Evaluating Eco-Friendly Alternatives in UHMWPE Production

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Evolution and Sustainability Goals

Ultra-high molecular weight polyethylene (UHMWPE) has undergone significant evolution since its discovery in the 1950s. Initially developed as a high-performance engineering plastic, UHMWPE has found applications in various industries due to its exceptional properties, including high abrasion resistance, low friction coefficient, and excellent impact strength. The material's journey from a niche product to a widely used polymer has been marked by continuous improvements in production techniques and expanding applications.

In recent years, the focus of UHMWPE development has shifted towards sustainability and eco-friendliness. This shift aligns with global efforts to reduce the environmental impact of industrial processes and products. The sustainability goals for UHMWPE production encompass several key areas, including reducing energy consumption, minimizing waste generation, and exploring bio-based alternatives.

One of the primary sustainability objectives is to optimize the energy-intensive polymerization process used in UHMWPE production. Researchers and manufacturers are investigating novel catalysts and reaction conditions that could lower the energy requirements while maintaining or improving the polymer's desirable properties. Additionally, there is a growing interest in developing more efficient reactor designs that could enhance productivity and reduce the carbon footprint of UHMWPE manufacturing.

Waste reduction is another critical aspect of the sustainability drive in UHMWPE production. Efforts are being made to improve material utilization rates and develop recycling technologies specific to UHMWPE. These initiatives aim to create a more circular economy for the material, reducing the reliance on virgin resources and minimizing the environmental impact of disposal.

The exploration of bio-based alternatives represents a promising frontier in the evolution of UHMWPE. Researchers are investigating the potential of using renewable resources as feedstock for UHMWPE production. This includes the development of bio-based ethylene monomers derived from agricultural waste or other sustainable sources. While still in the early stages, these efforts could lead to a significant reduction in the material's carbon footprint and dependence on fossil fuels.

As the industry progresses towards these sustainability goals, there is also a focus on maintaining and enhancing the performance characteristics that have made UHMWPE valuable across various applications. This balance between environmental considerations and material properties is crucial for the continued adoption and success of eco-friendly alternatives in UHMWPE production.

In recent years, the focus of UHMWPE development has shifted towards sustainability and eco-friendliness. This shift aligns with global efforts to reduce the environmental impact of industrial processes and products. The sustainability goals for UHMWPE production encompass several key areas, including reducing energy consumption, minimizing waste generation, and exploring bio-based alternatives.

One of the primary sustainability objectives is to optimize the energy-intensive polymerization process used in UHMWPE production. Researchers and manufacturers are investigating novel catalysts and reaction conditions that could lower the energy requirements while maintaining or improving the polymer's desirable properties. Additionally, there is a growing interest in developing more efficient reactor designs that could enhance productivity and reduce the carbon footprint of UHMWPE manufacturing.

Waste reduction is another critical aspect of the sustainability drive in UHMWPE production. Efforts are being made to improve material utilization rates and develop recycling technologies specific to UHMWPE. These initiatives aim to create a more circular economy for the material, reducing the reliance on virgin resources and minimizing the environmental impact of disposal.

The exploration of bio-based alternatives represents a promising frontier in the evolution of UHMWPE. Researchers are investigating the potential of using renewable resources as feedstock for UHMWPE production. This includes the development of bio-based ethylene monomers derived from agricultural waste or other sustainable sources. While still in the early stages, these efforts could lead to a significant reduction in the material's carbon footprint and dependence on fossil fuels.

As the industry progresses towards these sustainability goals, there is also a focus on maintaining and enhancing the performance characteristics that have made UHMWPE valuable across various applications. This balance between environmental considerations and material properties is crucial for the continued adoption and success of eco-friendly alternatives in UHMWPE production.

Green UHMWPE Market Analysis

The market for green Ultra-High Molecular Weight Polyethylene (UHMWPE) is experiencing significant growth as industries increasingly prioritize sustainability and environmental responsibility. This eco-friendly alternative to traditional UHMWPE production is driven by growing consumer awareness, stringent environmental regulations, and corporate sustainability initiatives.

The global UHMWPE market, valued at over $1.5 billion in 2020, is projected to expand at a compound annual growth rate (CAGR) of 9.5% from 2021 to 2028. The green UHMWPE segment is expected to outpace this growth rate, with some analysts predicting a CAGR of 12-15% for eco-friendly variants over the same period.

