Analysis of UHMWPE's Tensile Properties in Textile Industry

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Textile Evolution

The evolution of Ultra-High Molecular Weight Polyethylene (UHMWPE) in the textile industry represents a significant advancement in material science and engineering. Initially developed in the 1950s, UHMWPE has undergone substantial improvements in its production processes and applications over the decades.

In the early stages, UHMWPE was primarily used in industrial applications due to its high strength-to-weight ratio and excellent wear resistance. The 1970s marked a turning point when researchers began exploring its potential in the textile sector. The first breakthrough came with the development of gel spinning techniques, which allowed for the production of high-strength UHMWPE fibers.

The 1980s saw the commercialization of UHMWPE fibers under various trade names, such as Dyneema and Spectra. These fibers quickly gained attention for their exceptional tensile strength, which surpassed that of steel on a weight-for-weight basis. This period also witnessed the refinement of production methods, leading to improved fiber quality and consistency.

During the 1990s, UHMWPE textiles found their way into high-performance applications, including ballistic protection, cut-resistant gloves, and marine ropes. The focus shifted towards enhancing the fiber's properties, such as creep resistance and UV stability, to broaden its application range.

The early 2000s brought about significant advancements in UHMWPE fiber technology. Researchers developed multi-stage drawing processes that further increased the fiber's strength and modulus. This era also saw the introduction of surface treatments and coatings to improve the fiber's adhesion properties and compatibility with various matrices.

In recent years, the evolution of UHMWPE in textiles has been driven by the demand for sustainable and multifunctional materials. Efforts have been made to develop bio-based alternatives and improve the recyclability of UHMWPE products. Additionally, researchers have explored ways to incorporate smart features into UHMWPE textiles, such as self-healing properties and sensor integration.

The latest developments in UHMWPE textile evolution focus on nanotechnology and composite structures. By incorporating nanoparticles or creating hybrid fibers, scientists aim to enhance the material's performance in areas such as thermal management, electrical conductivity, and impact resistance. These advancements are opening up new possibilities for UHMWPE in advanced technical textiles and wearable technologies.

In the early stages, UHMWPE was primarily used in industrial applications due to its high strength-to-weight ratio and excellent wear resistance. The 1970s marked a turning point when researchers began exploring its potential in the textile sector. The first breakthrough came with the development of gel spinning techniques, which allowed for the production of high-strength UHMWPE fibers.

The 1980s saw the commercialization of UHMWPE fibers under various trade names, such as Dyneema and Spectra. These fibers quickly gained attention for their exceptional tensile strength, which surpassed that of steel on a weight-for-weight basis. This period also witnessed the refinement of production methods, leading to improved fiber quality and consistency.

During the 1990s, UHMWPE textiles found their way into high-performance applications, including ballistic protection, cut-resistant gloves, and marine ropes. The focus shifted towards enhancing the fiber's properties, such as creep resistance and UV stability, to broaden its application range.

The early 2000s brought about significant advancements in UHMWPE fiber technology. Researchers developed multi-stage drawing processes that further increased the fiber's strength and modulus. This era also saw the introduction of surface treatments and coatings to improve the fiber's adhesion properties and compatibility with various matrices.

In recent years, the evolution of UHMWPE in textiles has been driven by the demand for sustainable and multifunctional materials. Efforts have been made to develop bio-based alternatives and improve the recyclability of UHMWPE products. Additionally, researchers have explored ways to incorporate smart features into UHMWPE textiles, such as self-healing properties and sensor integration.

The latest developments in UHMWPE textile evolution focus on nanotechnology and composite structures. By incorporating nanoparticles or creating hybrid fibers, scientists aim to enhance the material's performance in areas such as thermal management, electrical conductivity, and impact resistance. These advancements are opening up new possibilities for UHMWPE in advanced technical textiles and wearable technologies.

Market Demand Analysis

The market demand for Ultra-High Molecular Weight Polyethylene (UHMWPE) in the textile industry has been steadily growing due to its exceptional tensile properties. This high-performance material offers a unique combination of strength, durability, and lightweight characteristics, making it increasingly attractive for various textile applications.

In the technical textile sector, UHMWPE fibers have gained significant traction, particularly in protective gear and high-performance clothing. The material's high tensile strength-to-weight ratio has led to its adoption in ballistic protection, cut-resistant gloves, and impact-resistant sportswear. These applications leverage UHMWPE's ability to absorb and dissipate energy, providing enhanced safety features without compromising comfort or mobility.

