The Intersection of UHMWPE and Smart Textile Development

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Smart Textile Evolution and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the textile industry, offering exceptional strength, durability, and versatility. The evolution of UHMWPE in smart textile development represents a significant leap forward in wearable technology and advanced fabric engineering. This intersection has opened up new possibilities for creating intelligent, responsive, and highly functional textiles that can adapt to various environmental conditions and user needs.

The journey of UHMWPE in smart textiles began with its introduction as a high-performance fiber in the late 20th century. Initially valued for its strength-to-weight ratio and resistance to abrasion, UHMWPE quickly found applications in protective gear and high-stress environments. As the concept of smart textiles gained traction in the early 2000s, researchers and engineers recognized the potential of integrating UHMWPE's unique properties with electronic and responsive elements.

The primary objective in the development of UHMWPE smart textiles is to create fabrics that combine the material's inherent strength and durability with advanced functionalities such as sensing, actuation, and data transmission. This fusion aims to produce textiles that can monitor physiological parameters, respond to environmental changes, and even communicate with external devices while maintaining the comfort and wearability expected from traditional fabrics.

One of the key milestones in this evolution has been the successful incorporation of conductive elements into UHMWPE fibers without compromising their mechanical properties. This breakthrough has enabled the creation of smart textiles that can conduct electricity, paving the way for integrated sensors and power distribution within the fabric structure. Researchers have also focused on developing methods to enhance the flexibility of UHMWPE-based smart textiles, addressing the challenge of maintaining softness and drape in high-strength materials.

The ongoing evolution of UHMWPE smart textiles is driven by the pursuit of multifunctionality. Current research objectives include improving the integration of energy harvesting and storage capabilities, enhancing the responsiveness of shape-memory UHMWPE composites, and developing self-healing properties to extend the lifespan of smart garments. Additionally, there is a growing emphasis on sustainability, with efforts directed towards creating recyclable and biodegradable UHMWPE smart textile solutions.

As the field progresses, the convergence of nanotechnology and UHMWPE smart textiles presents exciting possibilities. Researchers are exploring ways to incorporate nanoparticles and nanostructures into UHMWPE fibers to enhance their smart functionalities, such as improved sensing capabilities and more efficient energy management. The ultimate goal is to create a new generation of smart textiles that seamlessly blend the physical robustness of UHMWPE with advanced electronic and responsive features, opening up applications in healthcare, sports performance, military operations, and beyond.

The journey of UHMWPE in smart textiles began with its introduction as a high-performance fiber in the late 20th century. Initially valued for its strength-to-weight ratio and resistance to abrasion, UHMWPE quickly found applications in protective gear and high-stress environments. As the concept of smart textiles gained traction in the early 2000s, researchers and engineers recognized the potential of integrating UHMWPE's unique properties with electronic and responsive elements.

The primary objective in the development of UHMWPE smart textiles is to create fabrics that combine the material's inherent strength and durability with advanced functionalities such as sensing, actuation, and data transmission. This fusion aims to produce textiles that can monitor physiological parameters, respond to environmental changes, and even communicate with external devices while maintaining the comfort and wearability expected from traditional fabrics.

One of the key milestones in this evolution has been the successful incorporation of conductive elements into UHMWPE fibers without compromising their mechanical properties. This breakthrough has enabled the creation of smart textiles that can conduct electricity, paving the way for integrated sensors and power distribution within the fabric structure. Researchers have also focused on developing methods to enhance the flexibility of UHMWPE-based smart textiles, addressing the challenge of maintaining softness and drape in high-strength materials.

The ongoing evolution of UHMWPE smart textiles is driven by the pursuit of multifunctionality. Current research objectives include improving the integration of energy harvesting and storage capabilities, enhancing the responsiveness of shape-memory UHMWPE composites, and developing self-healing properties to extend the lifespan of smart garments. Additionally, there is a growing emphasis on sustainability, with efforts directed towards creating recyclable and biodegradable UHMWPE smart textile solutions.

As the field progresses, the convergence of nanotechnology and UHMWPE smart textiles presents exciting possibilities. Researchers are exploring ways to incorporate nanoparticles and nanostructures into UHMWPE fibers to enhance their smart functionalities, such as improved sensing capabilities and more efficient energy management. The ultimate goal is to create a new generation of smart textiles that seamlessly blend the physical robustness of UHMWPE with advanced electronic and responsive features, opening up applications in healthcare, sports performance, military operations, and beyond.

Market Analysis for UHMWPE Smart Textiles

The market for UHMWPE smart textiles is experiencing significant growth, driven by increasing demand for high-performance materials in various industries. Ultra-high-molecular-weight polyethylene (UHMWPE) fibers, known for their exceptional strength-to-weight ratio and durability, are being integrated with smart textile technologies to create innovative products with enhanced functionalities.

