Advancements in UHMWPE Fiber Production Techniques

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Fiber Evolution

Ultra-high molecular weight polyethylene (UHMWPE) fiber has undergone significant evolution since its inception in the 1950s. The journey of UHMWPE fiber production techniques can be traced through several key stages, each marked by technological breakthroughs and process innovations.

In the early stages, UHMWPE fiber production was limited by the challenges of processing high molecular weight polymers. The initial breakthrough came with the development of gel spinning techniques in the 1970s. This method allowed for the alignment of polymer chains, resulting in fibers with superior strength and modulus compared to conventional polyethylene fibers.

The 1980s saw the commercialization of UHMWPE fibers, with companies like DSM introducing products such as Dyneema. This period was characterized by improvements in gel spinning processes, focusing on enhancing fiber properties and increasing production efficiency. Researchers explored various solvents and spinning conditions to optimize fiber performance.

The 1990s and early 2000s marked a period of rapid advancement in UHMWPE fiber technology. Innovations in polymer synthesis led to the development of ultra-high molecular weight grades specifically tailored for fiber production. Concurrently, improvements in spinning and drawing techniques allowed for better control over fiber morphology and properties.

A significant milestone in UHMWPE fiber evolution was the introduction of multi-stage drawing processes. This technique enabled the production of fibers with even higher strength and modulus, pushing the boundaries of material performance. The implementation of advanced thermal treatments and surface modifications further enhanced fiber properties and expanded potential applications.

In recent years, the focus has shifted towards sustainability and cost-effectiveness in UHMWPE fiber production. Research efforts have been directed at developing eco-friendly solvents and reducing energy consumption in the manufacturing process. Additionally, there has been growing interest in exploring novel spinning techniques, such as electrospinning and melt spinning, to produce UHMWPE fibers with unique structures and properties.

The evolution of UHMWPE fiber production techniques has been driven by the continuous demand for stronger, lighter, and more versatile materials. Each advancement has contributed to expanding the application range of UHMWPE fibers, from ballistic protection and high-performance ropes to medical implants and aerospace components. As research continues, the potential for further improvements in UHMWPE fiber technology remains promising, with ongoing efforts to enhance fiber properties, reduce production costs, and develop more sustainable manufacturing processes.

In the early stages, UHMWPE fiber production was limited by the challenges of processing high molecular weight polymers. The initial breakthrough came with the development of gel spinning techniques in the 1970s. This method allowed for the alignment of polymer chains, resulting in fibers with superior strength and modulus compared to conventional polyethylene fibers.

The 1980s saw the commercialization of UHMWPE fibers, with companies like DSM introducing products such as Dyneema. This period was characterized by improvements in gel spinning processes, focusing on enhancing fiber properties and increasing production efficiency. Researchers explored various solvents and spinning conditions to optimize fiber performance.

The 1990s and early 2000s marked a period of rapid advancement in UHMWPE fiber technology. Innovations in polymer synthesis led to the development of ultra-high molecular weight grades specifically tailored for fiber production. Concurrently, improvements in spinning and drawing techniques allowed for better control over fiber morphology and properties.

A significant milestone in UHMWPE fiber evolution was the introduction of multi-stage drawing processes. This technique enabled the production of fibers with even higher strength and modulus, pushing the boundaries of material performance. The implementation of advanced thermal treatments and surface modifications further enhanced fiber properties and expanded potential applications.

In recent years, the focus has shifted towards sustainability and cost-effectiveness in UHMWPE fiber production. Research efforts have been directed at developing eco-friendly solvents and reducing energy consumption in the manufacturing process. Additionally, there has been growing interest in exploring novel spinning techniques, such as electrospinning and melt spinning, to produce UHMWPE fibers with unique structures and properties.

The evolution of UHMWPE fiber production techniques has been driven by the continuous demand for stronger, lighter, and more versatile materials. Each advancement has contributed to expanding the application range of UHMWPE fibers, from ballistic protection and high-performance ropes to medical implants and aerospace components. As research continues, the potential for further improvements in UHMWPE fiber technology remains promising, with ongoing efforts to enhance fiber properties, reduce production costs, and develop more sustainable manufacturing processes.

Market Demand Analysis

The market demand for Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers has been experiencing significant growth, driven by their exceptional properties and diverse applications across various industries. These fibers, known for their high strength-to-weight ratio, excellent chemical resistance, and superior wear resistance, have found increasing use in sectors such as defense, aerospace, marine, and sports equipment manufacturing.

In the defense sector, UHMWPE fibers are extensively used in the production of personal protective equipment, including ballistic vests and helmets. The growing emphasis on soldier safety and the need for lightweight yet highly protective gear have fueled the demand for these fibers. Similarly, in the aerospace industry, the push for lighter aircraft components to improve fuel efficiency has led to increased adoption of UHMWPE fiber-reinforced composites.