The outdoor and adventure sports market has also shown a rising demand for UHMWPE-based textiles. Manufacturers of climbing ropes, parachute cords, and sailing lines are increasingly incorporating UHMWPE fibers to improve product performance. The material's resistance to UV radiation and moisture, coupled with its high strength, makes it ideal for these demanding outdoor applications.

In the medical textile field, UHMWPE's biocompatibility and tensile properties have opened new avenues for innovation. The material is being explored for use in surgical sutures, implantable medical devices, and prosthetic components. Its low friction coefficient and wear resistance contribute to improved longevity and reduced complications in medical applications.

The industrial textile sector has also recognized the potential of UHMWPE, particularly in filtration systems and conveyor belts. The material's chemical resistance and high tensile strength allow for the creation of durable and efficient filtration media capable of withstanding harsh industrial environments.

As sustainability becomes a key focus in the textile industry, UHMWPE's recyclability and long lifespan are driving its adoption in eco-friendly textile solutions. Manufacturers are exploring ways to incorporate UHMWPE into circular economy models, further boosting its market appeal.

The global market for UHMWPE fibers in textiles is expected to experience robust growth in the coming years. This growth is driven by increasing awareness of the material's benefits, ongoing research and development efforts to enhance its properties, and the expansion of its applications across various industries. As manufacturers continue to innovate and develop new UHMWPE-based textile products, the market is likely to see diversification and expansion into new sectors, further solidifying the material's position in the textile industry.

In the technical textile sector, UHMWPE fibers have gained significant traction, particularly in protective gear and high-performance clothing. The material's high tensile strength-to-weight ratio has led to its adoption in ballistic protection, cut-resistant gloves, and impact-resistant sportswear. These applications leverage UHMWPE's ability to absorb and dissipate energy, providing enhanced safety features without compromising comfort or mobility.

The outdoor and adventure sports market has also shown a rising demand for UHMWPE-based textiles. Manufacturers of climbing ropes, parachute cords, and sailing lines are increasingly incorporating UHMWPE fibers to improve product performance. The material's resistance to UV radiation and moisture, coupled with its high strength, makes it ideal for these demanding outdoor applications.

In the medical textile field, UHMWPE's biocompatibility and tensile properties have opened new avenues for innovation. The material is being explored for use in surgical sutures, implantable medical devices, and prosthetic components. Its low friction coefficient and wear resistance contribute to improved longevity and reduced complications in medical applications.

The industrial textile sector has also recognized the potential of UHMWPE, particularly in filtration systems and conveyor belts. The material's chemical resistance and high tensile strength allow for the creation of durable and efficient filtration media capable of withstanding harsh industrial environments.

As sustainability becomes a key focus in the textile industry, UHMWPE's recyclability and long lifespan are driving its adoption in eco-friendly textile solutions. Manufacturers are exploring ways to incorporate UHMWPE into circular economy models, further boosting its market appeal.

The global market for UHMWPE fibers in textiles is expected to experience robust growth in the coming years. This growth is driven by increasing awareness of the material's benefits, ongoing research and development efforts to enhance its properties, and the expansion of its applications across various industries. As manufacturers continue to innovate and develop new UHMWPE-based textile products, the market is likely to see diversification and expansion into new sectors, further solidifying the material's position in the textile industry.

Current Challenges

The textile industry faces several significant challenges in harnessing the full potential of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers, particularly in relation to their tensile properties. One of the primary obstacles is the difficulty in achieving consistent fiber quality during the production process. The complex molecular structure of UHMWPE makes it challenging to maintain uniform properties throughout the fiber length, leading to variations in tensile strength and elongation.

Another critical challenge lies in the surface properties of UHMWPE fibers. Their inherently low surface energy and chemical inertness result in poor adhesion to matrices and coatings, limiting their application in composite materials and finished textile products. This adhesion issue significantly impacts the overall performance of UHMWPE-based textiles, particularly in applications requiring high strength-to-weight ratios.

The processing of UHMWPE fibers also presents substantial hurdles. The high melting point and viscosity of the polymer make conventional melt-spinning techniques ineffective. Gel-spinning, the preferred method for producing high-strength UHMWPE fibers, is a complex and energy-intensive process that requires precise control over numerous parameters. This complexity not only increases production costs but also limits the scalability of UHMWPE fiber manufacturing.

