Vacuum Pumps in Advanced Pulsed Laser Technology Development

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Tech Evolution and Objectives

Vacuum pumps have played a crucial role in the evolution of advanced pulsed laser technology. The development of these pumps has been closely intertwined with the progress in laser systems, as they are essential for creating and maintaining the vacuum environments necessary for optimal laser performance.

The history of vacuum pump technology in laser applications dates back to the early days of laser development in the 1960s. Initially, simple mechanical pumps were used to create low-pressure environments for laser operation. However, as laser technology advanced, the demand for higher vacuum levels and cleaner environments grew, driving innovations in pump design and capabilities.

In the 1970s and 1980s, the introduction of turbomolecular pumps marked a significant milestone in vacuum technology for laser systems. These pumps offered higher pumping speeds and the ability to achieve ultra-high vacuum levels, which were crucial for the development of more sophisticated laser systems, including pulsed lasers.

The 1990s saw the emergence of dry vacuum pumps, which eliminated the need for oil in the pumping mechanism. This innovation was particularly important for laser applications, as it reduced the risk of contamination in the vacuum chamber, a critical factor in maintaining laser performance and reliability.

As pulsed laser technology continued to advance into the 21st century, the demands on vacuum pumps increased further. The development of ultrafast lasers, with pulse durations in the femtosecond range, required even more precise control over the vacuum environment. This led to the creation of specialized vacuum pumps designed to handle the unique challenges posed by these advanced laser systems.

The current objectives in vacuum pump technology for advanced pulsed lasers focus on several key areas. First, there is a push for higher pumping speeds and lower ultimate pressures to support the development of more powerful and efficient laser systems. Second, researchers are working on improving the cleanliness of vacuum environments to minimize contamination and enhance laser performance.

Another important goal is the development of more compact and energy-efficient vacuum pumps. As laser systems become more integrated and portable, there is a growing need for smaller, lighter pumps that can maintain high-quality vacuums while consuming less power. This is particularly relevant for applications in industrial and scientific settings where space and energy efficiency are critical factors.

Looking ahead, the future objectives for vacuum pump technology in pulsed laser development include the integration of smart features and advanced materials. Researchers are exploring the use of AI and IoT technologies to create self-monitoring and self-optimizing vacuum systems that can adapt to changing conditions in real-time. Additionally, there is ongoing research into novel materials and pump designs that could further improve vacuum quality and reliability while reducing maintenance requirements.

The history of vacuum pump technology in laser applications dates back to the early days of laser development in the 1960s. Initially, simple mechanical pumps were used to create low-pressure environments for laser operation. However, as laser technology advanced, the demand for higher vacuum levels and cleaner environments grew, driving innovations in pump design and capabilities.

In the 1970s and 1980s, the introduction of turbomolecular pumps marked a significant milestone in vacuum technology for laser systems. These pumps offered higher pumping speeds and the ability to achieve ultra-high vacuum levels, which were crucial for the development of more sophisticated laser systems, including pulsed lasers.

The 1990s saw the emergence of dry vacuum pumps, which eliminated the need for oil in the pumping mechanism. This innovation was particularly important for laser applications, as it reduced the risk of contamination in the vacuum chamber, a critical factor in maintaining laser performance and reliability.

As pulsed laser technology continued to advance into the 21st century, the demands on vacuum pumps increased further. The development of ultrafast lasers, with pulse durations in the femtosecond range, required even more precise control over the vacuum environment. This led to the creation of specialized vacuum pumps designed to handle the unique challenges posed by these advanced laser systems.

The current objectives in vacuum pump technology for advanced pulsed lasers focus on several key areas. First, there is a push for higher pumping speeds and lower ultimate pressures to support the development of more powerful and efficient laser systems. Second, researchers are working on improving the cleanliness of vacuum environments to minimize contamination and enhance laser performance.

Another important goal is the development of more compact and energy-efficient vacuum pumps. As laser systems become more integrated and portable, there is a growing need for smaller, lighter pumps that can maintain high-quality vacuums while consuming less power. This is particularly relevant for applications in industrial and scientific settings where space and energy efficiency are critical factors.

Looking ahead, the future objectives for vacuum pump technology in pulsed laser development include the integration of smart features and advanced materials. Researchers are exploring the use of AI and IoT technologies to create self-monitoring and self-optimizing vacuum systems that can adapt to changing conditions in real-time. Additionally, there is ongoing research into novel materials and pump designs that could further improve vacuum quality and reliability while reducing maintenance requirements.

Market Demand for Advanced Pulsed Laser Systems

The market demand for advanced pulsed laser systems has been experiencing significant growth in recent years, driven by the increasing adoption of these systems across various industries. The global pulsed laser market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with the advanced segment showing even stronger growth potential.

