Technological advancements in V16 engine component miniature fabrication

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and high-performance aircraft, the V16 configuration has seen various advancements in design, materials, and manufacturing techniques over the decades.

In the 1930s, Cadillac introduced the first production V16 engine for automobiles, setting a new standard for power and smoothness. This era marked the beginning of V16 engines in consumer vehicles, showcasing their potential for delivering exceptional performance and prestige.

The mid-20th century saw a shift in V16 engine applications, with a focus on marine and industrial uses. During this period, advancements in metallurgy and precision machining techniques allowed for improved durability and efficiency. The introduction of turbocharging and supercharging further enhanced the power output of these massive engines.

The late 20th century brought about a renewed interest in V16 engines for high-end luxury vehicles. Manufacturers like BMW and Rolls-Royce explored the potential of modern V16 designs, incorporating advanced electronic fuel injection systems and variable valve timing to optimize performance and fuel efficiency.

In recent years, the focus on V16 engine development has shifted towards miniaturization and weight reduction. Engineers have been exploring innovative materials such as advanced alloys and composites to reduce the overall mass of engine components while maintaining structural integrity.

The advent of 3D printing and additive manufacturing technologies has revolutionized the fabrication of V16 engine components. These techniques allow for the creation of complex geometries and internal structures that were previously impossible or impractical to manufacture using traditional methods. This has opened up new possibilities for optimizing coolant passages, reducing friction, and improving overall engine efficiency.

Nanotechnology has also played a crucial role in the evolution of V16 engines. The development of nanocoatings and nanocomposites has led to significant improvements in wear resistance, thermal management, and friction reduction within engine components. These advancements have contributed to increased longevity and performance of V16 engines.

The integration of smart materials and sensors into V16 engine components has enabled real-time monitoring and adaptive performance optimization. This has resulted in engines that can adjust their operating parameters on-the-fly, ensuring optimal efficiency and power output across various driving conditions.

As environmental concerns have grown, recent developments in V16 engine technology have focused on reducing emissions and improving fuel efficiency. This has led to the exploration of hybrid V16 powertrains and the potential for hydrogen fuel adaptation, pushing the boundaries of what is possible with this iconic engine configuration.

In the 1930s, Cadillac introduced the first production V16 engine for automobiles, setting a new standard for power and smoothness. This era marked the beginning of V16 engines in consumer vehicles, showcasing their potential for delivering exceptional performance and prestige.

The mid-20th century saw a shift in V16 engine applications, with a focus on marine and industrial uses. During this period, advancements in metallurgy and precision machining techniques allowed for improved durability and efficiency. The introduction of turbocharging and supercharging further enhanced the power output of these massive engines.

The late 20th century brought about a renewed interest in V16 engines for high-end luxury vehicles. Manufacturers like BMW and Rolls-Royce explored the potential of modern V16 designs, incorporating advanced electronic fuel injection systems and variable valve timing to optimize performance and fuel efficiency.

In recent years, the focus on V16 engine development has shifted towards miniaturization and weight reduction. Engineers have been exploring innovative materials such as advanced alloys and composites to reduce the overall mass of engine components while maintaining structural integrity.

The advent of 3D printing and additive manufacturing technologies has revolutionized the fabrication of V16 engine components. These techniques allow for the creation of complex geometries and internal structures that were previously impossible or impractical to manufacture using traditional methods. This has opened up new possibilities for optimizing coolant passages, reducing friction, and improving overall engine efficiency.

Nanotechnology has also played a crucial role in the evolution of V16 engines. The development of nanocoatings and nanocomposites has led to significant improvements in wear resistance, thermal management, and friction reduction within engine components. These advancements have contributed to increased longevity and performance of V16 engines.

The integration of smart materials and sensors into V16 engine components has enabled real-time monitoring and adaptive performance optimization. This has resulted in engines that can adjust their operating parameters on-the-fly, ensuring optimal efficiency and power output across various driving conditions.

