Sodium Acetate in Textile Processing: New Frontiers

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Evolution

Sodium acetate has undergone a significant evolution in textile processing, transforming from a simple chemical compound to a versatile agent with multiple applications. The journey of sodium acetate in the textile industry began in the early 20th century when it was primarily used as a pH buffer in dyeing processes. Its ability to maintain stable pH levels in dye baths made it an essential component in achieving consistent and high-quality fabric coloration.

As textile manufacturing techniques advanced, so did the applications of sodium acetate. In the 1950s and 1960s, researchers discovered its potential as a mordant, enhancing the binding of dyes to fibers, particularly in wool and silk processing. This discovery led to improved color fastness and durability of textiles, marking a significant milestone in the evolution of sodium acetate's role in the industry.

The 1970s and 1980s saw a surge in environmental awareness, prompting the textile industry to seek more sustainable practices. Sodium acetate emerged as an eco-friendly alternative to harsher chemicals in various textile processes. Its biodegradability and low toxicity made it an attractive option for manufacturers looking to reduce their environmental footprint while maintaining product quality.

In the 1990s, sodium acetate found new applications in textile finishing processes. Its hygroscopic properties were harnessed to develop moisture management treatments for fabrics, enhancing comfort and performance in sportswear and technical textiles. This period also saw the compound being used in anti-static treatments, addressing the growing demand for static-free garments in the electronics industry.

The turn of the millennium brought about a renewed focus on nanotechnology in textile processing. Researchers began exploring the potential of sodium acetate in nanoparticle synthesis and application, opening up new avenues for fabric functionalization. This led to the development of advanced textiles with properties such as antimicrobial resistance, UV protection, and self-cleaning capabilities.

Recent years have witnessed a surge in smart textile research, with sodium acetate playing a crucial role in phase-change materials (PCMs). Its unique thermal properties allow it to absorb, store, and release heat, making it ideal for temperature-regulating fabrics. This application has found particular success in outdoor wear and bedding materials, showcasing the compound's versatility in addressing modern textile challenges.

As we look to the future, the evolution of sodium acetate in textile processing continues to unfold. Ongoing research is exploring its potential in sustainable dyeing techniques, advanced fiber treatments, and innovative fabric finishes. The compound's journey from a simple pH buffer to a multifaceted textile processing agent exemplifies the dynamic nature of technological advancement in the industry, promising exciting developments in the years to come.

As textile manufacturing techniques advanced, so did the applications of sodium acetate. In the 1950s and 1960s, researchers discovered its potential as a mordant, enhancing the binding of dyes to fibers, particularly in wool and silk processing. This discovery led to improved color fastness and durability of textiles, marking a significant milestone in the evolution of sodium acetate's role in the industry.

The 1970s and 1980s saw a surge in environmental awareness, prompting the textile industry to seek more sustainable practices. Sodium acetate emerged as an eco-friendly alternative to harsher chemicals in various textile processes. Its biodegradability and low toxicity made it an attractive option for manufacturers looking to reduce their environmental footprint while maintaining product quality.

In the 1990s, sodium acetate found new applications in textile finishing processes. Its hygroscopic properties were harnessed to develop moisture management treatments for fabrics, enhancing comfort and performance in sportswear and technical textiles. This period also saw the compound being used in anti-static treatments, addressing the growing demand for static-free garments in the electronics industry.

The turn of the millennium brought about a renewed focus on nanotechnology in textile processing. Researchers began exploring the potential of sodium acetate in nanoparticle synthesis and application, opening up new avenues for fabric functionalization. This led to the development of advanced textiles with properties such as antimicrobial resistance, UV protection, and self-cleaning capabilities.

Recent years have witnessed a surge in smart textile research, with sodium acetate playing a crucial role in phase-change materials (PCMs). Its unique thermal properties allow it to absorb, store, and release heat, making it ideal for temperature-regulating fabrics. This application has found particular success in outdoor wear and bedding materials, showcasing the compound's versatility in addressing modern textile challenges.

As we look to the future, the evolution of sodium acetate in textile processing continues to unfold. Ongoing research is exploring its potential in sustainable dyeing techniques, advanced fiber treatments, and innovative fabric finishes. The compound's journey from a simple pH buffer to a multifaceted textile processing agent exemplifies the dynamic nature of technological advancement in the industry, promising exciting developments in the years to come.