Furthermore, the textile industry struggles with the optimization of UHMWPE fiber properties for specific end-use applications. While these fibers exhibit exceptional tensile strength, their relatively low modulus compared to other high-performance fibers like carbon fiber can be a limitation in certain applications. Balancing strength, modulus, and other properties to meet diverse textile requirements remains a significant challenge.

The long-term performance of UHMWPE fibers in textile applications is another area of concern. Although these fibers demonstrate excellent resistance to many chemicals and environmental factors, they are susceptible to degradation under prolonged UV exposure and at elevated temperatures. This vulnerability can compromise the tensile properties over time, particularly in outdoor or high-temperature applications.

Lastly, the integration of UHMWPE fibers into existing textile manufacturing processes poses considerable challenges. Traditional textile machinery and techniques are often not optimized for handling these high-performance fibers, necessitating significant adaptations or investments in new equipment. This integration challenge extends to the development of suitable joining and finishing techniques that do not compromise the inherent strength of UHMWPE fibers.

Another critical challenge lies in the surface properties of UHMWPE fibers. Their inherently low surface energy and chemical inertness result in poor adhesion to matrices and coatings, limiting their application in composite materials and finished textile products. This adhesion issue significantly impacts the overall performance of UHMWPE-based textiles, particularly in applications requiring high strength-to-weight ratios.

The processing of UHMWPE fibers also presents substantial hurdles. The high melting point and viscosity of the polymer make conventional melt-spinning techniques ineffective. Gel-spinning, the preferred method for producing high-strength UHMWPE fibers, is a complex and energy-intensive process that requires precise control over numerous parameters. This complexity not only increases production costs but also limits the scalability of UHMWPE fiber manufacturing.

Furthermore, the textile industry struggles with the optimization of UHMWPE fiber properties for specific end-use applications. While these fibers exhibit exceptional tensile strength, their relatively low modulus compared to other high-performance fibers like carbon fiber can be a limitation in certain applications. Balancing strength, modulus, and other properties to meet diverse textile requirements remains a significant challenge.

The long-term performance of UHMWPE fibers in textile applications is another area of concern. Although these fibers demonstrate excellent resistance to many chemicals and environmental factors, they are susceptible to degradation under prolonged UV exposure and at elevated temperatures. This vulnerability can compromise the tensile properties over time, particularly in outdoor or high-temperature applications.

Lastly, the integration of UHMWPE fibers into existing textile manufacturing processes poses considerable challenges. Traditional textile machinery and techniques are often not optimized for handling these high-performance fibers, necessitating significant adaptations or investments in new equipment. This integration challenge extends to the development of suitable joining and finishing techniques that do not compromise the inherent strength of UHMWPE fibers.

Tensile Testing Methods

01 Improving tensile properties of UHMWPE fibers

Various methods are employed to enhance the tensile properties of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers. These include optimizing the drawing process, incorporating additives, and applying surface treatments. Such improvements result in increased strength, modulus, and overall mechanical performance of UHMWPE fibers for various applications.- Improving tensile properties of UHMWPE fibers: Various methods are employed to enhance the tensile properties of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers. These include optimizing the drawing process, incorporating additives, and applying surface treatments. Such improvements result in increased strength, modulus, and overall mechanical performance of UHMWPE fibers for various applications.

- UHMWPE composites for enhanced tensile strength: Composites incorporating UHMWPE are developed to achieve superior tensile properties. These composites often combine UHMWPE with other materials such as carbon fibers, nanoparticles, or other polymers. The resulting materials exhibit improved tensile strength, stiffness, and durability compared to pure UHMWPE.

- Processing techniques for optimizing UHMWPE tensile properties: Specific processing techniques are utilized to optimize the tensile properties of UHMWPE. These may include gel spinning, hot compaction, and various heat treatment methods. Such techniques aim to improve molecular orientation, crystallinity, and inter-chain interactions, thereby enhancing the material's tensile performance.

- Characterization and testing of UHMWPE tensile properties: Advanced methods for characterizing and testing the tensile properties of UHMWPE are developed. These include specialized tensile testing protocols, non-destructive evaluation techniques, and in-situ monitoring methods. Such approaches provide accurate and comprehensive data on the material's tensile behavior under various conditions.

