UHMWPE and Acoustic Impedance Matching in Sonar Equipment

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Sonar: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a promising material in sonar equipment, particularly in the context of acoustic impedance matching. The development of sonar technology has been driven by the need for improved underwater detection and communication capabilities, with a focus on enhancing signal quality and reducing acoustic losses.

The evolution of sonar systems can be traced back to the early 20th century, with significant advancements occurring during World War II. Since then, continuous research efforts have been directed towards improving the efficiency and performance of sonar equipment. One of the key challenges in this field has been the optimization of acoustic impedance matching between different media, such as water and transducer materials.

UHMWPE has gained attention in recent years due to its unique properties, including high strength-to-weight ratio, excellent chemical resistance, and low acoustic impedance. These characteristics make it an ideal candidate for use in sonar applications, particularly as an acoustic window or matching layer material.

The primary objective of research on UHMWPE in sonar equipment is to exploit its acoustic properties to enhance the overall performance of sonar systems. This includes improving signal transmission and reception, reducing acoustic losses, and increasing the sensitivity and range of sonar devices. Additionally, researchers aim to develop novel UHMWPE-based composites or structures that can further optimize acoustic impedance matching.

Another important goal is to investigate the long-term durability and reliability of UHMWPE in underwater environments. This involves studying its resistance to degradation, biofouling, and mechanical stress under various operational conditions. Researchers also seek to understand the impact of UHMWPE on the overall system performance, including its effects on beam forming, signal processing, and noise reduction.

The integration of UHMWPE into existing sonar technologies presents both opportunities and challenges. While its acoustic properties offer potential improvements, there are technical hurdles to overcome, such as ensuring proper bonding with other materials and maintaining structural integrity under high-pressure conditions.

As the field of underwater acoustics continues to advance, the role of materials science in sonar technology becomes increasingly crucial. The exploration of UHMWPE and its applications in acoustic impedance matching represents a convergence of materials engineering and sonar system design, with the potential to revolutionize underwater sensing and communication capabilities.

The evolution of sonar systems can be traced back to the early 20th century, with significant advancements occurring during World War II. Since then, continuous research efforts have been directed towards improving the efficiency and performance of sonar equipment. One of the key challenges in this field has been the optimization of acoustic impedance matching between different media, such as water and transducer materials.

UHMWPE has gained attention in recent years due to its unique properties, including high strength-to-weight ratio, excellent chemical resistance, and low acoustic impedance. These characteristics make it an ideal candidate for use in sonar applications, particularly as an acoustic window or matching layer material.

The primary objective of research on UHMWPE in sonar equipment is to exploit its acoustic properties to enhance the overall performance of sonar systems. This includes improving signal transmission and reception, reducing acoustic losses, and increasing the sensitivity and range of sonar devices. Additionally, researchers aim to develop novel UHMWPE-based composites or structures that can further optimize acoustic impedance matching.

Another important goal is to investigate the long-term durability and reliability of UHMWPE in underwater environments. This involves studying its resistance to degradation, biofouling, and mechanical stress under various operational conditions. Researchers also seek to understand the impact of UHMWPE on the overall system performance, including its effects on beam forming, signal processing, and noise reduction.

The integration of UHMWPE into existing sonar technologies presents both opportunities and challenges. While its acoustic properties offer potential improvements, there are technical hurdles to overcome, such as ensuring proper bonding with other materials and maintaining structural integrity under high-pressure conditions.

As the field of underwater acoustics continues to advance, the role of materials science in sonar technology becomes increasingly crucial. The exploration of UHMWPE and its applications in acoustic impedance matching represents a convergence of materials engineering and sonar system design, with the potential to revolutionize underwater sensing and communication capabilities.

Market Analysis for Advanced Sonar Materials

The market for advanced sonar materials, particularly Ultra-High Molecular Weight Polyethylene (UHMWPE) and acoustic impedance matching materials, is experiencing significant growth driven by increasing demand in naval defense, maritime security, and underwater exploration sectors. The global sonar system market, which heavily relies on these advanced materials, is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years.

UHMWPE has gained traction in sonar applications due to its exceptional properties, including high strength-to-weight ratio, excellent acoustic transparency, and resistance to corrosion. These characteristics make it an ideal material for sonar domes and acoustic windows, replacing traditional materials like rubber and fiber-reinforced composites. The market for UHMWPE in sonar equipment is expected to grow as navies worldwide upgrade their fleets and invest in more advanced underwater detection systems.