The global smart textile market is projected to expand rapidly, with UHMWPE-based smart textiles playing a crucial role in this growth. Key application areas include military and defense, sports and fitness, healthcare, and industrial safety. In the military sector, UHMWPE smart textiles are being utilized for advanced body armor and protective gear, offering improved ballistic protection while incorporating features such as vital sign monitoring and communication capabilities.

The sports and fitness industry is another major market driver for UHMWPE smart textiles. These materials are being used to develop high-performance sportswear that combines durability with smart functionalities like biometric tracking and temperature regulation. The lightweight nature of UHMWPE fibers makes them particularly attractive for applications where weight reduction is critical, such as in competitive sports equipment.

In the healthcare sector, UHMWPE smart textiles are finding applications in medical garments, wound dressings, and rehabilitation devices. The integration of sensors and conductive elements into UHMWPE fabrics enables real-time patient monitoring and data collection, contributing to improved healthcare outcomes and personalized treatment approaches.

The industrial safety market is also showing strong interest in UHMWPE smart textiles. These materials are being used to develop protective clothing with enhanced cut resistance and embedded sensors for environmental monitoring and worker safety tracking. The durability of UHMWPE fibers makes them ideal for harsh industrial environments where traditional textiles may fail.

Market trends indicate a growing preference for multifunctional smart textiles that can offer a combination of protective properties and intelligent features. This trend aligns well with the capabilities of UHMWPE-based smart textiles, positioning them favorably in the market. Additionally, there is increasing demand for sustainable and eco-friendly materials, which may drive further innovation in UHMWPE production and recycling processes.

The market for UHMWPE smart textiles is characterized by ongoing research and development efforts aimed at improving fiber properties, enhancing integration with electronic components, and expanding application areas. As manufacturing processes become more refined and scalable, the cost of UHMWPE smart textiles is expected to decrease, potentially opening up new market segments and applications.

The global smart textile market is projected to expand rapidly, with UHMWPE-based smart textiles playing a crucial role in this growth. Key application areas include military and defense, sports and fitness, healthcare, and industrial safety. In the military sector, UHMWPE smart textiles are being utilized for advanced body armor and protective gear, offering improved ballistic protection while incorporating features such as vital sign monitoring and communication capabilities.

The sports and fitness industry is another major market driver for UHMWPE smart textiles. These materials are being used to develop high-performance sportswear that combines durability with smart functionalities like biometric tracking and temperature regulation. The lightweight nature of UHMWPE fibers makes them particularly attractive for applications where weight reduction is critical, such as in competitive sports equipment.

In the healthcare sector, UHMWPE smart textiles are finding applications in medical garments, wound dressings, and rehabilitation devices. The integration of sensors and conductive elements into UHMWPE fabrics enables real-time patient monitoring and data collection, contributing to improved healthcare outcomes and personalized treatment approaches.

The industrial safety market is also showing strong interest in UHMWPE smart textiles. These materials are being used to develop protective clothing with enhanced cut resistance and embedded sensors for environmental monitoring and worker safety tracking. The durability of UHMWPE fibers makes them ideal for harsh industrial environments where traditional textiles may fail.

Market trends indicate a growing preference for multifunctional smart textiles that can offer a combination of protective properties and intelligent features. This trend aligns well with the capabilities of UHMWPE-based smart textiles, positioning them favorably in the market. Additionally, there is increasing demand for sustainable and eco-friendly materials, which may drive further innovation in UHMWPE production and recycling processes.

The market for UHMWPE smart textiles is characterized by ongoing research and development efforts aimed at improving fiber properties, enhancing integration with electronic components, and expanding application areas. As manufacturing processes become more refined and scalable, the cost of UHMWPE smart textiles is expected to decrease, potentially opening up new market segments and applications.

Technical Hurdles in UHMWPE Smart Fabric Integration

The integration of Ultra-High Molecular Weight Polyethylene (UHMWPE) into smart textiles presents several significant technical challenges. One of the primary hurdles is maintaining the exceptional strength and durability of UHMWPE while incorporating electronic components and sensors necessary for smart functionality. The high molecular weight and crystalline structure that give UHMWPE its desirable properties also make it difficult to bond with other materials or embed conductive elements.

Another major challenge lies in the thermal management of UHMWPE smart fabrics. UHMWPE has a relatively low melting point compared to other high-performance fibers, which can limit its use in applications where heat generation from electronic components is a concern. Developing effective heat dissipation mechanisms without compromising the fabric's structural integrity is crucial.

The integration of power sources poses yet another significant hurdle. Traditional batteries are often too rigid and bulky for seamless incorporation into UHMWPE fabrics. Researchers are exploring flexible and thin-film batteries, as well as energy harvesting technologies, but these solutions must be compatible with UHMWPE's chemical and physical properties.

Durability and washability of the integrated smart components present additional challenges. UHMWPE's resistance to chemicals and moisture, while beneficial in many applications, complicates the process of protecting electronic elements from damage during use and cleaning. Developing waterproof and chemical-resistant encapsulation methods for sensors and circuitry is essential.

