Acoustic Performance of UHMWPE-Filled Building Materials

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Acoustics Background

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a promising material in the field of acoustics, particularly in building applications. This high-performance polymer, known for its exceptional mechanical properties, has recently gained attention for its potential to enhance the acoustic performance of construction materials.

The acoustic properties of UHMWPE stem from its unique molecular structure. With extremely long chains of polyethylene molecules, UHMWPE exhibits a high degree of crystallinity and entanglement, resulting in a material with excellent sound absorption and damping characteristics. These properties make it an attractive option for addressing noise pollution concerns in urban environments and improving the overall acoustic comfort of buildings.

Historically, the use of UHMWPE in acoustics has been limited due to its high cost and processing challenges. However, recent advancements in manufacturing techniques and a growing emphasis on sustainable building practices have led to increased interest in UHMWPE-filled building materials. The polymer's durability and resistance to environmental factors also contribute to its appeal in long-term acoustic solutions.

Research into UHMWPE's acoustic performance has focused on several key areas. Studies have explored its effectiveness in reducing airborne sound transmission, impact noise reduction, and vibration damping. The material's ability to absorb sound energy across a wide frequency range has been of particular interest, as it addresses a common limitation of traditional acoustic materials.

The integration of UHMWPE into building materials takes various forms. It can be used as a filler in composite materials, incorporated into acoustic panels, or utilized in the production of specialized acoustic foams. Each application leverages the polymer's unique properties to enhance sound insulation and absorption in different building elements, from walls and floors to ceilings and facades.

As environmental concerns continue to shape the construction industry, UHMWPE's potential for recycling and its long lifespan align well with sustainable building practices. This aspect, combined with its acoustic benefits, positions UHMWPE-filled building materials as a promising solution for future architectural designs that prioritize both acoustic performance and environmental responsibility.

The ongoing research and development in this field aim to optimize the acoustic properties of UHMWPE-filled materials, reduce production costs, and expand their applications in the built environment. As urbanization accelerates and noise pollution becomes an increasingly pressing issue, the role of advanced materials like UHMWPE in creating quieter, more comfortable living and working spaces is likely to grow in significance.

The acoustic properties of UHMWPE stem from its unique molecular structure. With extremely long chains of polyethylene molecules, UHMWPE exhibits a high degree of crystallinity and entanglement, resulting in a material with excellent sound absorption and damping characteristics. These properties make it an attractive option for addressing noise pollution concerns in urban environments and improving the overall acoustic comfort of buildings.

Historically, the use of UHMWPE in acoustics has been limited due to its high cost and processing challenges. However, recent advancements in manufacturing techniques and a growing emphasis on sustainable building practices have led to increased interest in UHMWPE-filled building materials. The polymer's durability and resistance to environmental factors also contribute to its appeal in long-term acoustic solutions.

Research into UHMWPE's acoustic performance has focused on several key areas. Studies have explored its effectiveness in reducing airborne sound transmission, impact noise reduction, and vibration damping. The material's ability to absorb sound energy across a wide frequency range has been of particular interest, as it addresses a common limitation of traditional acoustic materials.

The integration of UHMWPE into building materials takes various forms. It can be used as a filler in composite materials, incorporated into acoustic panels, or utilized in the production of specialized acoustic foams. Each application leverages the polymer's unique properties to enhance sound insulation and absorption in different building elements, from walls and floors to ceilings and facades.

As environmental concerns continue to shape the construction industry, UHMWPE's potential for recycling and its long lifespan align well with sustainable building practices. This aspect, combined with its acoustic benefits, positions UHMWPE-filled building materials as a promising solution for future architectural designs that prioritize both acoustic performance and environmental responsibility.

The ongoing research and development in this field aim to optimize the acoustic properties of UHMWPE-filled materials, reduce production costs, and expand their applications in the built environment. As urbanization accelerates and noise pollution becomes an increasingly pressing issue, the role of advanced materials like UHMWPE in creating quieter, more comfortable living and working spaces is likely to grow in significance.

