Innovations in UHMWPE-Fortified Avalanche Protection Gear

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Avalanche Gear Evolution and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has revolutionized avalanche protection gear, marking a significant milestone in the evolution of safety equipment for winter sports enthusiasts and mountain professionals. The development of UHMWPE-fortified gear represents a convergence of materials science and outdoor safety technology, addressing the critical need for lightweight yet highly protective equipment in avalanche-prone environments.

The journey of UHMWPE in avalanche protection began with the recognition of its exceptional strength-to-weight ratio and impact resistance properties. These characteristics made it an ideal candidate for replacing traditional materials in avalanche airbags, backpacks, and protective clothing. The primary objective of this technological advancement has been to enhance user safety without compromising mobility or comfort, a balance that is crucial in high-risk mountain environments.

As the technology progressed, researchers and manufacturers focused on optimizing the integration of UHMWPE fibers into existing gear designs. This process involved extensive testing to ensure that the new materials could withstand the extreme forces and temperatures encountered during avalanches while maintaining flexibility and ease of use. The goal was to create gear that could effectively disperse impact energy, resist punctures from debris, and provide buoyancy in snow flow, all while being significantly lighter than previous generations of equipment.

Another key objective in the evolution of UHMWPE-fortified avalanche gear has been to improve its durability and longevity. Engineers have worked on developing coatings and manufacturing techniques that enhance the material's resistance to UV radiation, moisture, and abrasion, ensuring that the protective properties remain intact over extended periods of use in harsh mountain conditions.

The ongoing development of UHMWPE avalanche protection gear also aims to address the broader spectrum of risks associated with winter mountain activities. This includes incorporating features that aid in rescue operations, such as integrated beacon systems and reflective elements for improved visibility. The ultimate goal is to create a comprehensive safety system that not only protects the user during an avalanche but also facilitates rapid location and rescue if necessary.

Looking forward, the objectives for further innovation in UHMWPE-fortified avalanche gear include enhancing its adaptability to different body types and activity levels, improving its integration with other safety technologies, and exploring sustainable manufacturing processes to reduce environmental impact. Researchers are also investigating ways to further reduce weight while maintaining or improving protective capabilities, potentially through the development of new UHMWPE composites or hybrid materials.

The journey of UHMWPE in avalanche protection began with the recognition of its exceptional strength-to-weight ratio and impact resistance properties. These characteristics made it an ideal candidate for replacing traditional materials in avalanche airbags, backpacks, and protective clothing. The primary objective of this technological advancement has been to enhance user safety without compromising mobility or comfort, a balance that is crucial in high-risk mountain environments.

As the technology progressed, researchers and manufacturers focused on optimizing the integration of UHMWPE fibers into existing gear designs. This process involved extensive testing to ensure that the new materials could withstand the extreme forces and temperatures encountered during avalanches while maintaining flexibility and ease of use. The goal was to create gear that could effectively disperse impact energy, resist punctures from debris, and provide buoyancy in snow flow, all while being significantly lighter than previous generations of equipment.

Another key objective in the evolution of UHMWPE-fortified avalanche gear has been to improve its durability and longevity. Engineers have worked on developing coatings and manufacturing techniques that enhance the material's resistance to UV radiation, moisture, and abrasion, ensuring that the protective properties remain intact over extended periods of use in harsh mountain conditions.

The ongoing development of UHMWPE avalanche protection gear also aims to address the broader spectrum of risks associated with winter mountain activities. This includes incorporating features that aid in rescue operations, such as integrated beacon systems and reflective elements for improved visibility. The ultimate goal is to create a comprehensive safety system that not only protects the user during an avalanche but also facilitates rapid location and rescue if necessary.

Looking forward, the objectives for further innovation in UHMWPE-fortified avalanche gear include enhancing its adaptability to different body types and activity levels, improving its integration with other safety technologies, and exploring sustainable manufacturing processes to reduce environmental impact. Researchers are also investigating ways to further reduce weight while maintaining or improving protective capabilities, potentially through the development of new UHMWPE composites or hybrid materials.

