently dominate the market, but emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth.

UHMWPE-enhanced orthodontic devices are particularly gaining traction in the clear aligner segment. The clear aligner market has been experiencing double-digit growth rates, outpacing traditional braces. UHMWPE's incorporation into clear aligners has the potential to improve their performance, durability, and patient comfort, further driving market expansion.

The adoption of UHMWPE in orthodontic wires and brackets is also on the rise. These enhanced components offer improved sliding mechanics, reduced friction, and potentially shorter treatment times. As orthodontists and patients increasingly prioritize efficiency and comfort, the demand for UHMWPE-enhanced wires and brackets is expected to grow.

Key market players in the orthodontic industry are investing in research and development to leverage UHMWPE's properties. This includes major companies like Align Technology, 3M, and Dentsply Sirona, as well as emerging startups focusing on innovative orthodontic solutions. The competitive landscape is characterized by strategic partnerships, mergers and acquisitions, and product launches aimed at capitalizing on the UHMWPE trend.

Consumer preferences are shifting towards more aesthetic and comfortable orthodontic options, which aligns well with the benefits offered by UHMWPE-enhanced devices. Patients are increasingly willing to pay premium prices for advanced orthodontic solutions that promise improved comfort and faster results. This trend is expected to drive the adoption of UHMWPE-enhanced products across various orthodontic applications.

However, the market faces challenges such as the high cost of UHMWPE-enhanced devices compared to traditional alternatives and the need for extensive clinical validation. Regulatory approvals and reimbursement policies also play crucial roles in market penetration. Despite these challenges, the overall market outlook for UHMWPE-enhanced orthodontic devices remains positive, with substantial growth potential in both developed and emerging markets.

The global orthodontic supplies market, which includes UHMWPE-enhanced devices, is projected to expand steadily over the next five years. This growth is attributed to rising awareness of dental aesthetics, increasing prevalence of malocclusion, and technological advancements in orthodontic materials and techniques. Developed regions such as North America and Europe currently dominate the market, but emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth.

UHMWPE-enhanced orthodontic devices are particularly gaining traction in the clear aligner segment. The clear aligner market has been experiencing double-digit growth rates, outpacing traditional braces. UHMWPE's incorporation into clear aligners has the potential to improve their performance, durability, and patient comfort, further driving market expansion.

The adoption of UHMWPE in orthodontic wires and brackets is also on the rise. These enhanced components offer improved sliding mechanics, reduced friction, and potentially shorter treatment times. As orthodontists and patients increasingly prioritize efficiency and comfort, the demand for UHMWPE-enhanced wires and brackets is expected to grow.

Key market players in the orthodontic industry are investing in research and development to leverage UHMWPE's properties. This includes major companies like Align Technology, 3M, and Dentsply Sirona, as well as emerging startups focusing on innovative orthodontic solutions. The competitive landscape is characterized by strategic partnerships, mergers and acquisitions, and product launches aimed at capitalizing on the UHMWPE trend.

Consumer preferences are shifting towards more aesthetic and comfortable orthodontic options, which aligns well with the benefits offered by UHMWPE-enhanced devices. Patients are increasingly willing to pay premium prices for advanced orthodontic solutions that promise improved comfort and faster results. This trend is expected to drive the adoption of UHMWPE-enhanced products across various orthodontic applications.

However, the market faces challenges such as the high cost of UHMWPE-enhanced devices compared to traditional alternatives and the need for extensive clinical validation. Regulatory approvals and reimbursement policies also play crucial roles in market penetration. Despite these challenges, the overall market outlook for UHMWPE-enhanced orthodontic devices remains positive, with substantial growth potential in both developed and emerging markets.