Market Demand Analysis

The market demand for UHMWPE-filled building materials with enhanced acoustic performance has been steadily growing in recent years. This trend is driven by increasing urbanization, stricter building regulations, and a growing awareness of the importance of sound insulation in both residential and commercial spaces.

In the construction industry, there is a rising need for lightweight yet effective sound-absorbing materials. UHMWPE-filled composites offer a promising solution, combining the strength and durability of ultra-high-molecular-weight polyethylene with improved acoustic properties. This combination addresses the dual requirements of structural integrity and noise reduction, making it particularly attractive for modern building designs.

The residential sector represents a significant portion of the market demand. As urban populations grow and living spaces become more compact, the need for effective soundproofing between apartments and from external noise sources has become crucial. Homeowners and property developers are increasingly willing to invest in advanced acoustic solutions to improve quality of life and property values.

In the commercial sector, the demand is driven by the need for better acoustic environments in offices, schools, hospitals, and public spaces. The focus on employee well-being and productivity has led to a greater emphasis on creating quiet, comfortable work environments. UHMWPE-filled materials offer an opportunity to achieve this without compromising on space or aesthetics.

The automotive and transportation industries also contribute to the market demand, seeking lightweight materials with good acoustic properties for vehicle interiors. This cross-industry application further expands the potential market for UHMWPE-filled acoustic materials.

Geographically, the demand is particularly strong in developed regions with stringent building codes and noise regulations, such as Europe and North America. However, rapidly developing urban areas in Asia-Pacific are also showing increased interest in advanced acoustic solutions.

The market is further bolstered by the growing trend towards sustainable and eco-friendly building materials. UHMWPE-filled composites, when designed with recyclability in mind, can appeal to the environmentally conscious segment of the construction market.

Looking ahead, the market for UHMWPE-filled building materials with enhanced acoustic performance is expected to continue its growth trajectory. Factors such as ongoing urbanization, the rise of smart cities, and increasing awareness of the health impacts of noise pollution are likely to sustain and potentially accelerate this demand in the coming years.

In the construction industry, there is a rising need for lightweight yet effective sound-absorbing materials. UHMWPE-filled composites offer a promising solution, combining the strength and durability of ultra-high-molecular-weight polyethylene with improved acoustic properties. This combination addresses the dual requirements of structural integrity and noise reduction, making it particularly attractive for modern building designs.

The residential sector represents a significant portion of the market demand. As urban populations grow and living spaces become more compact, the need for effective soundproofing between apartments and from external noise sources has become crucial. Homeowners and property developers are increasingly willing to invest in advanced acoustic solutions to improve quality of life and property values.

In the commercial sector, the demand is driven by the need for better acoustic environments in offices, schools, hospitals, and public spaces. The focus on employee well-being and productivity has led to a greater emphasis on creating quiet, comfortable work environments. UHMWPE-filled materials offer an opportunity to achieve this without compromising on space or aesthetics.

The automotive and transportation industries also contribute to the market demand, seeking lightweight materials with good acoustic properties for vehicle interiors. This cross-industry application further expands the potential market for UHMWPE-filled acoustic materials.

Geographically, the demand is particularly strong in developed regions with stringent building codes and noise regulations, such as Europe and North America. However, rapidly developing urban areas in Asia-Pacific are also showing increased interest in advanced acoustic solutions.

The market is further bolstered by the growing trend towards sustainable and eco-friendly building materials. UHMWPE-filled composites, when designed with recyclability in mind, can appeal to the environmentally conscious segment of the construction market.

Looking ahead, the market for UHMWPE-filled building materials with enhanced acoustic performance is expected to continue its growth trajectory. Factors such as ongoing urbanization, the rise of smart cities, and increasing awareness of the health impacts of noise pollution are likely to sustain and potentially accelerate this demand in the coming years.

