Sodium Acetate: Pioneering Next‑Gen Thermal Management Solutions

JUN 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate TMS Background and Objectives

Sodium acetate has emerged as a promising candidate for next-generation thermal management solutions, offering unique properties that address the growing demand for efficient and sustainable heat storage and transfer systems. The evolution of this technology can be traced back to the early 20th century when the thermochemical properties of sodium acetate were first explored. However, it is only in recent decades that its potential for thermal management applications has gained significant attention.

The primary objective of sodium acetate-based thermal management systems (TMS) is to harness the material's phase change properties for effective heat storage and release. This technology aims to overcome the limitations of traditional thermal management solutions, such as low energy density and inefficient heat transfer. By utilizing sodium acetate's ability to absorb and release large amounts of latent heat during phase transitions, researchers and engineers seek to develop more compact, efficient, and responsive thermal management systems.

As global energy demands continue to rise and environmental concerns intensify, the development of advanced thermal management solutions has become increasingly critical. Sodium acetate TMS aligns with the broader trend towards sustainable and energy-efficient technologies, offering potential applications across various sectors, including building climate control, industrial process heating, and renewable energy storage.

The technical evolution of sodium acetate TMS has been marked by several key milestones. Early research focused on understanding the fundamental thermodynamic properties of sodium acetate trihydrate and its supercooling behavior. This laid the groundwork for subsequent developments in encapsulation techniques, nucleation control, and system integration. Recent advancements have centered on enhancing the material's thermal conductivity, improving cycle stability, and developing novel composite formulations to tailor performance characteristics.

Looking ahead, the objectives for sodium acetate TMS research and development are multifaceted. These include optimizing the material's thermophysical properties to achieve higher energy densities and faster charge/discharge rates, developing more robust and cost-effective encapsulation methods, and exploring innovative system designs for seamless integration into various applications. Additionally, there is a growing focus on addressing scalability challenges and improving long-term reliability to facilitate widespread commercial adoption.

As the technology continues to mature, interdisciplinary collaboration between materials scientists, chemical engineers, and thermal management experts will be crucial in realizing the full potential of sodium acetate-based solutions. The ultimate goal is to establish sodium acetate TMS as a versatile, high-performance alternative to conventional thermal management technologies, capable of meeting the diverse and evolving needs of modern energy systems and industrial processes.

The primary objective of sodium acetate-based thermal management systems (TMS) is to harness the material's phase change properties for effective heat storage and release. This technology aims to overcome the limitations of traditional thermal management solutions, such as low energy density and inefficient heat transfer. By utilizing sodium acetate's ability to absorb and release large amounts of latent heat during phase transitions, researchers and engineers seek to develop more compact, efficient, and responsive thermal management systems.

As global energy demands continue to rise and environmental concerns intensify, the development of advanced thermal management solutions has become increasingly critical. Sodium acetate TMS aligns with the broader trend towards sustainable and energy-efficient technologies, offering potential applications across various sectors, including building climate control, industrial process heating, and renewable energy storage.

The technical evolution of sodium acetate TMS has been marked by several key milestones. Early research focused on understanding the fundamental thermodynamic properties of sodium acetate trihydrate and its supercooling behavior. This laid the groundwork for subsequent developments in encapsulation techniques, nucleation control, and system integration. Recent advancements have centered on enhancing the material's thermal conductivity, improving cycle stability, and developing novel composite formulations to tailor performance characteristics.

Looking ahead, the objectives for sodium acetate TMS research and development are multifaceted. These include optimizing the material's thermophysical properties to achieve higher energy densities and faster charge/discharge rates, developing more robust and cost-effective encapsulation methods, and exploring innovative system designs for seamless integration into various applications. Additionally, there is a growing focus on addressing scalability challenges and improving long-term reliability to facilitate widespread commercial adoption.

As the technology continues to mature, interdisciplinary collaboration between materials scientists, chemical engineers, and thermal management experts will be crucial in realizing the full potential of sodium acetate-based solutions. The ultimate goal is to establish sodium acetate TMS as a versatile, high-performance alternative to conventional thermal management technologies, capable of meeting the diverse and evolving needs of modern energy systems and industrial processes.

Market Analysis for Sodium Acetate-based TMS

The market for sodium acetate-based thermal management solutions (TMS) is experiencing significant growth, driven by the increasing demand for efficient and sustainable energy storage technologies. This market is closely tied to the broader thermal energy storage sector, which is projected to expand rapidly in the coming years due to the global push for renewable energy integration and energy efficiency improvements.