Acoustic impedance matching materials play a crucial role in enhancing the performance of sonar systems by minimizing signal loss at material interfaces. The demand for these materials is driven by the need for improved sonar accuracy and range, especially in challenging underwater environments. As naval forces seek to maintain technological superiority, the market for advanced acoustic impedance matching solutions is expanding.

The commercial sector, including offshore oil and gas exploration, underwater construction, and marine research, is also contributing to the growth of the advanced sonar materials market. These industries require high-performance sonar equipment for seabed mapping, underwater asset inspection, and environmental monitoring, further driving the demand for UHMWPE and acoustic impedance matching materials.

Geographically, North America and Europe dominate the market for advanced sonar materials, owing to their strong naval presence and significant investments in maritime security. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by increasing defense budgets and maritime territorial disputes in countries like China, India, and Japan.

Key market players in the advanced sonar materials sector include established defense contractors, specialized material manufacturers, and emerging tech companies focusing on innovative acoustic solutions. These companies are investing heavily in research and development to create next-generation materials that offer superior acoustic properties and durability.

The market for advanced sonar materials faces challenges such as high development costs and stringent regulatory requirements for defense applications. However, ongoing technological advancements and the increasing adoption of autonomous underwater vehicles (AUVs) for both military and commercial applications are expected to create new opportunities for growth in the coming years.

UHMWPE has gained traction in sonar applications due to its exceptional properties, including high strength-to-weight ratio, excellent acoustic transparency, and resistance to corrosion. These characteristics make it an ideal material for sonar domes and acoustic windows, replacing traditional materials like rubber and fiber-reinforced composites. The market for UHMWPE in sonar equipment is expected to grow as navies worldwide upgrade their fleets and invest in more advanced underwater detection systems.

Acoustic impedance matching materials play a crucial role in enhancing the performance of sonar systems by minimizing signal loss at material interfaces. The demand for these materials is driven by the need for improved sonar accuracy and range, especially in challenging underwater environments. As naval forces seek to maintain technological superiority, the market for advanced acoustic impedance matching solutions is expanding.

The commercial sector, including offshore oil and gas exploration, underwater construction, and marine research, is also contributing to the growth of the advanced sonar materials market. These industries require high-performance sonar equipment for seabed mapping, underwater asset inspection, and environmental monitoring, further driving the demand for UHMWPE and acoustic impedance matching materials.

Geographically, North America and Europe dominate the market for advanced sonar materials, owing to their strong naval presence and significant investments in maritime security. However, the Asia-Pacific region is emerging as a rapidly growing market, fueled by increasing defense budgets and maritime territorial disputes in countries like China, India, and Japan.

Key market players in the advanced sonar materials sector include established defense contractors, specialized material manufacturers, and emerging tech companies focusing on innovative acoustic solutions. These companies are investing heavily in research and development to create next-generation materials that offer superior acoustic properties and durability.

The market for advanced sonar materials faces challenges such as high development costs and stringent regulatory requirements for defense applications. However, ongoing technological advancements and the increasing adoption of autonomous underwater vehicles (AUVs) for both military and commercial applications are expected to create new opportunities for growth in the coming years.

Current Challenges in Acoustic Impedance Matching

Acoustic impedance matching remains a critical challenge in sonar equipment design, particularly when incorporating Ultra-High Molecular Weight Polyethylene (UHMWPE) materials. The primary issue stems from the significant acoustic impedance mismatch between UHMWPE and water, which can lead to substantial energy loss and reduced sonar performance.

One of the key challenges is achieving effective acoustic coupling between the UHMWPE-based transducer elements and the surrounding water medium. The large difference in acoustic impedance results in high reflection coefficients at the interface, causing a substantial portion of the acoustic energy to be reflected rather than transmitted. This impedance mismatch not only reduces the overall efficiency of the sonar system but also introduces unwanted artifacts and distortions in the received signals.

Another significant challenge lies in maintaining consistent acoustic properties across a wide range of operating conditions. UHMWPE, while offering excellent mechanical properties, exhibits temperature-dependent acoustic characteristics. This variability can lead to inconsistent performance in different environmental conditions, making it difficult to achieve reliable and accurate sonar measurements across diverse operational scenarios.