Textile Market Demands

The textile industry is experiencing a significant shift in market demands, driven by evolving consumer preferences, sustainability concerns, and technological advancements. The use of sodium acetate in textile processing is gaining attention as manufacturers seek innovative solutions to meet these changing market needs.

Consumer demand for sustainable and eco-friendly textiles has surged in recent years. This trend has pushed manufacturers to explore alternative processing methods that reduce environmental impact while maintaining product quality. Sodium acetate, known for its biodegradability and low toxicity, aligns well with this market demand. Its potential to replace more harmful chemicals in textile processing has sparked interest among environmentally conscious consumers and brands alike.

Performance-enhanced textiles are another growing segment of the market. Consumers are increasingly seeking fabrics with advanced properties such as moisture-wicking, antimicrobial, and wrinkle-resistant features. Sodium acetate's versatility in textile processing offers opportunities to develop such high-performance materials, potentially meeting this rising demand for functional textiles.

The fast fashion industry, despite facing criticism for its environmental impact, continues to drive a significant portion of textile market demand. This sector requires efficient and cost-effective processing methods to maintain rapid production cycles. Sodium acetate's potential to streamline certain textile processing steps could appeal to manufacturers looking to optimize their operations while addressing sustainability concerns.

Technical textiles, used in industries such as automotive, healthcare, and construction, represent a rapidly growing market segment. These specialized fabrics often require precise chemical treatments to achieve specific properties. The exploration of sodium acetate in this context could open new avenues for developing advanced technical textiles that meet stringent industry requirements.

The global pandemic has also influenced textile market demands, with an increased focus on hygiene and protective properties. Textiles with antimicrobial or antiviral properties have seen a surge in demand. Research into sodium acetate's potential role in imparting such properties to fabrics could address this emerging market need.

As the textile industry faces increasing pressure to reduce water consumption and chemical waste, there is a growing demand for processing methods that are more resource-efficient. Sodium acetate's potential to improve dyeing efficiency and reduce water usage aligns with this market trend towards more sustainable production processes.

The market for organic and natural textiles continues to expand, driven by health-conscious consumers. While sodium acetate is a synthetic compound, its low environmental impact and potential to replace more harmful chemicals could make it an attractive option for manufacturers looking to bridge the gap between conventional and fully organic textile processing methods.

Consumer demand for sustainable and eco-friendly textiles has surged in recent years. This trend has pushed manufacturers to explore alternative processing methods that reduce environmental impact while maintaining product quality. Sodium acetate, known for its biodegradability and low toxicity, aligns well with this market demand. Its potential to replace more harmful chemicals in textile processing has sparked interest among environmentally conscious consumers and brands alike.

Performance-enhanced textiles are another growing segment of the market. Consumers are increasingly seeking fabrics with advanced properties such as moisture-wicking, antimicrobial, and wrinkle-resistant features. Sodium acetate's versatility in textile processing offers opportunities to develop such high-performance materials, potentially meeting this rising demand for functional textiles.

The fast fashion industry, despite facing criticism for its environmental impact, continues to drive a significant portion of textile market demand. This sector requires efficient and cost-effective processing methods to maintain rapid production cycles. Sodium acetate's potential to streamline certain textile processing steps could appeal to manufacturers looking to optimize their operations while addressing sustainability concerns.

Technical textiles, used in industries such as automotive, healthcare, and construction, represent a rapidly growing market segment. These specialized fabrics often require precise chemical treatments to achieve specific properties. The exploration of sodium acetate in this context could open new avenues for developing advanced technical textiles that meet stringent industry requirements.

The global pandemic has also influenced textile market demands, with an increased focus on hygiene and protective properties. Textiles with antimicrobial or antiviral properties have seen a surge in demand. Research into sodium acetate's potential role in imparting such properties to fabrics could address this emerging market need.

As the textile industry faces increasing pressure to reduce water consumption and chemical waste, there is a growing demand for processing methods that are more resource-efficient. Sodium acetate's potential to improve dyeing efficiency and reduce water usage aligns with this market trend towards more sustainable production processes.

The market for organic and natural textiles continues to expand, driven by health-conscious consumers. While sodium acetate is a synthetic compound, its low environmental impact and potential to replace more harmful chemicals could make it an attractive option for manufacturers looking to bridge the gap between conventional and fully organic textile processing methods.