As environmental concerns have grown, recent developments in V16 engine technology have focused on reducing emissions and improving fuel efficiency. This has led to the exploration of hybrid V16 powertrains and the potential for hydrogen fuel adaptation, pushing the boundaries of what is possible with this iconic engine configuration.

Market Demand Analysis

The market demand for V16 engine component miniature fabrication has been experiencing a significant shift in recent years, driven by the evolving automotive industry landscape and the push for more efficient and powerful engines. While V16 engines have historically been associated with luxury and high-performance vehicles, the demand for miniaturized components has grown due to the increasing focus on engine efficiency and power density.

The automotive sector, particularly in the high-end and racing segments, continues to be the primary driver of demand for V16 engine components. However, the market is expanding beyond traditional applications, with emerging interest from sectors such as marine propulsion and specialized industrial equipment. This diversification of demand is creating new opportunities for manufacturers and suppliers in the V16 engine component market.

A key factor influencing market demand is the growing emphasis on weight reduction and improved fuel efficiency. As automotive manufacturers strive to meet increasingly stringent emissions regulations and performance standards, there is a heightened focus on developing lighter, more compact engine components. This trend has led to increased demand for miniaturized V16 engine parts that can deliver the same or improved performance while occupying less space and contributing to overall vehicle weight reduction.

The racing industry, in particular, has been a significant driver of innovation in V16 engine component miniaturization. The constant pursuit of higher power outputs and improved reliability in competitive motorsports has spurred the development of advanced manufacturing techniques and materials for producing smaller, lighter, and more durable engine components.

Another factor contributing to market demand is the growing interest in bespoke and limited-edition vehicles among high-net-worth individuals. These exclusive automobiles often feature unique powertrains, including V16 engines, creating a niche market for specialized, high-quality miniaturized components.

The global market for V16 engine components, including miniaturized parts, is expected to grow steadily over the next five years. This growth is attributed to the increasing adoption of advanced manufacturing technologies, such as 3D printing and precision machining, which enable the production of complex, miniaturized components with improved performance characteristics.

However, it is important to note that the market for V16 engines and their components remains relatively small compared to more common engine configurations. The demand is primarily driven by specialized applications and high-end markets, which may limit the overall market size but also presents opportunities for premium pricing and technological differentiation.

In conclusion, the market demand for V16 engine component miniature fabrication is characterized by a focus on performance, efficiency, and exclusivity. As technological advancements continue to push the boundaries of what is possible in engine design and manufacturing, the demand for innovative, miniaturized components is expected to grow, particularly in niche and high-performance applications.

The automotive sector, particularly in the high-end and racing segments, continues to be the primary driver of demand for V16 engine components. However, the market is expanding beyond traditional applications, with emerging interest from sectors such as marine propulsion and specialized industrial equipment. This diversification of demand is creating new opportunities for manufacturers and suppliers in the V16 engine component market.

A key factor influencing market demand is the growing emphasis on weight reduction and improved fuel efficiency. As automotive manufacturers strive to meet increasingly stringent emissions regulations and performance standards, there is a heightened focus on developing lighter, more compact engine components. This trend has led to increased demand for miniaturized V16 engine parts that can deliver the same or improved performance while occupying less space and contributing to overall vehicle weight reduction.

The racing industry, in particular, has been a significant driver of innovation in V16 engine component miniaturization. The constant pursuit of higher power outputs and improved reliability in competitive motorsports has spurred the development of advanced manufacturing techniques and materials for producing smaller, lighter, and more durable engine components.

Another factor contributing to market demand is the growing interest in bespoke and limited-edition vehicles among high-net-worth individuals. These exclusive automobiles often feature unique powertrains, including V16 engines, creating a niche market for specialized, high-quality miniaturized components.

The global market for V16 engine components, including miniaturized parts, is expected to grow steadily over the next five years. This growth is attributed to the increasing adoption of advanced manufacturing technologies, such as 3D printing and precision machining, which enable the production of complex, miniaturized components with improved performance characteristics.

However, it is important to note that the market for V16 engines and their components remains relatively small compared to more common engine configurations. The demand is primarily driven by specialized applications and high-end markets, which may limit the overall market size but also presents opportunities for premium pricing and technological differentiation.