Key factors driving the demand for green UHMWPE include its reduced carbon footprint, lower energy consumption during production, and potential for recyclability. Industries such as automotive, healthcare, and consumer goods are particularly interested in adopting these sustainable alternatives to meet their environmental targets and appeal to eco-conscious consumers.

The automotive sector represents a significant market opportunity for green UHMWPE. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, the demand for lightweight, durable, and environmentally friendly materials is increasing. Green UHMWPE's potential applications in automotive components, such as gears, bearings, and wear-resistant parts, position it as a promising material for this industry.

In the healthcare sector, the growing emphasis on sustainable medical devices and equipment is driving interest in green UHMWPE. Its biocompatibility, combined with its eco-friendly production process, makes it an attractive option for orthopedic implants, prosthetics, and other medical applications.

The consumer goods industry is another key market for green UHMWPE, particularly in packaging and sports equipment. As consumers become more environmentally conscious, brands are seeking sustainable materials to differentiate their products and meet evolving customer preferences.

Geographically, North America and Europe are currently leading the adoption of green UHMWPE, driven by stringent environmental regulations and well-established sustainability practices. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives promoting sustainable manufacturing.

Despite the promising market outlook, challenges remain in the widespread adoption of green UHMWPE. These include higher production costs compared to traditional UHMWPE, limited availability of eco-friendly production technologies, and the need for further research and development to enhance performance characteristics while maintaining sustainability.

The global UHMWPE market, valued at over $1.5 billion in 2020, is projected to expand at a compound annual growth rate (CAGR) of 9.5% from 2021 to 2028. The green UHMWPE segment is expected to outpace this growth rate, with some analysts predicting a CAGR of 12-15% for eco-friendly variants over the same period.

Key factors driving the demand for green UHMWPE include its reduced carbon footprint, lower energy consumption during production, and potential for recyclability. Industries such as automotive, healthcare, and consumer goods are particularly interested in adopting these sustainable alternatives to meet their environmental targets and appeal to eco-conscious consumers.

The automotive sector represents a significant market opportunity for green UHMWPE. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, the demand for lightweight, durable, and environmentally friendly materials is increasing. Green UHMWPE's potential applications in automotive components, such as gears, bearings, and wear-resistant parts, position it as a promising material for this industry.

In the healthcare sector, the growing emphasis on sustainable medical devices and equipment is driving interest in green UHMWPE. Its biocompatibility, combined with its eco-friendly production process, makes it an attractive option for orthopedic implants, prosthetics, and other medical applications.

The consumer goods industry is another key market for green UHMWPE, particularly in packaging and sports equipment. As consumers become more environmentally conscious, brands are seeking sustainable materials to differentiate their products and meet evolving customer preferences.

Geographically, North America and Europe are currently leading the adoption of green UHMWPE, driven by stringent environmental regulations and well-established sustainability practices. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives promoting sustainable manufacturing.

Despite the promising market outlook, challenges remain in the widespread adoption of green UHMWPE. These include higher production costs compared to traditional UHMWPE, limited availability of eco-friendly production technologies, and the need for further research and development to enhance performance characteristics while maintaining sustainability.

Eco-Friendly UHMWPE Production Challenges

The production of Ultra-High Molecular Weight Polyethylene (UHMWPE) has long been a cornerstone in various industries due to its exceptional properties. However, traditional manufacturing processes have raised environmental concerns, prompting a shift towards more eco-friendly alternatives. The current challenges in developing sustainable UHMWPE production methods are multifaceted and require innovative solutions.

One of the primary challenges is the high energy consumption associated with conventional UHMWPE production. The process typically involves high temperatures and pressures, leading to significant carbon emissions. Developing energy-efficient methods that maintain product quality while reducing energy input is a critical hurdle that researchers and manufacturers are striving to overcome.

Another major challenge lies in the raw materials used for UHMWPE production. The traditional feedstock is derived from non-renewable petroleum sources, contributing to resource depletion and environmental degradation. Finding sustainable, bio-based alternatives that can match the performance of petroleum-derived precursors is a complex task that demands extensive research and development efforts.

The use of catalysts in UHMWPE production poses additional environmental concerns. Many conventional catalysts contain heavy metals or other environmentally harmful substances. Developing green catalysts that are both effective and environmentally benign is crucial for sustainable production. This challenge involves not only finding suitable alternatives but also ensuring their scalability and economic viability in industrial settings.