Market Analysis for Advanced Avalanche Protection

The market for advanced avalanche protection gear, particularly those incorporating Ultra-High Molecular Weight Polyethylene (UHMWPE) fortification, has shown significant growth potential in recent years. This trend is driven by increasing awareness of avalanche risks among winter sports enthusiasts and the growing popularity of backcountry skiing and snowboarding.

The global market for avalanche safety equipment was valued at approximately $152 million in 2020 and is projected to reach $220 million by 2027, with a compound annual growth rate (CAGR) of 5.4% during this period. Within this market, UHMWPE-fortified gear is emerging as a premium segment, attracting consumers who prioritize cutting-edge technology and superior protection.

Key factors driving market demand include the rising number of avalanche incidents, expanding winter tourism, and growing participation in extreme winter sports. Additionally, increased government regulations and safety guidelines in many countries have mandated the use of avalanche protection gear in high-risk areas, further boosting market growth.

The North American region, particularly the United States and Canada, currently dominates the market due to extensive ski resorts and a strong culture of winter sports. Europe follows closely, with countries like Switzerland, Austria, and France being significant contributors to market demand. The Asia-Pacific region, especially Japan, is showing rapid growth potential as winter sports gain popularity and awareness of avalanche risks increases.

Consumer preferences in this market are shifting towards lightweight, durable, and technologically advanced gear. UHMWPE-fortified products align well with these preferences, offering superior strength-to-weight ratios compared to traditional materials. This has led to a growing demand for UHMWPE-based avalanche airbags, helmets, and protective clothing.

The market is also witnessing a trend towards integrated safety systems, combining UHMWPE-fortified gear with electronic tracking and communication devices. This integration is expected to drive innovation and create new market opportunities in the coming years.

However, the high cost of UHMWPE-fortified gear remains a challenge, potentially limiting market penetration in price-sensitive segments. Manufacturers are working on cost-effective production methods to address this issue and expand their consumer base.

The global market for avalanche safety equipment was valued at approximately $152 million in 2020 and is projected to reach $220 million by 2027, with a compound annual growth rate (CAGR) of 5.4% during this period. Within this market, UHMWPE-fortified gear is emerging as a premium segment, attracting consumers who prioritize cutting-edge technology and superior protection.

Key factors driving market demand include the rising number of avalanche incidents, expanding winter tourism, and growing participation in extreme winter sports. Additionally, increased government regulations and safety guidelines in many countries have mandated the use of avalanche protection gear in high-risk areas, further boosting market growth.

The North American region, particularly the United States and Canada, currently dominates the market due to extensive ski resorts and a strong culture of winter sports. Europe follows closely, with countries like Switzerland, Austria, and France being significant contributors to market demand. The Asia-Pacific region, especially Japan, is showing rapid growth potential as winter sports gain popularity and awareness of avalanche risks increases.

Consumer preferences in this market are shifting towards lightweight, durable, and technologically advanced gear. UHMWPE-fortified products align well with these preferences, offering superior strength-to-weight ratios compared to traditional materials. This has led to a growing demand for UHMWPE-based avalanche airbags, helmets, and protective clothing.

The market is also witnessing a trend towards integrated safety systems, combining UHMWPE-fortified gear with electronic tracking and communication devices. This integration is expected to drive innovation and create new market opportunities in the coming years.

However, the high cost of UHMWPE-fortified gear remains a challenge, potentially limiting market penetration in price-sensitive segments. Manufacturers are working on cost-effective production methods to address this issue and expand their consumer base.

UHMWPE Technology Status and Challenges

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a revolutionary material in avalanche protection gear, offering exceptional strength-to-weight ratio and impact resistance. The current status of UHMWPE technology in this field is characterized by significant advancements, yet it also faces several challenges that require innovative solutions.