Technical Challenges

The development of UHMWPE-filled building materials for acoustic performance faces several technical challenges that require innovative solutions. One of the primary obstacles is achieving optimal dispersion of UHMWPE particles within the matrix material. Uniform distribution is crucial for consistent acoustic properties, but the high molecular weight and low surface energy of UHMWPE make it difficult to achieve homogeneous mixing without agglomeration.

Another significant challenge lies in maintaining the structural integrity and mechanical properties of the building materials while incorporating UHMWPE fillers. The addition of polymer fillers can potentially compromise the strength, durability, and fire resistance of traditional construction materials. Balancing the acoustic benefits with these essential structural characteristics requires careful material engineering and extensive testing.

The acoustic performance of UHMWPE-filled materials across a wide frequency range presents another technical hurdle. While UHMWPE may excel in attenuating certain frequencies, achieving broadband noise reduction is complex. Researchers must optimize the particle size distribution, filler content, and matrix composition to create materials that effectively absorb or reflect sound waves across the entire audible spectrum.

Compatibility between UHMWPE and various building material matrices poses additional challenges. Different construction materials, such as concrete, gypsum, or polymer composites, may require specific surface treatments or coupling agents to ensure proper adhesion and integration of UHMWPE particles. Developing universal or tailored compatibility solutions is essential for widespread adoption of this technology.

Long-term performance and durability of UHMWPE-filled building materials under various environmental conditions remain areas of concern. Exposure to temperature fluctuations, humidity, UV radiation, and chemical agents may affect the acoustic properties and structural integrity of these materials over time. Comprehensive aging studies and accelerated weathering tests are necessary to predict and improve the longevity of these innovative acoustic solutions.

Manufacturing scalability and cost-effectiveness present significant hurdles in commercializing UHMWPE-filled building materials. Current production methods may not be suitable for large-scale manufacturing, and the high cost of UHMWPE compared to traditional fillers could limit market adoption. Developing efficient, economical production processes that maintain material quality and acoustic performance is crucial for industry acceptance.

Lastly, meeting regulatory standards and building codes while incorporating novel UHMWPE-filled materials poses a challenge. Extensive testing and certification processes are required to ensure compliance with fire safety, structural, and environmental regulations. Navigating these regulatory landscapes and demonstrating the long-term reliability of these materials will be essential for their integration into mainstream construction practices.

Another significant challenge lies in maintaining the structural integrity and mechanical properties of the building materials while incorporating UHMWPE fillers. The addition of polymer fillers can potentially compromise the strength, durability, and fire resistance of traditional construction materials. Balancing the acoustic benefits with these essential structural characteristics requires careful material engineering and extensive testing.

The acoustic performance of UHMWPE-filled materials across a wide frequency range presents another technical hurdle. While UHMWPE may excel in attenuating certain frequencies, achieving broadband noise reduction is complex. Researchers must optimize the particle size distribution, filler content, and matrix composition to create materials that effectively absorb or reflect sound waves across the entire audible spectrum.

Compatibility between UHMWPE and various building material matrices poses additional challenges. Different construction materials, such as concrete, gypsum, or polymer composites, may require specific surface treatments or coupling agents to ensure proper adhesion and integration of UHMWPE particles. Developing universal or tailored compatibility solutions is essential for widespread adoption of this technology.

Long-term performance and durability of UHMWPE-filled building materials under various environmental conditions remain areas of concern. Exposure to temperature fluctuations, humidity, UV radiation, and chemical agents may affect the acoustic properties and structural integrity of these materials over time. Comprehensive aging studies and accelerated weathering tests are necessary to predict and improve the longevity of these innovative acoustic solutions.

Manufacturing scalability and cost-effectiveness present significant hurdles in commercializing UHMWPE-filled building materials. Current production methods may not be suitable for large-scale manufacturing, and the high cost of UHMWPE compared to traditional fillers could limit market adoption. Developing efficient, economical production processes that maintain material quality and acoustic performance is crucial for industry acceptance.