The marine industry has also shown a rising interest in UHMWPE fibers, particularly for ropes and cables used in offshore operations. These fibers offer superior strength and durability compared to traditional materials, making them ideal for demanding marine environments. In the sports equipment sector, UHMWPE fibers are increasingly used in the manufacture of high-performance products such as climbing ropes, fishing lines, and sports apparel, owing to their strength and lightweight properties.

The global UHMWPE fiber market has been witnessing steady growth, with projections indicating continued expansion in the coming years. This growth is attributed to the increasing awareness of the material's benefits and the ongoing research and development efforts to enhance its properties and production techniques. The automotive industry is emerging as a potential growth area for UHMWPE fibers, with applications in impact-resistant components and lightweight structural parts.

Despite the positive market outlook, challenges remain in the widespread adoption of UHMWPE fibers. The relatively high production costs compared to conventional materials and the limited processing options due to the fiber's unique properties pose barriers to market expansion. However, ongoing advancements in production techniques aim to address these challenges, potentially opening up new market opportunities.

The geographical distribution of UHMWPE fiber demand shows concentration in regions with strong defense, aerospace, and manufacturing sectors. North America and Europe currently lead in consumption, but rapid growth is expected in Asia-Pacific markets, driven by increasing industrial activities and defense modernization efforts in countries like China and India.

As environmental concerns gain prominence, the recyclability and sustainability aspects of UHMWPE fibers are becoming important factors influencing market demand. Manufacturers are increasingly focusing on developing eco-friendly production processes and exploring recycling options to align with global sustainability trends and regulatory requirements.

In the defense sector, UHMWPE fibers are extensively used in the production of personal protective equipment, including ballistic vests and helmets. The growing emphasis on soldier safety and the need for lightweight yet highly protective gear have fueled the demand for these fibers. Similarly, in the aerospace industry, the push for lighter aircraft components to improve fuel efficiency has led to increased adoption of UHMWPE fiber-reinforced composites.

The marine industry has also shown a rising interest in UHMWPE fibers, particularly for ropes and cables used in offshore operations. These fibers offer superior strength and durability compared to traditional materials, making them ideal for demanding marine environments. In the sports equipment sector, UHMWPE fibers are increasingly used in the manufacture of high-performance products such as climbing ropes, fishing lines, and sports apparel, owing to their strength and lightweight properties.

The global UHMWPE fiber market has been witnessing steady growth, with projections indicating continued expansion in the coming years. This growth is attributed to the increasing awareness of the material's benefits and the ongoing research and development efforts to enhance its properties and production techniques. The automotive industry is emerging as a potential growth area for UHMWPE fibers, with applications in impact-resistant components and lightweight structural parts.

Despite the positive market outlook, challenges remain in the widespread adoption of UHMWPE fibers. The relatively high production costs compared to conventional materials and the limited processing options due to the fiber's unique properties pose barriers to market expansion. However, ongoing advancements in production techniques aim to address these challenges, potentially opening up new market opportunities.

The geographical distribution of UHMWPE fiber demand shows concentration in regions with strong defense, aerospace, and manufacturing sectors. North America and Europe currently lead in consumption, but rapid growth is expected in Asia-Pacific markets, driven by increasing industrial activities and defense modernization efforts in countries like China and India.

As environmental concerns gain prominence, the recyclability and sustainability aspects of UHMWPE fibers are becoming important factors influencing market demand. Manufacturers are increasingly focusing on developing eco-friendly production processes and exploring recycling options to align with global sustainability trends and regulatory requirements.

Technical Challenges

The production of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers faces several significant technical challenges that hinder widespread adoption and limit performance improvements. One of the primary obstacles is the difficulty in achieving consistent molecular orientation during the fiber spinning process. The extremely long polymer chains of UHMWPE tend to entangle, making it challenging to align them properly, which is crucial for optimal fiber strength and stiffness.

Another major challenge lies in the gel-spinning process, a key step in UHMWPE fiber production. Maintaining precise control over temperature, pressure, and drawing ratios throughout this process is critical but technically demanding. Even minor fluctuations can lead to inconsistencies in fiber quality and properties, affecting the overall performance of the final product.

The high viscosity of UHMWPE melts presents additional difficulties in processing. This characteristic makes it challenging to extrude the material through small diameter spinnerets, limiting the fineness of the fibers that can be produced. Overcoming this limitation is essential for expanding the application range of UHMWPE fibers, particularly in areas requiring ultra-fine fibers.