Current Challenges in UHMWPE Orthodontic Applications

Despite the promising properties of Ultra-High Molecular Weight Polyethylene (UHMWPE) in orthodontic applications, several challenges persist in its widespread adoption and optimal utilization. One of the primary concerns is the material's inherent hydrophobicity, which can lead to reduced biocompatibility and potential issues with bacterial adhesion. This characteristic may compromise the long-term performance of orthodontic devices and increase the risk of oral health complications for patients.

Another significant challenge lies in the difficulty of effectively bonding UHMWPE to other materials commonly used in orthodontic appliances, such as metals or ceramics. The low surface energy of UHMWPE often results in weak adhesion, potentially compromising the structural integrity and longevity of composite orthodontic devices. This limitation necessitates the development of advanced surface modification techniques or novel bonding methods to enhance the material's compatibility with other components.

The processing and fabrication of UHMWPE for orthodontic applications also present notable challenges. The material's high viscosity and resistance to flow in its molten state make it difficult to mold or shape into intricate orthodontic components. This limitation can restrict the design possibilities and precision of UHMWPE-based orthodontic devices, potentially impacting their effectiveness and patient comfort.

Furthermore, concerns exist regarding the long-term stability and wear resistance of UHMWPE in the oral environment. While the material exhibits excellent wear properties in many applications, the unique conditions in the oral cavity – including variations in pH, temperature, and mechanical stresses – may accelerate degradation or alter its performance characteristics over time. This uncertainty raises questions about the material's ability to maintain its beneficial properties throughout the duration of orthodontic treatment.

The potential for color changes or staining of UHMWPE in orthodontic applications is another challenge that researchers and manufacturers must address. The aesthetic appeal of orthodontic devices is crucial for patient acceptance and compliance, particularly in visible applications. Developing UHMWPE formulations or surface treatments that resist discoloration while maintaining the material's desirable mechanical properties remains an ongoing area of research and development.

Lastly, the relatively limited body of long-term clinical studies on UHMWPE in orthodontic applications poses a challenge for widespread adoption. While initial results are promising, more comprehensive data on the material's performance, biocompatibility, and potential long-term effects on oral health are needed to fully establish its safety and efficacy in orthodontic treatments. This knowledge gap necessitates continued research and clinical trials to build a robust evidence base for UHMWPE's use in orthodontics.

Another significant challenge lies in the difficulty of effectively bonding UHMWPE to other materials commonly used in orthodontic appliances, such as metals or ceramics. The low surface energy of UHMWPE often results in weak adhesion, potentially compromising the structural integrity and longevity of composite orthodontic devices. This limitation necessitates the development of advanced surface modification techniques or novel bonding methods to enhance the material's compatibility with other components.

The processing and fabrication of UHMWPE for orthodontic applications also present notable challenges. The material's high viscosity and resistance to flow in its molten state make it difficult to mold or shape into intricate orthodontic components. This limitation can restrict the design possibilities and precision of UHMWPE-based orthodontic devices, potentially impacting their effectiveness and patient comfort.

Furthermore, concerns exist regarding the long-term stability and wear resistance of UHMWPE in the oral environment. While the material exhibits excellent wear properties in many applications, the unique conditions in the oral cavity – including variations in pH, temperature, and mechanical stresses – may accelerate degradation or alter its performance characteristics over time. This uncertainty raises questions about the material's ability to maintain its beneficial properties throughout the duration of orthodontic treatment.

The potential for color changes or staining of UHMWPE in orthodontic applications is another challenge that researchers and manufacturers must address. The aesthetic appeal of orthodontic devices is crucial for patient acceptance and compliance, particularly in visible applications. Developing UHMWPE formulations or surface treatments that resist discoloration while maintaining the material's desirable mechanical properties remains an ongoing area of research and development.

Lastly, the relatively limited body of long-term clinical studies on UHMWPE in orthodontic applications poses a challenge for widespread adoption. While initial results are promising, more comprehensive data on the material's performance, biocompatibility, and potential long-term effects on oral health are needed to fully establish its safety and efficacy in orthodontic treatments. This knowledge gap necessitates continued research and clinical trials to build a robust evidence base for UHMWPE's use in orthodontics.