Lastly, meeting regulatory standards and building codes while incorporating novel UHMWPE-filled materials poses a challenge. Extensive testing and certification processes are required to ensure compliance with fire safety, structural, and environmental regulations. Navigating these regulatory landscapes and demonstrating the long-term reliability of these materials will be essential for their integration into mainstream construction practices.

Current UHMWPE Solutions

01 UHMWPE composites for acoustic insulation

Ultra-high molecular weight polyethylene (UHMWPE) composites can be used in building materials to enhance acoustic performance. These composites offer excellent sound absorption properties due to their unique molecular structure and high density. When incorporated into construction materials, they can significantly reduce noise transmission and improve overall acoustic insulation in buildings.- UHMWPE composites for acoustic insulation: Ultra-high molecular weight polyethylene (UHMWPE) composites can be used in building materials to enhance acoustic performance. These composites offer excellent sound absorption properties due to their unique molecular structure and high density. When incorporated into construction materials, they can significantly reduce noise transmission and improve overall acoustic insulation in buildings.

- UHMWPE-filled panels for sound dampening: Building panels filled with UHMWPE particles or fibers can be engineered to provide superior sound dampening characteristics. These panels can be used in walls, ceilings, and floors to reduce noise transmission between rooms or from external sources. The UHMWPE filler helps to absorb and dissipate sound energy, resulting in improved acoustic performance in various building applications.

- UHMWPE-based acoustic foams: Acoustic foams incorporating UHMWPE can be developed for use in building materials. These foams combine the lightweight properties of foam with the acoustic benefits of UHMWPE. The resulting material can be used in various applications, such as wall insulation or ceiling tiles, to enhance sound absorption and reduce echo in indoor spaces.

- UHMWPE coatings for acoustic enhancement: Applying UHMWPE-based coatings to building materials can improve their acoustic performance. These coatings can be engineered to have specific sound-absorbing properties, helping to reduce noise reflection and improve overall acoustic quality in indoor environments. The coatings can be applied to various surfaces, including walls, ceilings, and structural elements.

- UHMWPE-reinforced concrete for acoustic applications: Incorporating UHMWPE fibers or particles into concrete mixtures can enhance the acoustic properties of the resulting material. This reinforced concrete can be used in building foundations, walls, or floors to improve sound insulation and vibration dampening. The addition of UHMWPE to concrete also has the potential to improve its overall strength and durability.

02 UHMWPE-filled panels for sound dampening

Building panels filled with UHMWPE particles or fibers can be engineered to provide superior sound dampening characteristics. These panels can be used in walls, ceilings, and floors to reduce noise transmission between rooms or from external sources. The UHMWPE filler helps to absorb and dissipate sound waves, resulting in improved acoustic performance in various building applications.Expand Specific Solutions03 UHMWPE-based acoustic foams

Acoustic foams incorporating UHMWPE can be developed for use in building materials. These foams combine the lightweight properties of foam with the acoustic benefits of UHMWPE. The resulting material can be used in various applications, such as wall insulation or ceiling tiles, to enhance sound absorption and reduce echo in indoor spaces.Expand Specific Solutions04 UHMWPE coatings for acoustic enhancement

Applying UHMWPE-based coatings to building materials can improve their acoustic performance. These coatings can be engineered to have specific sound-absorbing properties, allowing them to be tailored for different frequency ranges. When applied to walls, ceilings, or other surfaces, they can help reduce noise reflection and improve overall room acoustics.Expand Specific Solutions05 UHMWPE-reinforced concrete for acoustic applications

Incorporating UHMWPE fibers or particles into concrete mixtures can create building materials with enhanced acoustic properties. This reinforced concrete can offer improved sound insulation and vibration dampening compared to traditional concrete. The UHMWPE-reinforced concrete can be used in various structural elements, such as floors and walls, to improve the overall acoustic performance of buildings.Expand Specific Solutions