One of the key factors fueling this demand is the rising application of pulsed lasers in industrial manufacturing processes. Advanced pulsed laser systems are increasingly being utilized for precision cutting, welding, and drilling in industries such as automotive, aerospace, and electronics. The ability of these systems to deliver high-energy pulses with minimal heat-affected zones makes them ideal for processing a wide range of materials, including metals, ceramics, and composites.

In the medical and healthcare sector, the demand for advanced pulsed laser systems is also on the rise. These systems are finding applications in various medical procedures, including ophthalmology, dermatology, and dentistry. The non-invasive nature of laser-based treatments and their ability to provide precise and targeted therapy are driving their adoption in medical facilities worldwide.

The scientific research community represents another significant market for advanced pulsed laser systems. High-power, ultrafast pulsed lasers are essential tools in fields such as spectroscopy, microscopy, and particle physics. As research institutions and universities continue to invest in cutting-edge equipment, the demand for state-of-the-art pulsed laser systems is expected to grow.

Emerging technologies such as LiDAR (Light Detection and Ranging) for autonomous vehicles and 3D sensing in consumer electronics are creating new opportunities for advanced pulsed laser systems. The automotive industry, in particular, is showing increased interest in solid-state LiDAR systems that utilize pulsed laser technology for improved performance and reliability.

Geographically, North America and Europe currently dominate the market for advanced pulsed laser systems, owing to their strong industrial base and significant investments in research and development. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

As the demand for higher precision, faster processing speeds, and improved energy efficiency continues to grow across industries, manufacturers of advanced pulsed laser systems are focusing on developing more compact, powerful, and versatile solutions. This trend is expected to further drive market growth and innovation in the pulsed laser technology sector.

One of the key factors fueling this demand is the rising application of pulsed lasers in industrial manufacturing processes. Advanced pulsed laser systems are increasingly being utilized for precision cutting, welding, and drilling in industries such as automotive, aerospace, and electronics. The ability of these systems to deliver high-energy pulses with minimal heat-affected zones makes them ideal for processing a wide range of materials, including metals, ceramics, and composites.

In the medical and healthcare sector, the demand for advanced pulsed laser systems is also on the rise. These systems are finding applications in various medical procedures, including ophthalmology, dermatology, and dentistry. The non-invasive nature of laser-based treatments and their ability to provide precise and targeted therapy are driving their adoption in medical facilities worldwide.

The scientific research community represents another significant market for advanced pulsed laser systems. High-power, ultrafast pulsed lasers are essential tools in fields such as spectroscopy, microscopy, and particle physics. As research institutions and universities continue to invest in cutting-edge equipment, the demand for state-of-the-art pulsed laser systems is expected to grow.

Emerging technologies such as LiDAR (Light Detection and Ranging) for autonomous vehicles and 3D sensing in consumer electronics are creating new opportunities for advanced pulsed laser systems. The automotive industry, in particular, is showing increased interest in solid-state LiDAR systems that utilize pulsed laser technology for improved performance and reliability.

Geographically, North America and Europe currently dominate the market for advanced pulsed laser systems, owing to their strong industrial base and significant investments in research and development. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

As the demand for higher precision, faster processing speeds, and improved energy efficiency continues to grow across industries, manufacturers of advanced pulsed laser systems are focusing on developing more compact, powerful, and versatile solutions. This trend is expected to further drive market growth and innovation in the pulsed laser technology sector.

Vacuum Pump Challenges in Pulsed Laser Tech

The development of advanced pulsed laser technology has brought forth significant challenges in vacuum pump technology. As pulsed lasers become more powerful and precise, the demands on vacuum systems have intensified, pushing the limits of current vacuum pump capabilities. One of the primary challenges is maintaining ultra-high vacuum levels consistently during laser operation, which is crucial for ensuring beam quality and preventing unwanted interactions with residual gases.

Vacuum pumps in pulsed laser systems must contend with rapid pressure fluctuations caused by the pulsed nature of the laser. These sudden changes in pressure can lead to instability in the vacuum system, potentially compromising laser performance. Additionally, the high-energy pulses can cause outgassing from chamber walls and components, introducing contaminants that must be quickly and efficiently removed to maintain vacuum integrity.

Another significant challenge is the need for vibration-free operation. Advanced pulsed lasers often require extreme stability for precise beam control and alignment. Traditional vacuum pumps, particularly mechanical pumps, can introduce vibrations that interfere with laser operation. This has led to a demand for innovative pump designs that minimize vibration while maintaining high pumping speeds and ultimate pressures.

Heat management presents another hurdle in vacuum pump technology for pulsed lasers. The intense energy of the laser pulses can lead to localized heating within the vacuum chamber, affecting pump performance and potentially causing damage to sensitive components. Vacuum pumps must be designed to handle these thermal loads effectively while maintaining consistent performance.

The increasing complexity of pulsed laser systems also necessitates more sophisticated vacuum control and monitoring. Pumps must be capable of rapid response to changing conditions and integrate seamlessly with advanced control systems. This requires the development of smart pump technologies with enhanced sensors and communication capabilities.

