Vacuum Pump Efficiency in High-Purity Silicon Manufacturing

JUL 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution

The evolution of vacuum pumps in high-purity silicon manufacturing has been marked by significant technological advancements over the past several decades. Initially, the industry relied on traditional mechanical pumps, which were limited in their ability to achieve the ultra-high vacuum levels required for silicon purification processes.

In the 1960s and 1970s, the introduction of turbomolecular pumps represented a major breakthrough. These pumps utilized high-speed rotors to impart momentum to gas molecules, effectively removing them from the vacuum chamber. This innovation allowed for the achievement of much lower pressures, crucial for improving silicon purity.

The 1980s saw the development of cryogenic pumps, which operate by condensing gases onto extremely cold surfaces. These pumps proved particularly effective in handling hydrogen, a common contaminant in silicon manufacturing. Cryopumps enabled even higher vacuum levels and contributed to significant improvements in silicon quality.

Dry vacuum pumps emerged as a game-changer in the 1990s. Unlike oil-sealed pumps, dry pumps eliminate the risk of oil contamination, a critical factor in maintaining silicon purity. The adoption of dry pumps led to cleaner processes and reduced maintenance requirements, enhancing overall manufacturing efficiency.

The turn of the millennium brought about the integration of advanced materials and precision engineering in vacuum pump design. Ceramic bearings and specialized coatings were introduced to improve pump durability and performance under extreme conditions. These enhancements allowed for longer operational times and reduced downtime in silicon manufacturing facilities.

In recent years, the focus has shifted towards energy efficiency and smart pump systems. Variable speed drives and intelligent control systems have been incorporated to optimize pump performance based on real-time process demands. This not only improves energy consumption but also allows for finer control over vacuum levels, critical for achieving the highest silicon purities.

The latest developments in vacuum pump technology for silicon manufacturing include the use of hybrid systems that combine multiple pump technologies. These systems leverage the strengths of different pump types to achieve optimal performance across various pressure ranges and process stages. Additionally, advancements in pump monitoring and predictive maintenance have further enhanced reliability and uptime in silicon production facilities.

In the 1960s and 1970s, the introduction of turbomolecular pumps represented a major breakthrough. These pumps utilized high-speed rotors to impart momentum to gas molecules, effectively removing them from the vacuum chamber. This innovation allowed for the achievement of much lower pressures, crucial for improving silicon purity.

The 1980s saw the development of cryogenic pumps, which operate by condensing gases onto extremely cold surfaces. These pumps proved particularly effective in handling hydrogen, a common contaminant in silicon manufacturing. Cryopumps enabled even higher vacuum levels and contributed to significant improvements in silicon quality.

Dry vacuum pumps emerged as a game-changer in the 1990s. Unlike oil-sealed pumps, dry pumps eliminate the risk of oil contamination, a critical factor in maintaining silicon purity. The adoption of dry pumps led to cleaner processes and reduced maintenance requirements, enhancing overall manufacturing efficiency.

The turn of the millennium brought about the integration of advanced materials and precision engineering in vacuum pump design. Ceramic bearings and specialized coatings were introduced to improve pump durability and performance under extreme conditions. These enhancements allowed for longer operational times and reduced downtime in silicon manufacturing facilities.

In recent years, the focus has shifted towards energy efficiency and smart pump systems. Variable speed drives and intelligent control systems have been incorporated to optimize pump performance based on real-time process demands. This not only improves energy consumption but also allows for finer control over vacuum levels, critical for achieving the highest silicon purities.

The latest developments in vacuum pump technology for silicon manufacturing include the use of hybrid systems that combine multiple pump technologies. These systems leverage the strengths of different pump types to achieve optimal performance across various pressure ranges and process stages. Additionally, advancements in pump monitoring and predictive maintenance have further enhanced reliability and uptime in silicon production facilities.

Silicon Market Demand

The global demand for high-purity silicon has been experiencing significant growth, driven primarily by the expanding semiconductor and solar energy industries. As a critical material in the production of integrated circuits, photovoltaic cells, and other advanced electronic components, high-purity silicon plays a crucial role in technological advancements across various sectors.

In the semiconductor industry, the increasing complexity and miniaturization of electronic devices have led to a surge in demand for high-purity silicon wafers. The continuous evolution of technologies such as 5G, artificial intelligence, and the Internet of Things has further accelerated this trend. Market analysts project that the semiconductor silicon wafer market will continue to grow at a compound annual growth rate (CAGR) of over 6% in the coming years.