Surface modification of UHMWPE fibers remains a significant technical hurdle. The inert nature of the polymer surface makes it resistant to chemical treatments and adhesion, which can limit its use in composite materials and certain specialized applications. Developing effective and scalable surface treatment methods without compromising the fiber's inherent properties is an ongoing challenge.

The energy-intensive nature of UHMWPE fiber production also poses environmental and economic challenges. The process requires high temperatures and multiple stages, contributing to significant energy consumption and production costs. Improving energy efficiency while maintaining or enhancing fiber quality is a critical area of focus for researchers and manufacturers alike.

Scaling up production while maintaining consistent quality is another major technical challenge. As demand for UHMWPE fibers grows, manufacturers must find ways to increase production volumes without sacrificing the precise control needed at each stage of the process. This scaling issue is particularly pronounced in the transition from laboratory-scale to industrial-scale production.

Lastly, the development of new grades of UHMWPE fibers with enhanced properties, such as improved heat resistance or electrical conductivity, faces significant technical barriers. Incorporating additives or modifying the polymer structure without compromising the fiber's core mechanical properties requires advanced material science and processing techniques, which are still in the early stages of development.

Another major challenge lies in the gel-spinning process, a key step in UHMWPE fiber production. Maintaining precise control over temperature, pressure, and drawing ratios throughout this process is critical but technically demanding. Even minor fluctuations can lead to inconsistencies in fiber quality and properties, affecting the overall performance of the final product.

The high viscosity of UHMWPE melts presents additional difficulties in processing. This characteristic makes it challenging to extrude the material through small diameter spinnerets, limiting the fineness of the fibers that can be produced. Overcoming this limitation is essential for expanding the application range of UHMWPE fibers, particularly in areas requiring ultra-fine fibers.

Surface modification of UHMWPE fibers remains a significant technical hurdle. The inert nature of the polymer surface makes it resistant to chemical treatments and adhesion, which can limit its use in composite materials and certain specialized applications. Developing effective and scalable surface treatment methods without compromising the fiber's inherent properties is an ongoing challenge.

The energy-intensive nature of UHMWPE fiber production also poses environmental and economic challenges. The process requires high temperatures and multiple stages, contributing to significant energy consumption and production costs. Improving energy efficiency while maintaining or enhancing fiber quality is a critical area of focus for researchers and manufacturers alike.

Scaling up production while maintaining consistent quality is another major technical challenge. As demand for UHMWPE fibers grows, manufacturers must find ways to increase production volumes without sacrificing the precise control needed at each stage of the process. This scaling issue is particularly pronounced in the transition from laboratory-scale to industrial-scale production.

Lastly, the development of new grades of UHMWPE fibers with enhanced properties, such as improved heat resistance or electrical conductivity, faces significant technical barriers. Incorporating additives or modifying the polymer structure without compromising the fiber's core mechanical properties requires advanced material science and processing techniques, which are still in the early stages of development.