The manufacturing process itself poses technical difficulties. Traditional textile manufacturing methods may not be suitable for producing UHMWPE smart fabrics at scale. New techniques for weaving or knitting UHMWPE fibers with integrated electronic components need to be developed, ensuring uniform distribution of smart functionalities throughout the fabric.

Lastly, the challenge of maintaining flexibility and comfort while incorporating rigid electronic components cannot be overlooked. UHMWPE's natural stiffness, combined with the addition of smart elements, may result in fabrics that are less pliable than desired for certain applications. Innovative approaches to component miniaturization and strategic placement within the fabric structure are necessary to overcome this hurdle.

Another major challenge lies in the thermal management of UHMWPE smart fabrics. UHMWPE has a relatively low melting point compared to other high-performance fibers, which can limit its use in applications where heat generation from electronic components is a concern. Developing effective heat dissipation mechanisms without compromising the fabric's structural integrity is crucial.

The integration of power sources poses yet another significant hurdle. Traditional batteries are often too rigid and bulky for seamless incorporation into UHMWPE fabrics. Researchers are exploring flexible and thin-film batteries, as well as energy harvesting technologies, but these solutions must be compatible with UHMWPE's chemical and physical properties.

Durability and washability of the integrated smart components present additional challenges. UHMWPE's resistance to chemicals and moisture, while beneficial in many applications, complicates the process of protecting electronic elements from damage during use and cleaning. Developing waterproof and chemical-resistant encapsulation methods for sensors and circuitry is essential.

The manufacturing process itself poses technical difficulties. Traditional textile manufacturing methods may not be suitable for producing UHMWPE smart fabrics at scale. New techniques for weaving or knitting UHMWPE fibers with integrated electronic components need to be developed, ensuring uniform distribution of smart functionalities throughout the fabric.

Lastly, the challenge of maintaining flexibility and comfort while incorporating rigid electronic components cannot be overlooked. UHMWPE's natural stiffness, combined with the addition of smart elements, may result in fabrics that are less pliable than desired for certain applications. Innovative approaches to component miniaturization and strategic placement within the fabric structure are necessary to overcome this hurdle.

Current UHMWPE Smart Textile Solutions

01 Synthesis and processing of UHMWPE

Various methods for synthesizing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) are explored. These include polymerization techniques, extrusion processes, and molding methods to produce UHMWPE with desired properties. The focus is on improving the molecular weight, crystallinity, and overall performance of the material.- Composition and manufacturing of UHMWPE: Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene with extremely long molecular chains. The composition and manufacturing processes of UHMWPE are crucial for its unique properties. Various methods are employed to produce UHMWPE with specific characteristics, including different polymerization techniques and the use of additives to enhance its performance.

- UHMWPE fiber production and applications: UHMWPE fibers are known for their high strength-to-weight ratio and excellent chemical resistance. The production of UHMWPE fibers involves specialized processes such as gel spinning. These fibers find applications in various fields, including ballistic protection, marine ropes, and high-performance textiles. Continuous research focuses on improving fiber properties and expanding their use in different industries.

- UHMWPE in medical applications: UHMWPE is widely used in medical applications, particularly in orthopedic implants. Its biocompatibility, low friction coefficient, and wear resistance make it an ideal material for joint replacements and other medical devices. Research in this area focuses on improving the longevity and performance of UHMWPE-based medical implants through various surface treatments and modifications.

- Modification and enhancement of UHMWPE properties: Various techniques are employed to modify and enhance the properties of UHMWPE. These include crosslinking, blending with other polymers, and incorporation of nanoparticles. Such modifications aim to improve the material's mechanical strength, wear resistance, and thermal stability. Research in this area focuses on developing novel methods to tailor UHMWPE properties for specific applications.

- UHMWPE in composite materials: UHMWPE is used as a component in various composite materials to enhance their properties. These composites find applications in aerospace, automotive, and sports equipment industries. Research focuses on optimizing the interface between UHMWPE and other materials in composites, as well as developing new processing techniques to improve the overall performance of UHMWPE-based composites.

02 UHMWPE composites and blends

Development of UHMWPE-based composites and blends to enhance specific properties. This includes incorporating additives, reinforcing materials, or blending with other polymers to improve strength, wear resistance, or other characteristics. The aim is to create materials with superior performance for various applications.Expand Specific Solutions03 Surface modification of UHMWPE

Techniques for modifying the surface of UHMWPE to enhance its properties or compatibility with other materials. This may involve chemical treatments, plasma processing, or coating applications to improve adhesion, wettability, or biocompatibility of UHMWPE surfaces for specific uses.Expand Specific Solutions04 UHMWPE in medical applications

Utilization of UHMWPE in various medical applications, particularly in orthopedic implants and prosthetics. This includes developing specialized grades of UHMWPE with improved wear resistance, oxidation resistance, and biocompatibility for long-term use in the human body.Expand Specific Solutions05 UHMWPE fibers and films