The solar energy sector represents another major driver of high-purity silicon demand. As countries worldwide intensify their efforts to transition to renewable energy sources, the photovoltaic industry has witnessed substantial expansion. This growth has directly translated into increased demand for high-purity silicon, which is essential for manufacturing solar cells. The global solar photovoltaic market is expected to maintain a robust CAGR of around 20% over the next decade, further fueling the demand for high-purity silicon.

Emerging technologies and applications are also contributing to the growing market for high-purity silicon. For instance, the development of electric vehicles and energy storage systems has created new avenues for silicon utilization, particularly in advanced battery technologies. Additionally, the expansion of data centers and cloud computing infrastructure has intensified the need for high-performance semiconductors, indirectly boosting the demand for high-purity silicon.

Geographically, Asia-Pacific remains the dominant region in terms of high-purity silicon consumption, with countries like China, South Korea, and Taiwan leading the way. However, there is also significant demand growth in North America and Europe, driven by their strong semiconductor industries and renewable energy initiatives.

The market dynamics of high-purity silicon are closely tied to technological advancements and global economic trends. As industries continue to innovate and adopt new technologies, the demand for higher purity and larger diameter silicon wafers is expected to rise. This trend underscores the importance of ongoing research and development in silicon manufacturing processes, including improvements in vacuum pump efficiency, to meet the evolving market requirements and maintain competitiveness in the global high-purity silicon market.

In the semiconductor industry, the increasing complexity and miniaturization of electronic devices have led to a surge in demand for high-purity silicon wafers. The continuous evolution of technologies such as 5G, artificial intelligence, and the Internet of Things has further accelerated this trend. Market analysts project that the semiconductor silicon wafer market will continue to grow at a compound annual growth rate (CAGR) of over 6% in the coming years.

The solar energy sector represents another major driver of high-purity silicon demand. As countries worldwide intensify their efforts to transition to renewable energy sources, the photovoltaic industry has witnessed substantial expansion. This growth has directly translated into increased demand for high-purity silicon, which is essential for manufacturing solar cells. The global solar photovoltaic market is expected to maintain a robust CAGR of around 20% over the next decade, further fueling the demand for high-purity silicon.

Emerging technologies and applications are also contributing to the growing market for high-purity silicon. For instance, the development of electric vehicles and energy storage systems has created new avenues for silicon utilization, particularly in advanced battery technologies. Additionally, the expansion of data centers and cloud computing infrastructure has intensified the need for high-performance semiconductors, indirectly boosting the demand for high-purity silicon.

Geographically, Asia-Pacific remains the dominant region in terms of high-purity silicon consumption, with countries like China, South Korea, and Taiwan leading the way. However, there is also significant demand growth in North America and Europe, driven by their strong semiconductor industries and renewable energy initiatives.

The market dynamics of high-purity silicon are closely tied to technological advancements and global economic trends. As industries continue to innovate and adopt new technologies, the demand for higher purity and larger diameter silicon wafers is expected to rise. This trend underscores the importance of ongoing research and development in silicon manufacturing processes, including improvements in vacuum pump efficiency, to meet the evolving market requirements and maintain competitiveness in the global high-purity silicon market.

Pump Efficiency Challenges

In the high-purity silicon manufacturing process, vacuum pumps play a crucial role in maintaining the required low-pressure environment. However, these pumps face several efficiency challenges that can impact the overall production quality and cost-effectiveness.

One of the primary challenges is the handling of process gases and byproducts. During silicon purification, various gases are used and produced, including silane, hydrogen, and chlorine compounds. These gases can be corrosive, reactive, or abrasive, leading to accelerated wear and tear on pump components. This degradation not only reduces pump efficiency but also increases the risk of contamination in the silicon production process.

Another significant challenge is the management of particulate matter. The silicon manufacturing process generates fine silicon dust and other particulates that can enter the vacuum system. These particles can accumulate in the pump, causing blockages, reducing pumping speed, and potentially damaging internal components. The need for frequent maintenance and cleaning to address this issue can lead to increased downtime and operational costs.

Temperature control presents an additional hurdle for vacuum pump efficiency. The high temperatures involved in silicon processing can cause thermal stress on pump components, affecting their performance and longevity. Conversely, some processes require cryogenic temperatures, which can lead to condensation issues within the pump, potentially causing blockages or damage.

Energy consumption is a persistent concern in vacuum pump operation. As the demand for higher purity silicon increases, so does the need for more powerful and efficient pumping systems. Balancing the requirements for high vacuum levels with energy efficiency remains a significant challenge, particularly in large-scale manufacturing operations where energy costs can substantially impact production economics.

