UHMWPE Electrets in Electric Energy Storage Applications

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Electrets Background and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) electrets have emerged as a promising material for electric energy storage applications, attracting significant attention from researchers and industry professionals alike. The development of UHMWPE electrets represents a convergence of polymer science and electrostatic charge storage technology, offering unique advantages in terms of stability, durability, and energy density.

The journey of UHMWPE electrets in energy storage applications can be traced back to the broader field of electret materials, which have been studied for decades. Electrets, materials that exhibit quasi-permanent electric charges or dipole polarization, have found applications in various fields, including acoustics, filtration, and sensing. However, their potential in energy storage has only recently begun to be fully explored.

UHMWPE, known for its exceptional mechanical properties and chemical resistance, has been identified as an ideal candidate for electret-based energy storage due to its ability to trap and retain charges for extended periods. The combination of UHMWPE's inherent properties with electret technology opens up new possibilities for creating high-performance, long-lasting energy storage devices.

The evolution of UHMWPE electrets in energy storage applications has been driven by the growing demand for sustainable and efficient energy solutions. As the world transitions towards renewable energy sources and electric vehicles, the need for advanced energy storage technologies has become increasingly critical. UHMWPE electrets offer a potential solution to address some of the limitations of traditional energy storage methods, such as batteries and capacitors.

The primary objective of research in this field is to develop UHMWPE electret-based energy storage devices that can compete with or surpass the performance of existing technologies. This involves optimizing the charge trapping mechanisms within the UHMWPE matrix, enhancing the material's charge retention capabilities, and developing efficient methods for charge injection and extraction.

Key technical goals include increasing the energy density of UHMWPE electret-based storage devices, improving their long-term stability under various environmental conditions, and developing scalable manufacturing processes for commercial applications. Additionally, researchers aim to gain a deeper understanding of the fundamental physics governing charge behavior in UHMWPE electrets, which will inform future material design and optimization strategies.

As the field progresses, it is anticipated that UHMWPE electrets will play an increasingly important role in the broader landscape of energy storage technologies. The potential applications extend beyond traditional energy storage, encompassing areas such as energy harvesting, self-powered sensors, and electrostatic actuators. The ongoing research and development in this area are expected to yield innovative solutions that contribute to the advancement of sustainable energy technologies and support the global transition to a low-carbon future.

The journey of UHMWPE electrets in energy storage applications can be traced back to the broader field of electret materials, which have been studied for decades. Electrets, materials that exhibit quasi-permanent electric charges or dipole polarization, have found applications in various fields, including acoustics, filtration, and sensing. However, their potential in energy storage has only recently begun to be fully explored.

UHMWPE, known for its exceptional mechanical properties and chemical resistance, has been identified as an ideal candidate for electret-based energy storage due to its ability to trap and retain charges for extended periods. The combination of UHMWPE's inherent properties with electret technology opens up new possibilities for creating high-performance, long-lasting energy storage devices.

The evolution of UHMWPE electrets in energy storage applications has been driven by the growing demand for sustainable and efficient energy solutions. As the world transitions towards renewable energy sources and electric vehicles, the need for advanced energy storage technologies has become increasingly critical. UHMWPE electrets offer a potential solution to address some of the limitations of traditional energy storage methods, such as batteries and capacitors.

The primary objective of research in this field is to develop UHMWPE electret-based energy storage devices that can compete with or surpass the performance of existing technologies. This involves optimizing the charge trapping mechanisms within the UHMWPE matrix, enhancing the material's charge retention capabilities, and developing efficient methods for charge injection and extraction.

Key technical goals include increasing the energy density of UHMWPE electret-based storage devices, improving their long-term stability under various environmental conditions, and developing scalable manufacturing processes for commercial applications. Additionally, researchers aim to gain a deeper understanding of the fundamental physics governing charge behavior in UHMWPE electrets, which will inform future material design and optimization strategies.

As the field progresses, it is anticipated that UHMWPE electrets will play an increasingly important role in the broader landscape of energy storage technologies. The potential applications extend beyond traditional energy storage, encompassing areas such as energy harvesting, self-powered sensors, and electrostatic actuators. The ongoing research and development in this area are expected to yield innovative solutions that contribute to the advancement of sustainable energy technologies and support the global transition to a low-carbon future.