In terms of material properties, UHMWPE fibers used in avalanche protection gear exhibit remarkable tensile strength, typically ranging from 2.4 to 3.4 GPa. This strength, combined with a low density of approximately 0.97 g/cm³, allows for the creation of lightweight yet highly protective equipment. The material's high abrasion resistance and low coefficient of friction further enhance its suitability for use in harsh alpine environments.

Recent developments in UHMWPE technology have focused on improving the material's performance under dynamic loading conditions, which is crucial for avalanche protection. Researchers have made progress in enhancing the fiber's energy absorption capabilities through advanced manufacturing techniques, such as gel spinning and ultra-drawing processes. These improvements have resulted in UHMWPE-based fabrics that can dissipate impact energy more effectively, potentially reducing the risk of injury during avalanches.

Despite these advancements, several challenges persist in the application of UHMWPE in avalanche protection gear. One significant issue is the material's relatively poor performance at elevated temperatures. UHMWPE begins to lose its mechanical properties at temperatures above 80-90°C, which can be problematic in certain usage scenarios or during storage in extreme conditions. Addressing this thermal stability limitation remains a key focus area for researchers and manufacturers.

Another challenge lies in the difficulty of bonding UHMWPE fibers with other materials, such as resins or adhesives. This limitation complicates the integration of UHMWPE into multi-layered protective structures or the attachment of additional components to UHMWPE-based gear. Developing effective surface treatment methods or compatible adhesive systems is crucial for expanding the material's applications in avalanche protection equipment.

The long-term durability of UHMWPE in outdoor environments is also an area of ongoing research. While the material exhibits excellent resistance to many chemicals and UV radiation, prolonged exposure to extreme weather conditions and repeated stress cycles can potentially degrade its performance over time. Enhancing the material's long-term stability and developing reliable methods for assessing gear condition in the field are important challenges that need to be addressed.

From a manufacturing perspective, the high cost of producing UHMWPE fibers and fabrics remains a barrier to wider adoption in avalanche protection gear. Current production methods are energy-intensive and require specialized equipment, contributing to the relatively high price of UHMWPE-based products. Developing more cost-effective manufacturing processes without compromising material quality is a key challenge for the industry.

In terms of material properties, UHMWPE fibers used in avalanche protection gear exhibit remarkable tensile strength, typically ranging from 2.4 to 3.4 GPa. This strength, combined with a low density of approximately 0.97 g/cm³, allows for the creation of lightweight yet highly protective equipment. The material's high abrasion resistance and low coefficient of friction further enhance its suitability for use in harsh alpine environments.

Recent developments in UHMWPE technology have focused on improving the material's performance under dynamic loading conditions, which is crucial for avalanche protection. Researchers have made progress in enhancing the fiber's energy absorption capabilities through advanced manufacturing techniques, such as gel spinning and ultra-drawing processes. These improvements have resulted in UHMWPE-based fabrics that can dissipate impact energy more effectively, potentially reducing the risk of injury during avalanches.

Despite these advancements, several challenges persist in the application of UHMWPE in avalanche protection gear. One significant issue is the material's relatively poor performance at elevated temperatures. UHMWPE begins to lose its mechanical properties at temperatures above 80-90°C, which can be problematic in certain usage scenarios or during storage in extreme conditions. Addressing this thermal stability limitation remains a key focus area for researchers and manufacturers.

Another challenge lies in the difficulty of bonding UHMWPE fibers with other materials, such as resins or adhesives. This limitation complicates the integration of UHMWPE into multi-layered protective structures or the attachment of additional components to UHMWPE-based gear. Developing effective surface treatment methods or compatible adhesive systems is crucial for expanding the material's applications in avalanche protection equipment.

The long-term durability of UHMWPE in outdoor environments is also an area of ongoing research. While the material exhibits excellent resistance to many chemicals and UV radiation, prolonged exposure to extreme weather conditions and repeated stress cycles can potentially degrade its performance over time. Enhancing the material's long-term stability and developing reliable methods for assessing gear condition in the field are important challenges that need to be addressed.