Technical Challenges

The use of sodium acetate in textile processing faces several technical challenges that need to be addressed for its widespread adoption and optimization. One of the primary issues is the potential for salt buildup on textile fibers, which can affect the quality and appearance of the final product. This accumulation may lead to reduced fabric softness, increased stiffness, and potential discoloration, particularly in light-colored textiles.

Another significant challenge lies in maintaining consistent pH levels during the processing stages. Sodium acetate's buffering properties, while beneficial in many applications, can sometimes interfere with other chemical processes in textile treatment. This interference may result in uneven dyeing or finishing, requiring careful calibration of the entire chemical system used in textile production.

The environmental impact of sodium acetate usage also presents technical hurdles. While it is generally considered less harmful than some alternative chemicals, there are concerns about its disposal and potential effects on wastewater treatment systems. Developing efficient methods for recovering and recycling sodium acetate from textile processing effluents remains a critical area for improvement.

Furthermore, the interaction between sodium acetate and various fabric types poses challenges in terms of optimizing its application. Different fibers, such as natural cellulosic fibers, synthetic polymers, and blends, may react differently to sodium acetate treatments. This variability necessitates the development of tailored processes for each fabric type, which can be both time-consuming and resource-intensive.

The stability of sodium acetate solutions under various processing conditions is another area of concern. Temperature fluctuations, exposure to light, and interactions with other chemicals in the textile processing environment can potentially alter its effectiveness. Ensuring the consistent performance of sodium acetate across a wide range of processing parameters requires ongoing research and development efforts.

Lastly, the scalability of sodium acetate-based processes in large-scale textile manufacturing presents technical challenges. While its benefits may be evident in laboratory or small-scale applications, translating these advantages to industrial-scale operations without compromising efficiency or quality is a complex task. This scaling issue encompasses aspects such as uniform distribution of the chemical, maintaining process control, and managing increased volumes of treated textiles and waste products.

Another significant challenge lies in maintaining consistent pH levels during the processing stages. Sodium acetate's buffering properties, while beneficial in many applications, can sometimes interfere with other chemical processes in textile treatment. This interference may result in uneven dyeing or finishing, requiring careful calibration of the entire chemical system used in textile production.

The environmental impact of sodium acetate usage also presents technical hurdles. While it is generally considered less harmful than some alternative chemicals, there are concerns about its disposal and potential effects on wastewater treatment systems. Developing efficient methods for recovering and recycling sodium acetate from textile processing effluents remains a critical area for improvement.

Furthermore, the interaction between sodium acetate and various fabric types poses challenges in terms of optimizing its application. Different fibers, such as natural cellulosic fibers, synthetic polymers, and blends, may react differently to sodium acetate treatments. This variability necessitates the development of tailored processes for each fabric type, which can be both time-consuming and resource-intensive.

The stability of sodium acetate solutions under various processing conditions is another area of concern. Temperature fluctuations, exposure to light, and interactions with other chemicals in the textile processing environment can potentially alter its effectiveness. Ensuring the consistent performance of sodium acetate across a wide range of processing parameters requires ongoing research and development efforts.

Lastly, the scalability of sodium acetate-based processes in large-scale textile manufacturing presents technical challenges. While its benefits may be evident in laboratory or small-scale applications, translating these advantages to industrial-scale operations without compromising efficiency or quality is a complex task. This scaling issue encompasses aspects such as uniform distribution of the chemical, maintaining process control, and managing increased volumes of treated textiles and waste products.

Current Applications

01 Use of sodium acetate in chemical processes

Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications and laboratory settings.- Use of sodium acetate in chemical processes: Sodium acetate is utilized in various chemical processes, including as a catalyst, pH regulator, or reagent. It plays a role in reactions such as acetylation, esterification, and neutralization. The compound's properties make it suitable for applications in industrial chemistry and laboratory settings.

- Application in heat storage and thermal management: Sodium acetate is employed in heat storage systems and thermal management solutions. Its phase change properties allow it to absorb and release heat effectively, making it useful in heat packs, building materials for temperature regulation, and energy storage applications.

- Use in food and beverage industry: Sodium acetate finds applications in the food and beverage industry as a preservative, flavoring agent, and acidity regulator. It helps extend shelf life, enhance taste, and maintain product stability in various food products and beverages.

