Sodium Acetate in Food Processing: Innovations and Trends

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Evolution

Sodium acetate has undergone significant evolution in food processing since its initial introduction. The journey of this versatile compound began in the early 20th century when it was first recognized for its potential in food preservation. Initially, sodium acetate was primarily used as a pH regulator and preservative in various food products.

In the 1950s and 1960s, the food industry witnessed a surge in the use of sodium acetate as researchers discovered its ability to enhance flavors and extend shelf life. This period marked the beginning of its widespread adoption in processed foods, particularly in snack foods and baked goods. The compound's ability to act as a buffering agent and control acidity levels made it an invaluable ingredient in food formulations.

The 1970s and 1980s saw a shift towards more sophisticated applications of sodium acetate. Food scientists began exploring its potential as a texturizing agent and moisture regulator. This led to its incorporation in a wider range of products, including dairy, meat, and seafood. The compound's ability to improve the texture and mouthfeel of processed foods while maintaining stability became increasingly valued by manufacturers.

As consumer awareness and demand for "clean label" products grew in the 1990s and 2000s, the food industry faced new challenges. This prompted a reevaluation of sodium acetate's role in food processing. Researchers began investigating ways to optimize its use while minimizing overall sodium content in products. This period also saw the development of modified forms of sodium acetate, such as encapsulated variants, to enhance its functionality and controlled release in food systems.

In recent years, the evolution of sodium acetate has been driven by advancements in food technology and changing consumer preferences. The compound has found new applications in functional foods and nutraceuticals, where its properties are leveraged to deliver specific health benefits. Additionally, the rise of plant-based and alternative protein products has created new opportunities for sodium acetate as a flavor enhancer and preservative in these novel food categories.

The ongoing evolution of sodium acetate in food processing is characterized by a focus on sustainability and clean label solutions. Research is being conducted to develop bio-based sources of sodium acetate, aligning with the industry's push towards more environmentally friendly ingredients. Furthermore, efforts are being made to reduce the overall use of sodium acetate through the development of synergistic blends with other natural preservatives and flavor enhancers.

In the 1950s and 1960s, the food industry witnessed a surge in the use of sodium acetate as researchers discovered its ability to enhance flavors and extend shelf life. This period marked the beginning of its widespread adoption in processed foods, particularly in snack foods and baked goods. The compound's ability to act as a buffering agent and control acidity levels made it an invaluable ingredient in food formulations.

The 1970s and 1980s saw a shift towards more sophisticated applications of sodium acetate. Food scientists began exploring its potential as a texturizing agent and moisture regulator. This led to its incorporation in a wider range of products, including dairy, meat, and seafood. The compound's ability to improve the texture and mouthfeel of processed foods while maintaining stability became increasingly valued by manufacturers.

As consumer awareness and demand for "clean label" products grew in the 1990s and 2000s, the food industry faced new challenges. This prompted a reevaluation of sodium acetate's role in food processing. Researchers began investigating ways to optimize its use while minimizing overall sodium content in products. This period also saw the development of modified forms of sodium acetate, such as encapsulated variants, to enhance its functionality and controlled release in food systems.

In recent years, the evolution of sodium acetate has been driven by advancements in food technology and changing consumer preferences. The compound has found new applications in functional foods and nutraceuticals, where its properties are leveraged to deliver specific health benefits. Additionally, the rise of plant-based and alternative protein products has created new opportunities for sodium acetate as a flavor enhancer and preservative in these novel food categories.

The ongoing evolution of sodium acetate in food processing is characterized by a focus on sustainability and clean label solutions. Research is being conducted to develop bio-based sources of sodium acetate, aligning with the industry's push towards more environmentally friendly ingredients. Furthermore, efforts are being made to reduce the overall use of sodium acetate through the development of synergistic blends with other natural preservatives and flavor enhancers.

Market Demand Analysis

The market demand for sodium acetate in food processing has been steadily increasing due to its versatile applications and functional properties. As a food additive, sodium acetate serves multiple purposes, including pH regulation, flavor enhancement, and preservation, making it a valuable ingredient across various food sectors.