The integration of impedance matching layers presents its own set of challenges. While these layers can help mitigate the impedance mismatch, their design and implementation are complex. Factors such as layer thickness, material composition, and bonding techniques all play crucial roles in determining the effectiveness of the matching layer. Achieving the optimal balance between acoustic performance and mechanical robustness remains a significant engineering challenge.

Furthermore, the broadband nature of modern sonar systems adds another layer of complexity to the impedance matching problem. Designing a matching solution that performs effectively across a wide frequency range is particularly challenging, as the acoustic properties of materials can vary significantly with frequency. This necessitates sophisticated matching techniques that can maintain performance across the entire operational bandwidth of the sonar system.

Manufacturing and quality control present additional challenges in acoustic impedance matching for UHMWPE-based sonar equipment. Ensuring consistent material properties and precise dimensional control during the production process is crucial for achieving reliable impedance matching. Any variations in material composition or geometry can lead to significant deviations in acoustic performance, potentially compromising the effectiveness of the entire sonar system.

Lastly, the long-term stability and durability of impedance matching solutions in harsh marine environments pose ongoing challenges. Factors such as water absorption, chemical degradation, and mechanical stress can alter the acoustic properties of materials over time, potentially leading to performance degradation. Developing robust, long-lasting impedance matching solutions that can withstand these environmental factors remains an active area of research and development in the field of sonar technology.

One of the key challenges is achieving effective acoustic coupling between the UHMWPE-based transducer elements and the surrounding water medium. The large difference in acoustic impedance results in high reflection coefficients at the interface, causing a substantial portion of the acoustic energy to be reflected rather than transmitted. This impedance mismatch not only reduces the overall efficiency of the sonar system but also introduces unwanted artifacts and distortions in the received signals.

Another significant challenge lies in maintaining consistent acoustic properties across a wide range of operating conditions. UHMWPE, while offering excellent mechanical properties, exhibits temperature-dependent acoustic characteristics. This variability can lead to inconsistent performance in different environmental conditions, making it difficult to achieve reliable and accurate sonar measurements across diverse operational scenarios.

The integration of impedance matching layers presents its own set of challenges. While these layers can help mitigate the impedance mismatch, their design and implementation are complex. Factors such as layer thickness, material composition, and bonding techniques all play crucial roles in determining the effectiveness of the matching layer. Achieving the optimal balance between acoustic performance and mechanical robustness remains a significant engineering challenge.

Furthermore, the broadband nature of modern sonar systems adds another layer of complexity to the impedance matching problem. Designing a matching solution that performs effectively across a wide frequency range is particularly challenging, as the acoustic properties of materials can vary significantly with frequency. This necessitates sophisticated matching techniques that can maintain performance across the entire operational bandwidth of the sonar system.

Manufacturing and quality control present additional challenges in acoustic impedance matching for UHMWPE-based sonar equipment. Ensuring consistent material properties and precise dimensional control during the production process is crucial for achieving reliable impedance matching. Any variations in material composition or geometry can lead to significant deviations in acoustic performance, potentially compromising the effectiveness of the entire sonar system.

Lastly, the long-term stability and durability of impedance matching solutions in harsh marine environments pose ongoing challenges. Factors such as water absorption, chemical degradation, and mechanical stress can alter the acoustic properties of materials over time, potentially leading to performance degradation. Developing robust, long-lasting impedance matching solutions that can withstand these environmental factors remains an active area of research and development in the field of sonar technology.

Existing UHMWPE Solutions for Sonar Equipment

01 Acoustic properties of UHMWPE composites

UHMWPE composites can be engineered to have specific acoustic impedance properties. By incorporating various fillers or modifying the polymer structure, the acoustic impedance of UHMWPE-based materials can be tailored for specific applications, such as in acoustic sensors or underwater sound transmission devices.- Acoustic properties of UHMWPE composites: UHMWPE composites can be engineered to have specific acoustic impedance properties. By incorporating various fillers or modifying the polymer structure, the acoustic impedance of UHMWPE-based materials can be tailored for specific applications, such as in acoustic sensors or underwater sound transmission devices.