- Applications leveraging UHMWPE tensile properties: The exceptional tensile properties of UHMWPE are exploited in various applications. These include high-performance ropes and cables, ballistic protection materials, medical implants, and aerospace components. The material's high strength-to-weight ratio and excellent tensile characteristics make it suitable for demanding applications requiring superior mechanical performance.

02 UHMWPE composites for enhanced tensile strength

Developing UHMWPE composites by blending with other materials or reinforcing agents can significantly improve tensile properties. These composites often exhibit superior strength-to-weight ratios and enhanced mechanical characteristics compared to pure UHMWPE, making them suitable for high-performance applications.Expand Specific Solutions03 Processing techniques for optimized UHMWPE tensile properties

Advanced processing techniques such as gel spinning, hot compaction, and ram extrusion are utilized to optimize the tensile properties of UHMWPE. These methods focus on improving molecular orientation and crystallinity, resulting in enhanced tensile strength and modulus of the final UHMWPE products.Expand Specific Solutions04 Characterization and testing of UHMWPE tensile properties

Various characterization and testing methods are employed to accurately measure and analyze the tensile properties of UHMWPE. These include standardized tensile testing procedures, advanced imaging techniques, and computational modeling to understand the structure-property relationships and predict performance under different conditions.Expand Specific Solutions05 Applications leveraging UHMWPE tensile properties

The exceptional tensile properties of UHMWPE are exploited in numerous applications across industries. These include high-strength fibers for ballistic protection, medical implants with improved wear resistance, and durable components for industrial machinery. The material's unique combination of strength, toughness, and low friction makes it ideal for demanding environments.Expand Specific Solutions

Key Industry Players

The analysis of UHMWPE's tensile properties in the textile industry reveals a competitive landscape characterized by rapid growth and technological advancements. The market is in an expansion phase, with increasing demand across various sectors, including defense, aerospace, and sports. The global UHMWPE market size is projected to reach significant figures in the coming years, driven by its superior mechanical properties. Technologically, companies like DSM IP Assets BV, Honeywell International Technologies Ltd., and Beijing Tongyizhong New Material Technology Corp. are at the forefront, continuously innovating to enhance UHMWPE's performance. Research institutions such as Donghua University and Sichuan University are also contributing to the field's advancement, indicating a high level of academic-industry collaboration in this sector.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed Spectra® fiber, a UHMWPE product with high tensile strength and low weight. Their proprietary gel spinning process creates a highly oriented molecular structure, resulting in fibers with exceptional strength and durability[4]. Honeywell's recent advancements include the development of Spectra® Shield technology, which combines Spectra fiber with resins in a unique cross-ply configuration. This technology enhances the fiber's performance in applications requiring high tensile strength and impact resistance, such as body armor and industrial textiles[5]. Honeywell has also focused on improving the fiber's resistance to UV degradation and chemicals, expanding its use in outdoor and harsh environment applications[6].

Strengths: Excellent strength-to-weight ratio, high impact and cut resistance, and versatility in applications. Weaknesses: Higher cost compared to traditional fibers and limited colorfastness.

DSM IP Assets BV

Technical Solution: DSM has developed Dyneema®, an ultra-high molecular weight polyethylene (UHMWPE) fiber with exceptional tensile properties. Their technology involves gel spinning of UHMWPE to create fibers with a high degree of molecular orientation and crystallinity[1]. This process results in fibers with a strength-to-weight ratio up to 15 times stronger than steel. DSM's recent innovations include Dyneema® Carbon hybrid composites, which combine UHMWPE fibers with carbon fibers to enhance impact resistance and reduce weight in textile applications[2]. They have also introduced bio-based Dyneema®, derived from renewable resources, maintaining the same performance while reducing carbon footprint[3].

Strengths: Superior strength-to-weight ratio, high impact resistance, and sustainability initiatives with bio-based options. Weaknesses: Higher production costs compared to conventional fibers, and limited dyeability due to the fiber's chemical structure.

Innovative UHMWPE Fibers

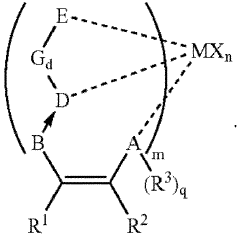

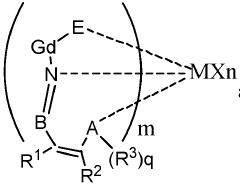

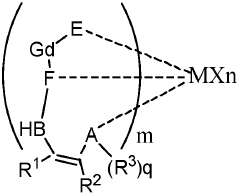

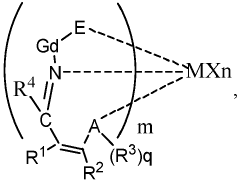

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Environmental Impact

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in the textile industry is a critical consideration for sustainable manufacturing practices. UHMWPE, known for its exceptional tensile properties, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of UHMWPE is its durability and longevity. The high tensile strength and wear resistance of UHMWPE-based textiles contribute to extended product lifespans, potentially reducing the need for frequent replacements and minimizing waste generation. This longevity can lead to a decrease in overall resource consumption and energy usage associated with textile production.