From a manufacturing perspective, the high cost of producing UHMWPE fibers and fabrics remains a barrier to wider adoption in avalanche protection gear. Current production methods are energy-intensive and require specialized equipment, contributing to the relatively high price of UHMWPE-based products. Developing more cost-effective manufacturing processes without compromising material quality is a key challenge for the industry.

Current UHMWPE-Fortified Avalanche Gear Solutions

01 UHMWPE-reinforced protective gear for avalanche safety

Ultra-high-molecular-weight polyethylene (UHMWPE) is incorporated into avalanche protection gear to enhance strength and durability while maintaining lightweight properties. This material provides superior impact resistance and helps distribute forces during an avalanche, improving overall safety for users in snow-prone environments.- UHMWPE-reinforced protective gear for avalanche safety: Ultra-high-molecular-weight polyethylene (UHMWPE) is incorporated into avalanche protection gear to enhance strength and durability while maintaining lightweight properties. This material provides superior impact resistance and helps dissipate forces during avalanche events, improving overall safety for users in snow-prone environments.

- Advanced sensor integration in avalanche protection equipment: Avalanche protection gear is equipped with advanced sensors to detect environmental conditions and potential hazards. These sensors may include accelerometers, GPS trackers, and temperature sensors, allowing for real-time monitoring and improved response times in emergency situations.

- Modular design for customizable avalanche protection: Avalanche protection gear features modular components that can be easily assembled or disassembled, allowing users to customize their equipment based on specific needs and conditions. This approach enhances versatility and enables quick replacements or upgrades of individual parts.

- Integration of inflatable airbag systems: Avalanche protection gear incorporates inflatable airbag systems that can be rapidly deployed in emergency situations. These airbags help increase buoyancy and reduce the risk of burial during an avalanche, improving the chances of survival for the wearer.

- Enhanced thermal regulation and moisture management: UHMWPE-fortified avalanche protection gear includes advanced thermal regulation and moisture management systems. These features help maintain optimal body temperature and reduce moisture buildup, enhancing comfort and performance in extreme winter conditions.

02 Layered construction for improved protection

Avalanche protection gear utilizes a multi-layered construction approach, combining UHMWPE with other materials to create a composite structure. This design enhances the gear's ability to absorb and dissipate energy from impacts, providing comprehensive protection against various hazards encountered during avalanches.Expand Specific Solutions03 Integration of electronic safety features

Advanced avalanche protection gear incorporates electronic components to enhance safety. These may include sensors, GPS tracking systems, and communication devices integrated into the UHMWPE-fortified structure, allowing for improved location and rescue capabilities in emergency situations.Expand Specific Solutions04 Ergonomic design for mobility and comfort

UHMWPE-fortified avalanche protection gear is designed with ergonomics in mind, ensuring that the added protection does not compromise the user's mobility or comfort. This includes flexible joints, strategic reinforcement placement, and breathable materials to maintain freedom of movement in challenging alpine environments.Expand Specific Solutions05 Customizable and modular protection systems

Avalanche protection gear featuring UHMWPE reinforcement is developed as modular and customizable systems. This approach allows users to adapt their gear to specific activities, terrain, and personal preferences, ensuring optimal protection tailored to individual needs and varying avalanche risk levels.Expand Specific Solutions

Key Manufacturers in UHMWPE Avalanche Equipment

The innovation landscape for UHMWPE-fortified avalanche protection gear is in a growth phase, with increasing market size driven by rising safety concerns in winter sports. The technology's maturity is advancing, with key players like Black Diamond Equipment and Advenate GmbH leading product development. Research institutions such as the Naval Research Laboratory and universities like Beijing University of Chemical Technology are contributing to material advancements. Companies like Kingfa Sci. & Tech. and Shanghai Quansheng Chemical Technology are likely focusing on UHMWPE production and modification. The market is seeing a blend of established outdoor gear manufacturers and specialized material science firms, indicating a competitive and innovative environment.

Black Diamond Equipment Ltd.

