Sample Matrix Effects in ICP-MS: Mitigation Techniques

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Matrix Effects Background and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the 1980s, becoming an indispensable analytical technique for elemental analysis across various industries including environmental monitoring, pharmaceuticals, food safety, and materials science. The technique's exceptional sensitivity, multi-element capability, and wide dynamic range have established it as the gold standard for trace element analysis. However, despite these advantages, ICP-MS faces persistent challenges related to matrix effects that can compromise analytical accuracy and reliability.

Matrix effects in ICP-MS refer to the phenomenon where sample components alter the analyte signal, leading to either enhancement or suppression of the measured response compared to calibration standards. These effects originate from various sources throughout the analytical process, including sample introduction, plasma conditions, ion extraction, and mass spectrometer performance. The complexity of these interactions has made matrix effects one of the most significant challenges in achieving accurate quantitative analysis using ICP-MS.

The historical development of ICP-MS has been marked by continuous efforts to address these matrix-related challenges. Early systems suffered from severe limitations when analyzing complex matrices, particularly those containing high dissolved solids or organic content. Subsequent technological advancements, including collision/reaction cell technology, improved sample introduction systems, and enhanced data processing algorithms, have progressively mitigated these issues, though not eliminated them entirely.

Current research trends focus on developing more robust methodologies for matrix effect compensation, including advanced calibration strategies, online matrix removal techniques, and innovative hardware designs. The integration of artificial intelligence and machine learning approaches for real-time signal correction represents an emerging frontier in this field.

The primary objective of this technical research is to comprehensively evaluate existing and emerging techniques for mitigating sample matrix effects in ICP-MS. Specifically, we aim to: (1) characterize the fundamental mechanisms underlying different types of matrix effects; (2) assess the effectiveness of current mitigation strategies across various sample types; (3) identify technological gaps and limitations in existing approaches; and (4) explore innovative solutions that could potentially overcome persistent challenges.

By addressing these objectives, we seek to enhance the analytical capabilities of ICP-MS, particularly for challenging sample matrices that currently require extensive preparation or suffer from compromised data quality. The ultimate goal is to develop more robust analytical protocols that maintain accuracy and precision regardless of sample complexity, thereby expanding the applicability of ICP-MS across an even broader range of scientific and industrial applications.

Matrix effects in ICP-MS refer to the phenomenon where sample components alter the analyte signal, leading to either enhancement or suppression of the measured response compared to calibration standards. These effects originate from various sources throughout the analytical process, including sample introduction, plasma conditions, ion extraction, and mass spectrometer performance. The complexity of these interactions has made matrix effects one of the most significant challenges in achieving accurate quantitative analysis using ICP-MS.

The historical development of ICP-MS has been marked by continuous efforts to address these matrix-related challenges. Early systems suffered from severe limitations when analyzing complex matrices, particularly those containing high dissolved solids or organic content. Subsequent technological advancements, including collision/reaction cell technology, improved sample introduction systems, and enhanced data processing algorithms, have progressively mitigated these issues, though not eliminated them entirely.

Current research trends focus on developing more robust methodologies for matrix effect compensation, including advanced calibration strategies, online matrix removal techniques, and innovative hardware designs. The integration of artificial intelligence and machine learning approaches for real-time signal correction represents an emerging frontier in this field.

The primary objective of this technical research is to comprehensively evaluate existing and emerging techniques for mitigating sample matrix effects in ICP-MS. Specifically, we aim to: (1) characterize the fundamental mechanisms underlying different types of matrix effects; (2) assess the effectiveness of current mitigation strategies across various sample types; (3) identify technological gaps and limitations in existing approaches; and (4) explore innovative solutions that could potentially overcome persistent challenges.

By addressing these objectives, we seek to enhance the analytical capabilities of ICP-MS, particularly for challenging sample matrices that currently require extensive preparation or suffer from compromised data quality. The ultimate goal is to develop more robust analytical protocols that maintain accuracy and precision regardless of sample complexity, thereby expanding the applicability of ICP-MS across an even broader range of scientific and industrial applications.