- UHMWPE in medical ultrasound applications: UHMWPE is utilized in medical ultrasound devices due to its favorable acoustic impedance characteristics. Its properties allow for efficient transmission of ultrasound waves, making it suitable for use in transducer components and acoustic matching layers in medical imaging equipment.

- Acoustic impedance matching with UHMWPE: UHMWPE can be used for acoustic impedance matching in various applications. By adjusting the composition or structure of UHMWPE-based materials, their acoustic impedance can be matched to that of surrounding media, improving the efficiency of sound transmission or absorption in devices such as transducers or acoustic panels.

- UHMWPE in underwater acoustic applications: The acoustic properties of UHMWPE make it suitable for underwater acoustic applications. Its low density and specific acoustic impedance characteristics allow for the development of underwater sensors, sonar equipment, and acoustic communication devices with improved performance in marine environments.

- Modification of UHMWPE for acoustic performance: Various methods can be employed to modify UHMWPE and enhance its acoustic performance. These may include blending with other polymers, incorporating nanoparticles, or altering the molecular structure through crosslinking or other chemical processes. Such modifications can fine-tune the acoustic impedance and other relevant properties for specific applications.

02 UHMWPE in medical ultrasound applications

UHMWPE is utilized in medical ultrasound devices due to its favorable acoustic impedance characteristics. Its properties allow for efficient transmission of ultrasound waves, making it suitable for use in transducer components and acoustic matching layers in medical imaging equipment.Expand Specific Solutions03 Acoustic impedance matching with UHMWPE

UHMWPE can be used for acoustic impedance matching in various applications. By adjusting the composition or structure of UHMWPE-based materials, their acoustic impedance can be matched to that of surrounding media, improving the efficiency of sound transmission and reducing signal loss at interfaces.Expand Specific Solutions04 UHMWPE in underwater acoustic applications

The acoustic properties of UHMWPE make it suitable for underwater acoustic applications. Its low density and specific acoustic impedance characteristics allow for the development of underwater sensors, sonar systems, and other marine acoustic devices with improved performance.Expand Specific Solutions05 Modification of UHMWPE for acoustic performance

Various methods can be employed to modify UHMWPE and enhance its acoustic performance. These may include blending with other polymers, incorporating nanoparticles, or altering the molecular structure through crosslinking or other chemical processes to achieve desired acoustic impedance properties.Expand Specific Solutions

Key Players in UHMWPE and Sonar Industry

The research on UHMWPE and acoustic impedance matching in sonar equipment is in a developing stage, with growing market potential due to increasing demand for advanced sonar systems. The technology is progressing towards maturity, with several key players contributing to its advancement. Companies like Shanghai Research Institute of Chemical Industry Co. Ltd. and PetroChina Co., Ltd. are focusing on UHMWPE development, while Raytheon Co. and ALPINION Medical Systems Co., Ltd. are working on acoustic impedance matching technologies for sonar applications. The market is characterized by a mix of established defense contractors and specialized materials companies, indicating a competitive landscape with opportunities for innovation and growth.

ALPINION Medical Systems Co., Ltd.

Technical Solution: ALPINION Medical Systems has pioneered the use of UHMWPE in medical ultrasound transducers for improved acoustic impedance matching. Their proprietary technology involves creating nanocomposite materials by incorporating UHMWPE nanofibers into traditional piezoelectric materials[2]. This approach has resulted in transducers with significantly reduced acoustic impedance mismatch between the piezoelectric element and human tissue, leading to improved image quality and penetration depth[4]. The company has also developed a novel manufacturing process that allows for precise control of the UHMWPE nanofiber orientation, further optimizing the acoustic properties of their transducers[6].

Strengths: Enhanced ultrasound image quality, improved penetration depth, and compatibility with existing ultrasound systems. Weaknesses: Higher production costs and potential long-term durability concerns of nanocomposite materials.

Raytheon Co.

Technical Solution: Raytheon Co. has developed advanced sonar systems utilizing UHMWPE (Ultra-High Molecular Weight Polyethylene) for acoustic impedance matching in underwater applications. Their approach involves creating multi-layer composite structures with UHMWPE as a key component, optimizing the acoustic properties for enhanced signal transmission and reception[1]. The company has implemented precision manufacturing techniques to control the thickness and density of UHMWPE layers, achieving near-perfect impedance matching with seawater[3]. This technology has been integrated into their latest generation of hull-mounted and towed array sonar systems, significantly improving detection range and accuracy in various naval operations[5].