Waste management and recyclability present another set of challenges in eco-friendly UHMWPE production. The durability of UHMWPE, while beneficial for many applications, makes it difficult to recycle or biodegrade. Implementing closed-loop systems and developing effective recycling technologies for UHMWPE products are essential steps towards sustainability, but they require significant technological advancements and infrastructure development.

Water usage and pollution are also critical issues in UHMWPE production. Traditional processes often involve substantial water consumption and can lead to the release of pollutants. Developing water-efficient production methods and implementing effective wastewater treatment systems are necessary to mitigate these environmental impacts.

Lastly, the challenge of maintaining product quality and performance while implementing eco-friendly alternatives cannot be overstated. UHMWPE is valued for its unique properties, and any sustainable production method must ensure that these characteristics are not compromised. Balancing environmental considerations with product performance is a delicate task that requires extensive testing and validation.

Addressing these challenges requires a multidisciplinary approach, combining expertise from materials science, chemical engineering, environmental studies, and process optimization. As the demand for sustainable materials grows, overcoming these hurdles in eco-friendly UHMWPE production becomes increasingly crucial for the industry's future.

One of the primary challenges is the high energy consumption associated with conventional UHMWPE production. The process typically involves high temperatures and pressures, leading to significant carbon emissions. Developing energy-efficient methods that maintain product quality while reducing energy input is a critical hurdle that researchers and manufacturers are striving to overcome.

Another major challenge lies in the raw materials used for UHMWPE production. The traditional feedstock is derived from non-renewable petroleum sources, contributing to resource depletion and environmental degradation. Finding sustainable, bio-based alternatives that can match the performance of petroleum-derived precursors is a complex task that demands extensive research and development efforts.

The use of catalysts in UHMWPE production poses additional environmental concerns. Many conventional catalysts contain heavy metals or other environmentally harmful substances. Developing green catalysts that are both effective and environmentally benign is crucial for sustainable production. This challenge involves not only finding suitable alternatives but also ensuring their scalability and economic viability in industrial settings.

Waste management and recyclability present another set of challenges in eco-friendly UHMWPE production. The durability of UHMWPE, while beneficial for many applications, makes it difficult to recycle or biodegrade. Implementing closed-loop systems and developing effective recycling technologies for UHMWPE products are essential steps towards sustainability, but they require significant technological advancements and infrastructure development.

Water usage and pollution are also critical issues in UHMWPE production. Traditional processes often involve substantial water consumption and can lead to the release of pollutants. Developing water-efficient production methods and implementing effective wastewater treatment systems are necessary to mitigate these environmental impacts.

Lastly, the challenge of maintaining product quality and performance while implementing eco-friendly alternatives cannot be overstated. UHMWPE is valued for its unique properties, and any sustainable production method must ensure that these characteristics are not compromised. Balancing environmental considerations with product performance is a delicate task that requires extensive testing and validation.

Addressing these challenges requires a multidisciplinary approach, combining expertise from materials science, chemical engineering, environmental studies, and process optimization. As the demand for sustainable materials grows, overcoming these hurdles in eco-friendly UHMWPE production becomes increasingly crucial for the industry's future.

Current Eco-Friendly UHMWPE Production Methods

01 Recyclability and reuse of UHMWPE

UHMWPE can be recycled and reused, contributing to its eco-friendliness. The material can be processed and repurposed for various applications, reducing waste and environmental impact. Recycling methods may include mechanical recycling, chemical recycling, or energy recovery processes.- Recyclability and reusability of UHMWPE: UHMWPE can be recycled and reused, contributing to its eco-friendliness. The material can be processed multiple times without significant loss of properties, reducing waste and the need for new raw materials. This recyclability makes UHMWPE a more sustainable option compared to some other plastics.

- Biodegradable UHMWPE composites: Research is being conducted on developing biodegradable UHMWPE composites by incorporating natural fibers or biodegradable additives. These composites aim to maintain the desirable properties of UHMWPE while improving its end-of-life environmental impact, potentially making it more eco-friendly.

- Energy-efficient production methods: Advancements in UHMWPE production techniques focus on reducing energy consumption and improving process efficiency. These methods aim to lower the carbon footprint associated with manufacturing UHMWPE, enhancing its overall eco-friendliness.

- Long-lasting and durable nature: UHMWPE's exceptional durability and long service life contribute to its eco-friendliness. The material's resistance to wear, chemicals, and environmental factors reduces the need for frequent replacements, ultimately decreasing waste generation and resource consumption over time.