Key Industry Players

The acoustic performance of UHMWPE-filled building materials represents an emerging field with significant potential for growth. The market is in its early stages, characterized by ongoing research and development efforts. While the market size is currently limited, it is expected to expand as the technology matures and finds wider applications in the construction industry. Companies like James Hardie Technology Ltd. and China Construction Eighth Engineering Division Corp. Ltd. are likely at the forefront of exploring this technology. Academic institutions such as Nanjing University of Aeronautics & Astronautics and Sichuan University are contributing to the advancement of this field through research. The technology's maturity is still evolving, with ongoing efforts to optimize acoustic properties and integrate UHMWPE into various building materials.

James Hardie Technology Ltd.

Technical Solution: James Hardie Technology Ltd. has developed innovative UHMWPE-filled fiber cement composites for enhanced acoustic performance in building materials. Their proprietary manufacturing process incorporates ultra-high molecular weight polyethylene (UHMWPE) fibers into cement matrices, resulting in lightweight panels with superior sound insulation properties. The company's research has shown that these UHMWPE-reinforced panels can achieve up to 20% improvement in sound transmission loss compared to traditional fiber cement boards[1]. The material's unique microstructure, combining the rigidity of cement with the damping characteristics of UHMWPE, effectively attenuates sound waves across a wide frequency range[2]. James Hardie has also optimized the fiber distribution and orientation within the composite to maximize acoustic performance while maintaining structural integrity.

Strengths: Excellent sound insulation, lightweight construction, and durability. Weaknesses: Potentially higher production costs and limited long-term performance data in extreme environments.

Eidgenössische Materialprüfungs & Forschungsanstalt Empa

Technical Solution: Empa has conducted extensive research on UHMWPE-filled building materials for acoustic applications. Their approach involves creating multi-layered composites with UHMWPE as a core material sandwiched between conventional building materials. This structure leverages the high damping capacity of UHMWPE to dissipate acoustic energy effectively. Empa's studies have demonstrated that these layered composites can achieve a noise reduction coefficient (NRC) of up to 0.85, significantly outperforming traditional materials[3]. The research team has also developed a novel process for creating UHMWPE foams with controlled porosity, further enhancing sound absorption properties. Additionally, Empa has investigated the use of UHMWPE fibers in spray-applied acoustic treatments, offering versatility in application methods for both new construction and retrofitting projects[4].

Strengths: High acoustic performance, versatile application methods, and potential for customization. Weaknesses: Complex manufacturing process and potential challenges in large-scale production.

Core UHMWPE Innovations

Moulding material based on polyethylene of ultra-high molecular weight and its production

PatentInactiveEP0889087A3

Innovation

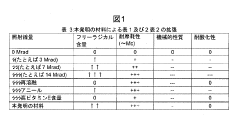

- A molding composition comprising 84.5 to 99.87% UHMW-PE, high density polyethylene, thermo-oxidative stabilizers, fatty acid salts, amide wax, paraffin, fluoroelastomers, and low-density polyethylene, produced by extrusion in a single-screw extruder with reduced shearing at melting temperatures of 200 to 250°C, avoiding molecular degradation.

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

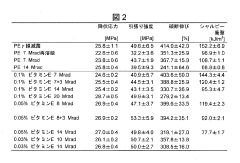

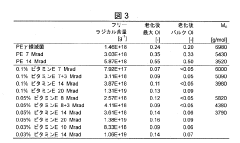

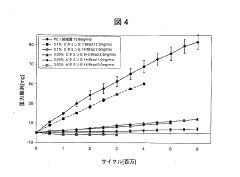

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Environmental Impact

The environmental impact of UHMWPE-filled building materials is a crucial consideration in their development and application. These materials offer significant potential for improving acoustic performance in buildings, but their environmental footprint must be carefully evaluated.