However, the production process of UHMWPE does raise some environmental concerns. The polymer is derived from petroleum-based sources, which contributes to the depletion of non-renewable resources and associated carbon emissions. The energy-intensive manufacturing process, including the synthesis of the polymer and subsequent fiber production, results in a significant carbon footprint.

Recycling UHMWPE presents challenges due to its high molecular weight and chemical stability. While theoretically recyclable, the process is complex and not widely implemented on a commercial scale. This limitation in recyclability can lead to increased landfill waste or incineration, both of which have negative environmental implications.

Water pollution is another consideration in the UHMWPE textile production process. The use of solvents and other chemicals during manufacturing may result in wastewater that requires careful treatment to prevent contamination of water bodies. Implementing advanced wastewater treatment systems is crucial to mitigate this environmental risk.

On the positive side, UHMWPE fibers have the potential to replace less environmentally friendly materials in certain applications. For instance, in protective gear and high-performance textiles, UHMWPE can substitute materials that may have more severe environmental impacts or shorter lifespans, thereby offering a net positive effect on sustainability.

The lightweight nature of UHMWPE fibers also contributes to potential energy savings in transportation and use phases of products. This characteristic can lead to reduced fuel consumption in applications such as automotive textiles or technical outdoor gear, indirectly lowering the overall environmental footprint.

As the textile industry moves towards more sustainable practices, research into bio-based alternatives for UHMWPE production is gaining traction. These efforts aim to reduce reliance on petroleum-based raw materials and potentially improve the polymer's end-of-life environmental profile.

In conclusion, while UHMWPE offers significant advantages in terms of product longevity and performance, its environmental impact remains a complex issue. Balancing the material's benefits against its production-related environmental costs is crucial for the textile industry's sustainable development. Future innovations in production methods, recycling technologies, and bio-based alternatives will be key to enhancing the environmental profile of UHMWPE in textile applications.

One of the primary environmental benefits of UHMWPE is its durability and longevity. The high tensile strength and wear resistance of UHMWPE-based textiles contribute to extended product lifespans, potentially reducing the need for frequent replacements and minimizing waste generation. This longevity can lead to a decrease in overall resource consumption and energy usage associated with textile production.

However, the production process of UHMWPE does raise some environmental concerns. The polymer is derived from petroleum-based sources, which contributes to the depletion of non-renewable resources and associated carbon emissions. The energy-intensive manufacturing process, including the synthesis of the polymer and subsequent fiber production, results in a significant carbon footprint.

Recycling UHMWPE presents challenges due to its high molecular weight and chemical stability. While theoretically recyclable, the process is complex and not widely implemented on a commercial scale. This limitation in recyclability can lead to increased landfill waste or incineration, both of which have negative environmental implications.

Water pollution is another consideration in the UHMWPE textile production process. The use of solvents and other chemicals during manufacturing may result in wastewater that requires careful treatment to prevent contamination of water bodies. Implementing advanced wastewater treatment systems is crucial to mitigate this environmental risk.

On the positive side, UHMWPE fibers have the potential to replace less environmentally friendly materials in certain applications. For instance, in protective gear and high-performance textiles, UHMWPE can substitute materials that may have more severe environmental impacts or shorter lifespans, thereby offering a net positive effect on sustainability.

The lightweight nature of UHMWPE fibers also contributes to potential energy savings in transportation and use phases of products. This characteristic can lead to reduced fuel consumption in applications such as automotive textiles or technical outdoor gear, indirectly lowering the overall environmental footprint.

As the textile industry moves towards more sustainable practices, research into bio-based alternatives for UHMWPE production is gaining traction. These efforts aim to reduce reliance on petroleum-based raw materials and potentially improve the polymer's end-of-life environmental profile.