Market Analysis for Advanced Analytical Instrumentation

The global market for advanced analytical instrumentation continues to expand, driven by increasing demands for precise elemental analysis across various industries. The ICP-MS (Inductively Coupled Plasma Mass Spectrometry) segment represents a significant portion of this market, valued at approximately $4.3 billion in 2022 with projections to reach $6.2 billion by 2027, growing at a CAGR of 7.6%. This growth is particularly notable in pharmaceutical, environmental monitoring, food safety, and semiconductor manufacturing sectors.

Sample matrix effects in ICP-MS have emerged as a critical challenge that directly impacts market dynamics. End-users increasingly demand solutions that can effectively mitigate these interferences without compromising analytical performance or increasing operational costs. This market need has created a competitive landscape where instrument manufacturers are racing to develop proprietary technologies addressing matrix effects.

Regional analysis reveals that North America currently holds the largest market share (approximately 38%), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by expanding industrial bases in China, India, and South Korea, coupled with strengthening regulatory frameworks for environmental and food safety testing.

The competitive landscape features established players like Agilent Technologies, Thermo Fisher Scientific, and PerkinElmer dominating with a combined market share of 65%. These companies have invested heavily in R&D focused on matrix effect mitigation technologies. Mid-tier competitors such as Shimadzu and Bruker are gaining ground through specialized solutions targeting specific industry applications where matrix effects are particularly problematic.

Customer segmentation analysis indicates that large analytical service laboratories and research institutions constitute 42% of the market, followed by pharmaceutical companies (28%), environmental testing facilities (17%), and food safety laboratories (13%). Each segment presents unique requirements regarding matrix effect mitigation, influencing purchasing decisions and technology adoption rates.

Price sensitivity varies significantly across market segments. While research institutions prioritize performance over cost, commercial testing laboratories seek solutions offering optimal balance between analytical capabilities and operational expenses. This dichotomy has led to tiered product offerings, with premium systems featuring advanced matrix effect mitigation technologies commanding price premiums of 30-40% over standard configurations.

Market forecasts suggest that technologies effectively addressing sample matrix effects will capture increasing market share, potentially reshaping competitive dynamics in the advanced analytical instrumentation sector over the next five years.

Sample matrix effects in ICP-MS have emerged as a critical challenge that directly impacts market dynamics. End-users increasingly demand solutions that can effectively mitigate these interferences without compromising analytical performance or increasing operational costs. This market need has created a competitive landscape where instrument manufacturers are racing to develop proprietary technologies addressing matrix effects.

Regional analysis reveals that North America currently holds the largest market share (approximately 38%), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by expanding industrial bases in China, India, and South Korea, coupled with strengthening regulatory frameworks for environmental and food safety testing.

The competitive landscape features established players like Agilent Technologies, Thermo Fisher Scientific, and PerkinElmer dominating with a combined market share of 65%. These companies have invested heavily in R&D focused on matrix effect mitigation technologies. Mid-tier competitors such as Shimadzu and Bruker are gaining ground through specialized solutions targeting specific industry applications where matrix effects are particularly problematic.

Customer segmentation analysis indicates that large analytical service laboratories and research institutions constitute 42% of the market, followed by pharmaceutical companies (28%), environmental testing facilities (17%), and food safety laboratories (13%). Each segment presents unique requirements regarding matrix effect mitigation, influencing purchasing decisions and technology adoption rates.

Price sensitivity varies significantly across market segments. While research institutions prioritize performance over cost, commercial testing laboratories seek solutions offering optimal balance between analytical capabilities and operational expenses. This dichotomy has led to tiered product offerings, with premium systems featuring advanced matrix effect mitigation technologies commanding price premiums of 30-40% over standard configurations.

Market forecasts suggest that technologies effectively addressing sample matrix effects will capture increasing market share, potentially reshaping competitive dynamics in the advanced analytical instrumentation sector over the next five years.

Current Challenges in ICP-MS Matrix Interference

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) faces significant challenges related to matrix interference, which continues to be a major limitation for accurate quantitative analysis. Matrix effects occur when components in the sample matrix affect the measurement of target analytes, leading to signal suppression or enhancement. These effects can originate from various sources including high dissolved solid content, organic compounds, and easily ionizable elements.