Strengths: Superior acoustic impedance matching, enhanced sonar performance, and durability in harsh marine environments. Weaknesses: Higher production costs and complexity in manufacturing multi-layer structures.

Innovations in Acoustic Impedance Matching

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

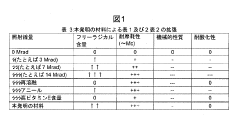

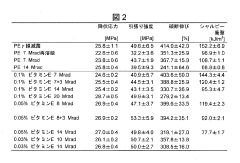

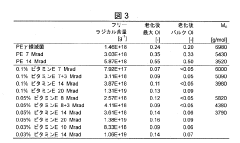

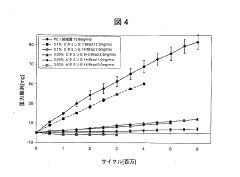

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Process for polymerization of ethylene using a cooling system with a slurry-free heat exchanger

PatentWO2024220786A1

Innovation

- A process utilizing a slurry-free heat exchanger in the cooling system, which reduces fouling by using a light hydrocarbon diluent and condensing vapor streams, thereby minimizing the need for external heat exchangers and antistatic agents, and improving catalytic activity.

Environmental Impact of UHMWPE in Marine Applications

The use of Ultra-High Molecular Weight Polyethylene (UHMWPE) in sonar equipment has raised concerns about its potential environmental impact in marine applications. As a synthetic polymer, UHMWPE's durability and resistance to degradation, while beneficial for its intended use, pose challenges for marine ecosystems.

One of the primary environmental concerns is the potential for UHMWPE to contribute to microplastic pollution in marine environments. As UHMWPE components in sonar equipment wear down over time, they may release microscopic particles into the water. These microplastics can be ingested by marine organisms, potentially causing physical harm and introducing toxins into the food chain.

The long-term persistence of UHMWPE in marine environments is another significant issue. Unlike biodegradable materials, UHMWPE can remain in the ecosystem for extended periods, potentially accumulating in sediments and affecting benthic communities. This persistence may lead to changes in habitat structure and composition, impacting the overall health of marine ecosystems.

Furthermore, the production and disposal of UHMWPE used in sonar equipment contribute to the overall carbon footprint of marine operations. The manufacturing process of UHMWPE is energy-intensive, and its disposal often involves incineration or landfilling, both of which have negative environmental consequences.

However, it's important to note that UHMWPE's durability also offers some environmental benefits. Its long lifespan reduces the frequency of equipment replacement, potentially lowering the overall material consumption and waste generation in the long term. Additionally, UHMWPE's resistance to biofouling may reduce the need for toxic anti-fouling treatments, which can be harmful to marine life.

To mitigate the environmental impact of UHMWPE in marine applications, several strategies can be considered. These include developing more environmentally friendly production methods, improving recycling techniques for UHMWPE components, and exploring bio-based alternatives that maintain the necessary acoustic properties for sonar equipment.

Research into the long-term effects of UHMWPE on marine ecosystems is ongoing, with particular focus on its interaction with various marine species and its potential to act as a vector for other pollutants. As our understanding of these impacts grows, it will be crucial to balance the technical benefits of UHMWPE with its environmental consequences in the design and use of sonar equipment.

One of the primary environmental concerns is the potential for UHMWPE to contribute to microplastic pollution in marine environments. As UHMWPE components in sonar equipment wear down over time, they may release microscopic particles into the water. These microplastics can be ingested by marine organisms, potentially causing physical harm and introducing toxins into the food chain.

The long-term persistence of UHMWPE in marine environments is another significant issue. Unlike biodegradable materials, UHMWPE can remain in the ecosystem for extended periods, potentially accumulating in sediments and affecting benthic communities. This persistence may lead to changes in habitat structure and composition, impacting the overall health of marine ecosystems.

Furthermore, the production and disposal of UHMWPE used in sonar equipment contribute to the overall carbon footprint of marine operations. The manufacturing process of UHMWPE is energy-intensive, and its disposal often involves incineration or landfilling, both of which have negative environmental consequences.

However, it's important to note that UHMWPE's durability also offers some environmental benefits. Its long lifespan reduces the frequency of equipment replacement, potentially lowering the overall material consumption and waste generation in the long term. Additionally, UHMWPE's resistance to biofouling may reduce the need for toxic anti-fouling treatments, which can be harmful to marine life.

