UHMWPE's Applications in Advanced Sports Equipment Manufacturing

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Sports Tech: Evolution and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a revolutionary material in the field of sports equipment manufacturing, marking a significant milestone in the evolution of sports technology. The journey of UHMWPE in sports began in the 1960s when it was first synthesized, but its potential in sports applications was not fully realized until the late 1980s and early 1990s.

The development of UHMWPE has been driven by the increasing demand for high-performance, lightweight, and durable materials in sports equipment. As athletes and sports enthusiasts sought gear that could enhance their performance and provide better protection, researchers and manufacturers turned to advanced materials like UHMWPE to meet these evolving needs.

Over the past three decades, UHMWPE has undergone significant advancements in terms of its properties and processing techniques. Early applications were limited due to challenges in molding and shaping the material. However, breakthroughs in manufacturing processes, such as gel spinning and compression molding, have greatly expanded the potential applications of UHMWPE in sports equipment.

The evolution of UHMWPE in sports technology has been marked by several key milestones. In the 1990s, it was first introduced in high-performance ski and snowboard bases, offering superior glide and durability. The early 2000s saw the integration of UHMWPE fibers in protective gear, such as helmets and body armor, leveraging its exceptional strength-to-weight ratio.

More recently, the development of UHMWPE composites has opened up new possibilities in racquet sports, cycling, and water sports. These composites combine the strength and lightweight properties of UHMWPE with other materials to create equipment with enhanced performance characteristics.

Looking ahead, the objectives for UHMWPE in sports technology are multifaceted. Researchers and manufacturers are focusing on further improving the material's properties, such as increasing its heat resistance and enhancing its ability to bond with other materials. There is also a growing emphasis on developing more sustainable production methods and exploring bio-based alternatives to traditional UHMWPE.

Another key objective is to expand the application of UHMWPE across a wider range of sports equipment. This includes exploring its potential in team sports equipment, athletic footwear, and even in the construction of sports facilities. The goal is to leverage UHMWPE's unique properties to create equipment that not only enhances performance but also improves safety and longevity.

The development of UHMWPE has been driven by the increasing demand for high-performance, lightweight, and durable materials in sports equipment. As athletes and sports enthusiasts sought gear that could enhance their performance and provide better protection, researchers and manufacturers turned to advanced materials like UHMWPE to meet these evolving needs.

Over the past three decades, UHMWPE has undergone significant advancements in terms of its properties and processing techniques. Early applications were limited due to challenges in molding and shaping the material. However, breakthroughs in manufacturing processes, such as gel spinning and compression molding, have greatly expanded the potential applications of UHMWPE in sports equipment.

The evolution of UHMWPE in sports technology has been marked by several key milestones. In the 1990s, it was first introduced in high-performance ski and snowboard bases, offering superior glide and durability. The early 2000s saw the integration of UHMWPE fibers in protective gear, such as helmets and body armor, leveraging its exceptional strength-to-weight ratio.

More recently, the development of UHMWPE composites has opened up new possibilities in racquet sports, cycling, and water sports. These composites combine the strength and lightweight properties of UHMWPE with other materials to create equipment with enhanced performance characteristics.

Looking ahead, the objectives for UHMWPE in sports technology are multifaceted. Researchers and manufacturers are focusing on further improving the material's properties, such as increasing its heat resistance and enhancing its ability to bond with other materials. There is also a growing emphasis on developing more sustainable production methods and exploring bio-based alternatives to traditional UHMWPE.

Another key objective is to expand the application of UHMWPE across a wider range of sports equipment. This includes exploring its potential in team sports equipment, athletic footwear, and even in the construction of sports facilities. The goal is to leverage UHMWPE's unique properties to create equipment that not only enhances performance but also improves safety and longevity.

Market Analysis: High-Performance Sports Equipment

The high-performance sports equipment market has experienced significant growth in recent years, driven by increasing consumer interest in sports and fitness activities, as well as advancements in material technologies. Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a key material in this sector, offering exceptional strength-to-weight ratio, durability, and impact resistance.