One of the primary challenges is spectral interference, where polyatomic ions formed from matrix components overlap with analyte signals at the same mass-to-charge ratio. For instance, argon oxide (⁴⁰Ar¹⁶O⁺) interferes with iron-56 detection, while chloride from sample matrices can form ⁴⁰Ar³⁵Cl⁺, interfering with arsenic-75 measurements. These interferences significantly compromise detection limits and quantification accuracy.

Non-spectral matrix effects present another substantial challenge. These manifest as signal suppression or enhancement due to changes in plasma conditions, ion extraction efficiency, or space-charge effects in the ion beam. Heavy matrices containing elements like Na, K, Ca, and Mg can reduce analyte sensitivity by up to 50-80% in severe cases, particularly affecting low-mass elements.

Sample introduction systems contribute additional complications. High-salt matrices can cause physical blockages in nebulizers and injector tubes, leading to signal drift and instrument downtime. Carbon deposition on sampler and skimmer cones from organic matrices alters ion transmission efficiency, requiring frequent maintenance and recalibration.

Memory effects represent a persistent challenge, particularly for elements like Hg, B, and I, which can adsorb onto sample introduction components. These residual signals can carry over between samples, creating false positives or elevated backgrounds that compromise detection capabilities for subsequent analyses.

The variability of matrix effects between different sample types further complicates analytical workflows. Environmental samples, biological fluids, and industrial materials each present unique interference patterns that require specialized mitigation strategies. This variability makes it difficult to develop universal correction methods applicable across diverse sample types.

Emerging applications in single-cell and nanoparticle analysis face additional matrix challenges due to the ultra-low analyte concentrations and complex biological matrices involved. The need for minimal sample preparation to preserve spatial information or particle integrity limits the application of traditional matrix removal techniques, creating a significant analytical challenge for these cutting-edge applications.

One of the primary challenges is spectral interference, where polyatomic ions formed from matrix components overlap with analyte signals at the same mass-to-charge ratio. For instance, argon oxide (⁴⁰Ar¹⁶O⁺) interferes with iron-56 detection, while chloride from sample matrices can form ⁴⁰Ar³⁵Cl⁺, interfering with arsenic-75 measurements. These interferences significantly compromise detection limits and quantification accuracy.

Non-spectral matrix effects present another substantial challenge. These manifest as signal suppression or enhancement due to changes in plasma conditions, ion extraction efficiency, or space-charge effects in the ion beam. Heavy matrices containing elements like Na, K, Ca, and Mg can reduce analyte sensitivity by up to 50-80% in severe cases, particularly affecting low-mass elements.

Sample introduction systems contribute additional complications. High-salt matrices can cause physical blockages in nebulizers and injector tubes, leading to signal drift and instrument downtime. Carbon deposition on sampler and skimmer cones from organic matrices alters ion transmission efficiency, requiring frequent maintenance and recalibration.

Memory effects represent a persistent challenge, particularly for elements like Hg, B, and I, which can adsorb onto sample introduction components. These residual signals can carry over between samples, creating false positives or elevated backgrounds that compromise detection capabilities for subsequent analyses.

The variability of matrix effects between different sample types further complicates analytical workflows. Environmental samples, biological fluids, and industrial materials each present unique interference patterns that require specialized mitigation strategies. This variability makes it difficult to develop universal correction methods applicable across diverse sample types.

Emerging applications in single-cell and nanoparticle analysis face additional matrix challenges due to the ultra-low analyte concentrations and complex biological matrices involved. The need for minimal sample preparation to preserve spatial information or particle integrity limits the application of traditional matrix removal techniques, creating a significant analytical challenge for these cutting-edge applications.