In the bakery industry, sodium acetate has gained significant traction as a mold inhibitor and acidity regulator. The growing consumer preference for extended shelf-life baked goods without compromising on taste or quality has driven the demand for sodium acetate in this segment. Manufacturers are increasingly incorporating it into bread, pastries, and other baked products to maintain freshness and prevent spoilage.

The meat processing industry has also witnessed a surge in sodium acetate usage. Its ability to act as a preservative and flavor enhancer has made it an essential component in processed meats, sausages, and cured products. With the rising consumption of convenience foods and ready-to-eat meat products, the demand for sodium acetate in this sector is expected to continue its upward trajectory.

In the dairy industry, sodium acetate has found applications in cheese production and yogurt manufacturing. Its pH-regulating properties help control acidity levels during fermentation processes, contributing to improved product consistency and quality. As the global dairy market expands, particularly in emerging economies, the demand for sodium acetate in this sector is projected to grow significantly.

The beverage industry has also embraced sodium acetate for its flavor-enhancing capabilities. It is commonly used in sports drinks, energy beverages, and flavored water to balance acidity and improve taste profiles. The growing health and wellness trend, coupled with the increasing popularity of functional beverages, is expected to drive further demand for sodium acetate in this segment.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth driver for sodium acetate in food processing. Rapid urbanization, changing dietary habits, and increasing disposable incomes in countries like China and India are fueling the demand for processed and convenience foods, consequently boosting the market for food additives like sodium acetate.

The global sodium acetate market in food processing is projected to experience steady growth over the coming years. Factors such as the expansion of the food and beverage industry, technological advancements in food preservation techniques, and the increasing adoption of clean label ingredients are expected to contribute to this growth. However, the market may face challenges from the growing consumer preference for natural and organic food products, which could potentially limit the use of synthetic additives like sodium acetate in certain segments.

In the bakery industry, sodium acetate has gained significant traction as a mold inhibitor and acidity regulator. The growing consumer preference for extended shelf-life baked goods without compromising on taste or quality has driven the demand for sodium acetate in this segment. Manufacturers are increasingly incorporating it into bread, pastries, and other baked products to maintain freshness and prevent spoilage.

The meat processing industry has also witnessed a surge in sodium acetate usage. Its ability to act as a preservative and flavor enhancer has made it an essential component in processed meats, sausages, and cured products. With the rising consumption of convenience foods and ready-to-eat meat products, the demand for sodium acetate in this sector is expected to continue its upward trajectory.

In the dairy industry, sodium acetate has found applications in cheese production and yogurt manufacturing. Its pH-regulating properties help control acidity levels during fermentation processes, contributing to improved product consistency and quality. As the global dairy market expands, particularly in emerging economies, the demand for sodium acetate in this sector is projected to grow significantly.

The beverage industry has also embraced sodium acetate for its flavor-enhancing capabilities. It is commonly used in sports drinks, energy beverages, and flavored water to balance acidity and improve taste profiles. The growing health and wellness trend, coupled with the increasing popularity of functional beverages, is expected to drive further demand for sodium acetate in this segment.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth driver for sodium acetate in food processing. Rapid urbanization, changing dietary habits, and increasing disposable incomes in countries like China and India are fueling the demand for processed and convenience foods, consequently boosting the market for food additives like sodium acetate.

The global sodium acetate market in food processing is projected to experience steady growth over the coming years. Factors such as the expansion of the food and beverage industry, technological advancements in food preservation techniques, and the increasing adoption of clean label ingredients are expected to contribute to this growth. However, the market may face challenges from the growing consumer preference for natural and organic food products, which could potentially limit the use of synthetic additives like sodium acetate in certain segments.

Technical Challenges

The use of sodium acetate in food processing faces several technical challenges that require innovative solutions. One of the primary issues is maintaining product stability and shelf life. Sodium acetate, while effective as a preservative, can sometimes interact with other food components, leading to changes in texture, flavor, or appearance over time. This necessitates careful formulation and testing to ensure optimal product quality throughout its intended shelf life.

Another significant challenge lies in the precise control of sodium acetate concentrations in food products. Achieving consistent levels across batches is crucial for maintaining uniform taste, preservation efficacy, and regulatory compliance. This requires sophisticated monitoring and dosing systems, as well as robust quality control processes. The development of more accurate and efficient measurement techniques for sodium acetate in complex food matrices remains an ongoing area of research.