Production and application of UHMWPE in fiber and film forms. This involves specialized processing techniques to create high-strength fibers or thin films with exceptional properties. These materials find use in applications requiring high tensile strength, cut resistance, or barrier properties.Expand Specific Solutions

Key Innovators in UHMWPE Smart Textile Industry

The intersection of UHMWPE and smart textile development represents an emerging field in advanced materials, currently in its early growth stage. The market size is expanding rapidly, driven by increasing demand for high-performance textiles in various industries. While the technology is still evolving, several key players are making significant strides. Companies like DSM IP Assets BV, Honeywell International Technologies Ltd., and Sheertex Inc. are at the forefront, leveraging their expertise in materials science to develop innovative UHMWPE-based smart textiles. Academic institutions such as Donghua University and the University of Southern California are contributing to research and development efforts, pushing the boundaries of what's possible in this field. The technology's maturity is progressing, with applications ranging from protective gear to advanced sportswear, indicating a promising future for this intersection of materials and smart technology.

DSM IP Assets BV

Technical Solution: DSM has developed Dyneema®, an ultra-high molecular weight polyethylene (UHMWPE) fiber, which they are integrating into smart textile applications. Their approach involves combining Dyneema's strength and lightweight properties with electronic components to create smart protective gear. For instance, they have developed impact-sensing fabrics that can detect and measure the force of impacts in sports applications[1]. DSM is also exploring the use of Dyneema in wearable technology for healthcare, incorporating sensors for vital sign monitoring into ultra-strong, comfortable fabrics[3]. Additionally, they are researching the integration of conductive materials with Dyneema to create textiles capable of data transmission and energy harvesting[5].

Strengths: Unparalleled strength-to-weight ratio of Dyneema, expertise in fiber technology. Weaknesses: Potential challenges in maintaining fiber properties when integrating electronic components, higher cost compared to conventional textiles.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell is combining its Spectra® UHMWPE fiber technology with advanced sensing and communication systems to create smart protective equipment. Their focus is on developing intelligent personal protective equipment (PPE) for industrial and defense applications. Honeywell's approach includes integrating temperature and chemical sensors into Spectra-based fabrics to create protective gear that can alert users to environmental hazards[7]. They are also exploring the use of UHMWPE in conjunction with their aerospace sensor technologies to develop smart helmets and body armor capable of monitoring impact forces and vital signs[9]. Additionally, Honeywell is researching the incorporation of their wireless communication technologies into UHMWPE-based textiles to enable real-time data transmission from wearable sensors[11].

Strengths: Extensive experience in both material science and sensing technologies, strong presence in industrial and defense markets. Weaknesses: May face challenges in miniaturizing robust sensing systems for integration into flexible textiles.

Breakthrough Technologies in UHMWPE Smart Fabrics

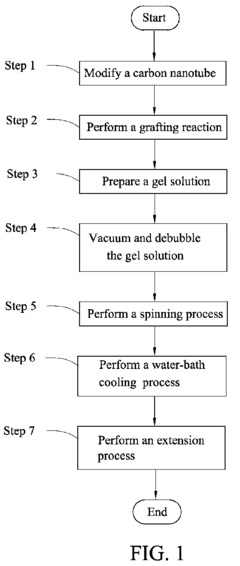

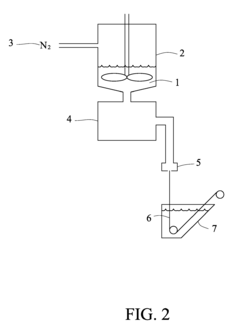

Ultra-high molecular weight polyethylene (uhmwpe)/inorganic nanocomposite material and high performance fiber manufacturing method thereof