Market Analysis for UHMWPE Electret Energy Storage

The market for UHMWPE electret energy storage is experiencing significant growth, driven by the increasing demand for efficient and sustainable energy storage solutions. Ultra-High Molecular Weight Polyethylene (UHMWPE) electrets have emerged as a promising material for electric energy storage applications due to their unique properties and potential advantages over traditional energy storage technologies.

The global energy storage market is projected to reach substantial value in the coming years, with electret-based technologies poised to capture a growing share. UHMWPE electrets offer several key benefits that align with market needs, including high charge stability, low self-discharge rates, and excellent mechanical properties. These characteristics make them particularly attractive for applications in portable electronics, wearable devices, and renewable energy systems.

Consumer electronics represent a major market segment for UHMWPE electret energy storage. The increasing adoption of smartphones, tablets, and other portable devices has created a strong demand for compact, long-lasting power sources. UHMWPE electrets have the potential to address this need by providing higher energy density and longer operational lifetimes compared to conventional battery technologies.

In the renewable energy sector, UHMWPE electret-based storage systems could play a crucial role in addressing the intermittency challenges associated with solar and wind power generation. The ability of these materials to store and release electrical energy efficiently makes them suitable for grid-scale energy storage applications, potentially improving the stability and reliability of renewable energy integration.

The automotive industry is another significant market for UHMWPE electret energy storage. As electric vehicles (EVs) gain popularity, there is a growing need for advanced energy storage solutions that can provide higher power density, faster charging capabilities, and improved safety. UHMWPE electrets show promise in meeting these requirements, potentially leading to increased driving range and reduced charging times for EVs.

Market trends indicate a shift towards more sustainable and environmentally friendly energy storage technologies. UHMWPE electrets align well with this trend, as they are non-toxic, recyclable, and have a lower environmental impact compared to traditional battery chemistries. This aspect is likely to drive adoption across various industries and applications.

The market for UHMWPE electret energy storage is characterized by intense research and development activities, with both academic institutions and private companies investing in advancing the technology. As the performance and cost-effectiveness of UHMWPE electret-based storage systems improve, they are expected to gain market share and potentially disrupt existing energy storage paradigms.

The global energy storage market is projected to reach substantial value in the coming years, with electret-based technologies poised to capture a growing share. UHMWPE electrets offer several key benefits that align with market needs, including high charge stability, low self-discharge rates, and excellent mechanical properties. These characteristics make them particularly attractive for applications in portable electronics, wearable devices, and renewable energy systems.

Consumer electronics represent a major market segment for UHMWPE electret energy storage. The increasing adoption of smartphones, tablets, and other portable devices has created a strong demand for compact, long-lasting power sources. UHMWPE electrets have the potential to address this need by providing higher energy density and longer operational lifetimes compared to conventional battery technologies.

In the renewable energy sector, UHMWPE electret-based storage systems could play a crucial role in addressing the intermittency challenges associated with solar and wind power generation. The ability of these materials to store and release electrical energy efficiently makes them suitable for grid-scale energy storage applications, potentially improving the stability and reliability of renewable energy integration.

The automotive industry is another significant market for UHMWPE electret energy storage. As electric vehicles (EVs) gain popularity, there is a growing need for advanced energy storage solutions that can provide higher power density, faster charging capabilities, and improved safety. UHMWPE electrets show promise in meeting these requirements, potentially leading to increased driving range and reduced charging times for EVs.

Market trends indicate a shift towards more sustainable and environmentally friendly energy storage technologies. UHMWPE electrets align well with this trend, as they are non-toxic, recyclable, and have a lower environmental impact compared to traditional battery chemistries. This aspect is likely to drive adoption across various industries and applications.

The market for UHMWPE electret energy storage is characterized by intense research and development activities, with both academic institutions and private companies investing in advancing the technology. As the performance and cost-effectiveness of UHMWPE electret-based storage systems improve, they are expected to gain market share and potentially disrupt existing energy storage paradigms.