The impact of sodium acetate on organoleptic properties presents another technical hurdle. While it can enhance certain flavors, excessive use may impart an undesirable taste or aftertaste to food products. Balancing the preservative benefits with sensory acceptability demands extensive sensory evaluation and consumer testing. Food scientists are continually exploring ways to mask or mitigate any negative sensory impacts without compromising the functional benefits of sodium acetate.

Environmental concerns and the push for more sustainable food processing methods also pose challenges. The production of sodium acetate traditionally involves energy-intensive processes and petrochemical-derived precursors. Developing greener synthesis routes and exploring bio-based alternatives are becoming increasingly important to meet sustainability goals and consumer expectations for environmentally friendly products.

Regulatory compliance and labeling requirements add another layer of complexity. As consumer preferences shift towards "clean label" products, there is growing pressure to reduce or replace synthetic additives like sodium acetate. This drives the need for natural alternatives or innovative processing techniques that can achieve similar preservation effects without the use of additives. Navigating the varying regulatory landscapes across different countries and regions also requires careful consideration in product development and marketing strategies.

Lastly, the interaction of sodium acetate with packaging materials presents ongoing technical challenges. Ensuring compatibility with various packaging types, preventing migration issues, and maintaining the integrity of both the packaging and the food product over time require extensive research and testing. As new packaging technologies emerge, such as active and intelligent packaging systems, understanding and optimizing their interactions with sodium acetate becomes increasingly important for ensuring food safety and quality.

Another significant challenge lies in the precise control of sodium acetate concentrations in food products. Achieving consistent levels across batches is crucial for maintaining uniform taste, preservation efficacy, and regulatory compliance. This requires sophisticated monitoring and dosing systems, as well as robust quality control processes. The development of more accurate and efficient measurement techniques for sodium acetate in complex food matrices remains an ongoing area of research.

The impact of sodium acetate on organoleptic properties presents another technical hurdle. While it can enhance certain flavors, excessive use may impart an undesirable taste or aftertaste to food products. Balancing the preservative benefits with sensory acceptability demands extensive sensory evaluation and consumer testing. Food scientists are continually exploring ways to mask or mitigate any negative sensory impacts without compromising the functional benefits of sodium acetate.

Environmental concerns and the push for more sustainable food processing methods also pose challenges. The production of sodium acetate traditionally involves energy-intensive processes and petrochemical-derived precursors. Developing greener synthesis routes and exploring bio-based alternatives are becoming increasingly important to meet sustainability goals and consumer expectations for environmentally friendly products.

Regulatory compliance and labeling requirements add another layer of complexity. As consumer preferences shift towards "clean label" products, there is growing pressure to reduce or replace synthetic additives like sodium acetate. This drives the need for natural alternatives or innovative processing techniques that can achieve similar preservation effects without the use of additives. Navigating the varying regulatory landscapes across different countries and regions also requires careful consideration in product development and marketing strategies.

Lastly, the interaction of sodium acetate with packaging materials presents ongoing technical challenges. Ensuring compatibility with various packaging types, preventing migration issues, and maintaining the integrity of both the packaging and the food product over time require extensive research and testing. As new packaging technologies emerge, such as active and intelligent packaging systems, understanding and optimizing their interactions with sodium acetate becomes increasingly important for ensuring food safety and quality.

Current Applications

01 Use of sodium acetate in chemical processes

Sodium acetate is utilized in various chemical processes, including as a catalyst, buffer, or reagent. It plays a role in reactions such as acetylation, esterification, and pH control. The compound's properties make it valuable in industrial applications and laboratory settings.- Use of sodium acetate in chemical processes: Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications, including the production of pharmaceuticals, textiles, and other chemical compounds.

- Application in heat storage and thermal management: Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It undergoes a phase change at specific temperatures, allowing it to store and release latent heat. This property is exploited in heat packs, building materials for temperature regulation, and energy storage systems.