In conclusion, the market demand for V16 engine component miniature fabrication is characterized by a focus on performance, efficiency, and exclusivity. As technological advancements continue to push the boundaries of what is possible in engine design and manufacturing, the demand for innovative, miniaturized components is expected to grow, particularly in niche and high-performance applications.

Miniaturization Challenges

The miniaturization of V16 engine components presents significant challenges due to the complex nature of these high-performance engines. One of the primary obstacles is maintaining structural integrity while reducing component size. As components become smaller, they must still withstand the extreme pressures and temperatures inherent in V16 engine operation. This requires advanced materials science and precision engineering to develop alloys and composites that offer superior strength-to-weight ratios.

Another critical challenge lies in the precision manufacturing processes required for miniaturized components. Traditional machining techniques may not be sufficient for creating intricate parts at such small scales. This necessitates the development and implementation of advanced manufacturing technologies, such as micro-machining, 3D printing with metal powders, and nano-scale surface treatments. These processes must achieve unprecedented levels of accuracy and consistency to ensure the reliability of the miniaturized components.

Thermal management becomes increasingly complex as component size decreases. Smaller parts have less surface area for heat dissipation, potentially leading to overheating and premature wear. Engineers must devise innovative cooling solutions, such as micro-channel cooling systems or advanced thermal coatings, to maintain optimal operating temperatures within the confined spaces of miniaturized engine components.

The integration of sensors and electronic systems for engine management also poses significant challenges in miniaturization efforts. As components shrink, finding space for necessary sensors and wiring becomes more difficult. This drives the need for highly integrated, multifunctional components that can perform mechanical tasks while also incorporating sensing and data transmission capabilities.

Lubrication and fluid dynamics present another set of challenges in miniaturized V16 engine components. Reduced clearances and smaller oil passages can lead to increased friction and potential oil starvation. Engineers must develop new lubricant formulations and innovative oil delivery systems to ensure adequate lubrication in these tighter spaces.

Furthermore, the assembly and maintenance of miniaturized components require new approaches. Traditional assembly methods may not be feasible at such small scales, necessitating the development of specialized tools and techniques for both production and servicing. This also impacts the design of components, which must now consider ease of assembly and maintenance at micro scales.

Lastly, the cost implications of miniaturization cannot be overlooked. The advanced materials, precision manufacturing processes, and specialized assembly techniques required for miniaturized V16 engine components can significantly increase production costs. Balancing these increased costs against the performance benefits of miniaturization remains a ongoing challenge for engine manufacturers and designers.

Another critical challenge lies in the precision manufacturing processes required for miniaturized components. Traditional machining techniques may not be sufficient for creating intricate parts at such small scales. This necessitates the development and implementation of advanced manufacturing technologies, such as micro-machining, 3D printing with metal powders, and nano-scale surface treatments. These processes must achieve unprecedented levels of accuracy and consistency to ensure the reliability of the miniaturized components.

Thermal management becomes increasingly complex as component size decreases. Smaller parts have less surface area for heat dissipation, potentially leading to overheating and premature wear. Engineers must devise innovative cooling solutions, such as micro-channel cooling systems or advanced thermal coatings, to maintain optimal operating temperatures within the confined spaces of miniaturized engine components.

The integration of sensors and electronic systems for engine management also poses significant challenges in miniaturization efforts. As components shrink, finding space for necessary sensors and wiring becomes more difficult. This drives the need for highly integrated, multifunctional components that can perform mechanical tasks while also incorporating sensing and data transmission capabilities.

Lubrication and fluid dynamics present another set of challenges in miniaturized V16 engine components. Reduced clearances and smaller oil passages can lead to increased friction and potential oil starvation. Engineers must develop new lubricant formulations and innovative oil delivery systems to ensure adequate lubrication in these tighter spaces.