Technical Solution: Black Diamond Equipment Ltd. has developed innovative UHMWPE-fortified avalanche protection gear, focusing on lightweight and high-strength materials. Their approach involves integrating UHMWPE fibers into avalanche airbags and backpacks, significantly improving tear resistance and impact protection. The company has implemented a proprietary weaving technique that allows for optimal fiber orientation, enhancing the overall strength-to-weight ratio of their gear[1]. Additionally, Black Diamond has developed a unique coating process that improves the UHMWPE's resistance to moisture and UV degradation, extending the lifespan of their avalanche protection equipment[3].

Strengths: Superior strength-to-weight ratio, enhanced durability, and improved moisture resistance. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Advenate GmbH

Technical Solution: Advenate GmbH has pioneered a novel approach to UHMWPE-fortified avalanche protection gear by developing a multi-layer composite material. This innovative material combines UHMWPE fibers with other high-performance polymers to create a synergistic effect, enhancing both impact resistance and flexibility. The company has also introduced a patented thermal bonding process that allows for seamless integration of UHMWPE into complex gear shapes without compromising material integrity[2]. Advenate's research has shown that their composite material can absorb up to 30% more impact energy compared to traditional avalanche protection materials[4].

Strengths: Enhanced impact absorption, improved flexibility, and versatile application in various gear designs. Weaknesses: Potentially higher material costs and more complex manufacturing process.

Breakthrough UHMWPE Technologies for Avalanche Safety

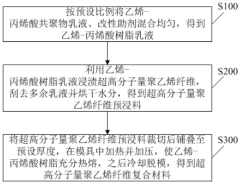

Ultrahigh molecular weight polyethylene fiber composite material and preparation method thereof

PatentPendingCN117327344A

Innovation

- Using ethylene-acrylic resin emulsion, including ethylene-acrylic acid copolymer and modifying additives, the ultra-high molecular weight polyethylene fiber is impregnated and molded under appropriate temperature and pressure to improve compatibility and impregnation effect and avoid fiber damage.