- Use in food industry and preservation: Sodium acetate serves as a food additive and preservative. It acts as an acidity regulator, flavor enhancer, and antimicrobial agent in various food products. Its ability to control pH and inhibit bacterial growth makes it valuable in extending the shelf life of processed foods and beverages.

- Application in wastewater treatment: Sodium acetate is employed in wastewater treatment processes. It can serve as a carbon source for denitrification in biological treatment systems, helping to remove nitrogen compounds from wastewater. Additionally, it may be used in pH adjustment and as a coagulant aid in certain treatment applications.

- Use in material science and manufacturing: Sodium acetate finds applications in material science and manufacturing processes. It is used in the production of certain polymers, as a component in coating formulations, and in the synthesis of various materials. Its properties contribute to improving material characteristics or facilitating specific manufacturing techniques.

02 Application in heat storage and thermal management

Sodium acetate is employed in heat storage and thermal management systems. Its phase change properties allow it to absorb and release heat effectively, making it useful in heat packs, building materials for temperature regulation, and energy storage applications.Expand Specific Solutions03 Use in food and beverage industry

Sodium acetate finds applications in the food and beverage industry as a preservative, flavoring agent, and acidity regulator. It helps extend shelf life, enhance taste, and maintain product stability in various food products.Expand Specific Solutions04 Application in textile and paper industries

In textile and paper industries, sodium acetate is used for various purposes such as dyeing, printing, and as a sizing agent. It helps improve color fastness, fabric softness, and paper quality.Expand Specific Solutions05 Use in environmental and waste treatment

Sodium acetate is employed in environmental and waste treatment processes. It can be used for pH adjustment in wastewater treatment, as a deicer for roads, and in certain bioremediation applications.Expand Specific Solutions

Industry Leaders

The sodium acetate market in food processing is experiencing steady growth, driven by increasing demand for food preservatives and flavor enhancers. The industry is in a mature phase, with established players like Unilever, Cargill, and International Flavors & Fragrances dominating the market. However, innovative companies such as Purac Biochem BV and Jiangsu Hengshun Vinegar Industry Co., Ltd. are introducing new applications and formulations, pushing the technological boundaries. The market size is projected to expand due to rising consumer awareness of food safety and shelf-life extension. While the technology is well-established, ongoing research by institutions like Texas A&M University and Tianjin University of Science & Technology is focusing on improving efficiency and exploring novel applications in food processing.

Purac Biochem BV

Technical Solution: Purac Biochem BV has made significant strides in the application of sodium acetate for food preservation and quality enhancement. Their research has focused on developing high-purity, food-grade sodium acetate that meets stringent quality standards for use in various food processing applications[2]. Purac has innovated in the area of sodium acetate production, utilizing sustainable fermentation processes to create bio-based sodium acetate with a lower environmental impact[4]. They have also explored the synergistic effects of sodium acetate with other organic acids, developing preservative blends that offer enhanced antimicrobial activity against a broad spectrum of food pathogens[6]. Furthermore, Purac has invested in research to optimize the use of sodium acetate in meat processing, particularly in improving the texture and shelf life of processed meats while maintaining a clean label approach[8].

Strengths: High-purity product offerings, sustainable production methods, and specialized preservative blends for meat processing. Weaknesses: Potential higher costs associated with bio-based production and the need for continuous innovation to maintain market leadership in clean label solutions.

Cargill, Inc.

Technical Solution: Cargill has developed innovative applications of sodium acetate in food processing, focusing on its use as a preservative and flavor enhancer. Their approach involves microencapsulation technology to improve the stability and controlled release of sodium acetate in various food products[1]. This method allows for better distribution and efficacy of the compound, particularly in processed meats and baked goods. Cargill has also explored the synergistic effects of sodium acetate with other preservatives, creating custom blends that offer enhanced antimicrobial properties while maintaining product quality[3]. Additionally, they have invested in research to optimize the use of sodium acetate in clean label formulations, addressing the growing consumer demand for natural ingredients[5].

Strengths: Advanced microencapsulation technology, custom preservative blends, and clean label solutions. Weaknesses: Potential higher costs associated with specialized formulations and the need for continuous research to stay ahead in the clean label trend.