The global sports equipment market was valued at $126.23 billion in 2021 and is projected to reach $178.66 billion by 2028, growing at a CAGR of 5.1% during the forecast period. Within this market, high-performance equipment represents a premium segment, with consumers willing to pay more for products that offer superior performance and durability.

UHMWPE has found applications across various sports categories, including winter sports, water sports, and protective gear. In the skiing and snowboarding industry, UHMWPE is used in the production of high-performance skis and snowboards, offering improved durability and reduced weight compared to traditional materials. The global ski equipment market size was valued at $1.44 billion in 2021 and is expected to expand at a CAGR of 2.3% from 2022 to 2030.

In water sports, UHMWPE fibers are utilized in the manufacturing of lightweight and durable kayaks, canoes, and paddleboards. The global water sports equipment market size was valued at $43.2 billion in 2021 and is projected to reach $55.2 billion by 2027, growing at a CAGR of 3.6% during the forecast period.

UHMWPE has also gained traction in the production of protective gear for various sports, including helmets, body armor, and impact-resistant padding. The global sports protective equipment market size was valued at $5.3 billion in 2021 and is expected to reach $7.9 billion by 2028, growing at a CAGR of 4.3% during the forecast period.

The adoption of UHMWPE in high-performance sports equipment manufacturing is driven by several factors, including the material's superior mechanical properties, lightweight nature, and resistance to abrasion and chemicals. These characteristics align well with the demands of professional athletes and enthusiasts seeking equipment that can enhance their performance and provide long-lasting durability.

As sustainability becomes an increasingly important factor in consumer purchasing decisions, manufacturers are exploring ways to incorporate recycled UHMWPE into their products. This trend is expected to further drive the adoption of UHMWPE in the high-performance sports equipment market, as it addresses both performance and environmental concerns.

The global sports equipment market was valued at $126.23 billion in 2021 and is projected to reach $178.66 billion by 2028, growing at a CAGR of 5.1% during the forecast period. Within this market, high-performance equipment represents a premium segment, with consumers willing to pay more for products that offer superior performance and durability.

UHMWPE has found applications across various sports categories, including winter sports, water sports, and protective gear. In the skiing and snowboarding industry, UHMWPE is used in the production of high-performance skis and snowboards, offering improved durability and reduced weight compared to traditional materials. The global ski equipment market size was valued at $1.44 billion in 2021 and is expected to expand at a CAGR of 2.3% from 2022 to 2030.

In water sports, UHMWPE fibers are utilized in the manufacturing of lightweight and durable kayaks, canoes, and paddleboards. The global water sports equipment market size was valued at $43.2 billion in 2021 and is projected to reach $55.2 billion by 2027, growing at a CAGR of 3.6% during the forecast period.

UHMWPE has also gained traction in the production of protective gear for various sports, including helmets, body armor, and impact-resistant padding. The global sports protective equipment market size was valued at $5.3 billion in 2021 and is expected to reach $7.9 billion by 2028, growing at a CAGR of 4.3% during the forecast period.

The adoption of UHMWPE in high-performance sports equipment manufacturing is driven by several factors, including the material's superior mechanical properties, lightweight nature, and resistance to abrasion and chemicals. These characteristics align well with the demands of professional athletes and enthusiasts seeking equipment that can enhance their performance and provide long-lasting durability.

As sustainability becomes an increasingly important factor in consumer purchasing decisions, manufacturers are exploring ways to incorporate recycled UHMWPE into their products. This trend is expected to further drive the adoption of UHMWPE in the high-performance sports equipment market, as it addresses both performance and environmental concerns.

UHMWPE Technical Challenges in Sports Applications

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in advanced sports equipment manufacturing, offering exceptional properties that enhance performance and durability. However, its integration into sports applications presents several technical challenges that require innovative solutions.