Established Matrix Effect Mitigation Strategies

01 Matrix effect reduction techniques in ICP-MS analysis

Various techniques can be employed to reduce matrix effects in ICP-MS analysis, including sample dilution, internal standardization, and matrix matching. These methods help to minimize signal suppression or enhancement caused by the sample matrix, leading to more accurate and reliable analytical results. Proper sample preparation and optimization of instrument parameters are crucial for effective matrix effect reduction.- Matrix effect reduction techniques in ICP-MS analysis: Various techniques can be employed to reduce matrix effects in ICP-MS analysis, including sample dilution, internal standardization, and matrix matching. These methods help minimize signal suppression or enhancement caused by the sample matrix, leading to more accurate and reliable analytical results. Proper sample preparation and calibration strategies are essential for overcoming matrix-related interferences in complex samples.

- Specialized sample introduction systems for ICP-MS: Advanced sample introduction systems have been developed to address matrix effects in ICP-MS. These include specialized nebulizers, spray chambers, and desolvation systems that can effectively reduce matrix-related interferences by controlling aerosol formation and transport. Such systems improve the stability of the plasma and enhance the overall analytical performance when dealing with complex sample matrices.

- Mathematical correction models for matrix effects: Mathematical models and algorithms can be applied to correct for matrix effects in ICP-MS analysis. These computational approaches include multivariate calibration methods, machine learning algorithms, and statistical models that can identify and compensate for matrix-induced signal variations. By applying these correction models, analysts can achieve more accurate quantification even in the presence of significant matrix effects.

- Collision/reaction cell technology for interference elimination: Collision and reaction cell technologies are effective approaches for eliminating spectral interferences and reducing matrix effects in ICP-MS. These cells, positioned between the plasma interface and the mass analyzer, use collision gases (like helium) or reaction gases (like hydrogen or ammonia) to remove polyatomic interferences through kinetic energy discrimination or chemical reactions, thereby improving detection limits and accuracy in complex matrices.

- Online matrix separation and preconcentration methods: Online separation and preconcentration techniques can be coupled with ICP-MS to minimize matrix effects. These include chromatographic methods (ion chromatography, HPLC), solid-phase extraction, and flow injection systems that separate analytes from the matrix components before introduction to the plasma. Such hyphenated techniques allow for selective determination of target elements while reducing matrix-related interferences and enhancing sensitivity.

02 Mathematical correction models for matrix effects

Mathematical models and algorithms can be applied to correct for matrix effects in ICP-MS analysis. These include multivariate calibration methods, machine learning approaches, and statistical correction models that can compensate for signal variations caused by matrix components. By applying these mathematical corrections, analysts can achieve more accurate quantification even in complex sample matrices.Expand Specific Solutions03 Specialized sample introduction systems

Specialized sample introduction systems can be used to mitigate matrix effects in ICP-MS. These include desolvation systems, aerosol dilution devices, and flow injection analysis systems that can modify how the sample enters the plasma. By controlling the sample introduction process, these systems can reduce the impact of matrix components on the analytical signal, improving measurement accuracy.Expand Specific Solutions04 Collision/reaction cell technology

Collision and reaction cell technologies are effective approaches for addressing matrix effects and spectral interferences in ICP-MS. These cells, positioned between the plasma interface and the mass analyzer, use collision gases (like helium) or reaction gases (like hydrogen or oxygen) to remove or reduce interferences through kinetic energy discrimination or chemical reactions, resulting in improved analytical performance for complex matrices.Expand Specific Solutions05 Matrix-specific calibration strategies

Matrix-specific calibration strategies involve developing calibration methods tailored to particular sample types. These include standard addition methods, isotope dilution techniques, and matrix-matched calibration approaches. By accounting for the specific matrix composition in the calibration process, these strategies can effectively compensate for matrix effects and provide more accurate quantitative results in ICP-MS analysis.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ICP-MS sample matrix effects mitigation market is currently in a growth phase, with increasing demand for accurate trace element analysis across pharmaceutical, environmental, and food safety sectors. The global market size is estimated at $1.2 billion, expanding at 7-8% CAGR. Leading players include Agilent Technologies, Thermo Fisher Scientific, and Waters Technology, who have developed advanced collision/reaction cell technologies and high-performance sample introduction systems. Emerging companies like Kimia Analytics are introducing innovative ICP torch designs with enhanced matrix tolerance. The technology landscape shows varying maturity levels, with established players focusing on integrated software solutions for automated correction, while research institutions like EPFL and University of Tokyo are pioneering novel plasma control techniques and machine learning algorithms for real-time matrix compensation.