Key Patents Review

Method of food preservation treatment methods

PatentActiveVN81816A

Innovation

- Combining sodium acetate with phosphate compounds (phytic acid or super phosphoric acid) for food preservation, enhancing antimicrobial effects while maintaining flavor.

- Using high-temperature treatment liquid (80°C or higher) to improve the effectiveness of the preservation method.

- Incorporating glycine into the treatment liquid to potentially enhance preservation effects or flavor retention.

Acetate powder and method for the preparation thereof

PatentWO2019091970A1

Innovation

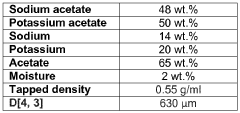

- A process involving the production of coated acetate particles with a high sodium acetate core and a potassium acetate coating, achieving a stable and free-flowing powder with a specific molar ratio and particle size range, which is achieved through a fluidized bed spray coating and drying method.

Regulatory Framework

The regulatory framework surrounding sodium acetate in food processing is complex and multifaceted, involving various international and national bodies. The Food and Drug Administration (FDA) in the United States classifies sodium acetate as Generally Recognized as Safe (GRAS), allowing its use in food products within specified limits. The European Food Safety Authority (EFSA) has also evaluated sodium acetate and approved its use as a food additive (E262) in the European Union.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international standards for food additives, including sodium acetate. These standards serve as a reference for many countries in developing their national regulations.

In recent years, there has been a trend towards stricter regulations on food additives, including sodium acetate. This is partly due to increasing consumer demand for clean label products and concerns about the potential health effects of certain additives. As a result, some countries have implemented more stringent limits on the use of sodium acetate in specific food categories.

The regulatory landscape for sodium acetate is not static and continues to evolve. Ongoing research into its safety and efficacy may lead to future regulatory changes. For instance, some regulatory bodies are considering revising the acceptable daily intake (ADI) levels for sodium acetate based on new scientific evidence.

Compliance with these regulations presents both challenges and opportunities for food manufacturers. On one hand, it requires careful formulation and labeling of products to ensure they meet regulatory standards. On the other hand, it drives innovation in food processing techniques and the development of alternative preservatives and pH regulators.

The regulatory framework also impacts international trade in food products containing sodium acetate. Differences in regulations between countries can create trade barriers, necessitating harmonization efforts. Organizations like the World Trade Organization (WTO) play a role in facilitating discussions on regulatory alignment to promote fair trade practices.

As the food industry continues to innovate, regulators face the challenge of keeping pace with new applications of sodium acetate. This includes its use in novel food products, such as plant-based alternatives and functional foods. Regulatory bodies are increasingly adopting risk-based approaches to assess the safety of new applications, balancing innovation with consumer protection.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international standards for food additives, including sodium acetate. These standards serve as a reference for many countries in developing their national regulations.

In recent years, there has been a trend towards stricter regulations on food additives, including sodium acetate. This is partly due to increasing consumer demand for clean label products and concerns about the potential health effects of certain additives. As a result, some countries have implemented more stringent limits on the use of sodium acetate in specific food categories.

The regulatory landscape for sodium acetate is not static and continues to evolve. Ongoing research into its safety and efficacy may lead to future regulatory changes. For instance, some regulatory bodies are considering revising the acceptable daily intake (ADI) levels for sodium acetate based on new scientific evidence.

Compliance with these regulations presents both challenges and opportunities for food manufacturers. On one hand, it requires careful formulation and labeling of products to ensure they meet regulatory standards. On the other hand, it drives innovation in food processing techniques and the development of alternative preservatives and pH regulators.

The regulatory framework also impacts international trade in food products containing sodium acetate. Differences in regulations between countries can create trade barriers, necessitating harmonization efforts. Organizations like the World Trade Organization (WTO) play a role in facilitating discussions on regulatory alignment to promote fair trade practices.

As the food industry continues to innovate, regulators face the challenge of keeping pace with new applications of sodium acetate. This includes its use in novel food products, such as plant-based alternatives and functional foods. Regulatory bodies are increasingly adopting risk-based approaches to assess the safety of new applications, balancing innovation with consumer protection.

Sustainability Aspects

Sustainability has become a critical consideration in the food processing industry, and the use of sodium acetate is no exception. As a food additive and preservative, sodium acetate's sustainability aspects encompass environmental, economic, and social dimensions.