One of the primary challenges is achieving optimal fiber alignment and orientation during the manufacturing process. UHMWPE fibers must be precisely aligned to maximize strength and minimize weight, which is crucial for high-performance sports equipment. Current manufacturing techniques struggle to consistently achieve the desired level of alignment, particularly in complex geometries or large-scale production.

Another significant hurdle is the bonding of UHMWPE to other materials. Due to its low surface energy and chemical inertness, UHMWPE exhibits poor adhesion properties. This makes it difficult to create strong, durable bonds with other components in sports equipment, such as metal frames or composite materials. Developing effective surface treatment methods or compatible adhesive systems remains an ongoing challenge.

The processing temperature limitations of UHMWPE also pose difficulties in manufacturing. The material's high melting point and tendency to degrade at elevated temperatures restrict the use of conventional molding and shaping techniques. This necessitates the development of specialized processing methods that can maintain the material's integrity while achieving the desired form and function.

Customization and tailoring of UHMWPE properties for specific sports applications present another technical challenge. Different sports require varying combinations of strength, flexibility, and impact resistance. Fine-tuning the molecular weight, crystallinity, and fiber orientation to meet these diverse requirements demands advanced material science expertise and precise manufacturing control.

Ensuring long-term performance stability of UHMWPE in sports equipment is also a significant concern. The material can be susceptible to creep and stress relaxation under prolonged loading, potentially compromising the equipment's performance over time. Developing strategies to mitigate these effects and maintain consistent properties throughout the product's lifecycle is crucial.

Lastly, the recyclability and end-of-life management of UHMWPE sports equipment pose environmental challenges. The material's high durability, while beneficial for performance, makes it resistant to degradation. Developing efficient recycling processes or biodegradable variants of UHMWPE that maintain its superior properties is an ongoing area of research and development in the sports equipment industry.

One of the primary challenges is achieving optimal fiber alignment and orientation during the manufacturing process. UHMWPE fibers must be precisely aligned to maximize strength and minimize weight, which is crucial for high-performance sports equipment. Current manufacturing techniques struggle to consistently achieve the desired level of alignment, particularly in complex geometries or large-scale production.

Another significant hurdle is the bonding of UHMWPE to other materials. Due to its low surface energy and chemical inertness, UHMWPE exhibits poor adhesion properties. This makes it difficult to create strong, durable bonds with other components in sports equipment, such as metal frames or composite materials. Developing effective surface treatment methods or compatible adhesive systems remains an ongoing challenge.

The processing temperature limitations of UHMWPE also pose difficulties in manufacturing. The material's high melting point and tendency to degrade at elevated temperatures restrict the use of conventional molding and shaping techniques. This necessitates the development of specialized processing methods that can maintain the material's integrity while achieving the desired form and function.

Customization and tailoring of UHMWPE properties for specific sports applications present another technical challenge. Different sports require varying combinations of strength, flexibility, and impact resistance. Fine-tuning the molecular weight, crystallinity, and fiber orientation to meet these diverse requirements demands advanced material science expertise and precise manufacturing control.

Ensuring long-term performance stability of UHMWPE in sports equipment is also a significant concern. The material can be susceptible to creep and stress relaxation under prolonged loading, potentially compromising the equipment's performance over time. Developing strategies to mitigate these effects and maintain consistent properties throughout the product's lifecycle is crucial.

Lastly, the recyclability and end-of-life management of UHMWPE sports equipment pose environmental challenges. The material's high durability, while beneficial for performance, makes it resistant to degradation. Developing efficient recycling processes or biodegradable variants of UHMWPE that maintain its superior properties is an ongoing area of research and development in the sports equipment industry.