Sodium acetate-based TMS offers several advantages over traditional thermal management systems, including high energy density, non-toxicity, and cost-effectiveness. These properties make it particularly attractive for applications in building heating and cooling, industrial process heat recovery, and renewable energy storage. The construction industry, in particular, is showing keen interest in sodium acetate-based phase change materials (PCMs) for passive temperature control in buildings, potentially reducing energy consumption and improving occupant comfort.

In the industrial sector, sodium acetate-based TMS is gaining traction for waste heat recovery applications. Industries with high thermal energy requirements, such as food processing, chemical manufacturing, and metallurgy, are exploring these solutions to improve energy efficiency and reduce operational costs. The ability of sodium acetate-based systems to store and release large amounts of thermal energy at relatively constant temperatures makes them ideal for such applications.

The renewable energy sector represents another significant market opportunity for sodium acetate-based TMS. As solar and wind power generation continues to grow, the need for efficient energy storage solutions becomes increasingly critical. Sodium acetate-based thermal storage systems can help address the intermittency issues associated with renewable energy sources, providing a reliable means of storing excess energy for use during periods of low generation.

Geographically, Europe is currently leading the adoption of sodium acetate-based TMS, driven by stringent energy efficiency regulations and ambitious climate goals. North America and Asia-Pacific are also showing strong growth potential, with increasing investments in sustainable building technologies and renewable energy infrastructure.

Despite the promising outlook, the market for sodium acetate-based TMS faces some challenges. These include the need for further research and development to optimize performance and reduce costs, as well as competition from other thermal storage technologies. Additionally, awareness and understanding of the technology among potential end-users remain limited, necessitating educational and marketing efforts to drive adoption.

Looking ahead, the market for sodium acetate-based TMS is expected to continue its growth trajectory. Factors such as increasing environmental regulations, rising energy costs, and the growing emphasis on sustainable technologies are likely to drive further adoption across various industries. As research and development efforts progress, improvements in system efficiency and cost-effectiveness are anticipated, potentially expanding the range of applications and market opportunities for sodium acetate-based thermal management solutions.

Sodium acetate-based TMS offers several advantages over traditional thermal management systems, including high energy density, non-toxicity, and cost-effectiveness. These properties make it particularly attractive for applications in building heating and cooling, industrial process heat recovery, and renewable energy storage. The construction industry, in particular, is showing keen interest in sodium acetate-based phase change materials (PCMs) for passive temperature control in buildings, potentially reducing energy consumption and improving occupant comfort.

In the industrial sector, sodium acetate-based TMS is gaining traction for waste heat recovery applications. Industries with high thermal energy requirements, such as food processing, chemical manufacturing, and metallurgy, are exploring these solutions to improve energy efficiency and reduce operational costs. The ability of sodium acetate-based systems to store and release large amounts of thermal energy at relatively constant temperatures makes them ideal for such applications.

The renewable energy sector represents another significant market opportunity for sodium acetate-based TMS. As solar and wind power generation continues to grow, the need for efficient energy storage solutions becomes increasingly critical. Sodium acetate-based thermal storage systems can help address the intermittency issues associated with renewable energy sources, providing a reliable means of storing excess energy for use during periods of low generation.

Geographically, Europe is currently leading the adoption of sodium acetate-based TMS, driven by stringent energy efficiency regulations and ambitious climate goals. North America and Asia-Pacific are also showing strong growth potential, with increasing investments in sustainable building technologies and renewable energy infrastructure.

Despite the promising outlook, the market for sodium acetate-based TMS faces some challenges. These include the need for further research and development to optimize performance and reduce costs, as well as competition from other thermal storage technologies. Additionally, awareness and understanding of the technology among potential end-users remain limited, necessitating educational and marketing efforts to drive adoption.

Looking ahead, the market for sodium acetate-based TMS is expected to continue its growth trajectory. Factors such as increasing environmental regulations, rising energy costs, and the growing emphasis on sustainable technologies are likely to drive further adoption across various industries. As research and development efforts progress, improvements in system efficiency and cost-effectiveness are anticipated, potentially expanding the range of applications and market opportunities for sodium acetate-based thermal management solutions.

Current State and Challenges in Thermal Management

The current state of thermal management is characterized by a growing demand for more efficient and sustainable solutions across various industries. Traditional methods, such as air cooling and liquid cooling systems, are reaching their limits in terms of performance and energy efficiency. This has led to increased interest in phase change materials (PCMs) like sodium acetate for thermal management applications.