From an environmental perspective, the production of sodium acetate has been scrutinized for its potential impact. Traditional manufacturing methods often involve the reaction of acetic acid with sodium hydroxide or sodium carbonate, processes that can be energy-intensive and generate waste. However, recent innovations have focused on developing more sustainable production techniques.

One such innovation is the use of biotechnological processes to produce sodium acetate. These methods employ microorganisms to convert renewable feedstocks, such as agricultural waste or byproducts, into acetic acid, which is then neutralized to form sodium acetate. This approach not only reduces reliance on petrochemical-derived raw materials but also minimizes waste generation and energy consumption.

The sustainability of sodium acetate in food processing extends to its role in food preservation. By extending the shelf life of various food products, sodium acetate contributes to reducing food waste, a significant global sustainability challenge. This indirect benefit aligns with the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production.

Economic sustainability is another crucial aspect to consider. The adoption of more efficient production methods for sodium acetate can lead to cost savings for manufacturers, potentially making food products more affordable for consumers. Additionally, the extended shelf life provided by sodium acetate can reduce transportation and storage costs, further enhancing economic sustainability throughout the food supply chain.

In terms of social sustainability, the use of sodium acetate in food processing raises questions about consumer health and safety. While generally recognized as safe (GRAS) by regulatory bodies, ongoing research continues to evaluate its long-term effects on human health. Transparency in labeling and consumer education about the role of sodium acetate in food preservation are essential for maintaining public trust and ensuring social sustainability.

The trend towards clean label products has also influenced the sustainability discourse surrounding sodium acetate. Some food manufacturers are exploring natural alternatives or reformulating products to reduce or eliminate synthetic additives. This shift presents both challenges and opportunities for the sodium acetate industry, driving research into more sustainable and consumer-friendly preservation methods.

As the food industry continues to evolve, the sustainability aspects of sodium acetate use will likely remain a focal point for innovation and improvement. Future developments may include more efficient production processes, bio-based alternatives, and enhanced functionality to address broader sustainability goals in food processing and preservation.

From an environmental perspective, the production of sodium acetate has been scrutinized for its potential impact. Traditional manufacturing methods often involve the reaction of acetic acid with sodium hydroxide or sodium carbonate, processes that can be energy-intensive and generate waste. However, recent innovations have focused on developing more sustainable production techniques.

One such innovation is the use of biotechnological processes to produce sodium acetate. These methods employ microorganisms to convert renewable feedstocks, such as agricultural waste or byproducts, into acetic acid, which is then neutralized to form sodium acetate. This approach not only reduces reliance on petrochemical-derived raw materials but also minimizes waste generation and energy consumption.

The sustainability of sodium acetate in food processing extends to its role in food preservation. By extending the shelf life of various food products, sodium acetate contributes to reducing food waste, a significant global sustainability challenge. This indirect benefit aligns with the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production.

Economic sustainability is another crucial aspect to consider. The adoption of more efficient production methods for sodium acetate can lead to cost savings for manufacturers, potentially making food products more affordable for consumers. Additionally, the extended shelf life provided by sodium acetate can reduce transportation and storage costs, further enhancing economic sustainability throughout the food supply chain.

In terms of social sustainability, the use of sodium acetate in food processing raises questions about consumer health and safety. While generally recognized as safe (GRAS) by regulatory bodies, ongoing research continues to evaluate its long-term effects on human health. Transparency in labeling and consumer education about the role of sodium acetate in food preservation are essential for maintaining public trust and ensuring social sustainability.

The trend towards clean label products has also influenced the sustainability discourse surrounding sodium acetate. Some food manufacturers are exploring natural alternatives or reformulating products to reduce or eliminate synthetic additives. This shift presents both challenges and opportunities for the sodium acetate industry, driving research into more sustainable and consumer-friendly preservation methods.

As the food industry continues to evolve, the sustainability aspects of sodium acetate use will likely remain a focal point for innovation and improvement. Future developments may include more efficient production processes, bio-based alternatives, and enhanced functionality to address broader sustainability goals in food processing and preservation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!