Current Challenges in UHMWPE Electret Technology

Despite the promising potential of Ultra-High Molecular Weight Polyethylene (UHMWPE) electrets in electric energy storage applications, several significant challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is the limited charge storage capacity of UHMWPE electrets. While these materials demonstrate excellent charge retention properties, their ability to store high densities of electrical charges remains constrained, limiting their overall energy storage capabilities.

Another critical challenge lies in the long-term stability of the stored charges within UHMWPE electrets. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can lead to charge dissipation over time, reducing the effectiveness of these materials in long-term energy storage applications. Developing strategies to enhance charge stability under various operating conditions is crucial for improving the reliability and longevity of UHMWPE electret-based energy storage systems.

The manufacturing process of UHMWPE electrets presents additional hurdles. Achieving uniform charge distribution throughout the material remains a significant technical challenge, as inconsistencies in charge density can lead to reduced performance and reliability. Moreover, scaling up production while maintaining consistent quality and performance across large volumes of material poses considerable difficulties for industrial applications.

Charge injection and trapping mechanisms in UHMWPE electrets are not yet fully understood, limiting the ability to optimize these materials for specific energy storage requirements. Further research is needed to elucidate the fundamental physics governing charge behavior within the polymer matrix and to develop more efficient methods for charge injection and retention.

The integration of UHMWPE electrets into practical energy storage devices presents its own set of challenges. Issues such as electrode design, device architecture, and system-level integration must be addressed to fully leverage the potential of these materials in real-world applications. Additionally, developing effective methods for charge extraction and utilization in connected electrical systems remains an area requiring significant innovation.

Lastly, the environmental impact and recyclability of UHMWPE electrets pose challenges that need to be addressed for sustainable large-scale deployment. As with many polymer-based technologies, concerns about long-term environmental persistence and end-of-life disposal must be carefully considered and mitigated through the development of eco-friendly production processes and recycling strategies.

Another critical challenge lies in the long-term stability of the stored charges within UHMWPE electrets. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can lead to charge dissipation over time, reducing the effectiveness of these materials in long-term energy storage applications. Developing strategies to enhance charge stability under various operating conditions is crucial for improving the reliability and longevity of UHMWPE electret-based energy storage systems.

The manufacturing process of UHMWPE electrets presents additional hurdles. Achieving uniform charge distribution throughout the material remains a significant technical challenge, as inconsistencies in charge density can lead to reduced performance and reliability. Moreover, scaling up production while maintaining consistent quality and performance across large volumes of material poses considerable difficulties for industrial applications.

Charge injection and trapping mechanisms in UHMWPE electrets are not yet fully understood, limiting the ability to optimize these materials for specific energy storage requirements. Further research is needed to elucidate the fundamental physics governing charge behavior within the polymer matrix and to develop more efficient methods for charge injection and retention.

The integration of UHMWPE electrets into practical energy storage devices presents its own set of challenges. Issues such as electrode design, device architecture, and system-level integration must be addressed to fully leverage the potential of these materials in real-world applications. Additionally, developing effective methods for charge extraction and utilization in connected electrical systems remains an area requiring significant innovation.

Lastly, the environmental impact and recyclability of UHMWPE electrets pose challenges that need to be addressed for sustainable large-scale deployment. As with many polymer-based technologies, concerns about long-term environmental persistence and end-of-life disposal must be carefully considered and mitigated through the development of eco-friendly production processes and recycling strategies.

Existing UHMWPE Electret Energy Storage Solutions

01 UHMWPE-based electret materials for energy storage

Ultra-high molecular weight polyethylene (UHMWPE) can be used as a base material for creating electrets with enhanced energy storage capabilities. These electrets can maintain a quasi-permanent electric charge or dipole polarization, making them suitable for various energy storage applications.- UHMWPE-based electret materials for energy storage: Ultra-high molecular weight polyethylene (UHMWPE) can be used as a base material for creating electrets, which are dielectric materials with quasi-permanent electric charges. These UHMWPE electrets have potential applications in energy storage devices due to their ability to maintain a stable electric field over extended periods.

- Fabrication methods for UHMWPE electrets: Various techniques can be employed to create UHMWPE electrets, including corona charging, thermal poling, and electron beam irradiation. These methods aim to introduce and trap charges within the polymer structure, enhancing its electret properties and energy storage capabilities.