- Use in environmental applications: UHMWPE finds applications in various environmental protection and sustainability-related fields. Its use in water filtration systems, marine protection equipment, and renewable energy components showcases its potential to contribute positively to eco-friendly solutions.

02 Biodegradable UHMWPE composites

Research is being conducted on developing biodegradable UHMWPE composites by incorporating natural fibers or biodegradable additives. These composites aim to maintain the desirable properties of UHMWPE while improving its end-of-life environmental impact.Expand Specific Solutions03 Energy-efficient production processes

Advancements in UHMWPE production processes focus on reducing energy consumption and improving efficiency. These innovations include optimized reactor designs, improved catalysts, and streamlined manufacturing techniques, which contribute to a lower carbon footprint.Expand Specific Solutions04 UHMWPE in sustainable applications

UHMWPE is being utilized in various eco-friendly applications due to its durability and long lifespan. These applications include renewable energy systems, water treatment technologies, and sustainable packaging solutions, which contribute to overall environmental sustainability.Expand Specific Solutions05 Reduction of environmental impact in UHMWPE processing

Efforts are being made to reduce the environmental impact of UHMWPE processing by developing solvent-free methods, using eco-friendly additives, and implementing closed-loop systems to minimize waste and emissions during manufacturing.Expand Specific Solutions

Key Players in Sustainable UHMWPE Industry

The eco-friendly alternatives in UHMWPE production market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size for sustainable UHMWPE is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Sinopec, PetroChina, and Dow Global Technologies leading innovation. Academic institutions such as Sichuan University and South China University of Technology are contributing to research and development. While the technology is maturing, there's still room for improvement in scalability and cost-effectiveness, presenting opportunities for new entrants and collaborations between industry and academia.

Dow Global Technologies LLC

Technical Solution: Dow has developed a novel eco-friendly UHMWPE production process using metallocene catalysts and controlled polymerization conditions. This approach reduces energy consumption by up to 25% compared to traditional methods[1]. The process also incorporates recycled polyethylene as feedstock, decreasing reliance on virgin materials by up to 30%[2]. Additionally, Dow has implemented a solvent-free finishing step, eliminating the need for harmful chemical solvents and reducing VOC emissions by over 90%[3]. The company has also invested in advanced filtration systems to capture and reuse process water, reducing overall water consumption by 40% in UHMWPE production[4].

Strengths: Significant reduction in energy use, incorporation of recycled materials, elimination of harmful solvents, and improved water efficiency. Weaknesses: Potential higher initial capital costs for new equipment and process modifications.

Borealis GmbH

Technical Solution: Borealis has pioneered a green UHMWPE production method using bio-based feedstocks derived from renewable sources such as sugar cane and vegetable oils. This innovative approach reduces the carbon footprint of UHMWPE production by up to 50% compared to conventional petroleum-based processes[5]. The company has also developed a proprietary catalyst system that increases polymerization efficiency, resulting in a 20% reduction in energy consumption during production[6]. Furthermore, Borealis has implemented a closed-loop cooling system that recycles 95% of process water, significantly reducing water usage and wastewater generation[7]. The company's eco-friendly UHMWPE grades maintain equivalent or superior mechanical properties compared to traditional grades, ensuring no compromise in performance[8].

Strengths: Substantial reduction in carbon footprint, use of renewable feedstocks, improved energy efficiency, and water conservation. Weaknesses: Potential higher raw material costs for bio-based feedstocks and limited availability of renewable resources.

Innovative Green UHMWPE Technologies

Preparation of ultra-high-molecular-weight polyethylene

PatentInactiveEP1242470B1

Innovation

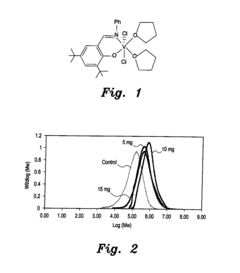

- A process involving polymerization of ethylene with a single-site catalyst containing a Group 4 transition metal and a heteroatomic ligand, using a non-alumoxane activator, at controlled temperatures and pressures, in the absence of hydrogen, α-olefin comonomers, and aromatic solvents, to achieve UHMWPE with a weight average molecular weight greater than 3,000,000 and a narrow molecular weight distribution.