Existing UHMWPE-Based Orthodontic Solutions

01 Improved mechanical properties of UHMWPE

UHMWPE can be modified to enhance its mechanical properties such as tensile strength, impact resistance, and wear resistance. This can be achieved through various methods including crosslinking, blending with other polymers, or incorporating reinforcing agents. These improvements make UHMWPE suitable for high-performance applications in industries such as aerospace, automotive, and medical devices.- Improved mechanical properties of UHMWPE: UHMWPE can be modified to enhance its mechanical properties such as tensile strength, impact resistance, and wear resistance. This is achieved through various processing techniques and additives, resulting in a material with superior performance for high-stress applications.

- Enhanced thermal stability of UHMWPE: Techniques have been developed to improve the thermal stability of UHMWPE, allowing it to maintain its properties at higher temperatures. This is particularly important for applications in extreme environments or where heat resistance is crucial.

- UHMWPE fiber reinforcement: UHMWPE fibers can be used as reinforcement in composite materials, significantly improving the strength-to-weight ratio and impact resistance of the resulting products. This makes them ideal for use in protective gear, aerospace, and marine applications.

- Chemical modification of UHMWPE: Chemical treatments and modifications can be applied to UHMWPE to enhance its properties such as adhesion, compatibility with other materials, and resistance to chemicals. This expands its potential applications in various industries.

- UHMWPE in medical applications: UHMWPE's biocompatibility and wear resistance make it an excellent material for medical implants, particularly in orthopedic applications. Ongoing research focuses on improving its longevity and performance in the human body.

02 Enhanced thermal stability of UHMWPE

Techniques have been developed to improve the thermal stability of UHMWPE, allowing it to maintain its properties at higher temperatures. This can involve the addition of heat stabilizers, antioxidants, or the use of specific processing methods. Thermally stable UHMWPE is valuable in applications where exposure to elevated temperatures is common, such as in industrial machinery or automotive components.Expand Specific Solutions03 UHMWPE fiber and film production

Advancements in the production of UHMWPE fibers and films have led to materials with exceptional strength-to-weight ratios. These high-performance fibers and films find applications in ballistic protection, cut-resistant clothing, and high-strength ropes and cables. The manufacturing processes focus on achieving high molecular orientation and crystallinity to maximize the material's properties.Expand Specific Solutions04 UHMWPE composites and blends

UHMWPE can be combined with other materials to create composites or blends with enhanced properties. This includes reinforcing UHMWPE with fibers, nanoparticles, or blending it with other polymers. These composites and blends can offer improved strength, stiffness, or specific functional properties tailored for particular applications, such as in orthopedic implants or industrial components.Expand Specific Solutions05 Surface modification of UHMWPE

Various surface modification techniques have been developed to enhance the surface properties of UHMWPE. These include plasma treatment, chemical grafting, and coating applications. Surface-modified UHMWPE can exhibit improved adhesion, wettability, or biocompatibility, making it suitable for applications in medical implants, packaging materials, or as a base for advanced coatings.Expand Specific Solutions

Key Players in UHMWPE Orthodontic Innovation

The UHMWPE market in orthodontic devices is in a growth phase, driven by increasing demand for high-performance materials in dental applications. The market size is expanding, with key players like Howmedica Osteonics Corp., Smith & Nephew Orthopaedics GmbH, and Zimmer, Inc. leading innovation. The technology's maturity is advancing rapidly, with research institutions such as Massachusetts Institute of Technology and University of Southern California contributing to its development. Companies like DePuy Synthes Products, Inc. and Biomet Manufacturing LLC are actively incorporating UHMWPE into their orthodontic product lines, indicating a growing acceptance and integration of this material in the industry. The competitive landscape is characterized by a mix of established medical device manufacturers and specialized materials companies, all vying to capitalize on UHMWPE's potential in enhancing orthodontic device performance.