Sodium acetate, a salt compound with unique thermal properties, is emerging as a promising candidate for next-generation thermal management solutions. Its ability to store and release large amounts of latent heat during phase transitions makes it particularly attractive for applications requiring precise temperature control and energy storage.

One of the primary challenges in thermal management is the need for materials that can effectively absorb, store, and release heat in a controlled manner. Sodium acetate addresses this challenge through its supercooling properties and high latent heat of fusion. When heated above its melting point (around 58°C) and then cooled, sodium acetate can remain in a liquid state well below its freezing point. This supercooled state can be maintained until triggered, at which point it rapidly crystallizes, releasing stored heat.

However, the widespread adoption of sodium acetate in thermal management faces several technical hurdles. One significant challenge is the need for improved encapsulation methods to prevent leakage and ensure long-term stability of the material. Current encapsulation techniques often struggle to maintain the integrity of the sodium acetate solution over extended periods and multiple phase change cycles.

Another challenge lies in optimizing the thermal conductivity of sodium acetate-based systems. While the material excels in heat storage capacity, its relatively low thermal conductivity can limit heat transfer rates, potentially reducing overall system efficiency. Researchers are exploring various approaches to enhance thermal conductivity, such as the incorporation of nanoparticles or the development of composite materials.

The integration of sodium acetate into existing thermal management systems also presents challenges. Engineers must develop innovative designs that can effectively utilize the unique properties of sodium acetate while ensuring compatibility with current infrastructure and manufacturing processes. This includes addressing issues related to system control, activation mechanisms for crystallization, and the development of reliable heat exchange interfaces.

Furthermore, scaling up the production and implementation of sodium acetate-based thermal management solutions requires overcoming economic and practical barriers. The cost-effectiveness of these systems compared to traditional methods must be demonstrated, particularly in large-scale applications. Additionally, ensuring the long-term reliability and performance consistency of sodium acetate solutions under various operating conditions remains a critical area of research and development.

Sodium acetate, a salt compound with unique thermal properties, is emerging as a promising candidate for next-generation thermal management solutions. Its ability to store and release large amounts of latent heat during phase transitions makes it particularly attractive for applications requiring precise temperature control and energy storage.

One of the primary challenges in thermal management is the need for materials that can effectively absorb, store, and release heat in a controlled manner. Sodium acetate addresses this challenge through its supercooling properties and high latent heat of fusion. When heated above its melting point (around 58°C) and then cooled, sodium acetate can remain in a liquid state well below its freezing point. This supercooled state can be maintained until triggered, at which point it rapidly crystallizes, releasing stored heat.

However, the widespread adoption of sodium acetate in thermal management faces several technical hurdles. One significant challenge is the need for improved encapsulation methods to prevent leakage and ensure long-term stability of the material. Current encapsulation techniques often struggle to maintain the integrity of the sodium acetate solution over extended periods and multiple phase change cycles.

Another challenge lies in optimizing the thermal conductivity of sodium acetate-based systems. While the material excels in heat storage capacity, its relatively low thermal conductivity can limit heat transfer rates, potentially reducing overall system efficiency. Researchers are exploring various approaches to enhance thermal conductivity, such as the incorporation of nanoparticles or the development of composite materials.

The integration of sodium acetate into existing thermal management systems also presents challenges. Engineers must develop innovative designs that can effectively utilize the unique properties of sodium acetate while ensuring compatibility with current infrastructure and manufacturing processes. This includes addressing issues related to system control, activation mechanisms for crystallization, and the development of reliable heat exchange interfaces.

Furthermore, scaling up the production and implementation of sodium acetate-based thermal management solutions requires overcoming economic and practical barriers. The cost-effectiveness of these systems compared to traditional methods must be demonstrated, particularly in large-scale applications. Additionally, ensuring the long-term reliability and performance consistency of sodium acetate solutions under various operating conditions remains a critical area of research and development.

Existing Sodium Acetate TMS Solutions

01 Phase change materials for thermal management

Sodium acetate is used as a phase change material for thermal management applications. It can absorb and release heat during phase transitions, making it effective for temperature regulation in various systems. This property is utilized in heat storage devices, thermal batteries, and temperature-controlled packaging.- Phase change materials for thermal management: Sodium acetate is used as a phase change material for thermal management applications. It can absorb and release heat during phase transitions, making it effective for temperature regulation in various systems. This property is utilized in heat storage devices, thermal batteries, and temperature-controlled packaging.