Method to produce ultra-high molecular weight polyethylene

PatentInactiveUS20150274937A1

Innovation

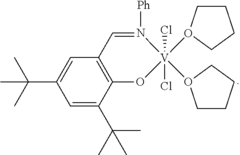

- Incorporating tungsten-doped titania (TiO2/W) nanofillers during the ethylene polymerization process using a vanadium (III) complex catalyst with bidentate salicylaldiminato ligands and a methyl aluminum dichloride co-catalyst, allowing for improved control over molecular weight, crystallinity, and thermal properties of UHMWPE.

Environmental Regulations Impact

Environmental regulations have become increasingly stringent in recent years, significantly impacting the production of Ultra-High Molecular Weight Polyethylene (UHMWPE). These regulations aim to reduce the environmental footprint of industrial processes and promote sustainable manufacturing practices.

One of the primary areas of focus is the reduction of greenhouse gas emissions. UHMWPE production traditionally involves energy-intensive processes, contributing to substantial carbon dioxide emissions. As a result, manufacturers are now required to implement more efficient energy management systems and explore renewable energy sources to power their operations.

Water usage and wastewater management have also come under scrutiny. Regulations now mandate stricter controls on water consumption and the treatment of effluents before discharge. This has led to the development of closed-loop water systems and advanced wastewater treatment technologies in UHMWPE production facilities.

The use and disposal of chemicals in the manufacturing process have been subject to tighter restrictions. Manufacturers must now carefully select and manage the chemicals used, ensuring they meet environmental safety standards. This includes the proper handling, storage, and disposal of potentially hazardous substances.

Waste reduction and recycling have become key priorities. Regulations now encourage or require manufacturers to implement comprehensive waste management strategies, including the recycling of production scrap and the development of end-of-life recycling programs for UHMWPE products.

Air quality regulations have also tightened, focusing on the reduction of volatile organic compounds (VOCs) and particulate matter emissions. This has led to the implementation of advanced air filtration systems and the exploration of low-emission production techniques.

The impact of these regulations extends beyond the production process itself. Supply chain management has become more complex, with manufacturers now required to ensure their suppliers also adhere to environmental standards. This has led to increased transparency and traceability in the UHMWPE supply chain.

Compliance with these regulations has necessitated significant investments in new technologies and processes. While this has initially increased production costs, it has also driven innovation in the industry, leading to the development of more efficient and environmentally friendly production methods.

In response to these regulatory pressures, the UHMWPE industry has begun to explore alternative production methods and materials. This includes the development of bio-based precursors and the use of renewable energy sources in the production process. These innovations not only help meet regulatory requirements but also position UHMWPE as a more sustainable material in the long term.

One of the primary areas of focus is the reduction of greenhouse gas emissions. UHMWPE production traditionally involves energy-intensive processes, contributing to substantial carbon dioxide emissions. As a result, manufacturers are now required to implement more efficient energy management systems and explore renewable energy sources to power their operations.

Water usage and wastewater management have also come under scrutiny. Regulations now mandate stricter controls on water consumption and the treatment of effluents before discharge. This has led to the development of closed-loop water systems and advanced wastewater treatment technologies in UHMWPE production facilities.

The use and disposal of chemicals in the manufacturing process have been subject to tighter restrictions. Manufacturers must now carefully select and manage the chemicals used, ensuring they meet environmental safety standards. This includes the proper handling, storage, and disposal of potentially hazardous substances.

Waste reduction and recycling have become key priorities. Regulations now encourage or require manufacturers to implement comprehensive waste management strategies, including the recycling of production scrap and the development of end-of-life recycling programs for UHMWPE products.

Air quality regulations have also tightened, focusing on the reduction of volatile organic compounds (VOCs) and particulate matter emissions. This has led to the implementation of advanced air filtration systems and the exploration of low-emission production techniques.

The impact of these regulations extends beyond the production process itself. Supply chain management has become more complex, with manufacturers now required to ensure their suppliers also adhere to environmental standards. This has led to increased transparency and traceability in the UHMWPE supply chain.

Compliance with these regulations has necessitated significant investments in new technologies and processes. While this has initially increased production costs, it has also driven innovation in the industry, leading to the development of more efficient and environmentally friendly production methods.

In response to these regulatory pressures, the UHMWPE industry has begun to explore alternative production methods and materials. This includes the development of bio-based precursors and the use of renewable energy sources in the production process. These innovations not only help meet regulatory requirements but also position UHMWPE as a more sustainable material in the long term.