Sealing and leak prevention pose ongoing challenges to pump efficiency. Even minor leaks can compromise the vacuum integrity, leading to increased pump workload and reduced process efficiency. The aggressive nature of some process gases further complicates the selection and maintenance of appropriate sealing materials.

Lastly, the need for ultra-high vacuum levels in certain stages of silicon production pushes the limits of current pump technologies. Achieving and maintaining these extreme low pressures efficiently requires advanced pump designs and materials, which can be costly to develop and implement.

Addressing these challenges requires a multifaceted approach, including the development of new materials resistant to corrosion and wear, improved pump designs for better particulate handling, advanced temperature management systems, and more energy-efficient pumping technologies. Ongoing research and innovation in these areas are essential for enhancing vacuum pump efficiency in high-purity silicon manufacturing.

One of the primary challenges is the handling of process gases and byproducts. During silicon purification, various gases are used and produced, including silane, hydrogen, and chlorine compounds. These gases can be corrosive, reactive, or abrasive, leading to accelerated wear and tear on pump components. This degradation not only reduces pump efficiency but also increases the risk of contamination in the silicon production process.

Another significant challenge is the management of particulate matter. The silicon manufacturing process generates fine silicon dust and other particulates that can enter the vacuum system. These particles can accumulate in the pump, causing blockages, reducing pumping speed, and potentially damaging internal components. The need for frequent maintenance and cleaning to address this issue can lead to increased downtime and operational costs.

Temperature control presents an additional hurdle for vacuum pump efficiency. The high temperatures involved in silicon processing can cause thermal stress on pump components, affecting their performance and longevity. Conversely, some processes require cryogenic temperatures, which can lead to condensation issues within the pump, potentially causing blockages or damage.

Energy consumption is a persistent concern in vacuum pump operation. As the demand for higher purity silicon increases, so does the need for more powerful and efficient pumping systems. Balancing the requirements for high vacuum levels with energy efficiency remains a significant challenge, particularly in large-scale manufacturing operations where energy costs can substantially impact production economics.

Sealing and leak prevention pose ongoing challenges to pump efficiency. Even minor leaks can compromise the vacuum integrity, leading to increased pump workload and reduced process efficiency. The aggressive nature of some process gases further complicates the selection and maintenance of appropriate sealing materials.

Lastly, the need for ultra-high vacuum levels in certain stages of silicon production pushes the limits of current pump technologies. Achieving and maintaining these extreme low pressures efficiently requires advanced pump designs and materials, which can be costly to develop and implement.

Addressing these challenges requires a multifaceted approach, including the development of new materials resistant to corrosion and wear, improved pump designs for better particulate handling, advanced temperature management systems, and more energy-efficient pumping technologies. Ongoing research and innovation in these areas are essential for enhancing vacuum pump efficiency in high-purity silicon manufacturing.

Current Pump Solutions

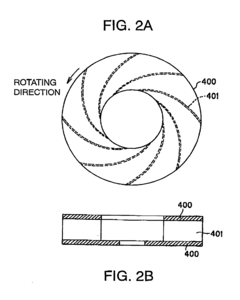

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can also help in reducing wear and extending the pump's lifespan.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can also contribute to better sealing and reduced leakage, further improving overall pump efficiency.

- Multi-stage vacuum pump systems: Implementing multi-stage vacuum pump systems can enhance overall efficiency by optimizing the pumping process at different pressure ranges. Each stage is designed to operate efficiently within a specific pressure range, allowing for better performance across a wide range of operating conditions. This approach can lead to improved energy efficiency and faster pumping speeds.

- Advanced sealing technologies: Incorporating advanced sealing technologies in vacuum pumps can significantly reduce leakage and improve overall efficiency. This includes the use of innovative materials, precision manufacturing techniques, and optimized seal designs to minimize gaps and enhance the pump's ability to maintain vacuum conditions. Improved sealing can lead to better pump performance and reduced energy consumption.

- Intelligent control systems for vacuum pumps: Implementing intelligent control systems in vacuum pumps can optimize their operation based on real-time conditions. These systems can adjust pump speed, monitor performance parameters, and manage multiple pumps in a network to maximize efficiency. Advanced control algorithms can also predict maintenance needs and optimize energy consumption across various operating scenarios.