Agilent Technologies, Inc.

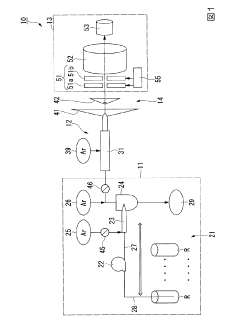

Technical Solution: Agilent has developed comprehensive matrix effect mitigation solutions for ICP-MS through their innovative High Matrix Introduction (HMI) technology. This system automatically adjusts plasma conditions by introducing a controlled flow of argon between the spray chamber and torch, effectively diluting the sample aerosol before it reaches the plasma. Their Octopole Reaction System (ORS) employs collision/reaction cell technology with helium collision mode to remove polyatomic interferences through kinetic energy discrimination. For extreme matrices, Agilent's Ultra High Matrix Introduction (UHMI) system can handle samples with up to 25% total dissolved solids without manual dilution. Their ICP-MS MassHunter software includes automated internal standardization and matrix-matched calibration capabilities to compensate for signal drift and matrix suppression effects. Agilent's instruments also feature optimized sample introduction systems with specialized nebulizers and spray chambers designed to minimize salt deposition and improve plasma stability with high-matrix samples.

Strengths: Agilent's integrated approach combining hardware solutions (HMI, ORS) with sophisticated software provides comprehensive matrix management. Their systems can handle extremely high dissolved solid content without manual dilution, increasing laboratory throughput and reducing contamination risks. Weaknesses: The proprietary nature of their collision/reaction cell technology may require specialized training and maintenance. Higher initial investment compared to simpler ICP-MS systems.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has pioneered advanced matrix effect mitigation in ICP-MS through their patented Triple Quadrupole (TQ-ICP-MS) technology. Their iCAP TQ ICP-MS system employs a unique three-quadrupole design that enables highly selective reaction chemistry in the collision/reaction cell. This approach allows for controlled chemical reactions that specifically target interfering species while preserving analytes of interest. Their Kinetic Energy Discrimination (KED) mode uses a combination of collision gas and energy barrier to effectively eliminate polyatomic interferences based on collision cross-section differences. For high-salt matrices, Thermo Fisher has developed specialized sample introduction components including the High Matrix Interface (HMI) and Total Consumption Nebulizer (TCN) systems that minimize salt deposition and reduce cone clogging. Their QCell collision/reaction cell technology with axial acceleration further enhances interference removal efficiency. Thermo's Qtegra software platform incorporates intelligent dilution protocols and automated quality control procedures specifically designed to address matrix-induced signal suppression and drift.

Strengths: The triple quadrupole technology provides superior selectivity for challenging matrices compared to single-quad systems, enabling accurate quantification even in complex samples. Their integrated software solutions offer comprehensive matrix correction algorithms. Weaknesses: The sophisticated TQ-ICP-MS systems require greater expertise to operate optimally and have higher operational costs. The multiple quadrupole design adds complexity to maintenance procedures.

Key Patents and Publications on Matrix Correction

Inductively coupled plasma mass spectrometry

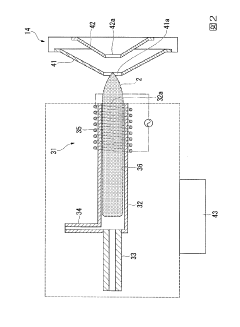

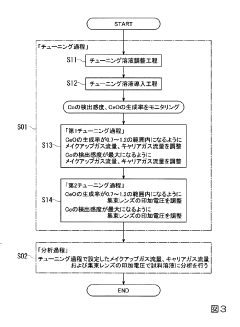

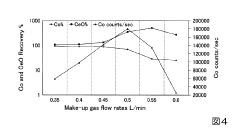

PatentInactiveJP2020027038A

Innovation

- The method involves tuning the ICP-MS system using a sample solution with a high-concentration acid matrix as a tuning liquid, adjusting carrier gas flow rates and focusing lens settings to control the production rate of coexisting element oxides within a specific range, thereby maximizing detection sensitivity.