PatentInactiveEP2308922A1

Innovation

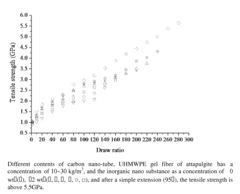

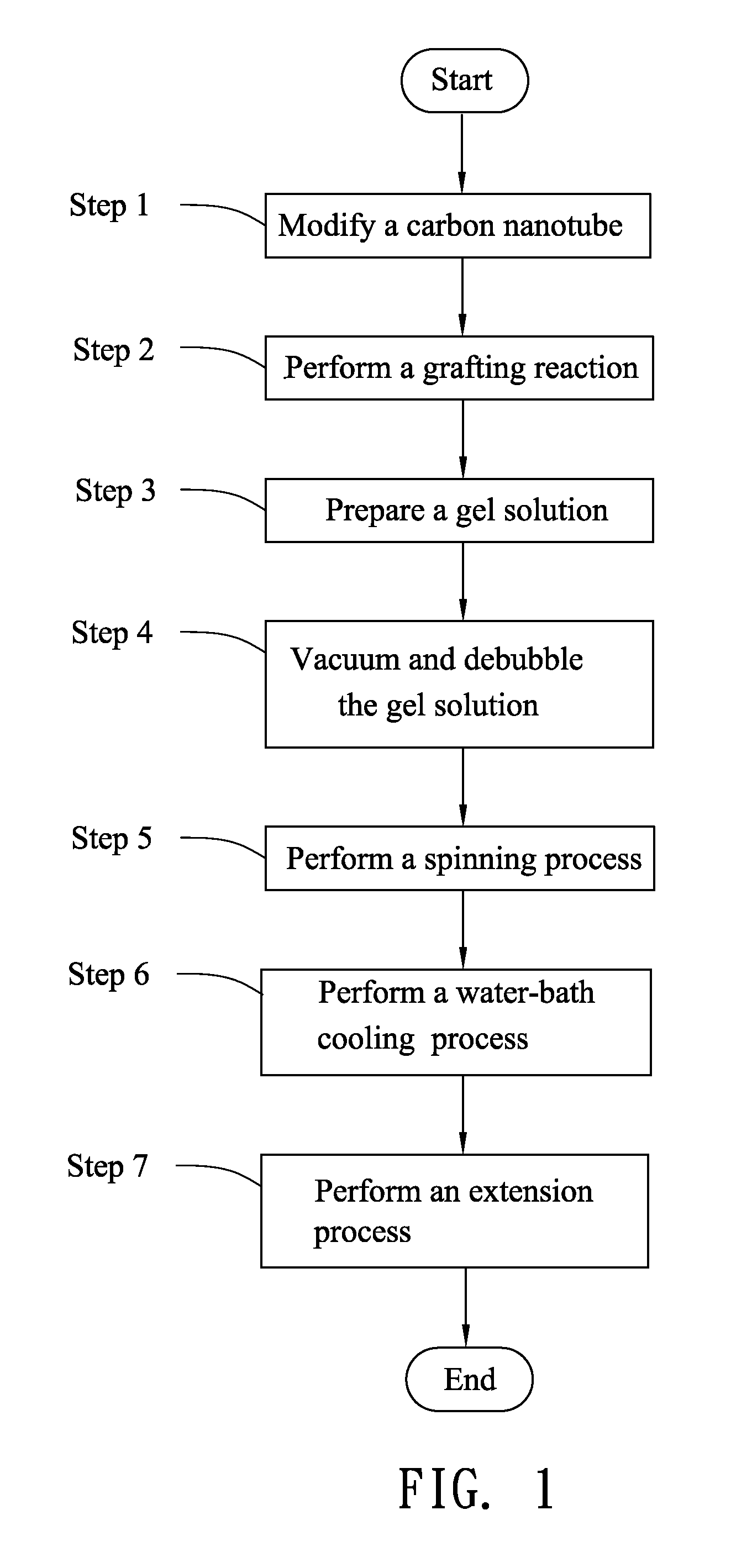

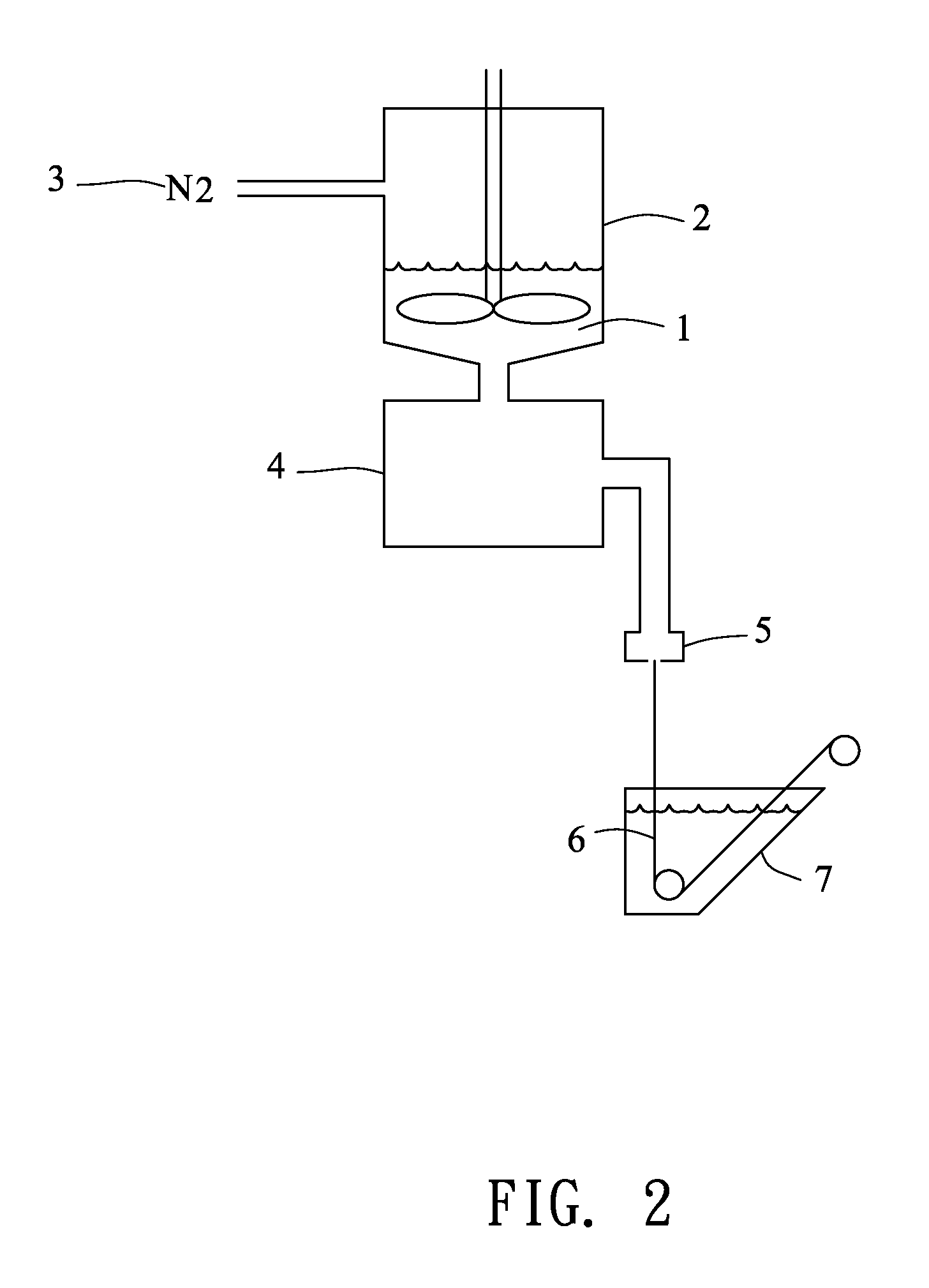

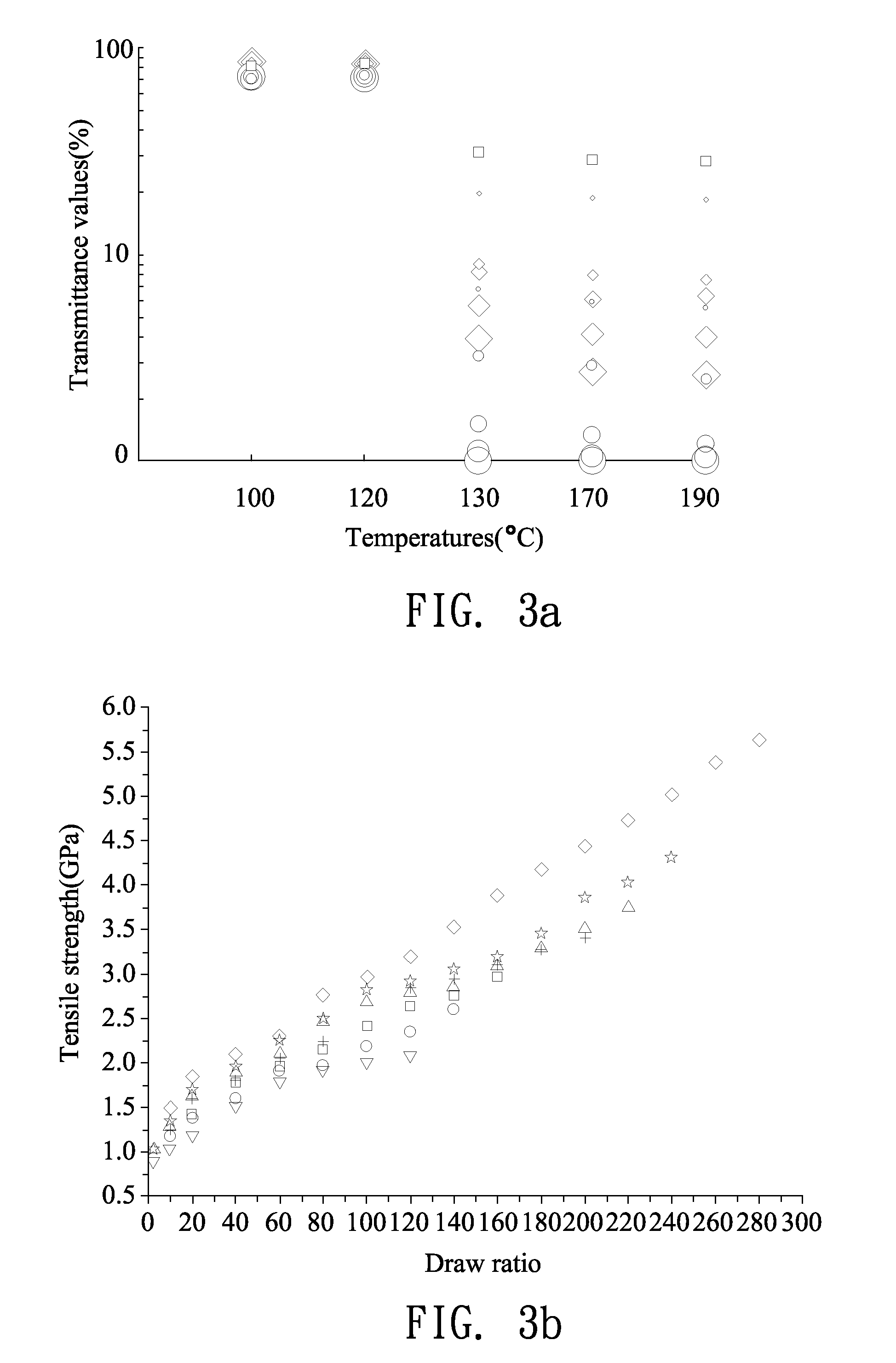

- A manufacturing process involving the uniform dispersion of inorganic nano substances like attapulgite, carbon nanotubes, sepiolite, and wollastonite into UHMWPE gel solutions, followed by specific processing steps including sudden air cooling and multi-stage temperature-changing drawing, to produce high-tenacity fibers with reduced crimp, light transmittance, and creep.

Ultra-High Molecular Weight Polyethylene (UHMWPE)Inorganic Nanocomposite Material and High Performance Fiber Manufacturing Method Thereof

PatentInactiveUS20110082262A1

Innovation

- A novel manufacturing process involving the uniform dispersion of inorganic nano substances like attapulgite, carbon nano-tubes, sepiolite, and wollastonite into UHMWPE gel solutions, followed by specific processing steps including sudden air cooling, water-phase solidification, and multi-stage temperature-changing drawing to produce high-tenacity fibers with reduced crimp, light transmittance, and improved strength.

Sustainability Aspects of UHMWPE Smart Textiles

The sustainability aspects of UHMWPE smart textiles are becoming increasingly important as the industry moves towards more environmentally conscious practices. UHMWPE (Ultra-High Molecular Weight Polyethylene) offers unique properties that contribute to the longevity and durability of smart textiles, potentially reducing the need for frequent replacements and thus minimizing waste.