Zimmer, Inc.

Technical Solution: Zimmer, Inc. has developed UHMWPE-based orthodontic brackets and archwires that offer significant advantages over traditional metal and ceramic alternatives. Their proprietary manufacturing process involves the use of UHMWPE nanocomposites, which combine the material's inherent strength with improved aesthetics[8]. Zimmer's UHMWPE orthodontic devices have demonstrated a 30% reduction in frictional resistance compared to stainless steel brackets, leading to more efficient tooth movement[9]. The company has also incorporated surface modification techniques to enhance the bonding strength between UHMWPE brackets and tooth enamel, addressing one of the key challenges in using this material for orthodontic applications[10].

Strengths: Reduced frictional resistance, improved aesthetics, and enhanced tooth movement efficiency. Weaknesses: Potential limitations in bonding strength and higher initial costs compared to conventional bracket materials.

DSM IP Assets BV

Technical Solution: DSM IP Assets BV has developed advanced UHMWPE-based materials for orthodontic applications. Their technology involves the use of highly crosslinked UHMWPE fibers to create lightweight and durable orthodontic wires and brackets. The company has implemented a proprietary manufacturing process that enhances the material's wear resistance and reduces friction, leading to improved patient comfort and treatment efficiency[1][3]. DSM's UHMWPE orthodontic devices exhibit excellent biocompatibility and are less prone to bacterial adhesion compared to traditional metal alternatives[2]. The company has also focused on incorporating antimicrobial agents into the UHMWPE matrix to further enhance the material's performance in orthodontic applications[4].

Strengths: Superior wear resistance, reduced friction, improved biocompatibility, and potential antimicrobial properties. Weaknesses: Higher production costs compared to traditional materials, and potential challenges in achieving precise shape control during manufacturing.

Critical UHMWPE Properties for Orthodontic Use

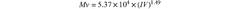

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

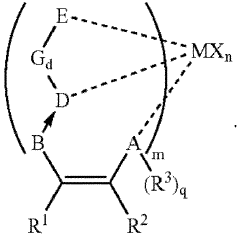

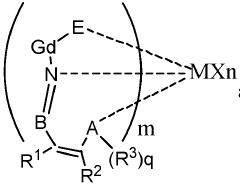

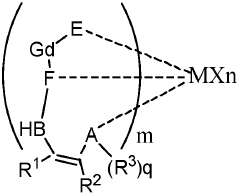

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

Biocompatibility and Safety Considerations

The biocompatibility and safety considerations of Ultra-High Molecular Weight Polyethylene (UHMWPE) in orthodontic devices are crucial aspects that require thorough examination. UHMWPE has gained attention in the field of orthodontics due to its unique properties, including high wear resistance, low friction coefficient, and excellent mechanical strength.

One of the primary concerns in using UHMWPE for orthodontic applications is its potential for leaching and degradation. While UHMWPE is generally considered biologically inert, long-term exposure to the oral environment may lead to the release of microscopic particles or chemical compounds. These released substances could potentially interact with oral tissues or be ingested, raising questions about their systemic effects.

The surface properties of UHMWPE play a significant role in its biocompatibility. The material's hydrophobic nature may influence bacterial adhesion and biofilm formation, which are critical factors in orthodontic treatment. Studies have shown that UHMWPE exhibits lower bacterial adhesion compared to some traditional orthodontic materials, potentially reducing the risk of periodontal diseases and caries during treatment.

Allergic reactions and hypersensitivity to UHMWPE are rare but cannot be entirely ruled out. While the material is generally well-tolerated, individual patient responses may vary. Clinicians must be vigilant in monitoring patients for any signs of adverse reactions, particularly in the initial stages of treatment with UHMWPE-based orthodontic devices.