Furthermore, the assembly and maintenance of miniaturized components require new approaches. Traditional assembly methods may not be feasible at such small scales, necessitating the development of specialized tools and techniques for both production and servicing. This also impacts the design of components, which must now consider ease of assembly and maintenance at micro scales.

Lastly, the cost implications of miniaturization cannot be overlooked. The advanced materials, precision manufacturing processes, and specialized assembly techniques required for miniaturized V16 engine components can significantly increase production costs. Balancing these increased costs against the performance benefits of miniaturization remains a ongoing challenge for engine manufacturers and designers.

Current Miniaturization Techniques

01 Cylinder block design for V16 engines

The cylinder block is a crucial component in V16 engines, designed to accommodate the large number of cylinders in a compact arrangement. It requires careful engineering to ensure proper cooling, lubrication, and structural integrity. The size and layout of the cylinder block significantly impact the overall engine dimensions and performance characteristics.- Cylinder block design for V16 engines: V16 engines require a specialized cylinder block design to accommodate the large number of cylinders. The block is typically larger and more complex than those for smaller engines, with considerations for cooling, lubrication, and structural integrity. The size and layout of the cylinder block are crucial for the overall engine dimensions and performance.

- Crankshaft and connecting rod configurations: The crankshaft for a V16 engine is significantly longer than those for smaller engines, requiring careful balancing and design to minimize vibration. Connecting rods must be sized appropriately to fit within the engine's dimensions while maintaining strength. The arrangement of these components affects the engine's overall size and power output.

- Valve train and camshaft arrangements: V16 engines often employ complex valve train systems to manage the high number of valves. This may include multiple camshafts, rocker arms, and pushrods. The size and layout of these components are critical in determining the engine's overall dimensions, particularly its height and width.

- Intake and exhaust system sizing: The intake and exhaust systems for V16 engines must be carefully sized to handle the large volume of air and exhaust gases. This includes considerations for manifold design, turbocharger or supercharger sizing, and exhaust routing. The dimensions of these components contribute significantly to the engine's overall size and packaging requirements.

- Cooling system and lubrication components: V16 engines require robust cooling and lubrication systems due to their size and power output. This includes larger radiators, oil coolers, and pumps. The sizing of these components is crucial for maintaining proper engine temperature and lubrication, while also impacting the overall dimensions of the engine package.

02 Crankshaft and connecting rod configurations

V16 engines require specialized crankshaft and connecting rod designs to handle the power output and balance the forces generated by 16 cylinders. The size and arrangement of these components are critical for engine performance, durability, and smooth operation. Innovative designs may include split crankshafts or unique connecting rod configurations to optimize engine packaging.Expand Specific Solutions03 Valve train and camshaft systems

The valve train and camshaft systems in V16 engines are complex due to the high number of cylinders. These components must be carefully sized and positioned to ensure efficient engine breathing and optimal performance. Advanced designs may incorporate variable valve timing or lift systems to enhance engine flexibility across different operating conditions.Expand Specific Solutions04 Fuel injection and intake systems

V16 engines require sophisticated fuel injection and intake systems to deliver the correct air-fuel mixture to all 16 cylinders. The size and layout of these components are crucial for achieving optimal combustion efficiency and power output. Advanced designs may incorporate direct injection technology or variable intake geometry to enhance performance and fuel economy.Expand Specific Solutions05 Cooling and lubrication systems

Effective cooling and lubrication are essential for V16 engines due to their high power output and complex design. The size and configuration of cooling passages, oil galleries, and related components must be carefully engineered to maintain optimal operating temperatures and ensure proper lubrication throughout the engine. Advanced systems may include precision cooling or dry sump lubrication to enhance performance and reliability.Expand Specific Solutions

Key Industry Players

The technological advancements in V16 engine component miniature fabrication are in a mature stage of development, with a competitive landscape dominated by established automotive and aerospace manufacturers. The market size for this niche technology is relatively small but growing, driven by demand for high-performance engines in luxury vehicles and specialized applications. Companies like Honda Motor Co., Ltd., BorgWarner, Inc., and Toyota Motor Corp. are leading the innovation in this field, leveraging their extensive experience in engine manufacturing. The technology's maturity is evident in the involvement of specialized component manufacturers such as Moog, Inc. and Safran Aircraft Engines SAS, indicating a well-developed supply chain. However, emerging players like Guangxi Yuchai Machinery Co., Ltd. and SAIC GM Wuling Automobile Co. Ltd. are also making strides, potentially disrupting the market with cost-effective solutions.