One of the key sustainability advantages of UHMWPE in smart textiles is its exceptional resistance to wear and tear. This characteristic ensures that products made with UHMWPE fibers have a significantly longer lifespan compared to traditional textiles, reducing the overall environmental impact associated with textile production and disposal. Additionally, the lightweight nature of UHMWPE contributes to reduced energy consumption during transportation and use, further enhancing its sustainability profile.

However, the production of UHMWPE itself presents some environmental challenges. The material is derived from petrochemicals, which are non-renewable resources. This raises concerns about the long-term sustainability of UHMWPE production and its carbon footprint. To address this issue, researchers are exploring bio-based alternatives and more efficient production methods that could reduce the environmental impact of UHMWPE manufacturing.

The recyclability of UHMWPE smart textiles is another critical aspect of their sustainability. While UHMWPE itself is recyclable, the integration of electronic components in smart textiles complicates the recycling process. Developing effective methods for separating and recycling the various components of UHMWPE smart textiles is crucial for improving their end-of-life sustainability.

Energy efficiency in the use phase of UHMWPE smart textiles is an area of ongoing research and development. The incorporation of energy harvesting technologies, such as piezoelectric or thermoelectric elements, could potentially make these textiles self-powered, reducing their reliance on external energy sources and improving their overall sustainability.

Water conservation is another sustainability aspect to consider. UHMWPE fibers have low moisture absorption properties, which can lead to reduced water consumption in washing and maintenance compared to traditional textiles. This characteristic not only conserves water but also extends the lifespan of the smart textile products.

As the development of UHMWPE smart textiles progresses, there is a growing focus on creating closed-loop systems for their production and disposal. This approach aims to minimize waste and maximize resource efficiency throughout the product lifecycle, from raw material extraction to end-of-life management.

One of the key sustainability advantages of UHMWPE in smart textiles is its exceptional resistance to wear and tear. This characteristic ensures that products made with UHMWPE fibers have a significantly longer lifespan compared to traditional textiles, reducing the overall environmental impact associated with textile production and disposal. Additionally, the lightweight nature of UHMWPE contributes to reduced energy consumption during transportation and use, further enhancing its sustainability profile.

However, the production of UHMWPE itself presents some environmental challenges. The material is derived from petrochemicals, which are non-renewable resources. This raises concerns about the long-term sustainability of UHMWPE production and its carbon footprint. To address this issue, researchers are exploring bio-based alternatives and more efficient production methods that could reduce the environmental impact of UHMWPE manufacturing.