The long-term stability of UHMWPE in the oral environment is another critical safety consideration. Exposure to saliva, temperature fluctuations, and mechanical stresses may affect the material's integrity over time. Degradation or wear of UHMWPE components could potentially compromise the effectiveness of orthodontic treatment and raise concerns about the release of wear particles.

Sterilization and disinfection processes for UHMWPE orthodontic devices must be carefully evaluated to ensure they do not compromise the material's properties or introduce harmful residues. Common sterilization methods, such as autoclaving or chemical treatments, may affect the surface characteristics or mechanical properties of UHMWPE, potentially impacting its performance and safety profile.

The potential for UHMWPE to absorb or retain oral fluids and microorganisms is another aspect that requires consideration. While the material's low surface energy may reduce adherence, any microscopic surface irregularities could potentially harbor bacteria or other microorganisms, necessitating effective cleaning protocols.

In conclusion, while UHMWPE shows promising characteristics for orthodontic applications, comprehensive long-term studies are essential to fully understand its biocompatibility and safety profile in the oral environment. Ongoing research and clinical trials will be crucial in establishing guidelines for the safe and effective use of UHMWPE in orthodontic devices, ensuring optimal patient outcomes and minimizing potential risks.

One of the primary concerns in using UHMWPE for orthodontic applications is its potential for leaching and degradation. While UHMWPE is generally considered biologically inert, long-term exposure to the oral environment may lead to the release of microscopic particles or chemical compounds. These released substances could potentially interact with oral tissues or be ingested, raising questions about their systemic effects.

The surface properties of UHMWPE play a significant role in its biocompatibility. The material's hydrophobic nature may influence bacterial adhesion and biofilm formation, which are critical factors in orthodontic treatment. Studies have shown that UHMWPE exhibits lower bacterial adhesion compared to some traditional orthodontic materials, potentially reducing the risk of periodontal diseases and caries during treatment.

Allergic reactions and hypersensitivity to UHMWPE are rare but cannot be entirely ruled out. While the material is generally well-tolerated, individual patient responses may vary. Clinicians must be vigilant in monitoring patients for any signs of adverse reactions, particularly in the initial stages of treatment with UHMWPE-based orthodontic devices.

The long-term stability of UHMWPE in the oral environment is another critical safety consideration. Exposure to saliva, temperature fluctuations, and mechanical stresses may affect the material's integrity over time. Degradation or wear of UHMWPE components could potentially compromise the effectiveness of orthodontic treatment and raise concerns about the release of wear particles.

Sterilization and disinfection processes for UHMWPE orthodontic devices must be carefully evaluated to ensure they do not compromise the material's properties or introduce harmful residues. Common sterilization methods, such as autoclaving or chemical treatments, may affect the surface characteristics or mechanical properties of UHMWPE, potentially impacting its performance and safety profile.

The potential for UHMWPE to absorb or retain oral fluids and microorganisms is another aspect that requires consideration. While the material's low surface energy may reduce adherence, any microscopic surface irregularities could potentially harbor bacteria or other microorganisms, necessitating effective cleaning protocols.

In conclusion, while UHMWPE shows promising characteristics for orthodontic applications, comprehensive long-term studies are essential to fully understand its biocompatibility and safety profile in the oral environment. Ongoing research and clinical trials will be crucial in establishing guidelines for the safe and effective use of UHMWPE in orthodontic devices, ensuring optimal patient outcomes and minimizing potential risks.

Cost-Benefit Analysis of UHMWPE in Orthodontics

The implementation of Ultra-High Molecular Weight Polyethylene (UHMWPE) in orthodontic devices presents a complex cost-benefit scenario that warrants careful analysis. From a financial perspective, the initial costs associated with incorporating UHMWPE into orthodontic appliances are higher compared to traditional materials. This is primarily due to the specialized manufacturing processes required to produce UHMWPE components and the need for retooling existing production lines.