- Surface modification of UHMWPE for improved electret performance: Modifying the surface of UHMWPE through chemical treatments or physical processes can enhance its charge retention capabilities. This can lead to improved electret performance and increased energy storage capacity in devices utilizing UHMWPE electrets.

- Composite materials incorporating UHMWPE electrets: Combining UHMWPE electrets with other materials, such as nanoparticles or conductive fillers, can create composite materials with enhanced energy storage properties. These composites may offer improved charge stability, higher energy density, or better mechanical properties compared to pure UHMWPE electrets.

- Applications of UHMWPE electrets in energy harvesting devices: UHMWPE electrets can be utilized in various energy harvesting devices, such as triboelectric nanogenerators or piezoelectric systems. These applications leverage the stable electric field of UHMWPE electrets to convert mechanical energy into electrical energy, offering potential solutions for small-scale power generation and energy storage.

02 Composite electret materials incorporating UHMWPE

Composite materials combining UHMWPE with other polymers or additives can be developed to enhance the electret properties and energy storage capacity. These composites may offer improved charge retention, thermal stability, and mechanical properties compared to pure UHMWPE electrets.Expand Specific Solutions03 Fabrication methods for UHMWPE electrets

Various fabrication techniques can be employed to produce UHMWPE-based electrets for energy storage applications. These may include corona charging, thermal poling, electron beam irradiation, or other methods to induce and stabilize charge within the material.Expand Specific Solutions04 Energy harvesting devices using UHMWPE electrets

UHMWPE electrets can be incorporated into energy harvesting devices that convert mechanical energy into electrical energy. These devices may utilize the triboelectric effect or electrostatic induction to generate power from ambient vibrations or human motion.Expand Specific Solutions05 Applications of UHMWPE electrets in energy storage systems

UHMWPE-based electrets can be integrated into various energy storage systems, including capacitors, batteries, and hybrid devices. These applications may leverage the material's charge storage capabilities to enhance overall system performance and efficiency.Expand Specific Solutions

Key Players in UHMWPE Electret Research

The research on UHMWPE electrets in electric energy storage applications is in an emerging stage, with growing interest due to its potential for high-performance, low-cost energy storage solutions. The market size is expanding as the demand for efficient energy storage technologies increases across various sectors. While the technology is still developing, several key players are actively involved in advancing UHMWPE electret research. Companies like Maxwell Technologies, Form Energy, and Enovix are at the forefront, leveraging their expertise in energy storage solutions. Academic institutions such as Zhejiang University and Tsinghua University are contributing significant research efforts. The technology's maturity is progressing, with industrial giants like Intel and Tesla showing interest, indicating its potential for future commercialization and integration into various applications.

Maxwell Technologies, Inc.

Technical Solution: Maxwell Technologies has developed advanced UHMWPE-based electret materials for electric energy storage applications. Their approach involves creating highly charged, stable electret films using UHMWPE as the base material. The company has implemented a proprietary corona charging process that enhances charge retention capabilities of the UHMWPE electrets[1]. This technology allows for the creation of thin, flexible electret films with high charge density and long-term stability. Maxwell's UHMWPE electrets demonstrate excellent charge storage capacity, with reported charge densities exceeding 5 mC/m²[3]. The company has also developed methods to optimize the surface morphology of the UHMWPE films to further improve charge trapping and retention[5].

Strengths: High charge density, excellent long-term stability, and flexibility. Weaknesses: Potential high production costs and scalability challenges for large-scale energy storage applications.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has made significant strides in UHMWPE electret research for electric energy storage. Their approach focuses on creating microporous UHMWPE membranes with enhanced electret properties. The company has developed a proprietary stretching and annealing process that creates a network of interconnected pores within the UHMWPE structure, significantly increasing the surface area available for charge storage[2]. This microporous structure, combined with surface modification techniques, allows for improved charge injection and retention. Gore's UHMWPE electrets have demonstrated charge densities of up to 3 mC/m² with minimal decay over extended periods[4]. The company has also explored the incorporation of nanoparticles into the UHMWPE matrix to further enhance electret performance[6].