Current UHMWPE Integration Methods in Sports Gear

01 Composition and properties of UHMWPE

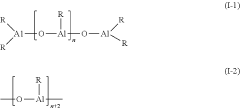

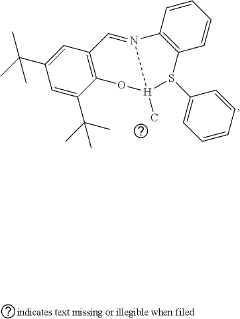

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of polyethylene with extremely long chains, resulting in a material with high molecular weight. It exhibits exceptional properties such as high impact strength, low friction coefficient, and excellent wear resistance. These characteristics make UHMWPE suitable for various applications in industries like medical, aerospace, and manufacturing.- Synthesis and processing of UHMWPE: Various methods for synthesizing and processing Ultra-High Molecular Weight Polyethylene (UHMWPE) are described. These include polymerization techniques, extrusion processes, and molding methods to produce UHMWPE with desired properties such as high molecular weight, improved strength, and enhanced wear resistance.

- UHMWPE composites and blends: Development of UHMWPE-based composites and blends with other materials to enhance specific properties. This includes incorporating fillers, reinforcing agents, or blending with other polymers to improve mechanical strength, thermal stability, or other functional characteristics of the resulting material.

- Surface modification of UHMWPE: Techniques for modifying the surface of UHMWPE to enhance its properties or compatibility with other materials. This may include chemical treatments, plasma treatments, or grafting methods to improve adhesion, wettability, or introduce functional groups on the UHMWPE surface.

- Applications of UHMWPE in medical devices: Use of UHMWPE in various medical applications, particularly in orthopedic implants and prosthetics. This includes the development of wear-resistant UHMWPE components for joint replacements, as well as methods to improve its biocompatibility and longevity in the human body.

- UHMWPE fibers and films: Production and applications of UHMWPE in fiber and film forms. This includes methods for spinning high-strength UHMWPE fibers, creating oriented films, and utilizing these materials in applications such as ballistic protection, high-performance textiles, and industrial uses requiring exceptional strength-to-weight ratios.

02 Processing methods for UHMWPE

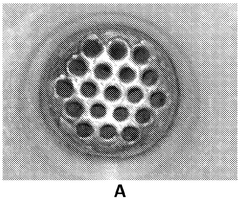

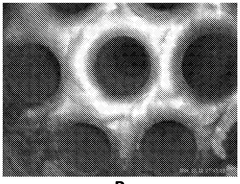

Various processing methods are employed to manufacture UHMWPE products, including compression molding, ram extrusion, and gel spinning. These techniques aim to maintain the material's unique properties while shaping it into desired forms. Advanced processing methods may involve crosslinking or the addition of reinforcing agents to further enhance the material's performance.Expand Specific Solutions03 UHMWPE fiber production and applications

UHMWPE fibers are produced through specialized processes, resulting in high-strength, lightweight materials. These fibers find applications in ballistic protection, cut-resistant gloves, and high-performance ropes and cables. The production methods focus on achieving optimal molecular orientation and crystallinity to maximize the fiber's mechanical properties.Expand Specific Solutions04 UHMWPE composites and blends

Researchers and manufacturers are developing UHMWPE composites and blends to enhance specific properties or introduce new functionalities. These may include the incorporation of nanoparticles, carbon fibers, or other polymers to improve strength, conductivity, or processability. Such developments expand the potential applications of UHMWPE in various industries.Expand Specific Solutions05 Medical applications of UHMWPE

UHMWPE is widely used in medical applications, particularly in orthopedic implants such as hip and knee replacements. The material's biocompatibility, low wear rate, and high durability make it ideal for long-term implants. Ongoing research focuses on improving the material's performance through surface modifications, antioxidant additions, and optimized manufacturing processes to enhance implant longevity.Expand Specific Solutions