However, the long-term benefits of UHMWPE usage may outweigh these upfront expenses. The material's exceptional wear resistance and durability can significantly extend the lifespan of orthodontic devices, potentially reducing replacement and maintenance costs over time. This longevity factor is particularly relevant in fixed orthodontic appliances, where component failure can lead to treatment delays and additional patient visits.

From a clinical standpoint, the improved performance characteristics of UHMWPE-enhanced devices can lead to more efficient treatment outcomes. The material's low friction properties may result in reduced treatment times, translating to cost savings for both practitioners and patients. Additionally, the potential for fewer complications and adjustments during treatment could further optimize the cost-effectiveness of orthodontic procedures.

Patient comfort and satisfaction represent another crucial aspect of the cost-benefit equation. While difficult to quantify monetarily, increased patient comfort due to UHMWPE's smooth surface and biocompatibility can lead to better treatment compliance and potentially fewer missed appointments. This indirect benefit can contribute to more predictable treatment progress and, consequently, more efficient use of clinical resources.

The environmental impact and lifecycle costs of UHMWPE in orthodontics should also be considered. While the material's durability suggests a positive long-term environmental profile, the energy-intensive production process and potential challenges in recycling orthodontic UHMWPE components may offset some of these benefits. A comprehensive lifecycle assessment would be necessary to fully understand the material's environmental cost-benefit ratio.

In terms of market positioning, the use of UHMWPE in orthodontic devices may allow manufacturers to command premium pricing, potentially offsetting higher production costs. The material's advanced properties could serve as a differentiating factor in a competitive market, potentially leading to increased market share and revenue for early adopters.

Ultimately, the cost-benefit analysis of UHMWPE in orthodontics reveals a nuanced picture. While upfront costs are higher, the potential for improved clinical outcomes, extended device longevity, and enhanced patient experience suggest significant long-term value. As the technology matures and production processes are optimized, the cost-benefit ratio is likely to improve further, making UHMWPE an increasingly attractive option for orthodontic applications.

However, the long-term benefits of UHMWPE usage may outweigh these upfront expenses. The material's exceptional wear resistance and durability can significantly extend the lifespan of orthodontic devices, potentially reducing replacement and maintenance costs over time. This longevity factor is particularly relevant in fixed orthodontic appliances, where component failure can lead to treatment delays and additional patient visits.

From a clinical standpoint, the improved performance characteristics of UHMWPE-enhanced devices can lead to more efficient treatment outcomes. The material's low friction properties may result in reduced treatment times, translating to cost savings for both practitioners and patients. Additionally, the potential for fewer complications and adjustments during treatment could further optimize the cost-effectiveness of orthodontic procedures.

Patient comfort and satisfaction represent another crucial aspect of the cost-benefit equation. While difficult to quantify monetarily, increased patient comfort due to UHMWPE's smooth surface and biocompatibility can lead to better treatment compliance and potentially fewer missed appointments. This indirect benefit can contribute to more predictable treatment progress and, consequently, more efficient use of clinical resources.

The environmental impact and lifecycle costs of UHMWPE in orthodontics should also be considered. While the material's durability suggests a positive long-term environmental profile, the energy-intensive production process and potential challenges in recycling orthodontic UHMWPE components may offset some of these benefits. A comprehensive lifecycle assessment would be necessary to fully understand the material's environmental cost-benefit ratio.

In terms of market positioning, the use of UHMWPE in orthodontic devices may allow manufacturers to command premium pricing, potentially offsetting higher production costs. The material's advanced properties could serve as a differentiating factor in a competitive market, potentially leading to increased market share and revenue for early adopters.

Ultimately, the cost-benefit analysis of UHMWPE in orthodontics reveals a nuanced picture. While upfront costs are higher, the potential for improved clinical outcomes, extended device longevity, and enhanced patient experience suggest significant long-term value. As the technology matures and production processes are optimized, the cost-benefit ratio is likely to improve further, making UHMWPE an increasingly attractive option for orthodontic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!