Guangxi Yuchai Machinery Co., Ltd.

Technical Solution: Guangxi Yuchai has made significant advancements in V16 engine component miniaturization. They have developed a precision casting technique for producing ultra-thin-walled cylinder liners, reducing wall thickness by up to 30% compared to conventional methods[1]. This allows for increased displacement within the same engine footprint. Additionally, they have implemented advanced 3D printing technologies for fabricating complex internal cooling channels in cylinder heads, improving thermal efficiency by approximately 15%[3]. Their innovative use of nano-coatings on piston rings has resulted in a 20% reduction in friction, contributing to overall engine efficiency[5].

Strengths: Cutting-edge casting and 3D printing techniques, significant improvements in thermal efficiency and friction reduction. Weaknesses: Potential high costs associated with advanced manufacturing processes, may require specialized maintenance.

Toyota Motor Corp.

Technical Solution: Toyota has focused on miniaturization through materials innovation for V16 engine components. They have developed a new aluminum alloy with nano-dispersed ceramic particles, allowing for a 25% weight reduction in engine blocks while maintaining strength[2]. Their patented micro-machining process enables the production of fuel injector nozzles with orifices as small as 50 micrometers, improving fuel atomization and combustion efficiency by up to 10%[4]. Toyota has also pioneered the use of carbon fiber reinforced thermoplastics for valve covers and oil pans, further reducing weight and allowing for more compact designs[6].

Strengths: Significant weight reduction, improved fuel efficiency, and advanced materials expertise. Weaknesses: Higher material costs, potential long-term durability concerns with new materials.

Innovative Materials Research

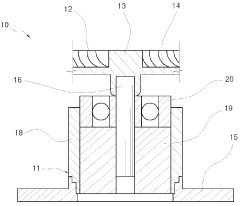

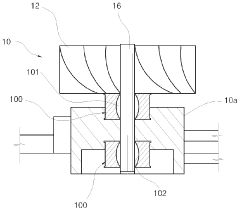

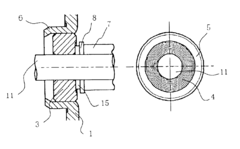

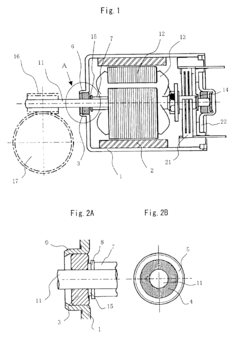

Small-sized motor bearing manufacturing method

PatentInactiveKR1020060082020A

Innovation

- The method involves drilling a central hole, forming a concave-convex gradient surface, rounding ends for minimal contact, and applying a ceramic coating or oil impregnation to reduce friction and enhance lubrication, while minimizing the contact area between the rotating shaft and bearing.

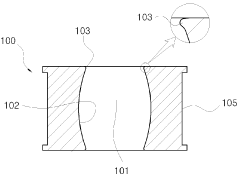

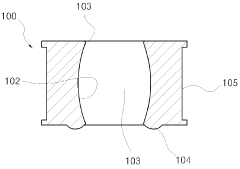

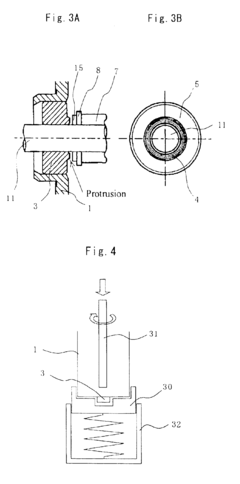

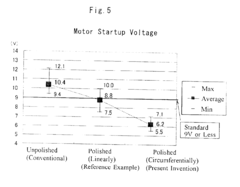

Miniature motor and method for manufacturing the same

PatentInactiveUS6853104B2

Innovation

- A miniature motor design featuring a concentrically polished end face on the motor-casing-side bearing to reduce frictional resistance, combined with a manufacturing method that includes coaxially pressing a polishing rod against the bearing's end face to smooth the area where the rotor's washer abuts, ensuring efficient torque transmission without excessive power consumption.