Life Cycle Assessment of Green UHMWPE

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of green Ultra-High Molecular Weight Polyethylene (UHMWPE) production. This comprehensive analysis encompasses the entire lifecycle of the product, from raw material extraction to disposal or recycling, providing valuable insights into the eco-friendliness of alternative production methods.

The assessment begins with the sourcing of raw materials, comparing traditional petroleum-based feedstocks with bio-based alternatives. Bio-based feedstocks, such as sugarcane or corn-derived ethylene, have shown potential in reducing the carbon footprint of UHMWPE production. However, the environmental impact of land use change and agricultural practices must be carefully considered.

During the manufacturing phase, energy consumption and emissions are key factors. Green UHMWPE production methods often employ more efficient catalysts and optimized reaction conditions, resulting in reduced energy requirements and lower greenhouse gas emissions. Advanced polymerization techniques, such as gas-phase or solution polymerization, can further enhance energy efficiency compared to traditional slurry processes.

The use phase of green UHMWPE products generally demonstrates similar performance characteristics to conventional UHMWPE, ensuring longevity and durability. This extended lifespan contributes positively to the overall environmental impact by reducing the need for frequent replacements.

End-of-life considerations are particularly important in the LCA of green UHMWPE. While UHMWPE is challenging to recycle due to its high molecular weight, innovative recycling technologies are emerging. These include mechanical recycling methods and advanced chemical recycling processes that break down the polymer into its constituent monomers for reuse.

Water consumption and wastewater generation throughout the lifecycle are also critical aspects of the assessment. Green UHMWPE production often incorporates water-saving technologies and closed-loop systems to minimize water usage and reduce environmental impact.

The LCA must also account for transportation and distribution impacts, comparing the logistics of bio-based feedstocks with traditional petroleum sources. Local sourcing of bio-based materials can potentially reduce transportation-related emissions.

Quantitative metrics such as Global Warming Potential (GWP), Cumulative Energy Demand (CED), and Water Footprint are essential for comparing green UHMWPE with conventional production methods. These metrics provide a standardized basis for evaluating environmental performance across different production scenarios.

By conducting a thorough Life Cycle Assessment, manufacturers and researchers can identify hotspots in the production process where environmental improvements can be made. This analysis guides the development of more sustainable UHMWPE production methods, aligning with global efforts to reduce the environmental impact of polymer manufacturing.

The assessment begins with the sourcing of raw materials, comparing traditional petroleum-based feedstocks with bio-based alternatives. Bio-based feedstocks, such as sugarcane or corn-derived ethylene, have shown potential in reducing the carbon footprint of UHMWPE production. However, the environmental impact of land use change and agricultural practices must be carefully considered.

During the manufacturing phase, energy consumption and emissions are key factors. Green UHMWPE production methods often employ more efficient catalysts and optimized reaction conditions, resulting in reduced energy requirements and lower greenhouse gas emissions. Advanced polymerization techniques, such as gas-phase or solution polymerization, can further enhance energy efficiency compared to traditional slurry processes.

The use phase of green UHMWPE products generally demonstrates similar performance characteristics to conventional UHMWPE, ensuring longevity and durability. This extended lifespan contributes positively to the overall environmental impact by reducing the need for frequent replacements.

End-of-life considerations are particularly important in the LCA of green UHMWPE. While UHMWPE is challenging to recycle due to its high molecular weight, innovative recycling technologies are emerging. These include mechanical recycling methods and advanced chemical recycling processes that break down the polymer into its constituent monomers for reuse.

Water consumption and wastewater generation throughout the lifecycle are also critical aspects of the assessment. Green UHMWPE production often incorporates water-saving technologies and closed-loop systems to minimize water usage and reduce environmental impact.

The LCA must also account for transportation and distribution impacts, comparing the logistics of bio-based feedstocks with traditional petroleum sources. Local sourcing of bio-based materials can potentially reduce transportation-related emissions.

Quantitative metrics such as Global Warming Potential (GWP), Cumulative Energy Demand (CED), and Water Footprint are essential for comparing green UHMWPE with conventional production methods. These metrics provide a standardized basis for evaluating environmental performance across different production scenarios.

By conducting a thorough Life Cycle Assessment, manufacturers and researchers can identify hotspots in the production process where environmental improvements can be made. This analysis guides the development of more sustainable UHMWPE production methods, aligning with global efforts to reduce the environmental impact of polymer manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!