Key Players in UHMWPE Sports Equipment Manufacturing

The UHMWPE market in advanced sports equipment manufacturing is in a growth phase, driven by increasing demand for high-performance materials in sports gear. The market size is expanding, with a projected CAGR of 9.5% from 2021 to 2028. Technologically, UHMWPE applications are maturing, with companies like DSM IP Assets BV, Celanese Corp.'s Ticona LLC, and SABIC Global Technologies BV leading innovation. These firms are developing advanced UHMWPE formulations for improved strength, durability, and lightweight properties in sports equipment. Research institutions such as Cambridge Polymer Group, Inc. and universities like Sichuan University are contributing to technological advancements, focusing on enhancing UHMWPE's performance characteristics for specialized sports applications.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a range of UHMWPE fibers and resins specifically for sports equipment manufacturing. Their Dyneema® fiber is used in high-performance sports gear due to its exceptional strength-to-weight ratio. In tennis rackets, Dyneema® strings offer improved power and control[1]. For cycling, SABIC's UHMWPE is used in lightweight, durable bike frames and components. In water sports, their materials are utilized in sailcloth and ropes for enhanced performance and longevity[2]. SABIC has also introduced UHMWPE-based solutions for protective sports equipment, such as helmets and body armor, leveraging the material's impact resistance and energy absorption properties[3].

Strengths: Wide range of UHMWPE products tailored for various sports applications, global manufacturing capabilities, and strong R&D focus. Weaknesses: Potential higher cost compared to traditional materials, which may limit adoption in some market segments.

Cambridge Polymer Group, Inc.

Technical Solution: Cambridge Polymer Group specializes in the development and testing of advanced polymer materials, including UHMWPE for sports applications. They have focused on enhancing the wear resistance and longevity of UHMWPE in high-stress sporting environments. Their research has led to improvements in UHMWPE formulations for use in artificial turf fibers, providing better durability and natural grass-like performance[10]. In the field of racquet sports, Cambridge Polymer Group has developed testing methodologies to evaluate the performance of UHMWPE strings, contributing to advancements in string technology[11]. They have also worked on optimizing UHMWPE blends for use in sports shoe soles, aiming to improve traction and wear resistance in various playing conditions.

Strengths: Strong focus on research and development, expertise in material testing and characterization, and ability to customize UHMWPE formulations for specific sports applications. Weaknesses: Smaller scale compared to major manufacturers, which may limit production capabilities and market reach.

Innovative UHMWPE Formulations for Sports Use

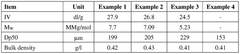

Method for continuously producing ultra-high molecular weight polyethylene by using slurry polymerization

PatentPendingUS20240092948A1

Innovation

- A continuous process using 2-6 ethylene slurry polymerization reaction tanks connected in series, where polymerization temperatures, pressures, and gas phase compositions are controlled within specific ranges to ensure consistent conditions across tanks, allowing for full catalyst activity and precise control of molecular weight, resulting in ultra-high viscosity-average molecular weight polyethylene with low metal and ash content.

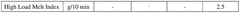

Process for polymerization of ethylene using a cooling system with a slurry-free heat exchanger

PatentWO2024220786A1

Innovation

- A process utilizing a slurry-free heat exchanger in the cooling system, which reduces fouling by using a light hydrocarbon diluent and condensing vapor streams, thereby minimizing the need for external heat exchangers and antistatic agents, and improving catalytic activity.

Environmental Impact of UHMWPE in Sports Equipment

The environmental impact of UHMWPE in sports equipment is a crucial consideration as the material gains popularity in advanced manufacturing processes. UHMWPE, or Ultra-High Molecular Weight Polyethylene, offers exceptional strength-to-weight ratio and durability, making it an attractive choice for various sports applications. However, its environmental footprint warrants careful examination.

UHMWPE production involves energy-intensive processes, contributing to greenhouse gas emissions. The material's high molecular weight requires significant energy input during polymerization and processing stages. This energy consumption, often derived from fossil fuels, raises concerns about the carbon footprint associated with UHMWPE-based sports equipment.

Despite its durability, UHMWPE poses challenges in end-of-life management. The material's resistance to degradation, while beneficial for product longevity, complicates recycling efforts. Traditional recycling methods struggle to process UHMWPE effectively, potentially leading to increased landfill waste or incineration, both of which have negative environmental consequences.