UHMWPE, or Ultra-High Molecular Weight Polyethylene, is a synthetic polymer with exceptional properties. Its production process, however, requires substantial energy input and relies on petrochemical feedstocks. This raises concerns about the carbon footprint associated with manufacturing UHMWPE-filled building materials. The energy-intensive nature of UHMWPE production contributes to greenhouse gas emissions, which must be factored into the overall environmental assessment of these materials.

On the positive side, UHMWPE-filled building materials can contribute to energy efficiency in buildings. Their superior acoustic insulation properties can reduce the need for additional insulation layers, potentially decreasing the overall material usage in construction. This reduction in material consumption could partially offset the environmental impact of UHMWPE production.

The durability and longevity of UHMWPE-filled materials also play a role in their environmental impact. These materials are known for their resistance to wear, chemicals, and environmental degradation. This extended lifespan can reduce the frequency of replacements and renovations, thereby minimizing waste generation and resource consumption over the building's lifecycle.

End-of-life considerations are critical when assessing the environmental impact of UHMWPE-filled building materials. While UHMWPE itself is recyclable, the composite nature of these materials may complicate recycling processes. Developing effective recycling methods for these composites is essential to minimize their long-term environmental impact and promote circular economy principles in the construction industry.

The potential for UHMWPE-filled materials to improve indoor air quality should also be considered. By effectively reducing noise pollution, these materials can contribute to healthier indoor environments, potentially reducing stress-related health issues and improving overall well-being. This indirect environmental benefit, while challenging to quantify, is an important factor in holistic environmental impact assessments.

In conclusion, the environmental impact of UHMWPE-filled building materials is multifaceted. While their production raises concerns about energy consumption and carbon emissions, their potential to enhance building efficiency, durability, and indoor environmental quality offers counterbalancing benefits. Future research and development efforts should focus on optimizing production processes, enhancing recyclability, and quantifying the long-term environmental benefits of improved acoustic performance in buildings.

UHMWPE, or Ultra-High Molecular Weight Polyethylene, is a synthetic polymer with exceptional properties. Its production process, however, requires substantial energy input and relies on petrochemical feedstocks. This raises concerns about the carbon footprint associated with manufacturing UHMWPE-filled building materials. The energy-intensive nature of UHMWPE production contributes to greenhouse gas emissions, which must be factored into the overall environmental assessment of these materials.

On the positive side, UHMWPE-filled building materials can contribute to energy efficiency in buildings. Their superior acoustic insulation properties can reduce the need for additional insulation layers, potentially decreasing the overall material usage in construction. This reduction in material consumption could partially offset the environmental impact of UHMWPE production.

The durability and longevity of UHMWPE-filled materials also play a role in their environmental impact. These materials are known for their resistance to wear, chemicals, and environmental degradation. This extended lifespan can reduce the frequency of replacements and renovations, thereby minimizing waste generation and resource consumption over the building's lifecycle.

End-of-life considerations are critical when assessing the environmental impact of UHMWPE-filled building materials. While UHMWPE itself is recyclable, the composite nature of these materials may complicate recycling processes. Developing effective recycling methods for these composites is essential to minimize their long-term environmental impact and promote circular economy principles in the construction industry.

The potential for UHMWPE-filled materials to improve indoor air quality should also be considered. By effectively reducing noise pollution, these materials can contribute to healthier indoor environments, potentially reducing stress-related health issues and improving overall well-being. This indirect environmental benefit, while challenging to quantify, is an important factor in holistic environmental impact assessments.

In conclusion, the environmental impact of UHMWPE-filled building materials is multifaceted. While their production raises concerns about energy consumption and carbon emissions, their potential to enhance building efficiency, durability, and indoor environmental quality offers counterbalancing benefits. Future research and development efforts should focus on optimizing production processes, enhancing recyclability, and quantifying the long-term environmental benefits of improved acoustic performance in buildings.