- Application in textile and paper industries: Sodium acetate is used in textile and paper industries for various purposes. In textiles, it can serve as a mordant in dyeing processes or as a neutralizing agent. In paper production, it may be used for pH control or as an additive to improve paper properties.

- Use in pharmaceutical and personal care products: Sodium acetate is utilized in pharmaceutical formulations and personal care products. It can act as a buffering agent, pH adjuster, or stabilizer in various medications, topical treatments, and cosmetic preparations.

02 Application in heat storage and thermal management

Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It undergoes phase changes at specific temperatures, allowing it to store and release heat effectively. This property is exploited in heat packs, building materials, and energy storage solutions.Expand Specific Solutions03 Use in food and beverage industry

Sodium acetate serves as a food additive and preservative in the food and beverage industry. It acts as a flavoring agent, acidity regulator, and antimicrobial agent. Its use helps extend shelf life and maintain product quality in various food products.Expand Specific Solutions04 Application in textile and leather processing

Sodium acetate is employed in textile and leather processing industries. It is used in dyeing processes, as a mordant, and in leather tanning. Its properties help improve color fastness, texture, and overall quality of textiles and leather products.Expand Specific Solutions05 Use in pharmaceutical and medical applications

Sodium acetate finds applications in pharmaceutical formulations and medical treatments. It is used as a buffering agent in intravenous fluids, dialysis solutions, and as an electrolyte replacement. Its role in maintaining pH balance makes it valuable in various medical contexts.Expand Specific Solutions

Industry Leaders

The textile processing industry, particularly in the application of sodium acetate, is experiencing a dynamic phase of innovation and growth. The market is expanding rapidly, driven by increasing demand for sustainable and efficient textile processing solutions. While the technology is maturing, there's still significant room for advancement and optimization. Key players like BASF Corp., Unilever Plc, and DuPont de Nemours, Inc. are leading the charge in research and development, focusing on eco-friendly applications and process improvements. Emerging companies such as ColorZen LLC and Acticell GmbH are also making notable contributions, particularly in specialized areas like dyeing and finishing. The competitive landscape is characterized by a mix of established chemical giants and innovative startups, each striving to capture market share in this evolving sector.

BASF Corp.

Technical Solution: BASF has developed an innovative sodium acetate-based textile processing solution that enhances fabric performance and sustainability. Their approach involves using sodium acetate as a key component in a novel finishing treatment that improves moisture management and reduces the need for harmful chemicals. The process incorporates sodium acetate into the fabric structure, creating a hydrophilic surface that enhances moisture wicking and quick-drying properties[1]. Additionally, BASF's technology utilizes sodium acetate as a pH buffer in dyeing processes, leading to more consistent and vibrant colors while reducing water and energy consumption[3]. The company has also explored the use of sodium acetate in flame-retardant treatments for textiles, offering a more environmentally friendly alternative to traditional methods[5].

Strengths: Improved fabric performance, reduced chemical usage, enhanced sustainability. Weaknesses: Potential higher initial costs, may require modifications to existing production processes.

Celanese International Corp.

Technical Solution: Celanese has pioneered a sodium acetate-based technology for textile processing that focuses on improving fabric durability and reducing environmental impact. Their approach involves incorporating sodium acetate into a proprietary polymer blend that can be applied to fabrics during the finishing stage. This treatment enhances the fabric's resistance to wear and tear, increases colorfastness, and improves overall longevity[2]. Celanese's process also utilizes sodium acetate as a catalyst in a novel cross-linking method, which strengthens fiber bonds without the need for formaldehyde-based resins[4]. Furthermore, the company has developed a sodium acetate-infused coating that provides antimicrobial properties to textiles, addressing growing consumer demand for hygienic fabrics[6].

Strengths: Enhanced fabric durability, improved product longevity, reduced environmental impact. Weaknesses: May increase production costs, potential limitations in application to certain fabric types.