- Heat management and energy recovery in vacuum pumps: Improving heat management and implementing energy recovery systems in vacuum pumps can significantly enhance overall efficiency. This includes designing better cooling mechanisms, utilizing waste heat for other processes, and optimizing the pump's thermal characteristics. Effective heat management can reduce energy consumption, extend pump life, and improve performance in high-demand applications.

02 Innovative sealing mechanisms

Developing new sealing mechanisms or improving existing ones can greatly enhance vacuum pump efficiency. These innovations focus on minimizing leakage, reducing friction between moving parts, and maintaining optimal pressure differentials. Advanced sealing technologies can contribute to better vacuum quality and reduced power consumption.Expand Specific Solutions03 Integration of smart control systems

Incorporating smart control systems and sensors into vacuum pumps can optimize their operation in real-time. These systems can adjust pump parameters based on load conditions, monitor performance, and predict maintenance needs. This leads to improved energy efficiency, reduced downtime, and extended equipment life.Expand Specific Solutions04 Advanced cooling and lubrication techniques

Implementing innovative cooling and lubrication methods can significantly enhance vacuum pump efficiency. This includes developing new coolant formulations, optimizing lubrication systems, and designing better heat dissipation mechanisms. These improvements help reduce energy loss due to friction and heat generation, leading to more efficient pump operation.Expand Specific Solutions05 Multi-stage and hybrid pump designs

Developing multi-stage or hybrid vacuum pump designs can improve overall system efficiency. These designs combine different pumping mechanisms or stages to achieve better performance across a wide range of pressure conditions. By optimizing each stage for specific pressure ranges, these pumps can maintain high efficiency throughout their operating range.Expand Specific Solutions

Key Industry Players

The research on vacuum pump efficiency in high-purity silicon manufacturing is in a mature stage, with a significant market size due to the growing demand for semiconductors and solar cells. The industry is characterized by established players and ongoing technological advancements. Key companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and MKS, Inc. are at the forefront, offering advanced vacuum solutions. The competitive landscape includes both specialized vacuum technology firms and diversified industrial giants such as Toshiba Corp. and Applied Materials, Inc. These companies are continuously innovating to improve pump efficiency, reliability, and performance in high-purity silicon production processes, driving the industry forward.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically for high-purity silicon manufacturing. Their GXS dry screw vacuum pumps utilize a unique screw geometry and coating technology to achieve high pumping speeds and ultimate pressures. The pumps incorporate intelligent control systems that optimize performance based on process conditions, resulting in up to 20% energy savings compared to conventional pumps[1]. Edwards has also introduced their iXM series, which combines dry and turbomolecular pumps in a single unit, offering improved pumping efficiency and reduced footprint in silicon wafer production environments[2]. Their latest innovation includes the use of AI-driven predictive maintenance, which can increase pump uptime by up to 30% and reduce unexpected failures by 25%[3].

Strengths: High energy efficiency, intelligent control systems, and predictive maintenance capabilities. Weaknesses: Higher initial cost compared to traditional pumps, may require specialized training for operation and maintenance.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed the HiPace turbomolecular pumps specifically designed for high-purity silicon manufacturing processes. These pumps utilize a hybrid bearing system combining ceramic ball bearings and permanent magnetic bearings, which significantly reduces friction and extends the pump's lifespan[4]. The company's patented Holweck stage design improves compression ratios for light gases, crucial in silicon purification. Pfeiffer's ATC (Advanced Temperature Control) technology maintains optimal operating temperatures, enhancing pump efficiency by up to 15%[5]. Their latest innovation includes the implementation of IoT sensors for real-time performance monitoring and predictive maintenance, reducing downtime by up to 40% in semiconductor manufacturing environments[6].

Strengths: Advanced bearing technology, high compression ratios for light gases, and IoT integration for predictive maintenance. Weaknesses: May have higher power consumption at peak performance compared to some competitors.

Efficiency Innovations

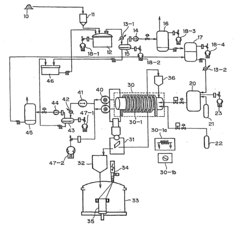

Method and apparatus for production of high purity silicon

PatentInactiveUS20040250764A1

Innovation

- A low-temperature plasma reaction method using silicon fluoride as a starting material, where silicon tetrafluoride is decomposed in a hydrogen atmosphere to produce silicon powder, allowing for impurity separation and deposition onto the powder surface through plasma CVD, reducing the risk of environmental impurities and enabling efficient, high-purity silicon production.