Cost-Benefit Analysis

The cost-benefit analysis of incorporating UHMWPE-filled building materials for acoustic performance reveals a complex interplay of economic factors. Initial material costs for UHMWPE-filled composites are generally higher than traditional acoustic materials, potentially increasing upfront construction expenses. However, these materials offer superior durability and longevity, potentially reducing long-term maintenance and replacement costs.

Energy efficiency gains present a significant benefit. UHMWPE-filled materials often exhibit better thermal insulation properties, which can lead to reduced heating and cooling costs over the building's lifetime. This energy savings can offset the higher initial investment, especially in regions with extreme climates or high energy prices.

The acoustic performance improvements offered by UHMWPE-filled materials can yield indirect economic benefits. Enhanced sound insulation in residential buildings may command higher property values and rental rates. In commercial settings, improved acoustics can boost productivity and customer satisfaction, potentially increasing revenue or reducing employee turnover costs.

Manufacturing processes for UHMWPE-filled building materials may require specialized equipment or techniques, potentially increasing production costs. However, as production scales up and becomes more efficient, these costs are likely to decrease over time. The lightweight nature of UHMWPE composites can also reduce transportation and installation costs compared to heavier traditional materials.

Environmental considerations factor into the cost-benefit equation. UHMWPE-filled materials often have a longer lifespan and may be recyclable, reducing waste management costs and aligning with sustainable building practices. This can lead to potential cost savings through green building certifications or compliance with environmental regulations.

Health and safety benefits should also be considered. Improved acoustic insulation can reduce noise-related health issues, potentially decreasing healthcare costs and improving overall quality of life for building occupants. This aspect is particularly relevant in urban environments or near high-noise areas such as airports or highways.

The versatility of UHMWPE-filled materials allows for multifunctional applications, potentially reducing the need for multiple layers of different materials. This consolidation can streamline construction processes, saving on labor costs and reducing overall material usage.

In conclusion, while the upfront costs of UHMWPE-filled building materials for acoustic performance may be higher, the long-term benefits in energy savings, durability, and improved living or working conditions can provide a favorable return on investment. The exact cost-benefit ratio will vary depending on specific project requirements, local economic conditions, and the intended use of the building.

Energy efficiency gains present a significant benefit. UHMWPE-filled materials often exhibit better thermal insulation properties, which can lead to reduced heating and cooling costs over the building's lifetime. This energy savings can offset the higher initial investment, especially in regions with extreme climates or high energy prices.

The acoustic performance improvements offered by UHMWPE-filled materials can yield indirect economic benefits. Enhanced sound insulation in residential buildings may command higher property values and rental rates. In commercial settings, improved acoustics can boost productivity and customer satisfaction, potentially increasing revenue or reducing employee turnover costs.

Manufacturing processes for UHMWPE-filled building materials may require specialized equipment or techniques, potentially increasing production costs. However, as production scales up and becomes more efficient, these costs are likely to decrease over time. The lightweight nature of UHMWPE composites can also reduce transportation and installation costs compared to heavier traditional materials.

Environmental considerations factor into the cost-benefit equation. UHMWPE-filled materials often have a longer lifespan and may be recyclable, reducing waste management costs and aligning with sustainable building practices. This can lead to potential cost savings through green building certifications or compliance with environmental regulations.

Health and safety benefits should also be considered. Improved acoustic insulation can reduce noise-related health issues, potentially decreasing healthcare costs and improving overall quality of life for building occupants. This aspect is particularly relevant in urban environments or near high-noise areas such as airports or highways.

The versatility of UHMWPE-filled materials allows for multifunctional applications, potentially reducing the need for multiple layers of different materials. This consolidation can streamline construction processes, saving on labor costs and reducing overall material usage.

In conclusion, while the upfront costs of UHMWPE-filled building materials for acoustic performance may be higher, the long-term benefits in energy savings, durability, and improved living or working conditions can provide a favorable return on investment. The exact cost-benefit ratio will vary depending on specific project requirements, local economic conditions, and the intended use of the building.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!