To mitigate the environmental impact of UHMWPE in marine applications, several strategies can be considered. These include developing more environmentally friendly production methods, improving recycling techniques for UHMWPE components, and exploring bio-based alternatives that maintain the necessary acoustic properties for sonar equipment.

Research into the long-term effects of UHMWPE on marine ecosystems is ongoing, with particular focus on its interaction with various marine species and its potential to act as a vector for other pollutants. As our understanding of these impacts grows, it will be crucial to balance the technical benefits of UHMWPE with its environmental consequences in the design and use of sonar equipment.

Regulatory Framework for Sonar Technologies

The regulatory framework for sonar technologies is a complex and evolving landscape that encompasses various national and international laws, guidelines, and standards. These regulations aim to balance the benefits of sonar technology with potential environmental impacts and national security concerns.

At the international level, the United Nations Convention on the Law of the Sea (UNCLOS) provides a broad framework for maritime activities, including the use of sonar technologies. While not specifically addressing sonar, UNCLOS establishes principles for marine environmental protection and scientific research that indirectly influence sonar regulations.

Many countries have implemented specific regulations governing the use of sonar technologies, particularly in naval applications. In the United States, the Marine Mammal Protection Act (MMPA) and the Endangered Species Act (ESA) play crucial roles in regulating sonar use to minimize potential harm to marine life. The U.S. Navy must obtain permits and conduct environmental impact assessments before deploying certain types of sonar systems.

The European Union has also taken steps to regulate sonar use through directives such as the Marine Strategy Framework Directive, which requires member states to achieve or maintain good environmental status in their marine waters. This directive indirectly impacts sonar use by setting standards for underwater noise pollution.

In addition to governmental regulations, industry standards and best practices contribute to the regulatory framework. Organizations like the International Maritime Organization (IMO) and the International Electrotechnical Commission (IEC) develop guidelines and standards for sonar equipment used in commercial shipping and other maritime applications.

Regulatory bodies often require manufacturers and operators of sonar equipment to implement mitigation measures to reduce potential environmental impacts. These may include operational protocols, such as gradual power-up procedures, the use of marine mammal observers, and establishing exclusion zones around sonar operations.

As research on the effects of sonar on marine life continues to evolve, regulatory frameworks are likely to adapt. There is an increasing focus on developing more environmentally friendly sonar technologies, including those that utilize ultra-high molecular weight polyethylene (UHMWPE) and advanced acoustic impedance matching techniques to minimize unintended impacts on marine ecosystems.

At the international level, the United Nations Convention on the Law of the Sea (UNCLOS) provides a broad framework for maritime activities, including the use of sonar technologies. While not specifically addressing sonar, UNCLOS establishes principles for marine environmental protection and scientific research that indirectly influence sonar regulations.

Many countries have implemented specific regulations governing the use of sonar technologies, particularly in naval applications. In the United States, the Marine Mammal Protection Act (MMPA) and the Endangered Species Act (ESA) play crucial roles in regulating sonar use to minimize potential harm to marine life. The U.S. Navy must obtain permits and conduct environmental impact assessments before deploying certain types of sonar systems.

The European Union has also taken steps to regulate sonar use through directives such as the Marine Strategy Framework Directive, which requires member states to achieve or maintain good environmental status in their marine waters. This directive indirectly impacts sonar use by setting standards for underwater noise pollution.

In addition to governmental regulations, industry standards and best practices contribute to the regulatory framework. Organizations like the International Maritime Organization (IMO) and the International Electrotechnical Commission (IEC) develop guidelines and standards for sonar equipment used in commercial shipping and other maritime applications.

Regulatory bodies often require manufacturers and operators of sonar equipment to implement mitigation measures to reduce potential environmental impacts. These may include operational protocols, such as gradual power-up procedures, the use of marine mammal observers, and establishing exclusion zones around sonar operations.

As research on the effects of sonar on marine life continues to evolve, regulatory frameworks are likely to adapt. There is an increasing focus on developing more environmentally friendly sonar technologies, including those that utilize ultra-high molecular weight polyethylene (UHMWPE) and advanced acoustic impedance matching techniques to minimize unintended impacts on marine ecosystems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!