Validation Protocols for Matrix Effect Assessment

Validation protocols for matrix effect assessment in ICP-MS analysis require systematic approaches to identify, quantify, and mitigate sample matrix interferences. These protocols typically begin with the establishment of baseline performance using certified reference materials (CRMs) that closely match the sample matrix of interest. The selection of appropriate CRMs is critical as they provide traceable standards against which matrix effects can be reliably measured and evaluated.

Standard addition methods represent a cornerstone of validation protocols, involving the addition of known concentrations of analytes to the sample matrix. By comparing the response slopes between standard solutions and spiked samples, analysts can quantitatively determine the extent of matrix suppression or enhancement. This approach is particularly valuable when matrix-matched standards are unavailable or when dealing with complex, variable matrices.

Internal standardization validation forms another essential component, requiring careful selection of internal standards that behave similarly to the analytes of interest under matrix influence. Validation protocols should include experiments to verify that the chosen internal standards effectively compensate for matrix effects across the concentration range of interest and across different sample types within the analytical batch.

Recovery studies constitute a practical validation approach, where known amounts of analytes are spiked into real samples at different concentration levels. Acceptable recovery ranges (typically 80-120%) must be established based on the specific application requirements and regulatory guidelines. Statistical evaluation of recovery data across multiple samples provides robust evidence of method performance under matrix influence.

Method comparison studies should be incorporated into validation protocols, comparing ICP-MS results with those obtained using orthogonal techniques such as atomic absorption spectroscopy or neutron activation analysis. Such comparisons help identify method-specific biases that may be attributed to matrix effects rather than true concentration differences.

Robustness testing forms the final critical element of validation protocols, evaluating method performance across deliberate variations in sample preparation procedures, instrument parameters, and matrix compositions. This testing should include challenges with increasingly complex matrices to establish the boundaries of reliable performance and identify conditions under which additional matrix mitigation strategies become necessary.

Documentation of all validation experiments, statistical analyses, and acceptance criteria is essential for regulatory compliance and method transfer purposes. The validation protocol should clearly define the types and levels of matrix effects considered acceptable for the intended analytical purpose, establishing decision rules for when additional mitigation techniques must be employed.

Standard addition methods represent a cornerstone of validation protocols, involving the addition of known concentrations of analytes to the sample matrix. By comparing the response slopes between standard solutions and spiked samples, analysts can quantitatively determine the extent of matrix suppression or enhancement. This approach is particularly valuable when matrix-matched standards are unavailable or when dealing with complex, variable matrices.

Internal standardization validation forms another essential component, requiring careful selection of internal standards that behave similarly to the analytes of interest under matrix influence. Validation protocols should include experiments to verify that the chosen internal standards effectively compensate for matrix effects across the concentration range of interest and across different sample types within the analytical batch.

Recovery studies constitute a practical validation approach, where known amounts of analytes are spiked into real samples at different concentration levels. Acceptable recovery ranges (typically 80-120%) must be established based on the specific application requirements and regulatory guidelines. Statistical evaluation of recovery data across multiple samples provides robust evidence of method performance under matrix influence.

Method comparison studies should be incorporated into validation protocols, comparing ICP-MS results with those obtained using orthogonal techniques such as atomic absorption spectroscopy or neutron activation analysis. Such comparisons help identify method-specific biases that may be attributed to matrix effects rather than true concentration differences.

Robustness testing forms the final critical element of validation protocols, evaluating method performance across deliberate variations in sample preparation procedures, instrument parameters, and matrix compositions. This testing should include challenges with increasingly complex matrices to establish the boundaries of reliable performance and identify conditions under which additional matrix mitigation strategies become necessary.

Documentation of all validation experiments, statistical analyses, and acceptance criteria is essential for regulatory compliance and method transfer purposes. The validation protocol should clearly define the types and levels of matrix effects considered acceptable for the intended analytical purpose, establishing decision rules for when additional mitigation techniques must be employed.