The recyclability of UHMWPE smart textiles is another critical aspect of their sustainability. While UHMWPE itself is recyclable, the integration of electronic components in smart textiles complicates the recycling process. Developing effective methods for separating and recycling the various components of UHMWPE smart textiles is crucial for improving their end-of-life sustainability.

Energy efficiency in the use phase of UHMWPE smart textiles is an area of ongoing research and development. The incorporation of energy harvesting technologies, such as piezoelectric or thermoelectric elements, could potentially make these textiles self-powered, reducing their reliance on external energy sources and improving their overall sustainability.

Water conservation is another sustainability aspect to consider. UHMWPE fibers have low moisture absorption properties, which can lead to reduced water consumption in washing and maintenance compared to traditional textiles. This characteristic not only conserves water but also extends the lifespan of the smart textile products.

As the development of UHMWPE smart textiles progresses, there is a growing focus on creating closed-loop systems for their production and disposal. This approach aims to minimize waste and maximize resource efficiency throughout the product lifecycle, from raw material extraction to end-of-life management.

Standardization Challenges for UHMWPE Smart Textiles

The standardization of UHMWPE smart textiles presents a complex challenge due to the unique properties of ultra-high molecular weight polyethylene (UHMWPE) and the rapidly evolving field of smart textiles. As these two technologies converge, the need for comprehensive and adaptable standards becomes increasingly apparent.

One of the primary challenges in standardization is the diverse range of UHMWPE fiber properties and their integration with smart textile components. UHMWPE fibers can vary significantly in terms of molecular weight, crystallinity, and mechanical properties, which directly impact their performance in smart textile applications. Establishing standardized testing methods to accurately measure and compare these properties across different manufacturers and production batches is crucial.

The integration of electronic components and sensors into UHMWPE fabrics introduces additional complexities. Current standards for electronic textiles may not adequately address the unique characteristics of UHMWPE, such as its high strength-to-weight ratio and chemical resistance. Developing new standards or adapting existing ones to account for these properties is essential for ensuring consistent performance and reliability in UHMWPE smart textiles.

Durability and longevity testing pose another significant challenge. UHMWPE's exceptional wear resistance and chemical stability may require the development of new accelerated aging protocols and long-term performance evaluation methods. These standards must consider the interaction between the UHMWPE fibers and the embedded smart components over extended periods and under various environmental conditions.

The multifunctional nature of UHMWPE smart textiles also complicates standardization efforts. These textiles may simultaneously serve as structural reinforcements, protective gear, and data collection platforms. Developing standards that address this multifunctionality while ensuring interoperability with existing systems and technologies is a complex task that requires collaboration across multiple industries and regulatory bodies.

Safety standards for UHMWPE smart textiles present another critical area for development. This includes electrical safety considerations for powered components, as well as standards for flame resistance and toxicity, particularly in applications where the textiles may be exposed to extreme conditions or come into direct contact with the user's skin.

Lastly, the rapid pace of innovation in both UHMWPE fiber technology and smart textile development necessitates a flexible and adaptable approach to standardization. Standards must be designed to accommodate future advancements while providing a stable framework for current technologies. This balance between specificity and adaptability is crucial for fostering innovation while ensuring product quality and safety.

One of the primary challenges in standardization is the diverse range of UHMWPE fiber properties and their integration with smart textile components. UHMWPE fibers can vary significantly in terms of molecular weight, crystallinity, and mechanical properties, which directly impact their performance in smart textile applications. Establishing standardized testing methods to accurately measure and compare these properties across different manufacturers and production batches is crucial.

The integration of electronic components and sensors into UHMWPE fabrics introduces additional complexities. Current standards for electronic textiles may not adequately address the unique characteristics of UHMWPE, such as its high strength-to-weight ratio and chemical resistance. Developing new standards or adapting existing ones to account for these properties is essential for ensuring consistent performance and reliability in UHMWPE smart textiles.

Durability and longevity testing pose another significant challenge. UHMWPE's exceptional wear resistance and chemical stability may require the development of new accelerated aging protocols and long-term performance evaluation methods. These standards must consider the interaction between the UHMWPE fibers and the embedded smart components over extended periods and under various environmental conditions.

The multifunctional nature of UHMWPE smart textiles also complicates standardization efforts. These textiles may simultaneously serve as structural reinforcements, protective gear, and data collection platforms. Developing standards that address this multifunctionality while ensuring interoperability with existing systems and technologies is a complex task that requires collaboration across multiple industries and regulatory bodies.

Safety standards for UHMWPE smart textiles present another critical area for development. This includes electrical safety considerations for powered components, as well as standards for flame resistance and toxicity, particularly in applications where the textiles may be exposed to extreme conditions or come into direct contact with the user's skin.

Lastly, the rapid pace of innovation in both UHMWPE fiber technology and smart textile development necessitates a flexible and adaptable approach to standardization. Standards must be designed to accommodate future advancements while providing a stable framework for current technologies. This balance between specificity and adaptability is crucial for fostering innovation while ensuring product quality and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!