- Thermal management in electronic devices: Sodium acetate-based thermal management solutions are applied in electronic devices to regulate temperature and prevent overheating. These systems can be integrated into smartphones, computers, and other electronic equipment to enhance performance and extend device lifespan.

- Energy storage and heat recovery systems: Sodium acetate is used in energy storage and heat recovery systems. It can store excess heat from industrial processes or renewable energy sources and release it when needed, improving overall energy efficiency and reducing waste heat.

- Temperature-controlled packaging and transportation: Sodium acetate-based thermal management solutions are employed in packaging and transportation of temperature-sensitive goods. These systems help maintain stable temperatures for pharmaceuticals, food products, and other perishable items during storage and shipping.

- Building and construction applications: Sodium acetate thermal management systems are integrated into building materials and construction elements for improved temperature regulation. These applications include thermal energy storage in walls, floors, and ceilings to enhance energy efficiency and occupant comfort in buildings.

02 Thermal energy storage systems

Sodium acetate is employed in thermal energy storage systems due to its high latent heat of fusion. These systems can store excess heat during off-peak hours and release it when needed, improving energy efficiency in buildings and industrial processes. The material's ability to supercool also allows for long-term heat storage.Expand Specific Solutions03 Heat packs and warmers

Sodium acetate is commonly used in reusable heat packs and hand warmers. When activated, the supersaturated solution crystallizes, releasing heat. These products provide portable, on-demand heating for personal use, medical applications, and outdoor activities.Expand Specific Solutions04 Temperature-sensitive actuators and sensors

The phase change properties of sodium acetate are utilized in temperature-sensitive actuators and sensors. These devices can respond to temperature changes by expanding or contracting, making them useful in various applications such as automatic fire protection systems, temperature-controlled valves, and thermal switches.Expand Specific Solutions05 Thermal management in electronics and batteries

Sodium acetate-based thermal management solutions are applied in electronics and battery systems to regulate temperature and prevent overheating. This includes the use of sodium acetate in cooling pads, heat sinks, and thermal interface materials to enhance heat dissipation and maintain optimal operating temperatures for electronic components and energy storage devices.Expand Specific Solutions

Key Players in Sodium Acetate TMS Industry

The sodium acetate thermal management solutions market is in an early growth stage, with increasing interest in sustainable energy storage technologies. The market size is expanding as industries seek efficient thermal management solutions. Technologically, the field is evolving rapidly, with companies like Sunamp Ltd. and Neothermal Energy Storage, Inc. leading innovation in heat battery systems using phase change materials. Established players such as Siemens Corp. and BSH Hausgeräte GmbH are also entering the market, leveraging their expertise in energy and appliance sectors. Academic institutions like Dalian University of Technology and Xi'an Jiaotong University are contributing to research and development, indicating a growing focus on advancing the technology's potential applications and efficiency.

Sunamp Ltd.

Technical Solution: Sunamp Ltd. has developed advanced thermal energy storage systems using sodium acetate trihydrate (SAT) as a phase change material (PCM). Their patented technology, known as Sunamp Heat Batteries, utilizes the latent heat of fusion of SAT to store and release thermal energy efficiently. The company has engineered a proprietary nucleation technique to overcome supercooling issues commonly associated with SAT, ensuring reliable and consistent phase change cycles[1]. Sunamp's heat batteries can store 4-5 times more energy than water for the same volume, providing high-density thermal storage solutions for domestic and industrial applications[2]. The company has also developed methods to enhance the thermal conductivity of SAT, improving heat transfer rates and overall system performance[3].

Strengths: High energy density, compact design, and long cycle life. Weaknesses: Potential for phase separation in large-scale applications and the need for specialized heat exchangers to maximize efficiency.

Neothermal Energy Storage, Inc.

Technical Solution: Neothermal Energy Storage has pioneered the development of thermal batteries using sodium acetate as the core material. Their innovative approach involves encapsulating sodium acetate in a proprietary polymer matrix, creating a stable and long-lasting thermal storage medium. This encapsulation technique addresses the common issues of phase separation and supercooling associated with sodium acetate trihydrate[4]. The company's thermal batteries can operate across a wide temperature range, from -20°C to 120°C, making them suitable for various applications, including building heating and cooling, industrial process heat, and renewable energy integration[5]. Neothermal's technology boasts a high energy density of up to 300 kWh/m³, significantly outperforming traditional water-based thermal storage systems[6].

Strengths: Wide operating temperature range and high energy density. Weaknesses: Higher initial costs compared to conventional systems and potential scalability challenges for large-scale implementations.