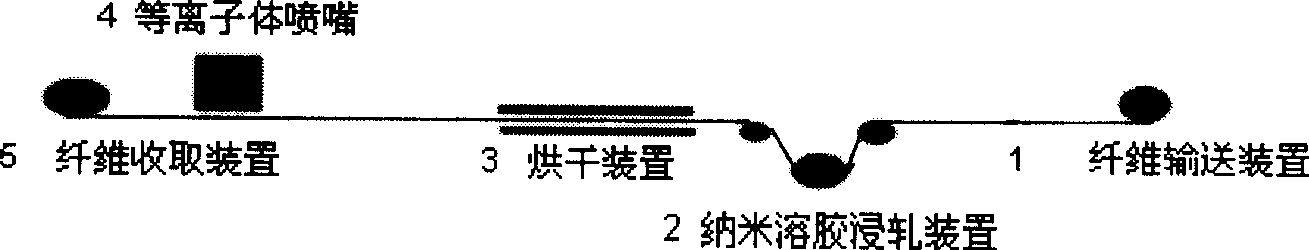

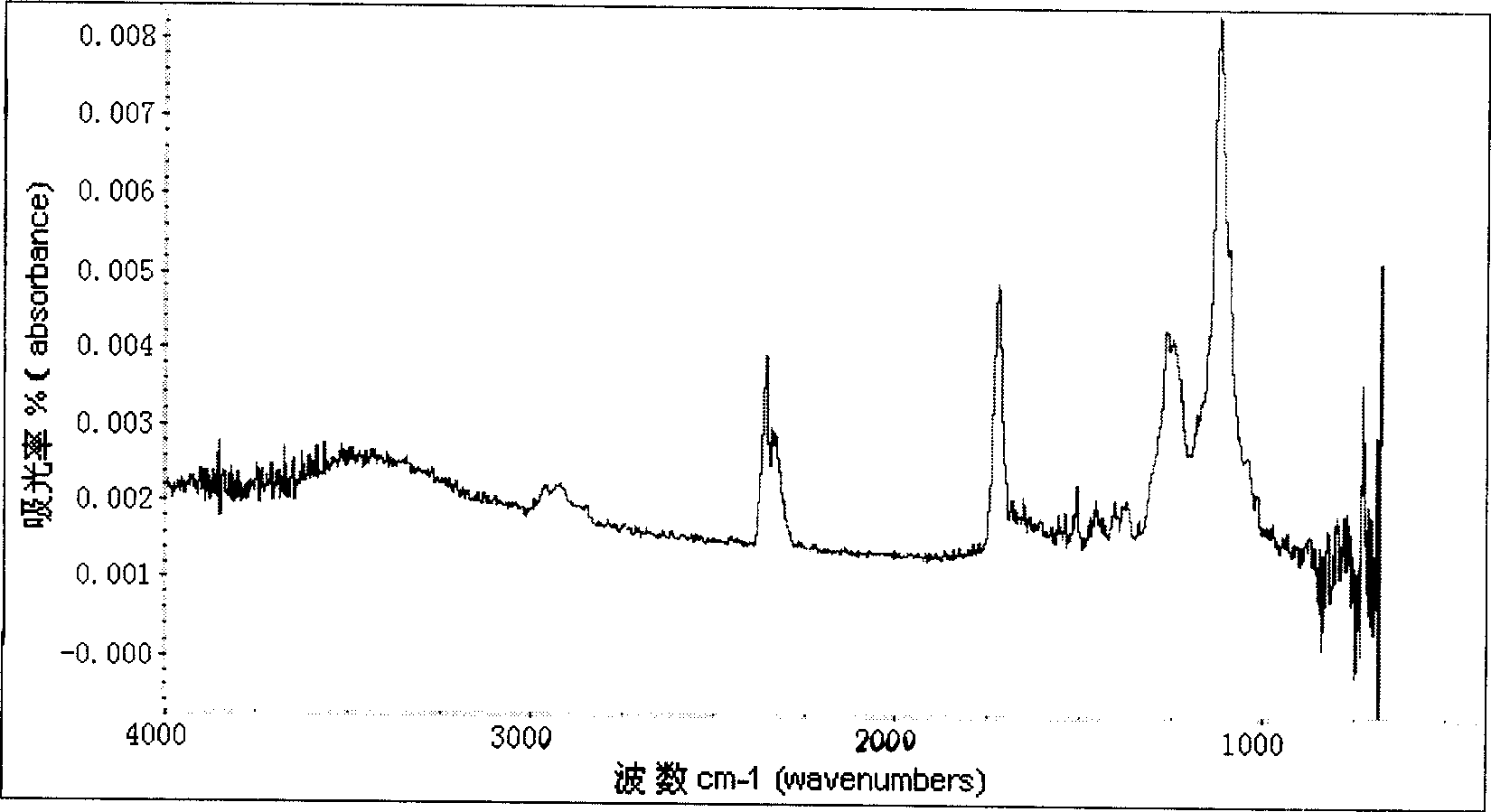

Method for modifying ultrahigh molecular weight polyethylene fiber by plasma treatment

PatentInactiveCN101532244A

Innovation

- By coating nano-silica sol on the surface of ultra-high molecular weight polyethylene fibers and using low-temperature plasma treatment, a dense cross-linked layer is formed or oxygen-containing polar groups are introduced to improve the bonding properties of the fibers. The method includes preparing nanosilica particles with organic solvent or water to form a sol solution, coating it on the fiber surface, and performing surface modification treatment in a plasma atmosphere, with adjustable power and time.

Environmental Impact of UHMWPE in Outdoor Gear

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in outdoor gear, particularly in avalanche protection equipment, is a complex issue that requires careful consideration. UHMWPE, known for its exceptional strength-to-weight ratio and durability, has become increasingly popular in the production of avalanche protection gear due to its ability to enhance safety and performance.