Contamination control is another critical challenge. As laser powers increase, even minute particles or molecular contaminants can cause significant damage to optical components or affect beam quality. Vacuum pumps must not only maintain low pressures but also effectively trap and remove potential contaminants, including those generated by the pump itself.

Lastly, as pulsed laser technology pushes into new frontiers, such as extreme ultraviolet (EUV) lithography and high-energy physics experiments, vacuum pumps face the challenge of operating in increasingly harsh environments. This includes exposure to high radiation levels, corrosive gases, and extreme temperatures, necessitating the development of more robust and resilient pump technologies.

Vacuum pumps in pulsed laser systems must contend with rapid pressure fluctuations caused by the pulsed nature of the laser. These sudden changes in pressure can lead to instability in the vacuum system, potentially compromising laser performance. Additionally, the high-energy pulses can cause outgassing from chamber walls and components, introducing contaminants that must be quickly and efficiently removed to maintain vacuum integrity.

Another significant challenge is the need for vibration-free operation. Advanced pulsed lasers often require extreme stability for precise beam control and alignment. Traditional vacuum pumps, particularly mechanical pumps, can introduce vibrations that interfere with laser operation. This has led to a demand for innovative pump designs that minimize vibration while maintaining high pumping speeds and ultimate pressures.

Heat management presents another hurdle in vacuum pump technology for pulsed lasers. The intense energy of the laser pulses can lead to localized heating within the vacuum chamber, affecting pump performance and potentially causing damage to sensitive components. Vacuum pumps must be designed to handle these thermal loads effectively while maintaining consistent performance.

The increasing complexity of pulsed laser systems also necessitates more sophisticated vacuum control and monitoring. Pumps must be capable of rapid response to changing conditions and integrate seamlessly with advanced control systems. This requires the development of smart pump technologies with enhanced sensors and communication capabilities.

Contamination control is another critical challenge. As laser powers increase, even minute particles or molecular contaminants can cause significant damage to optical components or affect beam quality. Vacuum pumps must not only maintain low pressures but also effectively trap and remove potential contaminants, including those generated by the pump itself.

Lastly, as pulsed laser technology pushes into new frontiers, such as extreme ultraviolet (EUV) lithography and high-energy physics experiments, vacuum pumps face the challenge of operating in increasingly harsh environments. This includes exposure to high radiation levels, corrosive gases, and extreme temperatures, necessitating the development of more robust and resilient pump technologies.

Current Vacuum Solutions for Pulsed Lasers

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. Features may include corrosion-resistant materials, contamination control mechanisms, and integration with process control systems.

- Energy-efficient vacuum pump systems: Energy efficiency in vacuum pump systems has been a focus of recent innovations. These developments include improved motor designs, advanced control systems for optimized operation, and heat recovery mechanisms. Such improvements lead to reduced power consumption and lower operating costs in industrial applications.

- Vacuum pump noise reduction techniques: Various methods have been developed to reduce noise levels in vacuum pump operation. These techniques may involve redesigning pump casings, implementing sound-absorbing materials, and optimizing internal components to minimize vibration. The resulting quieter operation is particularly beneficial in noise-sensitive environments.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations may combine different pump types in series or parallel arrangements, allowing for optimized performance across a wide range of pressure conditions. Such designs are particularly useful in applications requiring both high vacuum and high throughput.

02 Specialized vacuum pumps for specific applications

Vacuum pumps have been developed for specific industrial and scientific applications. These specialized pumps are designed to meet unique requirements such as high vacuum levels, corrosive gas handling, or operation in extreme environments. Custom features and materials are incorporated to ensure optimal performance in these specialized applications.Expand Specific Solutions03 Integration of vacuum pumps in semiconductor manufacturing

Vacuum pumps play a crucial role in semiconductor manufacturing processes. Innovations in this area focus on integrating vacuum pumps into semiconductor production equipment, ensuring contamination-free environments, and maintaining precise vacuum levels required for various fabrication steps. These advancements contribute to improved yield and quality in semiconductor production.Expand Specific Solutions04 Historical developments in vacuum pump technology

The evolution of vacuum pump technology spans several decades, with significant advancements in pump designs, materials, and operating principles. Historical patents showcase early innovations in rotary pumps, piston pumps, and other vacuum-generating mechanisms. These developments laid the foundation for modern vacuum pump technology.Expand Specific Solutions05 Energy-efficient and environmentally friendly vacuum pumps

Recent innovations in vacuum pump technology focus on improving energy efficiency and reducing environmental impact. These advancements include the development of oil-free pumps, variable speed drives, and heat recovery systems. Such improvements contribute to lower energy consumption, reduced maintenance requirements, and minimized environmental footprint in various industrial applications.Expand Specific Solutions

Key Players in Vacuum Pump and Laser Industry

The research on vacuum pumps in advanced pulsed laser technology development is in a mature stage, with a competitive landscape dominated by established players. The market size is substantial, driven by increasing applications in industrial manufacturing, scientific research, and defense sectors. Companies like Edwards Japan Ltd., IPG Photonics Corp., and Lumentum Operations LLC are at the forefront, leveraging their expertise in laser technology and vacuum systems. The technology's maturity is evident in the diverse range of applications and the continuous improvements in efficiency and performance. However, there's still room for innovation, particularly in miniaturization and integration with emerging technologies, keeping the field dynamic and competitive.