Core Innovations in Sodium Acetate TMS

Means for storing heat

PatentWO2003012002A2

Innovation

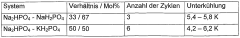

- A mixture of sodium acetate trihydrate with alkali metal hydrogen phosphates and their hydrates, such as disodium hydrogen phosphate and potassium dihydrogen phosphate, is used as nucleating agents, dissolved in water or organic solvents, evaporated, rehydrated, and mixed with sodium acetate trihydrate to enhance nucleation reliability and allow operation up to 80°C without cooling below room temperature.

Heat device having a latent-heat storage means

PatentActiveEP3096723A2

Innovation

- Incorporating a latent heat storage medium, specifically a phase change material like sodium acetate, which absorbs and releases heat during endothermic and exothermic state changes, to regulate the temperature of the heating device, ensuring safer and more comfortable heat delivery.

Environmental Impact of Sodium Acetate TMS

The environmental impact of Sodium Acetate Thermal Management Solutions (TMS) is a critical consideration in the development and implementation of this technology. As a phase change material (PCM), sodium acetate trihydrate offers several environmental advantages over traditional thermal management systems.

Firstly, sodium acetate is non-toxic and biodegradable, making it an environmentally friendly alternative to many synthetic PCMs. This characteristic significantly reduces the potential for environmental contamination in case of leaks or disposal. The material's biodegradability ensures that it can be safely reintegrated into natural ecosystems without long-term harmful effects.

In terms of energy efficiency, sodium acetate TMS can contribute to reduced energy consumption in various applications. By effectively storing and releasing thermal energy, these systems can help minimize the need for active cooling or heating, thereby lowering overall energy demands. This reduction in energy consumption translates to decreased greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

The production of sodium acetate also has a relatively low environmental footprint compared to some alternative PCMs. It can be synthesized from readily available and renewable resources, such as acetic acid derived from biomass fermentation. This aspect of its production chain supports the circular economy concept and reduces dependence on fossil fuel-based raw materials.

However, it is important to consider the full life cycle of sodium acetate TMS. While the material itself is environmentally friendly, the manufacturing process of the containment systems and associated components may have environmental impacts. Efforts to minimize these impacts through sustainable manufacturing practices and materials selection are crucial for maximizing the overall environmental benefits of the technology.

In applications such as building thermal management, sodium acetate TMS can contribute to improved energy efficiency and reduced carbon footprints. By stabilizing indoor temperatures and reducing the load on HVAC systems, these solutions can play a significant role in creating more sustainable built environments.

The recyclability of sodium acetate further enhances its environmental credentials. At the end of its useful life in a TMS application, the material can be recovered and repurposed, minimizing waste and supporting closed-loop material cycles. This aspect is particularly valuable in the context of growing concerns about resource depletion and waste management.

As the technology advances, ongoing research is focused on optimizing the environmental performance of sodium acetate TMS. This includes improving the efficiency of heat transfer, enhancing the longevity of the systems, and developing more sustainable encapsulation methods. These efforts aim to further reduce the environmental impact while maximizing the thermal management benefits of the technology.

Firstly, sodium acetate is non-toxic and biodegradable, making it an environmentally friendly alternative to many synthetic PCMs. This characteristic significantly reduces the potential for environmental contamination in case of leaks or disposal. The material's biodegradability ensures that it can be safely reintegrated into natural ecosystems without long-term harmful effects.

In terms of energy efficiency, sodium acetate TMS can contribute to reduced energy consumption in various applications. By effectively storing and releasing thermal energy, these systems can help minimize the need for active cooling or heating, thereby lowering overall energy demands. This reduction in energy consumption translates to decreased greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

The production of sodium acetate also has a relatively low environmental footprint compared to some alternative PCMs. It can be synthesized from readily available and renewable resources, such as acetic acid derived from biomass fermentation. This aspect of its production chain supports the circular economy concept and reduces dependence on fossil fuel-based raw materials.

However, it is important to consider the full life cycle of sodium acetate TMS. While the material itself is environmentally friendly, the manufacturing process of the containment systems and associated components may have environmental impacts. Efforts to minimize these impacts through sustainable manufacturing practices and materials selection are crucial for maximizing the overall environmental benefits of the technology.

In applications such as building thermal management, sodium acetate TMS can contribute to improved energy efficiency and reduced carbon footprints. By stabilizing indoor temperatures and reducing the load on HVAC systems, these solutions can play a significant role in creating more sustainable built environments.