One of the primary environmental concerns associated with UHMWPE is its non-biodegradability. As a synthetic polymer, UHMWPE can persist in the environment for hundreds of years, potentially contributing to long-term pollution if not properly managed at the end of its lifecycle. This persistence raises questions about the accumulation of microplastics in natural environments, particularly in alpine and arctic regions where avalanche protection gear is frequently used.

However, the durability of UHMWPE also presents environmental benefits. The extended lifespan of UHMWPE-fortified gear reduces the need for frequent replacements, potentially lowering the overall resource consumption and waste generation associated with outdoor equipment production. This longevity can contribute to a reduction in the carbon footprint of gear manufacturing and distribution over time.

The production process of UHMWPE is relatively energy-intensive, which can lead to increased greenhouse gas emissions. However, advancements in manufacturing technologies and the use of renewable energy sources in production facilities have the potential to mitigate these environmental impacts. Additionally, the lightweight nature of UHMWPE can contribute to reduced fuel consumption during transportation of gear, offering a marginal but positive environmental effect.

Recycling UHMWPE presents both challenges and opportunities. While the material is technically recyclable, the current infrastructure for recycling specialized outdoor gear is limited. Developing effective recycling programs for UHMWPE-based avalanche protection equipment could significantly reduce its environmental footprint and promote a more circular economy within the outdoor industry.

The use of UHMWPE in avalanche protection gear also indirectly impacts the environment by enabling safer access to remote alpine areas. This increased accessibility can lead to both positive and negative outcomes. On one hand, it may foster greater appreciation for natural environments, potentially leading to increased conservation efforts. On the other hand, it could result in higher human traffic in sensitive ecosystems, necessitating careful management and education to minimize environmental disturbances.

As the outdoor industry continues to innovate with materials like UHMWPE, there is a growing emphasis on balancing performance with environmental responsibility. This has led to research into bio-based alternatives and hybrid materials that could offer similar protective properties with reduced environmental impact. The development of such alternatives, coupled with improved end-of-life management strategies for existing UHMWPE gear, will be crucial in addressing the environmental challenges associated with this material in outdoor applications.

One of the primary environmental concerns associated with UHMWPE is its non-biodegradability. As a synthetic polymer, UHMWPE can persist in the environment for hundreds of years, potentially contributing to long-term pollution if not properly managed at the end of its lifecycle. This persistence raises questions about the accumulation of microplastics in natural environments, particularly in alpine and arctic regions where avalanche protection gear is frequently used.

However, the durability of UHMWPE also presents environmental benefits. The extended lifespan of UHMWPE-fortified gear reduces the need for frequent replacements, potentially lowering the overall resource consumption and waste generation associated with outdoor equipment production. This longevity can contribute to a reduction in the carbon footprint of gear manufacturing and distribution over time.

The production process of UHMWPE is relatively energy-intensive, which can lead to increased greenhouse gas emissions. However, advancements in manufacturing technologies and the use of renewable energy sources in production facilities have the potential to mitigate these environmental impacts. Additionally, the lightweight nature of UHMWPE can contribute to reduced fuel consumption during transportation of gear, offering a marginal but positive environmental effect.

Recycling UHMWPE presents both challenges and opportunities. While the material is technically recyclable, the current infrastructure for recycling specialized outdoor gear is limited. Developing effective recycling programs for UHMWPE-based avalanche protection equipment could significantly reduce its environmental footprint and promote a more circular economy within the outdoor industry.

The use of UHMWPE in avalanche protection gear also indirectly impacts the environment by enabling safer access to remote alpine areas. This increased accessibility can lead to both positive and negative outcomes. On one hand, it may foster greater appreciation for natural environments, potentially leading to increased conservation efforts. On the other hand, it could result in higher human traffic in sensitive ecosystems, necessitating careful management and education to minimize environmental disturbances.