Current Manufacturing

01 Gel spinning process for UHMWPE fiber production

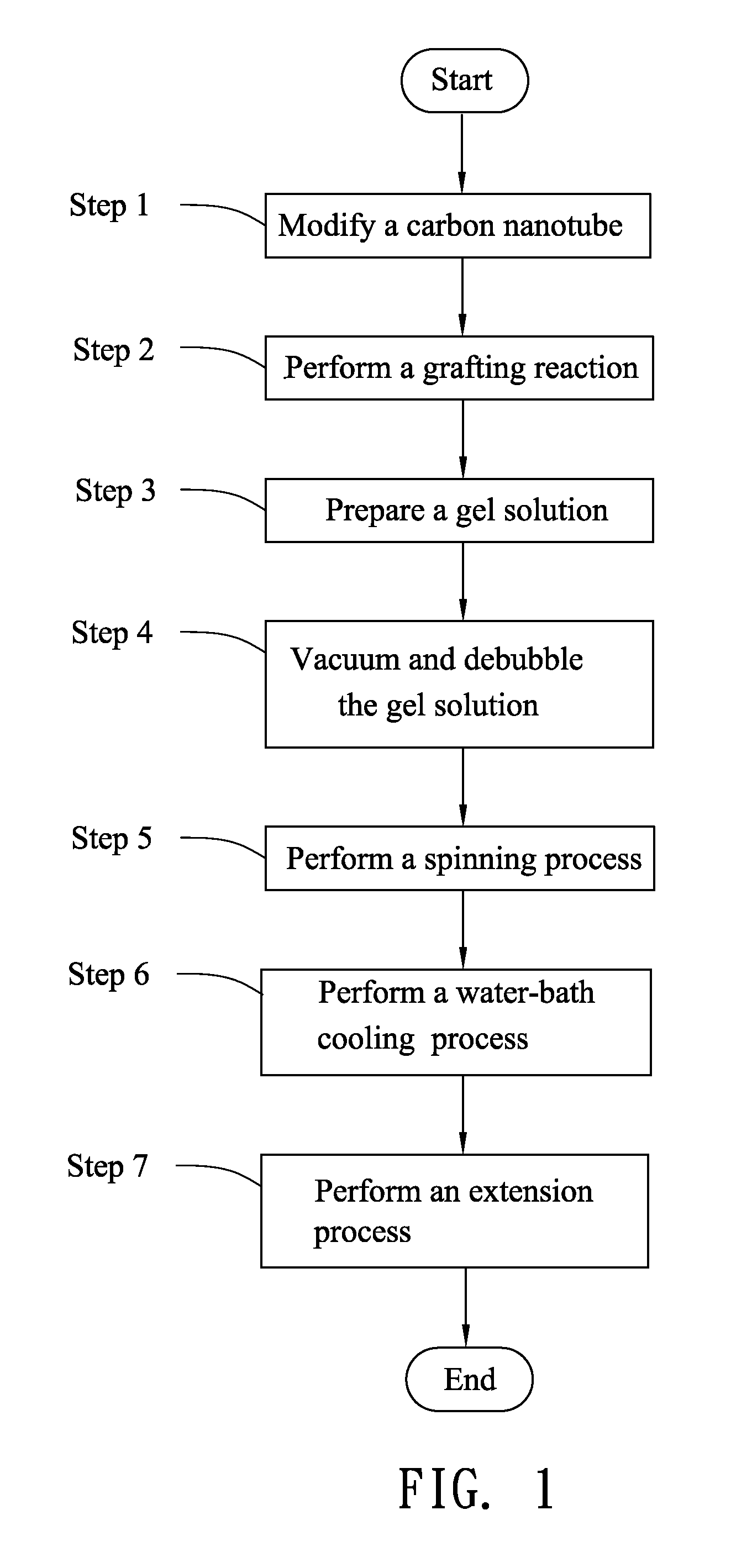

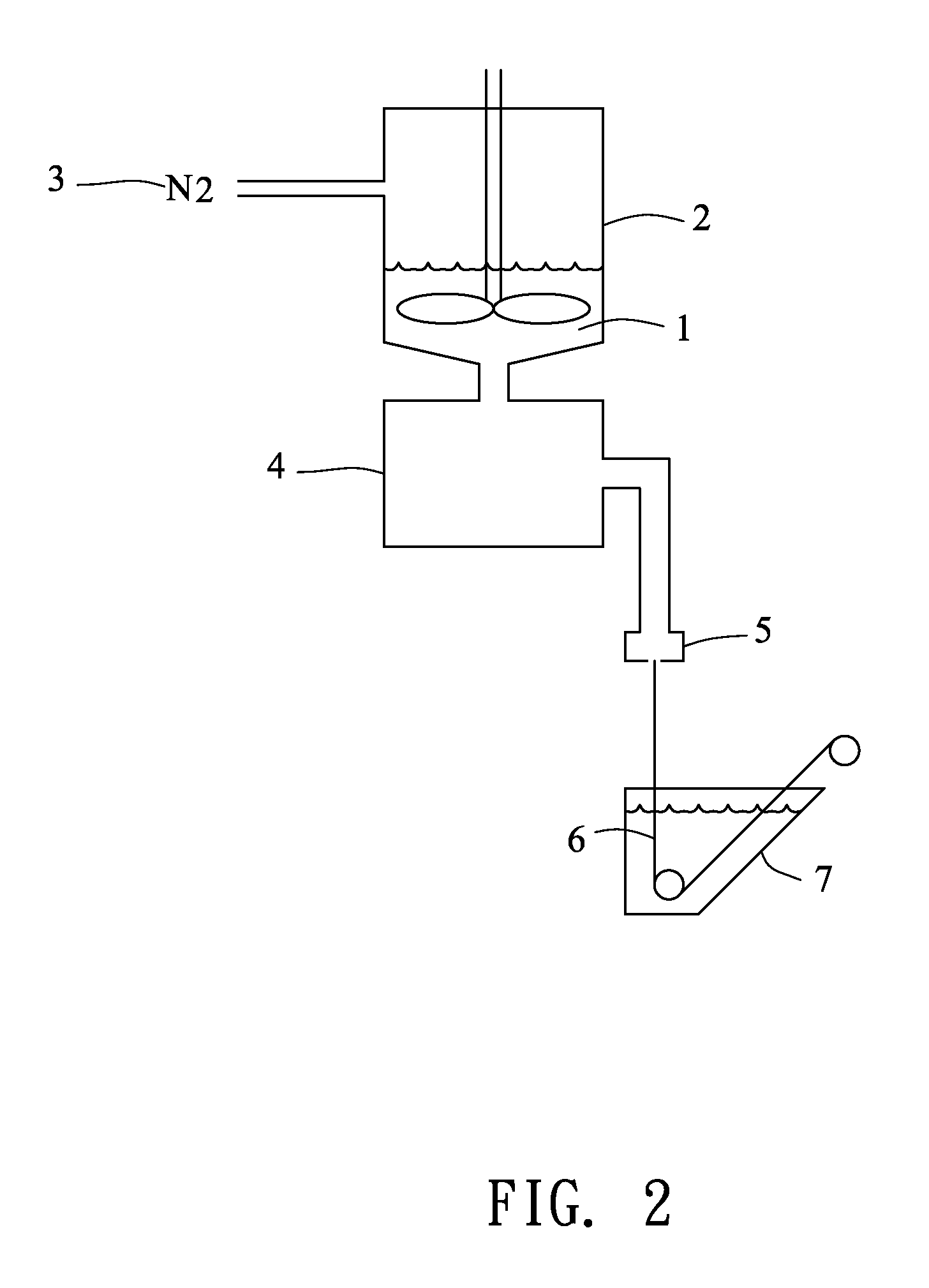

The gel spinning process is a key technique for producing UHMWPE fibers. This method involves dissolving UHMWPE in a solvent at high temperatures, extruding the solution through a spinneret, and then cooling and stretching the resulting gel-like filaments. This process allows for the production of high-strength, high-modulus fibers with excellent properties.- Gel spinning process for UHMWPE fiber production: The gel spinning process is a key technique for producing UHMWPE fibers. This method involves dissolving UHMWPE in a solvent at high temperatures, extruding the solution through a spinneret, and then cooling and stretching the resulting gel-like filaments. This process allows for the production of high-strength, high-modulus fibers with excellent properties.

- Optimization of UHMWPE molecular weight and distribution: Controlling the molecular weight and its distribution is crucial for enhancing the properties of UHMWPE fibers. Techniques involve selecting specific catalyst systems and polymerization conditions to achieve the desired molecular weight range and narrow distribution, which contributes to improved fiber strength and processability.

- Surface modification and coating of UHMWPE fibers: Various surface modification techniques are employed to enhance the properties of UHMWPE fibers. These include plasma treatment, chemical etching, and application of specialized coatings. Such modifications improve the fiber's adhesion to matrices in composites, increase its chemical resistance, and enhance its overall performance in specific applications.

- Multi-stage drawing and heat treatment processes: Advanced drawing and heat treatment techniques are utilized to further improve the mechanical properties of UHMWPE fibers. These processes involve multiple stages of stretching at different temperatures, often combined with precise heat treatments. This results in enhanced molecular orientation, increased crystallinity, and superior tensile strength of the fibers.

- Innovative spinning and post-processing equipment: Development of specialized equipment for UHMWPE fiber production focuses on improving efficiency and fiber quality. This includes advanced spinnerets, precision control systems for gel spinning, and novel post-processing equipment for drawing and heat treatment. These innovations contribute to better fiber uniformity, increased production rates, and enhanced overall fiber performance.