However, UHMWPE's longevity can be viewed as an environmental advantage. Sports equipment made with this material tends to have a longer lifespan compared to alternatives, reducing the frequency of replacements and, consequently, the overall resource consumption and waste generation in the long term.

Recent advancements in recycling technologies offer promising solutions for UHMWPE waste management. Mechanical recycling methods, such as grinding and reprocessing, show potential for reclaiming UHMWPE from discarded sports equipment. Additionally, chemical recycling techniques are being explored to break down UHMWPE into its base components, enabling the production of new high-quality materials.

The use of UHMWPE in sports equipment manufacturing also presents opportunities for weight reduction in products. Lighter equipment can lead to reduced fuel consumption in transportation, both during distribution and when carried by athletes during travel. This weight advantage indirectly contributes to lowering the overall carbon footprint of sports activities.

As the sports industry increasingly prioritizes sustainability, manufacturers are exploring bio-based alternatives to traditional UHMWPE. Research into renewable sources for polyethylene production, such as sugarcane-derived ethanol, shows potential for reducing the material's reliance on fossil fuels and improving its environmental profile.

In conclusion, while UHMWPE offers significant performance benefits in sports equipment, its environmental impact remains a complex issue. Balancing the material's durability and performance advantages against its production energy requirements and end-of-life challenges is crucial. Ongoing research and development in recycling technologies and bio-based alternatives hold promise for mitigating UHMWPE's environmental footprint in the sports equipment industry.

UHMWPE production involves energy-intensive processes, contributing to greenhouse gas emissions. The material's high molecular weight requires significant energy input during polymerization and processing stages. This energy consumption, often derived from fossil fuels, raises concerns about the carbon footprint associated with UHMWPE-based sports equipment.

Despite its durability, UHMWPE poses challenges in end-of-life management. The material's resistance to degradation, while beneficial for product longevity, complicates recycling efforts. Traditional recycling methods struggle to process UHMWPE effectively, potentially leading to increased landfill waste or incineration, both of which have negative environmental consequences.

However, UHMWPE's longevity can be viewed as an environmental advantage. Sports equipment made with this material tends to have a longer lifespan compared to alternatives, reducing the frequency of replacements and, consequently, the overall resource consumption and waste generation in the long term.

Recent advancements in recycling technologies offer promising solutions for UHMWPE waste management. Mechanical recycling methods, such as grinding and reprocessing, show potential for reclaiming UHMWPE from discarded sports equipment. Additionally, chemical recycling techniques are being explored to break down UHMWPE into its base components, enabling the production of new high-quality materials.

The use of UHMWPE in sports equipment manufacturing also presents opportunities for weight reduction in products. Lighter equipment can lead to reduced fuel consumption in transportation, both during distribution and when carried by athletes during travel. This weight advantage indirectly contributes to lowering the overall carbon footprint of sports activities.

As the sports industry increasingly prioritizes sustainability, manufacturers are exploring bio-based alternatives to traditional UHMWPE. Research into renewable sources for polyethylene production, such as sugarcane-derived ethanol, shows potential for reducing the material's reliance on fossil fuels and improving its environmental profile.

In conclusion, while UHMWPE offers significant performance benefits in sports equipment, its environmental impact remains a complex issue. Balancing the material's durability and performance advantages against its production energy requirements and end-of-life challenges is crucial. Ongoing research and development in recycling technologies and bio-based alternatives hold promise for mitigating UHMWPE's environmental footprint in the sports equipment industry.

Safety Standards for UHMWPE-Based Sports Products

Safety standards for UHMWPE-based sports products are crucial in ensuring the protection and well-being of athletes and recreational users. These standards encompass a wide range of requirements, from material properties to product performance under various conditions.

The International Organization for Standardization (ISO) has developed specific guidelines for UHMWPE materials used in sports equipment. ISO 11542-1 and ISO 11542-2 outline the requirements for UHMWPE molding and extrusion materials, including mechanical, thermal, and physical properties. These standards ensure consistency and quality in the raw materials used for manufacturing sports products.