Key Innovations

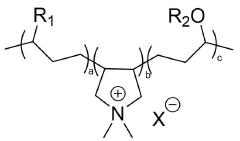

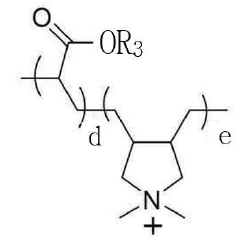

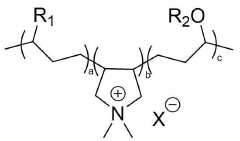

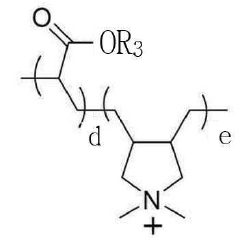

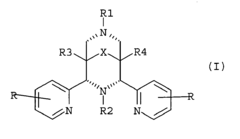

Cationizing agents for dyeing textiles with minimal amount of neutral salt, preparation method thereof, and method for dyeing textiles using same

PatentActiveKR1020210147766A

Innovation

- A novel polymeric cationizing agent, represented by Formulas 1 and 2, is used to modify fiber surfaces, reducing neutral salt usage by 50% or more, and enabling excellent dyeability without uneven dyeing through electrostatic bonding.

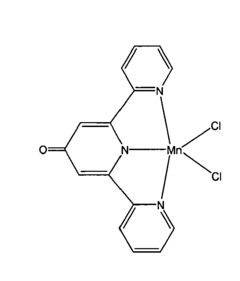

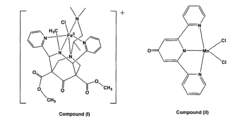

Bleaching composition

PatentInactiveEP1840198A1

Innovation

- A bleaching composition comprising 2-60 wt% surfactant and 0.01-40 wt% periodate salt, used in an aqueous medium with 0.2 g/L to 5 g/L surfactant and 0.2 mmolar to 25 mmolar periodate ions, along with a transition metal catalyst, to treat textiles at a pH range of 4 to 13, followed by rinsing and drying, effectively addressing stain removal and whitening.

Environmental Impact

The use of sodium acetate in textile processing has significant environmental implications that warrant careful consideration. As the industry moves towards more sustainable practices, understanding and mitigating the environmental impact of this chemical becomes crucial.

Sodium acetate, while generally considered less harmful than some other textile processing chemicals, still poses potential risks to aquatic ecosystems when discharged in wastewater. Its high solubility in water means it can easily enter water bodies, potentially altering pH levels and affecting aquatic life. However, its biodegradability is a positive factor, as it can be broken down by natural processes over time, reducing long-term environmental accumulation.

The production of sodium acetate also contributes to the overall environmental footprint of textile processing. The manufacturing process involves the reaction of acetic acid with sodium hydroxide or sodium carbonate, which requires energy and resources. This production chain contributes to greenhouse gas emissions and resource depletion, albeit on a smaller scale compared to some other industrial chemicals.

Water consumption is another critical environmental aspect to consider. Textile processing using sodium acetate often involves multiple washing and rinsing steps, leading to high water usage. This not only strains local water resources but also increases the volume of wastewater that needs treatment before discharge.

On the positive side, recent advancements in sodium acetate application techniques have shown promise in reducing overall chemical and water consumption in textile processing. Innovations in low-liquor ratio dyeing and finishing processes utilizing sodium acetate have demonstrated potential for significant water savings and reduced effluent generation.

The environmental impact of sodium acetate also extends to its role in improving dye fixation and color fastness. By enhancing these properties, it indirectly contributes to the longevity of textiles, potentially reducing the frequency of garment replacement and associated environmental costs of textile production and disposal.

As the textile industry continues to evolve, there is a growing focus on developing closed-loop systems that recycle and reuse chemicals like sodium acetate. These systems aim to minimize waste discharge and reduce the overall environmental impact of textile processing. Research into more efficient recovery and purification methods for sodium acetate from process streams is ongoing, with the potential to significantly reduce its environmental footprint.

Sodium acetate, while generally considered less harmful than some other textile processing chemicals, still poses potential risks to aquatic ecosystems when discharged in wastewater. Its high solubility in water means it can easily enter water bodies, potentially altering pH levels and affecting aquatic life. However, its biodegradability is a positive factor, as it can be broken down by natural processes over time, reducing long-term environmental accumulation.

The production of sodium acetate also contributes to the overall environmental footprint of textile processing. The manufacturing process involves the reaction of acetic acid with sodium hydroxide or sodium carbonate, which requires energy and resources. This production chain contributes to greenhouse gas emissions and resource depletion, albeit on a smaller scale compared to some other industrial chemicals.

Water consumption is another critical environmental aspect to consider. Textile processing using sodium acetate often involves multiple washing and rinsing steps, leading to high water usage. This not only strains local water resources but also increases the volume of wastewater that needs treatment before discharge.