IMRA America, Inc.

Technical Solution: IMRA America has developed advanced femtosecond fiber lasers with integrated vacuum systems for precise material processing. Their technology utilizes high-repetition-rate ultrashort pulse lasers combined with specialized vacuum pumps to maintain a controlled environment during laser-material interactions. This approach enables enhanced ablation efficiency and reduced heat-affected zones in micromachining applications[1]. The company's proprietary FCPA (Fiber Chirped Pulse Amplification) technology allows for high peak power and excellent beam quality, crucial for advanced pulsed laser systems[2]. IMRA's vacuum-assisted laser processing systems have demonstrated improved precision in cutting and drilling of sensitive materials, such as semiconductors and medical devices[3].

Strengths: Expertise in ultrafast fiber laser technology, integrated vacuum systems for improved processing precision. Weaknesses: Potentially higher system complexity and cost compared to non-vacuum alternatives.

IPG Photonics Corp.

Technical Solution: IPG Photonics has made significant strides in high-power fiber lasers for industrial applications, incorporating vacuum technology in their pulsed laser systems. Their approach focuses on developing robust pump laser diodes and fiber amplifiers that can operate efficiently in vacuum environments, crucial for space-based and high-altitude applications[4]. IPG's pulsed fiber lasers utilize advanced pump combiners and fiber Bragg gratings to achieve high peak powers while maintaining beam quality in vacuum conditions[5]. The company has also developed specialized cooling systems for their lasers to manage heat dissipation in low-pressure environments, enabling sustained high-power operation[6]. IPG's vacuum-compatible lasers have found applications in satellite communications, remote sensing, and advanced manufacturing processes requiring controlled atmospheres.

Strengths: Industry-leading fiber laser technology, expertise in high-power systems for vacuum environments. Weaknesses: May face challenges in ultra-high vacuum applications requiring specialized materials and sealing techniques.

Innovative Vacuum Pump Technologies

Vacuum pumping system

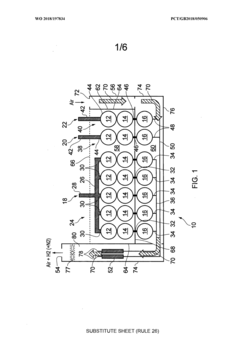

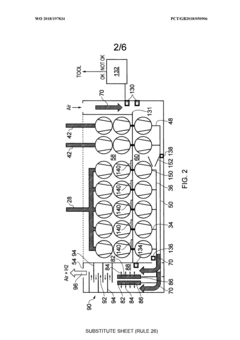

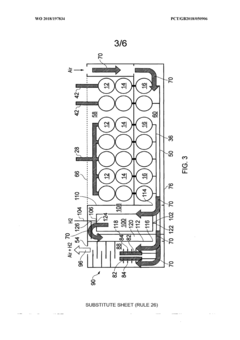

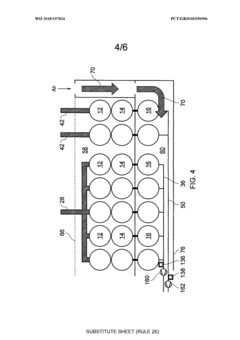

PatentWO2018197834A1

Innovation

- A vacuum pumping system that dilutes flammable gases with air to below their lower flammability limit, using a housing with distinct pressure regions and airflow generators to mix air with the gas stream, preventing ignition and allowing safe emission, and incorporating hydrogen recovery systems to recycle valuable gases.