In the field of protective gear, such as helmets and body armor, UHMWPE-based products must adhere to rigorous impact resistance standards. The American Society for Testing and Materials (ASTM) has established ASTM F1446 for bicycle helmets and ASTM F1952 for downhill mountain biking and BMX cycling helmets. These standards specify impact attenuation requirements, which UHMWPE-based helmets must meet or exceed.

For water sports equipment, like personal flotation devices (PFDs) made with UHMWPE fibers, standards such as the European EN ISO 12402 series and the U.S. Coast Guard regulations apply. These standards address buoyancy, durability, and performance in various water conditions, ensuring that UHMWPE-based PFDs provide adequate safety for users.

In the realm of winter sports, UHMWPE-based skis and snowboards must comply with ISO 6289 for alpine skis and ISO 5902 for snowboards. These standards cover aspects such as bending and torsional stiffness, as well as binding mounting strength, which are critical for the safety and performance of these products.

The tensile strength and abrasion resistance of UHMWPE fibers used in climbing ropes and harnesses are regulated by standards like EN 892 for dynamic mountaineering ropes and EN 12277 for harnesses. These standards ensure that the equipment can withstand the extreme forces encountered during falls and prolonged use in harsh environments.

As UHMWPE continues to find new applications in sports equipment, regulatory bodies and industry associations are working to develop and update safety standards. The focus is on addressing the unique properties of UHMWPE, such as its high strength-to-weight ratio and excellent impact resistance, while ensuring that products meet or exceed the safety requirements of traditional materials.

Manufacturers of UHMWPE-based sports products must not only comply with these standards but also conduct extensive testing and quality control throughout the production process. This includes regular material property assessments, product performance evaluations, and durability testing to ensure consistent compliance with safety standards and maintain the integrity of their products in real-world use scenarios.

The International Organization for Standardization (ISO) has developed specific guidelines for UHMWPE materials used in sports equipment. ISO 11542-1 and ISO 11542-2 outline the requirements for UHMWPE molding and extrusion materials, including mechanical, thermal, and physical properties. These standards ensure consistency and quality in the raw materials used for manufacturing sports products.

In the field of protective gear, such as helmets and body armor, UHMWPE-based products must adhere to rigorous impact resistance standards. The American Society for Testing and Materials (ASTM) has established ASTM F1446 for bicycle helmets and ASTM F1952 for downhill mountain biking and BMX cycling helmets. These standards specify impact attenuation requirements, which UHMWPE-based helmets must meet or exceed.

For water sports equipment, like personal flotation devices (PFDs) made with UHMWPE fibers, standards such as the European EN ISO 12402 series and the U.S. Coast Guard regulations apply. These standards address buoyancy, durability, and performance in various water conditions, ensuring that UHMWPE-based PFDs provide adequate safety for users.

In the realm of winter sports, UHMWPE-based skis and snowboards must comply with ISO 6289 for alpine skis and ISO 5902 for snowboards. These standards cover aspects such as bending and torsional stiffness, as well as binding mounting strength, which are critical for the safety and performance of these products.

The tensile strength and abrasion resistance of UHMWPE fibers used in climbing ropes and harnesses are regulated by standards like EN 892 for dynamic mountaineering ropes and EN 12277 for harnesses. These standards ensure that the equipment can withstand the extreme forces encountered during falls and prolonged use in harsh environments.

As UHMWPE continues to find new applications in sports equipment, regulatory bodies and industry associations are working to develop and update safety standards. The focus is on addressing the unique properties of UHMWPE, such as its high strength-to-weight ratio and excellent impact resistance, while ensuring that products meet or exceed the safety requirements of traditional materials.

Manufacturers of UHMWPE-based sports products must not only comply with these standards but also conduct extensive testing and quality control throughout the production process. This includes regular material property assessments, product performance evaluations, and durability testing to ensure consistent compliance with safety standards and maintain the integrity of their products in real-world use scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!