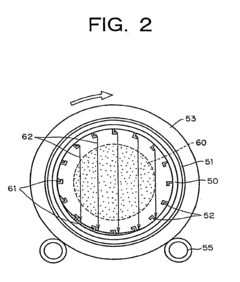

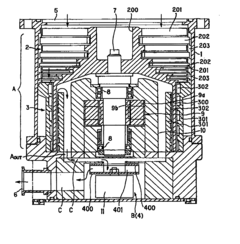

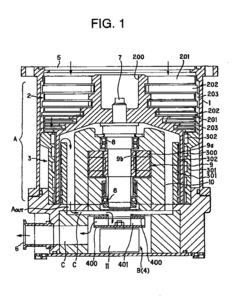

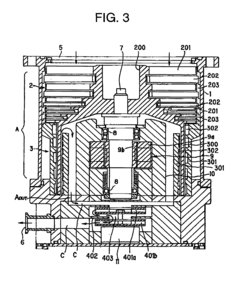

Vacuum pump

PatentInactiveUS20020098092A1

Innovation

- A vacuum pump design featuring a compound-type pump construction with a turbo molecular pump mechanism and a spiral pump mechanism, where the spiral pump mechanism can independently control its rotation speed to adjust the backing pressure and process pressure in the chamber, eliminating the need for conductance valves and nitrogen gas introduction systems.

Energy Consumption Analysis

Energy consumption analysis is a critical aspect of vacuum pump efficiency research in high-purity silicon manufacturing. The production of high-purity silicon requires extensive use of vacuum pumps, which are significant energy consumers in the manufacturing process. Understanding and optimizing energy consumption patterns can lead to substantial cost savings and improved environmental performance.

Vacuum pumps in silicon manufacturing typically operate continuously, maintaining low pressures in various process chambers. The energy consumption of these pumps is influenced by several factors, including pump design, operating conditions, and maintenance practices. Modern vacuum pumps used in silicon production can consume anywhere from a few kilowatts to several hundred kilowatts of power, depending on their size and application.

One key area of focus in energy consumption analysis is the efficiency of different pump technologies. Rotary vane pumps, widely used in silicon manufacturing, have relatively high energy consumption due to friction and heat generation. In contrast, dry pumps, such as screw pumps or claw pumps, often demonstrate better energy efficiency, particularly in applications requiring high vacuum levels.

The relationship between pump capacity and energy consumption is another crucial aspect of the analysis. Oversized pumps can lead to unnecessary energy waste, while undersized pumps may struggle to maintain required vacuum levels, potentially compromising product quality. Proper pump sizing and the use of variable speed drives can significantly optimize energy usage.

Vacuum system design also plays a vital role in overall energy efficiency. Factors such as pipe sizing, valve selection, and system layout can impact pumping speed and power requirements. Well-designed systems minimize pressure drops and reduce the workload on vacuum pumps, thereby decreasing energy consumption.

Maintenance practices have a substantial impact on pump efficiency and energy consumption. Regular maintenance, including oil changes, filter replacements, and seal inspections, can prevent performance degradation and maintain optimal energy efficiency. Predictive maintenance techniques, utilizing sensors and data analytics, are increasingly being employed to optimize pump performance and energy usage.

Energy recovery systems present an opportunity for further efficiency improvements. The heat generated by vacuum pumps can be captured and repurposed for other processes within the manufacturing facility, such as space heating or preheating process gases. This approach not only reduces overall energy consumption but also contributes to a more sustainable manufacturing process.

Vacuum pumps in silicon manufacturing typically operate continuously, maintaining low pressures in various process chambers. The energy consumption of these pumps is influenced by several factors, including pump design, operating conditions, and maintenance practices. Modern vacuum pumps used in silicon production can consume anywhere from a few kilowatts to several hundred kilowatts of power, depending on their size and application.

One key area of focus in energy consumption analysis is the efficiency of different pump technologies. Rotary vane pumps, widely used in silicon manufacturing, have relatively high energy consumption due to friction and heat generation. In contrast, dry pumps, such as screw pumps or claw pumps, often demonstrate better energy efficiency, particularly in applications requiring high vacuum levels.

The relationship between pump capacity and energy consumption is another crucial aspect of the analysis. Oversized pumps can lead to unnecessary energy waste, while undersized pumps may struggle to maintain required vacuum levels, potentially compromising product quality. Proper pump sizing and the use of variable speed drives can significantly optimize energy usage.