Environmental and Regulatory Considerations

The environmental impact of ICP-MS analysis has become increasingly important as regulatory frameworks worldwide evolve to address laboratory waste management and environmental protection. Sample matrix effects mitigation techniques must be evaluated not only for their analytical effectiveness but also for their environmental footprint and regulatory compliance. Current environmental regulations in many jurisdictions specifically address the disposal of acid digests, organic solvents, and heavy metal standards commonly used in ICP-MS analysis.

The use of strong acids for sample preparation, particularly hydrofluoric acid and aqua regia, faces increasing regulatory scrutiny due to their corrosive nature and potential environmental harm. Laboratories must implement proper neutralization protocols before disposal, with many regions requiring pH adjustment to between 6.0-9.0. Additionally, heavy metal content in waste streams is strictly regulated, with threshold limits becoming progressively more stringent in developed nations.

Alternative sample preparation methods such as microwave-assisted digestion and enzymatic extraction are gaining regulatory favor as they typically require smaller volumes of reagents and generate less hazardous waste. The environmental benefits of these approaches include reduced chemical consumption, lower energy requirements, and diminished waste treatment needs, aligning with green chemistry principles increasingly embedded in laboratory regulations.

Regulatory frameworks like the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the US EPA's Resource Conservation and Recovery Act (RCRA) directly impact ICP-MS operations by imposing documentation requirements for chemical usage and waste disposal. Laboratories must maintain detailed records of waste generation and treatment, with many jurisdictions implementing mandatory reporting systems for heavy metal disposal.

The global trend toward sustainable laboratory practices has prompted the development of matrix effect mitigation techniques that align with environmental objectives. Online dilution systems that minimize reagent consumption, collision/reaction cell technologies that reduce the need for chemical separations, and mathematical correction models that decrease the requirement for multiple standard preparations all contribute to environmentally preferable analytical workflows.

Certification programs such as ISO 14001 for environmental management systems are increasingly being adopted by analytical laboratories, requiring documented procedures for minimizing the environmental impact of analytical processes including ICP-MS. This regulatory landscape is driving innovation in matrix effect mitigation that balances analytical performance with environmental responsibility, creating a new paradigm where technical excellence must coexist with ecological stewardship.

The use of strong acids for sample preparation, particularly hydrofluoric acid and aqua regia, faces increasing regulatory scrutiny due to their corrosive nature and potential environmental harm. Laboratories must implement proper neutralization protocols before disposal, with many regions requiring pH adjustment to between 6.0-9.0. Additionally, heavy metal content in waste streams is strictly regulated, with threshold limits becoming progressively more stringent in developed nations.

Alternative sample preparation methods such as microwave-assisted digestion and enzymatic extraction are gaining regulatory favor as they typically require smaller volumes of reagents and generate less hazardous waste. The environmental benefits of these approaches include reduced chemical consumption, lower energy requirements, and diminished waste treatment needs, aligning with green chemistry principles increasingly embedded in laboratory regulations.

Regulatory frameworks like the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the US EPA's Resource Conservation and Recovery Act (RCRA) directly impact ICP-MS operations by imposing documentation requirements for chemical usage and waste disposal. Laboratories must maintain detailed records of waste generation and treatment, with many jurisdictions implementing mandatory reporting systems for heavy metal disposal.

The global trend toward sustainable laboratory practices has prompted the development of matrix effect mitigation techniques that align with environmental objectives. Online dilution systems that minimize reagent consumption, collision/reaction cell technologies that reduce the need for chemical separations, and mathematical correction models that decrease the requirement for multiple standard preparations all contribute to environmentally preferable analytical workflows.

Certification programs such as ISO 14001 for environmental management systems are increasingly being adopted by analytical laboratories, requiring documented procedures for minimizing the environmental impact of analytical processes including ICP-MS. This regulatory landscape is driving innovation in matrix effect mitigation that balances analytical performance with environmental responsibility, creating a new paradigm where technical excellence must coexist with ecological stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!