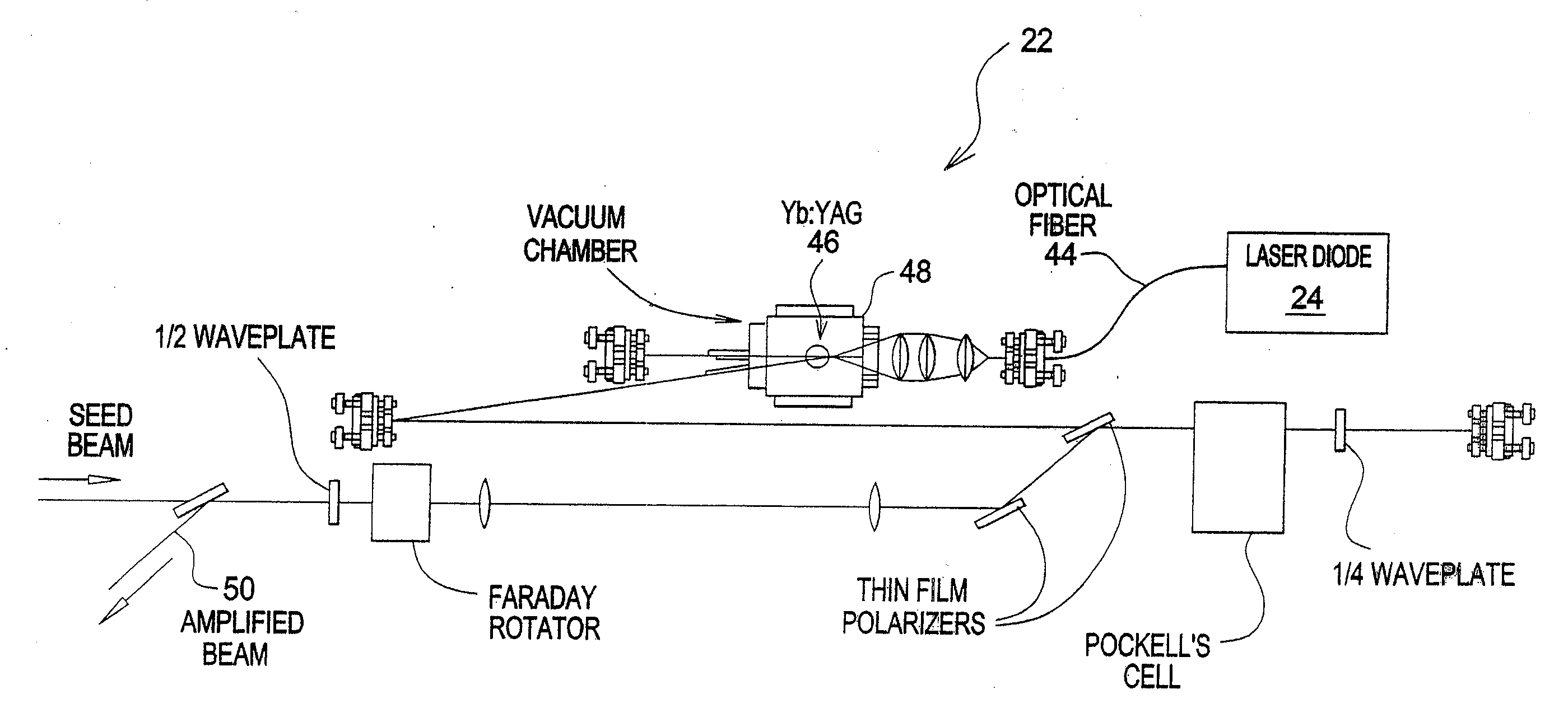

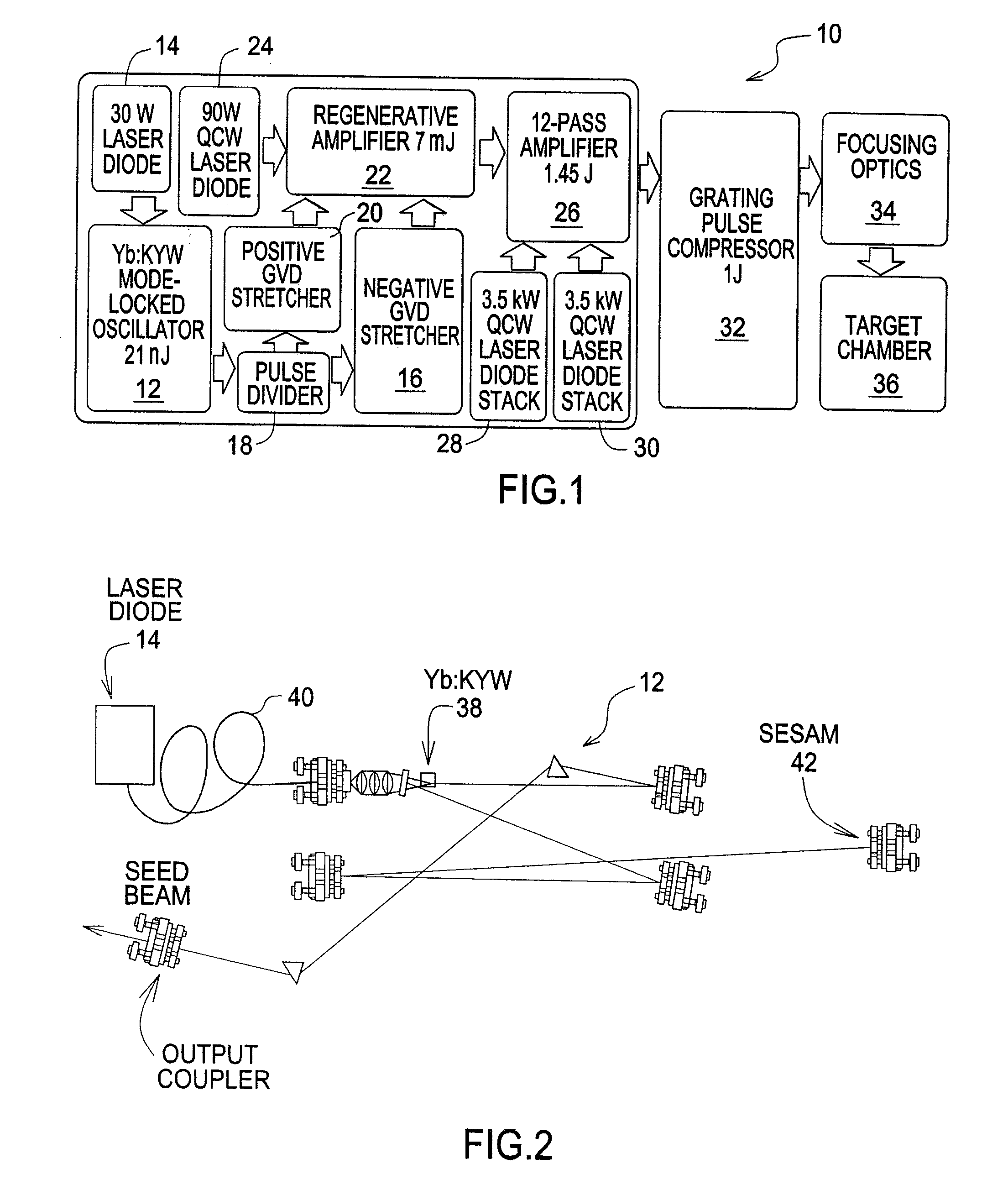

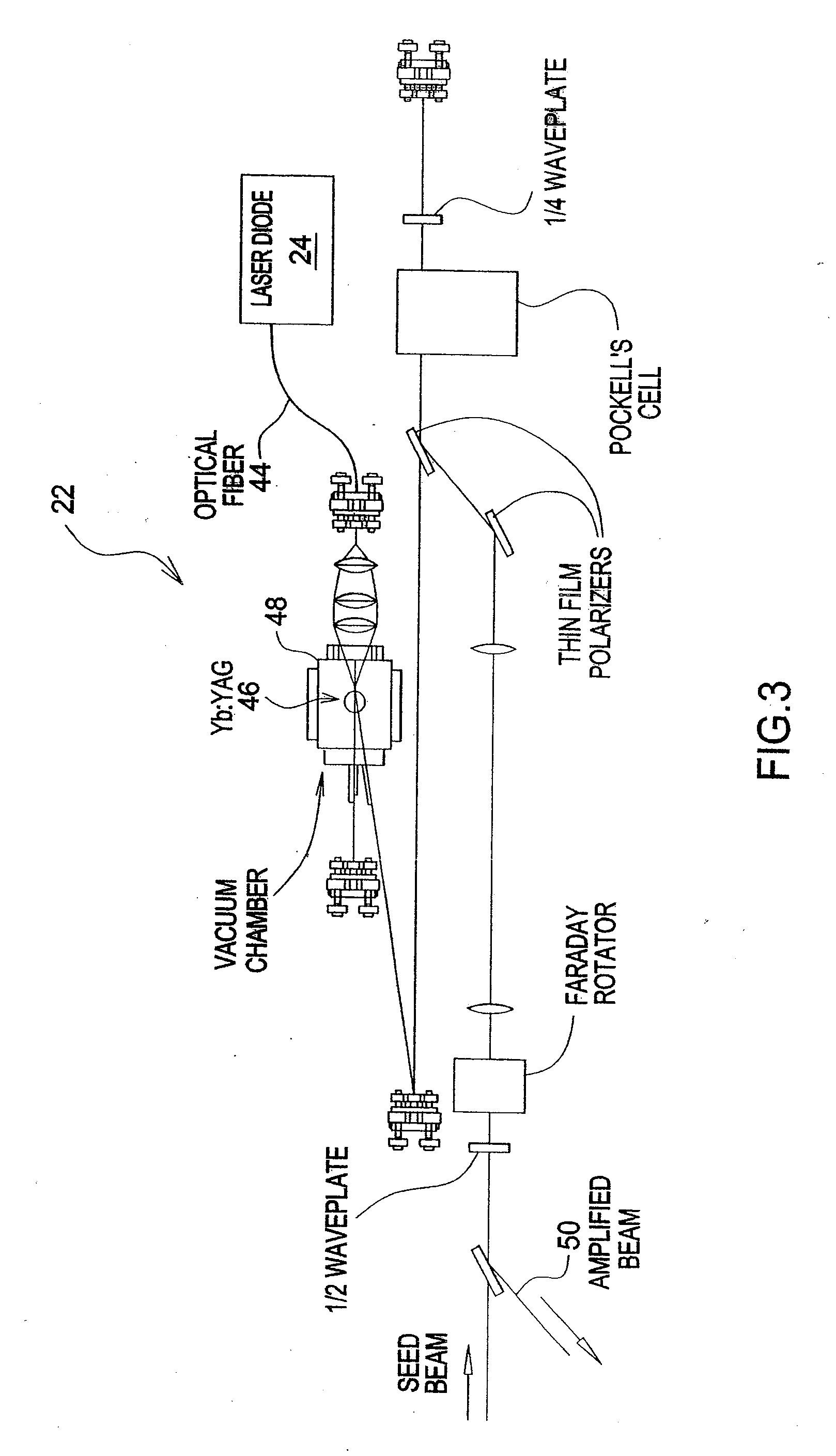

High repetition-rate, all laser diode-pumped extreme ultraviolet/soft x-ray laser and pump system

PatentInactiveUS20100040105A1

Innovation

- A compact, all-diode-pumped chirped pulse amplification system using a laser diode-pumped mode-locked oscillator, pulse dividers, stretchers, amplifiers, and a pulse compressor to generate sub-10 ps infrared laser pulses with energies over 0.5 J at high repetition rates, directing these pulses to create a plasma for EUV/SXR laser radiation.

Vacuum Standards and Certifications

In the realm of advanced pulsed laser technology development, vacuum standards and certifications play a crucial role in ensuring the reliability, safety, and performance of vacuum pumps. These standards provide a framework for manufacturers, researchers, and end-users to evaluate and compare vacuum equipment across different applications and industries.

The International Organization for Standardization (ISO) has established several key standards relevant to vacuum technology. ISO 21360 series, for instance, focuses on standard methods for measuring the performance characteristics of vacuum pumps. This includes ISO 21360-1, which specifies methods for measuring the volume flow rate of vacuum pumps, and ISO 21360-2, which deals with the measurement of ultimate pressure.

Another significant standard is ISO 3529, which defines terms and definitions related to vacuum technology. This standard ensures consistency in terminology across the industry, facilitating clear communication and understanding among professionals working with vacuum systems in pulsed laser applications.