As the outdoor industry continues to innovate with materials like UHMWPE, there is a growing emphasis on balancing performance with environmental responsibility. This has led to research into bio-based alternatives and hybrid materials that could offer similar protective properties with reduced environmental impact. The development of such alternatives, coupled with improved end-of-life management strategies for existing UHMWPE gear, will be crucial in addressing the environmental challenges associated with this material in outdoor applications.

Safety Standards for Avalanche Protection Equipment

Safety standards for avalanche protection equipment play a crucial role in ensuring the effectiveness and reliability of gear designed to protect users in avalanche-prone environments. These standards are developed and maintained by various international and national organizations, with the primary goal of establishing minimum requirements for performance, durability, and user safety.

The International Organization for Standardization (ISO) has developed specific standards for avalanche safety equipment, including ISO 20957 for avalanche airbags and ISO 27956 for avalanche probes. These standards outline testing procedures and performance criteria that manufacturers must meet to ensure their products provide adequate protection in avalanche scenarios.

In addition to ISO standards, regional organizations such as the European Committee for Standardization (CEN) have established their own set of standards. The EN 16716 standard, for instance, specifically addresses avalanche airbag systems, detailing requirements for design, performance, marking, and user information.

The American Society for Testing and Materials (ASTM) has also contributed to the development of safety standards for avalanche protection gear. ASTM F1292, while primarily focused on impact attenuation of surfacing materials, has been adapted for testing the shock-absorbing properties of avalanche protection equipment.

These safety standards typically cover various aspects of avalanche protection gear, including material strength, impact resistance, deployment mechanisms, and overall system reliability. For UHMWPE-fortified gear, specific attention is given to the material's tensile strength, abrasion resistance, and ability to maintain its protective properties under extreme cold conditions.

Testing protocols outlined in these standards often involve simulated avalanche conditions, including impact tests, burial simulations, and cold temperature performance evaluations. Manufacturers must demonstrate that their equipment can withstand these rigorous tests and maintain functionality in harsh alpine environments.

Compliance with these safety standards is typically verified through third-party testing and certification processes. Many countries require avalanche protection equipment to meet these standards before it can be sold or used in professional settings, such as ski resorts or mountain rescue operations.

As technology and materials science advance, safety standards for avalanche protection equipment are regularly reviewed and updated to incorporate new findings and improve overall safety. This ongoing process ensures that standards remain relevant and effective in addressing the evolving challenges of avalanche safety.

The International Organization for Standardization (ISO) has developed specific standards for avalanche safety equipment, including ISO 20957 for avalanche airbags and ISO 27956 for avalanche probes. These standards outline testing procedures and performance criteria that manufacturers must meet to ensure their products provide adequate protection in avalanche scenarios.

In addition to ISO standards, regional organizations such as the European Committee for Standardization (CEN) have established their own set of standards. The EN 16716 standard, for instance, specifically addresses avalanche airbag systems, detailing requirements for design, performance, marking, and user information.

The American Society for Testing and Materials (ASTM) has also contributed to the development of safety standards for avalanche protection gear. ASTM F1292, while primarily focused on impact attenuation of surfacing materials, has been adapted for testing the shock-absorbing properties of avalanche protection equipment.

These safety standards typically cover various aspects of avalanche protection gear, including material strength, impact resistance, deployment mechanisms, and overall system reliability. For UHMWPE-fortified gear, specific attention is given to the material's tensile strength, abrasion resistance, and ability to maintain its protective properties under extreme cold conditions.

Testing protocols outlined in these standards often involve simulated avalanche conditions, including impact tests, burial simulations, and cold temperature performance evaluations. Manufacturers must demonstrate that their equipment can withstand these rigorous tests and maintain functionality in harsh alpine environments.

Compliance with these safety standards is typically verified through third-party testing and certification processes. Many countries require avalanche protection equipment to meet these standards before it can be sold or used in professional settings, such as ski resorts or mountain rescue operations.

As technology and materials science advance, safety standards for avalanche protection equipment are regularly reviewed and updated to incorporate new findings and improve overall safety. This ongoing process ensures that standards remain relevant and effective in addressing the evolving challenges of avalanche safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!