02 Optimization of UHMWPE molecular weight and distribution

Controlling the molecular weight and molecular weight distribution of UHMWPE is crucial for fiber production. Techniques involve selecting appropriate polymerization catalysts and conditions to achieve the desired molecular characteristics. This optimization impacts the fiber's strength, processability, and overall performance.Expand Specific Solutions03 Surface treatment and functionalization of UHMWPE fibers

Various surface treatment techniques are employed to enhance the properties of UHMWPE fibers. These include plasma treatment, chemical etching, and the application of functional coatings. Such treatments improve the fiber's adhesion to matrices, increase its hydrophilicity, and enable better compatibility with other materials in composite applications.Expand Specific Solutions04 Multi-stage drawing and orientation processes

UHMWPE fiber production often involves multi-stage drawing and orientation processes to enhance fiber properties. These techniques include hot drawing, cold drawing, and ultra-drawing steps, which align the polymer chains and increase the fiber's strength and modulus. The precise control of drawing temperatures, ratios, and speeds is critical for achieving optimal fiber performance.Expand Specific Solutions05 Innovative spinning and post-treatment equipment

The development of specialized equipment for UHMWPE fiber production has led to improvements in fiber quality and production efficiency. This includes advanced spinnerets, precision control systems for gel spinning, and novel post-treatment equipment for drawing and annealing. These innovations enable better control over fiber morphology and properties.Expand Specific Solutions

Industry Leaders

The UHMWPE fiber production industry is in a growth phase, driven by increasing demand in various applications such as defense, aerospace, and sports. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with key players like DSM IP Assets BV, DuPont de Nemours, Inc., and China Petroleum & Chemical Corp. leading innovation. These companies, along with emerging players such as Beijing Tongyizhong New Material Technology Corp. and Changshu SUPER Fibers Co., Ltd., are investing heavily in R&D to improve fiber properties and production efficiency. The competitive landscape is characterized by a mix of established multinational corporations and specialized regional manufacturers, each striving to gain market share through technological advancements and product differentiation.