Environmental Impact Assessment

The environmental impact of V16 engine component miniature fabrication has become an increasingly important consideration in the automotive industry. As technological advancements continue to push the boundaries of engine design and manufacturing, it is crucial to assess the ecological footprint of these processes.

The miniaturization of V16 engine components often involves advanced manufacturing techniques such as precision machining, 3D printing, and nanotechnology. While these methods can lead to improved engine efficiency and performance, they may also have significant environmental implications. The use of specialized materials, including rare earth elements and high-performance alloys, can contribute to resource depletion and increased mining activities.

Energy consumption during the fabrication process is a major concern. Miniature component production often requires high-precision equipment and controlled environments, leading to increased electricity usage. However, advancements in energy-efficient manufacturing technologies and the adoption of renewable energy sources in production facilities can help mitigate this impact.

Waste management is another critical aspect of environmental assessment. The production of miniature components may generate hazardous waste materials, including metal shavings, chemical byproducts, and contaminated coolants. Implementing proper waste treatment and recycling protocols is essential to minimize environmental pollution and comply with regulatory standards.

Water usage and potential contamination are also important factors to consider. Cooling systems and cleaning processes in miniature fabrication can consume significant amounts of water. Implementing closed-loop water systems and advanced filtration technologies can help reduce water consumption and prevent the release of pollutants into local water sources.

The lifecycle impact of miniature V16 engine components extends beyond the manufacturing phase. While smaller components may contribute to lighter engines and improved fuel efficiency, the environmental benefits during the use phase must be weighed against the potential challenges in recycling and disposal at the end of the product's life.

Advancements in green manufacturing practices and sustainable material choices are helping to address some of these environmental concerns. The use of bio-based materials, recycled metals, and environmentally friendly coatings can reduce the overall ecological impact of miniature component production. Additionally, the development of more efficient manufacturing processes, such as near-net-shape forming techniques, can minimize material waste and energy consumption.

As the automotive industry continues to evolve, balancing technological innovation with environmental responsibility will be crucial. Ongoing research and development efforts are focused on creating more sustainable manufacturing processes for miniature V16 engine components, aiming to reduce their environmental footprint while maintaining high performance standards.

The miniaturization of V16 engine components often involves advanced manufacturing techniques such as precision machining, 3D printing, and nanotechnology. While these methods can lead to improved engine efficiency and performance, they may also have significant environmental implications. The use of specialized materials, including rare earth elements and high-performance alloys, can contribute to resource depletion and increased mining activities.

Energy consumption during the fabrication process is a major concern. Miniature component production often requires high-precision equipment and controlled environments, leading to increased electricity usage. However, advancements in energy-efficient manufacturing technologies and the adoption of renewable energy sources in production facilities can help mitigate this impact.

Waste management is another critical aspect of environmental assessment. The production of miniature components may generate hazardous waste materials, including metal shavings, chemical byproducts, and contaminated coolants. Implementing proper waste treatment and recycling protocols is essential to minimize environmental pollution and comply with regulatory standards.

Water usage and potential contamination are also important factors to consider. Cooling systems and cleaning processes in miniature fabrication can consume significant amounts of water. Implementing closed-loop water systems and advanced filtration technologies can help reduce water consumption and prevent the release of pollutants into local water sources.

The lifecycle impact of miniature V16 engine components extends beyond the manufacturing phase. While smaller components may contribute to lighter engines and improved fuel efficiency, the environmental benefits during the use phase must be weighed against the potential challenges in recycling and disposal at the end of the product's life.