In conclusion, while UHMWPE offers significant advantages in terms of product longevity and performance, its environmental impact remains a complex issue. Balancing the material's benefits against its production-related environmental costs is crucial for the textile industry's sustainable development. Future innovations in production methods, recycling technologies, and bio-based alternatives will be key to enhancing the environmental profile of UHMWPE in textile applications.

Regulatory Compliance

In the textile industry, regulatory compliance for Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers and products is a critical aspect that manufacturers and suppliers must address. The regulatory landscape for UHMWPE in textiles encompasses various standards and guidelines set by international, national, and industry-specific bodies.

One of the primary regulatory considerations for UHMWPE in textiles is safety compliance. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have established specific standards for testing and evaluating the tensile properties of UHMWPE fibers. These standards ensure that the fibers meet minimum strength and durability requirements for their intended applications.

Environmental regulations also play a significant role in the use of UHMWPE in textiles. As sustainability becomes increasingly important in the industry, manufacturers must adhere to guidelines regarding the production, use, and disposal of UHMWPE products. This includes compliance with regulations on chemical usage, waste management, and recycling processes.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the use of UHMWPE in textiles. Manufacturers and importers must ensure that their UHMWPE products do not contain restricted substances above specified thresholds and provide necessary safety information to downstream users.

For applications in personal protective equipment (PPE), UHMWPE fibers must meet stringent regulatory requirements. In the United States, the Occupational Safety and Health Administration (OSHA) sets standards for protective clothing made from UHMWPE, particularly in industries where cut and puncture resistance are crucial.

Quality control regulations are another important aspect of compliance for UHMWPE in textiles. Manufacturers must implement and maintain quality management systems that meet international standards such as ISO 9001. These systems ensure consistent product quality and traceability throughout the supply chain.

Labeling and marketing claims for UHMWPE textile products are subject to regulatory oversight. In many jurisdictions, claims about the performance characteristics of UHMWPE fibers, such as tensile strength or abrasion resistance, must be substantiated and comply with truth-in-advertising regulations.

As UHMWPE finds new applications in advanced textiles, regulatory bodies continue to evolve their guidelines. Manufacturers and researchers must stay informed about emerging regulations, particularly in areas such as nanotechnology and smart textiles, where UHMWPE may be integrated with other materials or technologies.

Compliance with these diverse regulatory requirements necessitates ongoing investment in testing, documentation, and quality assurance processes. Companies working with UHMWPE in the textile industry must maintain robust compliance programs to navigate the complex regulatory landscape and ensure their products meet all applicable standards and regulations.

One of the primary regulatory considerations for UHMWPE in textiles is safety compliance. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have established specific standards for testing and evaluating the tensile properties of UHMWPE fibers. These standards ensure that the fibers meet minimum strength and durability requirements for their intended applications.

Environmental regulations also play a significant role in the use of UHMWPE in textiles. As sustainability becomes increasingly important in the industry, manufacturers must adhere to guidelines regarding the production, use, and disposal of UHMWPE products. This includes compliance with regulations on chemical usage, waste management, and recycling processes.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts the use of UHMWPE in textiles. Manufacturers and importers must ensure that their UHMWPE products do not contain restricted substances above specified thresholds and provide necessary safety information to downstream users.

For applications in personal protective equipment (PPE), UHMWPE fibers must meet stringent regulatory requirements. In the United States, the Occupational Safety and Health Administration (OSHA) sets standards for protective clothing made from UHMWPE, particularly in industries where cut and puncture resistance are crucial.

Quality control regulations are another important aspect of compliance for UHMWPE in textiles. Manufacturers must implement and maintain quality management systems that meet international standards such as ISO 9001. These systems ensure consistent product quality and traceability throughout the supply chain.

Labeling and marketing claims for UHMWPE textile products are subject to regulatory oversight. In many jurisdictions, claims about the performance characteristics of UHMWPE fibers, such as tensile strength or abrasion resistance, must be substantiated and comply with truth-in-advertising regulations.

As UHMWPE finds new applications in advanced textiles, regulatory bodies continue to evolve their guidelines. Manufacturers and researchers must stay informed about emerging regulations, particularly in areas such as nanotechnology and smart textiles, where UHMWPE may be integrated with other materials or technologies.

Compliance with these diverse regulatory requirements necessitates ongoing investment in testing, documentation, and quality assurance processes. Companies working with UHMWPE in the textile industry must maintain robust compliance programs to navigate the complex regulatory landscape and ensure their products meet all applicable standards and regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!