DSM IP Assets BV

Technical Solution: DSM has developed advanced gel spinning techniques for UHMWPE fiber production, focusing on improving molecular orientation and crystallinity. Their process involves dissolving UHMWPE in a solvent at high temperatures, extruding the solution through a spinneret, and then cooling and stretching the fibers to achieve high strength and modulus. DSM's Dyneema® fibers, produced using this method, exhibit exceptional strength-to-weight ratios, with tensile strengths up to 40 cN/dtex and moduli reaching 1500 cN/dtex [1][3]. The company has also implemented continuous polymerization and spinning processes, allowing for better control over molecular weight distribution and fiber properties.

Strengths: High-performance fibers with superior strength-to-weight ratios; Established brand recognition with Dyneema®. Weaknesses: Energy-intensive production process; Reliance on petrochemical-based raw materials.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered advancements in UHMWPE fiber production through its Tyvek® and Kevlar® technologies. For UHMWPE, DuPont employs a multi-stage drawing process that enhances molecular alignment and crystallinity. Their method involves initial gel spinning followed by a series of hot and cold drawing steps, which can increase the draw ratio up to 100:1 [2]. This results in fibers with tensile strengths exceeding 3 GPa and moduli of over 100 GPa. DuPont has also developed surface treatment techniques to improve fiber-matrix adhesion in composites, enhancing the overall performance of UHMWPE-reinforced materials [4].

Strengths: Extensive experience in high-performance fiber production; Diverse application portfolio. Weaknesses: High production costs; Challenges in recycling and end-of-life disposal.

Key Innovations

Method for continuously producing ultra-high molecular weight polyethylene by using slurry polymerization

PatentPendingUS20240092948A1

Innovation

- A continuous process using 2-6 ethylene slurry polymerization reaction tanks connected in series, where polymerization temperatures, pressures, and gas phase compositions are controlled within specific ranges to ensure consistent conditions across tanks, allowing for full catalyst activity and precise control of molecular weight, resulting in ultra-high viscosity-average molecular weight polyethylene with low metal and ash content.

Ultra-High Molecular Weight Polyethylene (UHMWPE)Inorganic Nanocomposite Material and High Performance Fiber Manufacturing Method Thereof