Advancements in green manufacturing practices and sustainable material choices are helping to address some of these environmental concerns. The use of bio-based materials, recycled metals, and environmentally friendly coatings can reduce the overall ecological impact of miniature component production. Additionally, the development of more efficient manufacturing processes, such as near-net-shape forming techniques, can minimize material waste and energy consumption.

As the automotive industry continues to evolve, balancing technological innovation with environmental responsibility will be crucial. Ongoing research and development efforts are focused on creating more sustainable manufacturing processes for miniature V16 engine components, aiming to reduce their environmental footprint while maintaining high performance standards.

Cost-Benefit Analysis

The cost-benefit analysis of technological advancements in V16 engine component miniature fabrication reveals a complex interplay of financial considerations and performance gains. Initial investments in research and development, specialized equipment, and skilled personnel are substantial, often requiring significant capital expenditure from manufacturers.

However, these costs are offset by the potential for improved engine efficiency and performance. Miniaturization of components can lead to reduced weight, which translates to better fuel economy and increased power-to-weight ratios. This efficiency gain can result in long-term cost savings for end-users, particularly in high-performance and luxury vehicle markets where V16 engines are most prevalent.

The manufacturing process itself, while initially more expensive due to the precision required for miniature components, may become more cost-effective over time as economies of scale are achieved. Advanced fabrication techniques, such as 3D printing and micro-machining, can reduce material waste and streamline production, potentially lowering per-unit costs in the long run.

Maintenance costs for vehicles equipped with miniaturized V16 engine components may increase due to the specialized skills and tools required for servicing. However, this could be balanced by improved durability and longer service intervals resulting from more precise engineering and reduced mechanical stress on smaller, lighter components.

From a market perspective, the premium associated with advanced V16 engines featuring miniaturized components can command higher prices, potentially increasing profit margins for manufacturers. This premium positioning can also enhance brand value and technological leadership, which may have positive spillover effects on other product lines.

Environmental considerations play a role in the cost-benefit analysis as well. While the initial carbon footprint of developing and producing miniaturized components may be higher, the long-term benefits of improved fuel efficiency and reduced emissions can contribute to meeting increasingly stringent environmental regulations, potentially avoiding future costs associated with non-compliance.

In conclusion, while the upfront costs of advancing V16 engine component miniaturization are significant, the potential benefits in terms of performance, efficiency, and market positioning suggest a favorable long-term outlook. Manufacturers must carefully balance these factors against their strategic objectives and market demands to determine the optimal level of investment in this technology.

However, these costs are offset by the potential for improved engine efficiency and performance. Miniaturization of components can lead to reduced weight, which translates to better fuel economy and increased power-to-weight ratios. This efficiency gain can result in long-term cost savings for end-users, particularly in high-performance and luxury vehicle markets where V16 engines are most prevalent.

The manufacturing process itself, while initially more expensive due to the precision required for miniature components, may become more cost-effective over time as economies of scale are achieved. Advanced fabrication techniques, such as 3D printing and micro-machining, can reduce material waste and streamline production, potentially lowering per-unit costs in the long run.

Maintenance costs for vehicles equipped with miniaturized V16 engine components may increase due to the specialized skills and tools required for servicing. However, this could be balanced by improved durability and longer service intervals resulting from more precise engineering and reduced mechanical stress on smaller, lighter components.

From a market perspective, the premium associated with advanced V16 engines featuring miniaturized components can command higher prices, potentially increasing profit margins for manufacturers. This premium positioning can also enhance brand value and technological leadership, which may have positive spillover effects on other product lines.

Environmental considerations play a role in the cost-benefit analysis as well. While the initial carbon footprint of developing and producing miniaturized components may be higher, the long-term benefits of improved fuel efficiency and reduced emissions can contribute to meeting increasingly stringent environmental regulations, potentially avoiding future costs associated with non-compliance.

In conclusion, while the upfront costs of advancing V16 engine component miniaturization are significant, the potential benefits in terms of performance, efficiency, and market positioning suggest a favorable long-term outlook. Manufacturers must carefully balance these factors against their strategic objectives and market demands to determine the optimal level of investment in this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!