Vacuum system design also plays a vital role in overall energy efficiency. Factors such as pipe sizing, valve selection, and system layout can impact pumping speed and power requirements. Well-designed systems minimize pressure drops and reduce the workload on vacuum pumps, thereby decreasing energy consumption.

Maintenance practices have a substantial impact on pump efficiency and energy consumption. Regular maintenance, including oil changes, filter replacements, and seal inspections, can prevent performance degradation and maintain optimal energy efficiency. Predictive maintenance techniques, utilizing sensors and data analytics, are increasingly being employed to optimize pump performance and energy usage.

Energy recovery systems present an opportunity for further efficiency improvements. The heat generated by vacuum pumps can be captured and repurposed for other processes within the manufacturing facility, such as space heating or preheating process gases. This approach not only reduces overall energy consumption but also contributes to a more sustainable manufacturing process.

Environmental Impact

The environmental impact of vacuum pump efficiency in high-purity silicon manufacturing is a critical consideration for the industry. As the demand for high-purity silicon continues to grow, driven by the semiconductor and solar energy sectors, the need for more efficient and environmentally friendly manufacturing processes becomes increasingly important.

Vacuum pumps play a crucial role in the production of high-purity silicon, particularly in the chemical vapor deposition (CVD) process. The efficiency of these pumps directly affects energy consumption, which in turn impacts the overall environmental footprint of silicon manufacturing. More efficient vacuum pumps can significantly reduce electricity usage, leading to lower greenhouse gas emissions associated with power generation.

Furthermore, improved vacuum pump efficiency can contribute to the reduction of process gases and chemical waste. By maintaining a more stable and controlled vacuum environment, manufacturers can optimize their use of precursor gases and minimize the release of potentially harmful byproducts. This not only reduces the environmental impact but also improves the overall yield and quality of the silicon produced.

Water consumption is another environmental concern in high-purity silicon manufacturing. Vacuum pumps often require cooling systems, and more efficient pumps may lead to reduced cooling needs. This can result in substantial water savings, particularly in regions where water scarcity is a pressing issue.

The lifecycle impact of vacuum pumps should also be considered. More efficient pumps typically have longer operational lifespans, reducing the frequency of replacement and the associated environmental costs of manufacturing and disposing of pump equipment. Additionally, advanced pump designs may incorporate more recyclable materials or be more easily refurbished, further minimizing their long-term environmental impact.

Noise pollution is an often-overlooked environmental aspect of industrial processes. Efficient vacuum pumps tend to operate more quietly, reducing noise levels in manufacturing facilities and potentially improving working conditions for employees while minimizing disturbance to surrounding communities.

As environmental regulations become more stringent globally, the focus on vacuum pump efficiency in high-purity silicon manufacturing aligns with broader sustainability goals. Companies investing in more efficient technologies may gain competitive advantages through reduced operational costs and improved compliance with environmental standards.

Vacuum pumps play a crucial role in the production of high-purity silicon, particularly in the chemical vapor deposition (CVD) process. The efficiency of these pumps directly affects energy consumption, which in turn impacts the overall environmental footprint of silicon manufacturing. More efficient vacuum pumps can significantly reduce electricity usage, leading to lower greenhouse gas emissions associated with power generation.

Furthermore, improved vacuum pump efficiency can contribute to the reduction of process gases and chemical waste. By maintaining a more stable and controlled vacuum environment, manufacturers can optimize their use of precursor gases and minimize the release of potentially harmful byproducts. This not only reduces the environmental impact but also improves the overall yield and quality of the silicon produced.

Water consumption is another environmental concern in high-purity silicon manufacturing. Vacuum pumps often require cooling systems, and more efficient pumps may lead to reduced cooling needs. This can result in substantial water savings, particularly in regions where water scarcity is a pressing issue.

The lifecycle impact of vacuum pumps should also be considered. More efficient pumps typically have longer operational lifespans, reducing the frequency of replacement and the associated environmental costs of manufacturing and disposing of pump equipment. Additionally, advanced pump designs may incorporate more recyclable materials or be more easily refurbished, further minimizing their long-term environmental impact.

Noise pollution is an often-overlooked environmental aspect of industrial processes. Efficient vacuum pumps tend to operate more quietly, reducing noise levels in manufacturing facilities and potentially improving working conditions for employees while minimizing disturbance to surrounding communities.

As environmental regulations become more stringent globally, the focus on vacuum pump efficiency in high-purity silicon manufacturing aligns with broader sustainability goals. Companies investing in more efficient technologies may gain competitive advantages through reduced operational costs and improved compliance with environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!