PatentInactiveUS20110082262A1

Innovation

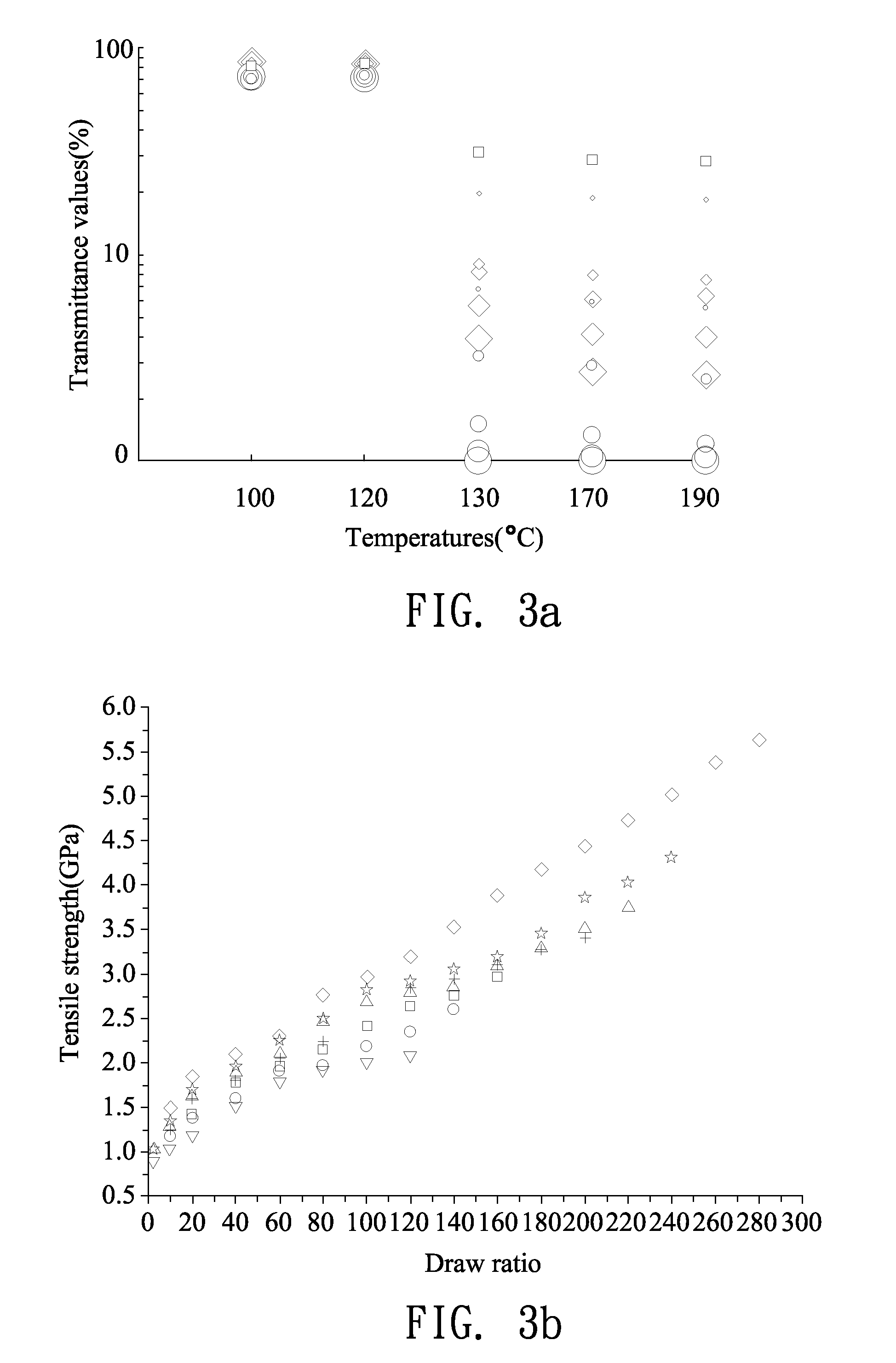

- A novel manufacturing process involving the uniform dispersion of inorganic nano substances like attapulgite, carbon nano-tubes, sepiolite, and wollastonite into UHMWPE gel solutions, followed by specific processing steps including sudden air cooling, water-phase solidification, and multi-stage temperature-changing drawing to produce high-tenacity fibers with reduced crimp, light transmittance, and improved strength.

Environmental Impact

The production of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers has significant environmental implications that warrant careful consideration. These fibers, known for their exceptional strength-to-weight ratio and durability, have found applications in various industries, from aerospace to medical devices. However, their production process raises several environmental concerns.

One of the primary environmental impacts of UHMWPE fiber production is energy consumption. The gel-spinning process, which is the most common method for producing these fibers, requires high temperatures and pressures. This energy-intensive process contributes to increased carbon emissions, particularly if the energy source is not renewable. Manufacturers are increasingly exploring ways to optimize energy efficiency in their production lines to mitigate this impact.

Chemical usage in UHMWPE fiber production also poses environmental challenges. The process involves solvents and other chemicals that, if not properly managed, can lead to air and water pollution. Proper handling, recycling, and disposal of these chemicals are crucial to minimize environmental contamination. Some advanced production techniques are focusing on reducing the use of harmful solvents or replacing them with more environmentally friendly alternatives.

Water consumption is another significant factor in the environmental footprint of UHMWPE fiber production. The process requires substantial amounts of water for cooling and washing. Implementing water recycling systems and improving water efficiency in the production process can help reduce the overall water footprint of these fibers.

The durability of UHMWPE fibers presents a double-edged sword from an environmental perspective. On one hand, their long lifespan reduces the need for frequent replacements, potentially lowering overall resource consumption. On the other hand, their resistance to degradation poses challenges for end-of-life disposal. Developing effective recycling methods for UHMWPE fibers is an area of ongoing research to address this issue.

Advancements in production techniques are increasingly focusing on improving the environmental profile of UHMWPE fibers. This includes exploring bio-based alternatives to traditional petroleum-derived polyethylene, which could significantly reduce the carbon footprint of these fibers. Additionally, research into more efficient production methods that require less energy and fewer resources is ongoing.

The environmental impact of UHMWPE fiber production extends beyond the manufacturing process to the entire lifecycle of the products. As these fibers find applications in lightweight materials for vehicles and aircraft, they contribute to fuel efficiency and reduced emissions during use. However, the challenge lies in balancing these benefits against the environmental costs of production and end-of-life management.

One of the primary environmental impacts of UHMWPE fiber production is energy consumption. The gel-spinning process, which is the most common method for producing these fibers, requires high temperatures and pressures. This energy-intensive process contributes to increased carbon emissions, particularly if the energy source is not renewable. Manufacturers are increasingly exploring ways to optimize energy efficiency in their production lines to mitigate this impact.