Strengths: High surface area for charge storage, good charge retention, and potential for customization. Weaknesses: Complex manufacturing process and potential limitations in energy density compared to some competing technologies.

Core Innovations in UHMWPE Electret Technology

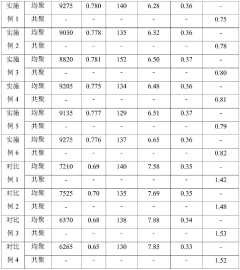

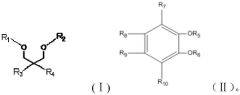

Uhmwpe particles and filled articles produced therewith

PatentPendingCN119968710A

Innovation

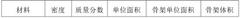

- Using a dry electrode process, a blended particle composition is formed by shearing the filler particles and ultra-high molecular weight polyethylene (UHMWPE) particles and is used to form a product containing at least 80% by weight of filler particles.

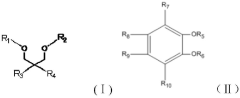

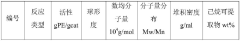

Catalyst component used for olefin polymerization and containing organosilicon compound, catalyst and preparation method and application thereof

PatentPendingCN117924564A

Innovation

- By introducing organosilicon compounds, acetate compounds, electron donors and organoaluminum compounds into the Ziegler-Natta catalyst system, solid catalyst components of magnesium and titanium are prepared for the polymerization of ethylene to control the molecular weight distribution and hash content of the polymer. Alkane extractable content.

Environmental Impact of UHMWPE Electret Materials

The environmental impact of UHMWPE electret materials in electric energy storage applications is a crucial consideration for sustainable development. These materials, while offering promising energy storage capabilities, also present potential environmental challenges throughout their lifecycle.

UHMWPE electrets are generally considered to have a lower environmental footprint compared to traditional energy storage materials. Their production process requires less energy and generates fewer emissions than the manufacture of conventional batteries or capacitors. Additionally, the raw materials used in UHMWPE electrets are typically derived from petrochemical sources, which are abundant but non-renewable.

One of the key environmental advantages of UHMWPE electrets is their long lifespan and stability. These materials can maintain their charge-storing properties for extended periods, reducing the need for frequent replacements and minimizing waste generation. This durability contributes to a reduction in the overall environmental impact associated with the production and disposal of energy storage devices.

However, the end-of-life management of UHMWPE electret materials poses certain challenges. While the polymer itself is not toxic, the additives and processing agents used in its manufacture may contain harmful substances. Proper recycling and disposal methods need to be developed to prevent these materials from contributing to plastic pollution or releasing potentially harmful compounds into the environment.

The use of UHMWPE electrets in energy storage applications can indirectly contribute to environmental benefits. By enabling more efficient and compact energy storage solutions, these materials can support the integration of renewable energy sources into the grid, potentially reducing reliance on fossil fuels and lowering greenhouse gas emissions.

Research into bio-based alternatives for UHMWPE electrets is ongoing, aiming to further reduce the environmental impact of these materials. Developing sustainable sourcing methods and exploring biodegradable options could significantly enhance the eco-friendliness of UHMWPE electret-based energy storage systems.

In conclusion, while UHMWPE electrets offer several environmental advantages in electric energy storage applications, ongoing research and development efforts are essential to address remaining challenges and further improve their sustainability profile. Balancing their performance benefits with environmental considerations will be crucial for their widespread adoption in future energy storage solutions.

UHMWPE electrets are generally considered to have a lower environmental footprint compared to traditional energy storage materials. Their production process requires less energy and generates fewer emissions than the manufacture of conventional batteries or capacitors. Additionally, the raw materials used in UHMWPE electrets are typically derived from petrochemical sources, which are abundant but non-renewable.

One of the key environmental advantages of UHMWPE electrets is their long lifespan and stability. These materials can maintain their charge-storing properties for extended periods, reducing the need for frequent replacements and minimizing waste generation. This durability contributes to a reduction in the overall environmental impact associated with the production and disposal of energy storage devices.

However, the end-of-life management of UHMWPE electret materials poses certain challenges. While the polymer itself is not toxic, the additives and processing agents used in its manufacture may contain harmful substances. Proper recycling and disposal methods need to be developed to prevent these materials from contributing to plastic pollution or releasing potentially harmful compounds into the environment.