On the positive side, recent advancements in sodium acetate application techniques have shown promise in reducing overall chemical and water consumption in textile processing. Innovations in low-liquor ratio dyeing and finishing processes utilizing sodium acetate have demonstrated potential for significant water savings and reduced effluent generation.

The environmental impact of sodium acetate also extends to its role in improving dye fixation and color fastness. By enhancing these properties, it indirectly contributes to the longevity of textiles, potentially reducing the frequency of garment replacement and associated environmental costs of textile production and disposal.

As the textile industry continues to evolve, there is a growing focus on developing closed-loop systems that recycle and reuse chemicals like sodium acetate. These systems aim to minimize waste discharge and reduce the overall environmental impact of textile processing. Research into more efficient recovery and purification methods for sodium acetate from process streams is ongoing, with the potential to significantly reduce its environmental footprint.

Regulatory Framework

The regulatory framework surrounding the use of sodium acetate in textile processing is evolving to address environmental concerns and ensure product safety. Governments and international organizations are implementing stricter guidelines to regulate the use of chemicals in the textile industry, including sodium acetate.

Environmental regulations play a crucial role in shaping the use of sodium acetate in textile processing. Many countries have established limits on the discharge of effluents containing sodium acetate and other chemicals used in textile manufacturing. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, for instance, requires manufacturers and importers to assess and manage the risks associated with chemicals used in their products.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemicals in textile processing under the Toxic Substances Control Act (TSCA). The agency has established reporting requirements and restrictions on certain chemical substances, including those used in textile manufacturing.

Product safety regulations also impact the use of sodium acetate in textile processing. The Consumer Product Safety Commission (CPSC) in the United States and similar agencies in other countries set standards for textile products to ensure they are safe for consumer use. These regulations often include limits on chemical residues in finished textile products.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for the use of chemicals in textile processing. These standards aim to promote sustainable practices and minimize environmental impact while ensuring product quality and safety.

The textile industry has also implemented voluntary initiatives to address environmental and safety concerns. Programs like the Zero Discharge of Hazardous Chemicals (ZDHC) initiative encourage manufacturers to eliminate hazardous chemicals from their supply chains and promote the use of safer alternatives.

As sustainability becomes increasingly important in the textile industry, regulations are likely to become more stringent. Future regulatory frameworks may focus on promoting circular economy principles, encouraging the use of biodegradable chemicals, and reducing water consumption in textile processing.

Compliance with these regulations presents both challenges and opportunities for textile manufacturers. While adhering to stricter guidelines may require significant investments in new technologies and processes, it also drives innovation in sustainable textile processing methods. Companies that proactively adapt to evolving regulatory requirements are better positioned to meet consumer demands for environmentally friendly products and maintain a competitive edge in the global market.

Environmental regulations play a crucial role in shaping the use of sodium acetate in textile processing. Many countries have established limits on the discharge of effluents containing sodium acetate and other chemicals used in textile manufacturing. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, for instance, requires manufacturers and importers to assess and manage the risks associated with chemicals used in their products.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemicals in textile processing under the Toxic Substances Control Act (TSCA). The agency has established reporting requirements and restrictions on certain chemical substances, including those used in textile manufacturing.

Product safety regulations also impact the use of sodium acetate in textile processing. The Consumer Product Safety Commission (CPSC) in the United States and similar agencies in other countries set standards for textile products to ensure they are safe for consumer use. These regulations often include limits on chemical residues in finished textile products.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for the use of chemicals in textile processing. These standards aim to promote sustainable practices and minimize environmental impact while ensuring product quality and safety.

The textile industry has also implemented voluntary initiatives to address environmental and safety concerns. Programs like the Zero Discharge of Hazardous Chemicals (ZDHC) initiative encourage manufacturers to eliminate hazardous chemicals from their supply chains and promote the use of safer alternatives.

As sustainability becomes increasingly important in the textile industry, regulations are likely to become more stringent. Future regulatory frameworks may focus on promoting circular economy principles, encouraging the use of biodegradable chemicals, and reducing water consumption in textile processing.

Compliance with these regulations presents both challenges and opportunities for textile manufacturers. While adhering to stricter guidelines may require significant investments in new technologies and processes, it also drives innovation in sustainable textile processing methods. Companies that proactively adapt to evolving regulatory requirements are better positioned to meet consumer demands for environmentally friendly products and maintain a competitive edge in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!