Chemical usage in UHMWPE fiber production also poses environmental challenges. The process involves solvents and other chemicals that, if not properly managed, can lead to air and water pollution. Proper handling, recycling, and disposal of these chemicals are crucial to minimize environmental contamination. Some advanced production techniques are focusing on reducing the use of harmful solvents or replacing them with more environmentally friendly alternatives.

Water consumption is another significant factor in the environmental footprint of UHMWPE fiber production. The process requires substantial amounts of water for cooling and washing. Implementing water recycling systems and improving water efficiency in the production process can help reduce the overall water footprint of these fibers.

The durability of UHMWPE fibers presents a double-edged sword from an environmental perspective. On one hand, their long lifespan reduces the need for frequent replacements, potentially lowering overall resource consumption. On the other hand, their resistance to degradation poses challenges for end-of-life disposal. Developing effective recycling methods for UHMWPE fibers is an area of ongoing research to address this issue.

Advancements in production techniques are increasingly focusing on improving the environmental profile of UHMWPE fibers. This includes exploring bio-based alternatives to traditional petroleum-derived polyethylene, which could significantly reduce the carbon footprint of these fibers. Additionally, research into more efficient production methods that require less energy and fewer resources is ongoing.

The environmental impact of UHMWPE fiber production extends beyond the manufacturing process to the entire lifecycle of the products. As these fibers find applications in lightweight materials for vehicles and aircraft, they contribute to fuel efficiency and reduced emissions during use. However, the challenge lies in balancing these benefits against the environmental costs of production and end-of-life management.

Regulatory Framework

The regulatory framework surrounding UHMWPE fiber production is complex and multifaceted, encompassing various aspects of environmental protection, worker safety, and product quality standards. At the international level, organizations such as the International Organization for Standardization (ISO) have established guidelines for the production and testing of high-performance fibers, including UHMWPE.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in regulating workplace safety in UHMWPE fiber production facilities. OSHA standards cover areas such as chemical exposure limits, personal protective equipment requirements, and machinery safety protocols. The Environmental Protection Agency (EPA) oversees environmental compliance, focusing on emissions control and waste management in the production process.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects UHMWPE fiber manufacturers operating in or exporting to EU countries. REACH requires companies to register chemical substances used in production and demonstrate their safe use throughout the supply chain.

Product quality and performance standards for UHMWPE fibers are governed by various industry-specific regulations. For instance, in the medical field, the Food and Drug Administration (FDA) in the United States regulates the use of UHMWPE fibers in medical devices and implants. Similarly, the European Medicines Agency (EMA) oversees such applications in the EU.

As UHMWPE fibers find increasing use in ballistic protection, regulatory bodies such as the National Institute of Justice (NIJ) in the United States have established standards for testing and certifying body armor materials. These standards influence the production techniques and quality control measures employed by manufacturers.

The global nature of UHMWPE fiber production necessitates compliance with trade regulations and import/export controls. Manufacturers must navigate complex international trade agreements and tariff structures, which can impact production decisions and market access.

As advancements in UHMWPE fiber production techniques continue, regulatory frameworks are evolving to address new challenges. Emerging areas of focus include nanomaterial regulations, as some production techniques involve nanostructured materials, and sustainability requirements, driven by increasing emphasis on environmental impact and circular economy principles.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in regulating workplace safety in UHMWPE fiber production facilities. OSHA standards cover areas such as chemical exposure limits, personal protective equipment requirements, and machinery safety protocols. The Environmental Protection Agency (EPA) oversees environmental compliance, focusing on emissions control and waste management in the production process.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects UHMWPE fiber manufacturers operating in or exporting to EU countries. REACH requires companies to register chemical substances used in production and demonstrate their safe use throughout the supply chain.

Product quality and performance standards for UHMWPE fibers are governed by various industry-specific regulations. For instance, in the medical field, the Food and Drug Administration (FDA) in the United States regulates the use of UHMWPE fibers in medical devices and implants. Similarly, the European Medicines Agency (EMA) oversees such applications in the EU.

As UHMWPE fibers find increasing use in ballistic protection, regulatory bodies such as the National Institute of Justice (NIJ) in the United States have established standards for testing and certifying body armor materials. These standards influence the production techniques and quality control measures employed by manufacturers.

The global nature of UHMWPE fiber production necessitates compliance with trade regulations and import/export controls. Manufacturers must navigate complex international trade agreements and tariff structures, which can impact production decisions and market access.

As advancements in UHMWPE fiber production techniques continue, regulatory frameworks are evolving to address new challenges. Emerging areas of focus include nanomaterial regulations, as some production techniques involve nanostructured materials, and sustainability requirements, driven by increasing emphasis on environmental impact and circular economy principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!