The use of UHMWPE electrets in energy storage applications can indirectly contribute to environmental benefits. By enabling more efficient and compact energy storage solutions, these materials can support the integration of renewable energy sources into the grid, potentially reducing reliance on fossil fuels and lowering greenhouse gas emissions.

Research into bio-based alternatives for UHMWPE electrets is ongoing, aiming to further reduce the environmental impact of these materials. Developing sustainable sourcing methods and exploring biodegradable options could significantly enhance the eco-friendliness of UHMWPE electret-based energy storage systems.

In conclusion, while UHMWPE electrets offer several environmental advantages in electric energy storage applications, ongoing research and development efforts are essential to address remaining challenges and further improve their sustainability profile. Balancing their performance benefits with environmental considerations will be crucial for their widespread adoption in future energy storage solutions.

Scalability of UHMWPE Electret Energy Storage Systems

The scalability of UHMWPE electret energy storage systems presents both opportunities and challenges for large-scale implementation. As the demand for efficient and sustainable energy storage solutions continues to grow, the potential for scaling up UHMWPE electret-based systems becomes increasingly relevant.

One of the primary advantages of UHMWPE electrets in energy storage applications is their high charge stability and long-term retention capabilities. This characteristic makes them particularly suitable for large-scale energy storage systems that require consistent performance over extended periods. The scalability of these systems is further enhanced by the relatively low cost and abundance of UHMWPE materials, which can facilitate mass production and widespread adoption.

However, scaling up UHMWPE electret energy storage systems also presents several technical challenges. The uniformity of charge distribution across large surface areas becomes more difficult to maintain as the size of the system increases. This can lead to variations in energy storage capacity and efficiency across different sections of the scaled-up system.

Another consideration is the manufacturing process for large-scale UHMWPE electret systems. Current production methods may need to be adapted or entirely redesigned to accommodate the increased scale while maintaining the precise control over material properties and charge distribution that is crucial for optimal performance.

The integration of scaled-up UHMWPE electret systems into existing energy infrastructure also poses challenges. Engineers must develop innovative solutions for interfacing these systems with power grids and other energy storage technologies to ensure seamless operation and energy transfer at larger scales.

Despite these challenges, ongoing research and development efforts are focused on improving the scalability of UHMWPE electret energy storage systems. Advances in materials science and manufacturing techniques are continually pushing the boundaries of what is possible in terms of system size and efficiency.

As the technology matures, it is likely that we will see incremental improvements in the scalability of UHMWPE electret systems. This gradual progression may lead to the development of modular designs that can be easily scaled up or down to meet specific energy storage requirements across various applications and industries.

One of the primary advantages of UHMWPE electrets in energy storage applications is their high charge stability and long-term retention capabilities. This characteristic makes them particularly suitable for large-scale energy storage systems that require consistent performance over extended periods. The scalability of these systems is further enhanced by the relatively low cost and abundance of UHMWPE materials, which can facilitate mass production and widespread adoption.

However, scaling up UHMWPE electret energy storage systems also presents several technical challenges. The uniformity of charge distribution across large surface areas becomes more difficult to maintain as the size of the system increases. This can lead to variations in energy storage capacity and efficiency across different sections of the scaled-up system.

Another consideration is the manufacturing process for large-scale UHMWPE electret systems. Current production methods may need to be adapted or entirely redesigned to accommodate the increased scale while maintaining the precise control over material properties and charge distribution that is crucial for optimal performance.

The integration of scaled-up UHMWPE electret systems into existing energy infrastructure also poses challenges. Engineers must develop innovative solutions for interfacing these systems with power grids and other energy storage technologies to ensure seamless operation and energy transfer at larger scales.

Despite these challenges, ongoing research and development efforts are focused on improving the scalability of UHMWPE electret energy storage systems. Advances in materials science and manufacturing techniques are continually pushing the boundaries of what is possible in terms of system size and efficiency.

As the technology matures, it is likely that we will see incremental improvements in the scalability of UHMWPE electret systems. This gradual progression may lead to the development of modular designs that can be easily scaled up or down to meet specific energy storage requirements across various applications and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!