For vacuum measurement and calibration, ISO 14707 provides guidelines for the calibration of vacuum gauges, ensuring accurate pressure readings in vacuum systems. This is particularly important in pulsed laser technology, where precise pressure control can significantly impact laser performance and stability.

In addition to ISO standards, regional certifications also play a role in vacuum pump quality assurance. In Europe, the CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area. For vacuum pumps used in pulsed laser systems, this often includes compliance with the Machinery Directive (2006/42/EC) and the Electromagnetic Compatibility Directive (2014/30/EU).

In the United States, the UL (Underwriters Laboratories) certification is widely recognized for electrical safety. Vacuum pumps used in advanced laser systems often require UL certification to ensure they meet stringent safety requirements for electrical equipment.

For applications in cleanroom environments, which are common in advanced laser technology development, ISO 14644 standards are particularly relevant. These standards define cleanroom classifications and provide guidelines for testing and monitoring to maintain the required level of cleanliness, which is crucial for preventing contamination in sensitive laser systems.

Adherence to these standards and certifications not only ensures the quality and safety of vacuum pumps but also facilitates international trade and collaboration in the field of pulsed laser technology. As the technology continues to advance, these standards are regularly reviewed and updated to keep pace with new developments and requirements in the industry.

The International Organization for Standardization (ISO) has established several key standards relevant to vacuum technology. ISO 21360 series, for instance, focuses on standard methods for measuring the performance characteristics of vacuum pumps. This includes ISO 21360-1, which specifies methods for measuring the volume flow rate of vacuum pumps, and ISO 21360-2, which deals with the measurement of ultimate pressure.

Another significant standard is ISO 3529, which defines terms and definitions related to vacuum technology. This standard ensures consistency in terminology across the industry, facilitating clear communication and understanding among professionals working with vacuum systems in pulsed laser applications.

For vacuum measurement and calibration, ISO 14707 provides guidelines for the calibration of vacuum gauges, ensuring accurate pressure readings in vacuum systems. This is particularly important in pulsed laser technology, where precise pressure control can significantly impact laser performance and stability.

In addition to ISO standards, regional certifications also play a role in vacuum pump quality assurance. In Europe, the CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area. For vacuum pumps used in pulsed laser systems, this often includes compliance with the Machinery Directive (2006/42/EC) and the Electromagnetic Compatibility Directive (2014/30/EU).

In the United States, the UL (Underwriters Laboratories) certification is widely recognized for electrical safety. Vacuum pumps used in advanced laser systems often require UL certification to ensure they meet stringent safety requirements for electrical equipment.

For applications in cleanroom environments, which are common in advanced laser technology development, ISO 14644 standards are particularly relevant. These standards define cleanroom classifications and provide guidelines for testing and monitoring to maintain the required level of cleanliness, which is crucial for preventing contamination in sensitive laser systems.