The recyclability of sodium acetate further enhances its environmental credentials. At the end of its useful life in a TMS application, the material can be recovered and repurposed, minimizing waste and supporting closed-loop material cycles. This aspect is particularly valuable in the context of growing concerns about resource depletion and waste management.

As the technology advances, ongoing research is focused on optimizing the environmental performance of sodium acetate TMS. This includes improving the efficiency of heat transfer, enhancing the longevity of the systems, and developing more sustainable encapsulation methods. These efforts aim to further reduce the environmental impact while maximizing the thermal management benefits of the technology.

Safety Regulations for Sodium Acetate TMS

The implementation of Sodium Acetate Thermal Management Systems (TMS) necessitates adherence to stringent safety regulations to ensure the protection of users, equipment, and the environment. These regulations encompass various aspects of the system's design, installation, operation, and maintenance. Firstly, material safety standards are crucial, requiring the use of corrosion-resistant containers and piping to prevent leaks and contamination. The storage and handling of sodium acetate must comply with chemical safety guidelines, including proper labeling, storage conditions, and handling procedures.

Temperature control is a critical safety aspect of Sodium Acetate TMS. Regulations mandate the incorporation of reliable temperature monitoring and control systems to prevent overheating or rapid crystallization, which could lead to system failures or safety hazards. These systems must include fail-safe mechanisms and redundancies to ensure continuous operation even in the event of component failures.

Pressure management is another key area addressed by safety regulations. The system must be designed to withstand the pressure variations that occur during phase changes, with pressure relief valves and expansion tanks integrated to prevent overpressurization. Regular pressure testing and maintenance protocols are typically required to ensure the ongoing integrity of the system.

Electrical safety standards are also applicable to Sodium Acetate TMS, particularly concerning the heating elements and control systems. These components must be properly insulated, grounded, and protected against moisture and corrosion. Emergency shut-off mechanisms are mandatory to allow for rapid system deactivation in case of malfunctions or accidents.

Environmental regulations play a significant role in the implementation of Sodium Acetate TMS. These systems must be designed to minimize the risk of environmental contamination in case of leaks or spills. Proper disposal procedures for spent sodium acetate solutions and system components are typically outlined in environmental safety guidelines.

Occupational safety regulations are equally important, requiring proper training for personnel involved in the installation, operation, and maintenance of Sodium Acetate TMS. This includes the use of appropriate personal protective equipment (PPE) when handling sodium acetate or working on the system. Emergency response procedures must be established and regularly practiced to ensure swift and effective action in case of accidents or system failures.

Lastly, documentation and record-keeping requirements are often stipulated in safety regulations. This includes maintaining detailed system specifications, operational logs, maintenance records, and incident reports. Regular safety audits and inspections may be mandated to ensure ongoing compliance with all applicable regulations and standards.

Temperature control is a critical safety aspect of Sodium Acetate TMS. Regulations mandate the incorporation of reliable temperature monitoring and control systems to prevent overheating or rapid crystallization, which could lead to system failures or safety hazards. These systems must include fail-safe mechanisms and redundancies to ensure continuous operation even in the event of component failures.

Pressure management is another key area addressed by safety regulations. The system must be designed to withstand the pressure variations that occur during phase changes, with pressure relief valves and expansion tanks integrated to prevent overpressurization. Regular pressure testing and maintenance protocols are typically required to ensure the ongoing integrity of the system.

Electrical safety standards are also applicable to Sodium Acetate TMS, particularly concerning the heating elements and control systems. These components must be properly insulated, grounded, and protected against moisture and corrosion. Emergency shut-off mechanisms are mandatory to allow for rapid system deactivation in case of malfunctions or accidents.

Environmental regulations play a significant role in the implementation of Sodium Acetate TMS. These systems must be designed to minimize the risk of environmental contamination in case of leaks or spills. Proper disposal procedures for spent sodium acetate solutions and system components are typically outlined in environmental safety guidelines.

Occupational safety regulations are equally important, requiring proper training for personnel involved in the installation, operation, and maintenance of Sodium Acetate TMS. This includes the use of appropriate personal protective equipment (PPE) when handling sodium acetate or working on the system. Emergency response procedures must be established and regularly practiced to ensure swift and effective action in case of accidents or system failures.

Lastly, documentation and record-keeping requirements are often stipulated in safety regulations. This includes maintaining detailed system specifications, operational logs, maintenance records, and incident reports. Regular safety audits and inspections may be mandated to ensure ongoing compliance with all applicable regulations and standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!