Adherence to these standards and certifications not only ensures the quality and safety of vacuum pumps but also facilitates international trade and collaboration in the field of pulsed laser technology. As the technology continues to advance, these standards are regularly reviewed and updated to keep pace with new developments and requirements in the industry.

Environmental Impact of Vacuum Technologies

The environmental impact of vacuum technologies, particularly in the context of advanced pulsed laser technology development, is a critical consideration for sustainable technological progress. Vacuum pumps, essential components in these systems, contribute significantly to the overall environmental footprint of laser technology applications.

One of the primary environmental concerns associated with vacuum technologies is energy consumption. Vacuum pumps require substantial electrical power to operate, especially when maintaining high vacuum levels necessary for advanced pulsed laser systems. This energy demand contributes to increased carbon emissions if the power source is not from renewable energy. Manufacturers and research institutions are increasingly focusing on developing more energy-efficient vacuum pump designs to mitigate this impact.

Another environmental aspect to consider is the use of working fluids in certain types of vacuum pumps. Oil-sealed rotary vane pumps, for instance, use lubricating oils that can potentially lead to environmental contamination if not properly managed. Leaks or improper disposal of these oils can result in soil and water pollution. As a response, there has been a shift towards dry vacuum pump technologies that eliminate the need for oil, reducing the risk of environmental contamination.

The production and disposal of vacuum pump components also have environmental implications. Many pumps contain materials that are difficult to recycle, such as specialized alloys and composite materials. This creates challenges in terms of waste management and resource conservation. Efforts are being made to design pumps with more recyclable materials and to establish better end-of-life management practices for these devices.

Noise pollution is another environmental concern associated with vacuum technologies. High-performance vacuum pumps can generate significant noise levels, which can be detrimental to both human health and local ecosystems. This has led to the development of noise-reduction technologies and enclosures to minimize the acoustic impact of vacuum systems in research and industrial settings.

In the context of advanced pulsed laser technology, the environmental impact of vacuum technologies extends to the broader system requirements. The need for ultra-high vacuum conditions in some laser applications necessitates the use of multiple pumping stages and additional equipment, further increasing the overall environmental footprint. Researchers are exploring ways to optimize vacuum system designs to reduce resource requirements while maintaining the necessary performance levels for cutting-edge laser technologies.

As the field of advanced pulsed laser technology continues to evolve, there is a growing emphasis on developing more environmentally friendly vacuum solutions. This includes research into alternative pumping mechanisms, such as getter pumps and cryogenic pumps, which have the potential to reduce energy consumption and minimize the use of environmentally harmful materials. Additionally, the integration of smart control systems and predictive maintenance algorithms is helping to optimize pump operation, reducing unnecessary energy usage and extending equipment lifespan.

One of the primary environmental concerns associated with vacuum technologies is energy consumption. Vacuum pumps require substantial electrical power to operate, especially when maintaining high vacuum levels necessary for advanced pulsed laser systems. This energy demand contributes to increased carbon emissions if the power source is not from renewable energy. Manufacturers and research institutions are increasingly focusing on developing more energy-efficient vacuum pump designs to mitigate this impact.

Another environmental aspect to consider is the use of working fluids in certain types of vacuum pumps. Oil-sealed rotary vane pumps, for instance, use lubricating oils that can potentially lead to environmental contamination if not properly managed. Leaks or improper disposal of these oils can result in soil and water pollution. As a response, there has been a shift towards dry vacuum pump technologies that eliminate the need for oil, reducing the risk of environmental contamination.

The production and disposal of vacuum pump components also have environmental implications. Many pumps contain materials that are difficult to recycle, such as specialized alloys and composite materials. This creates challenges in terms of waste management and resource conservation. Efforts are being made to design pumps with more recyclable materials and to establish better end-of-life management practices for these devices.

Noise pollution is another environmental concern associated with vacuum technologies. High-performance vacuum pumps can generate significant noise levels, which can be detrimental to both human health and local ecosystems. This has led to the development of noise-reduction technologies and enclosures to minimize the acoustic impact of vacuum systems in research and industrial settings.

In the context of advanced pulsed laser technology, the environmental impact of vacuum technologies extends to the broader system requirements. The need for ultra-high vacuum conditions in some laser applications necessitates the use of multiple pumping stages and additional equipment, further increasing the overall environmental footprint. Researchers are exploring ways to optimize vacuum system designs to reduce resource requirements while maintaining the necessary performance levels for cutting-edge laser technologies.

As the field of advanced pulsed laser technology continues to evolve, there is a growing emphasis on developing more environmentally friendly vacuum solutions. This includes research into alternative pumping mechanisms, such as getter pumps and cryogenic pumps, which have the potential to reduce energy consumption and minimize the use of environmentally harmful materials. Additionally, the integration of smart control systems and predictive maintenance algorithms is helping to optimize pump operation, reducing unnecessary energy usage and extending equipment lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!