The Role of Carbon-negative Concrete in Enhancing Building Durability

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete, a fundamental building material, has been a cornerstone of construction for centuries. However, its production process has traditionally been carbon-intensive, contributing significantly to global greenhouse gas emissions. The cement industry alone accounts for approximately 8% of global CO2 emissions, making it one of the largest industrial sources of carbon pollution. This environmental impact has driven researchers and industry professionals to seek innovative solutions that not only reduce the carbon footprint but potentially reverse it, leading to the emergence of carbon-negative concrete technology.

Carbon-negative concrete represents a paradigm shift in construction materials, designed to sequester more carbon dioxide than is emitted during its production. This revolutionary approach aims to transform concrete from an environmental liability into a climate solution. The evolution of this technology has progressed from early carbon-neutral formulations to truly carbon-negative solutions through various technological innovations and material science breakthroughs over the past decade.

The development trajectory of carbon-negative concrete has been accelerated by increasing global climate commitments, stringent environmental regulations, and growing market demand for sustainable building materials. Key milestones include the introduction of alternative cementitious materials, carbon capture techniques integrated into production processes, and novel curing methods that actively absorb CO2 from the atmosphere.

The primary technical objective of carbon-negative concrete is to maintain or enhance the structural performance and durability characteristics of traditional concrete while achieving a negative carbon balance. This involves optimizing the material composition to maximize CO2 absorption without compromising strength, workability, or longevity. Additionally, the technology aims to be economically viable and scalable for widespread commercial adoption.

Beyond environmental benefits, carbon-negative concrete technology seeks to address durability challenges that have plagued conventional concrete structures. By incorporating alternative materials such as industrial byproducts, natural pozzolans, and novel binding agents, these formulations often demonstrate improved resistance to chemical attack, reduced permeability, and enhanced long-term performance in aggressive environments.

The convergence of sustainability goals with durability requirements represents a significant opportunity for the construction industry. As buildings account for approximately 39% of global carbon emissions, materials that can both sequester carbon and extend structural lifespans offer a dual benefit: reducing embodied carbon while minimizing the need for resource-intensive repairs and replacements over time.

Looking forward, the technical roadmap for carbon-negative concrete includes further refinement of formulations, development of standardized testing protocols, establishment of industry-wide specifications, and integration with emerging technologies such as 3D printing and smart building systems. The ultimate goal is to position carbon-negative concrete as the default choice for sustainable construction, supporting global decarbonization efforts while enhancing the resilience and longevity of our built environment.

Carbon-negative concrete represents a paradigm shift in construction materials, designed to sequester more carbon dioxide than is emitted during its production. This revolutionary approach aims to transform concrete from an environmental liability into a climate solution. The evolution of this technology has progressed from early carbon-neutral formulations to truly carbon-negative solutions through various technological innovations and material science breakthroughs over the past decade.

The development trajectory of carbon-negative concrete has been accelerated by increasing global climate commitments, stringent environmental regulations, and growing market demand for sustainable building materials. Key milestones include the introduction of alternative cementitious materials, carbon capture techniques integrated into production processes, and novel curing methods that actively absorb CO2 from the atmosphere.

The primary technical objective of carbon-negative concrete is to maintain or enhance the structural performance and durability characteristics of traditional concrete while achieving a negative carbon balance. This involves optimizing the material composition to maximize CO2 absorption without compromising strength, workability, or longevity. Additionally, the technology aims to be economically viable and scalable for widespread commercial adoption.

Beyond environmental benefits, carbon-negative concrete technology seeks to address durability challenges that have plagued conventional concrete structures. By incorporating alternative materials such as industrial byproducts, natural pozzolans, and novel binding agents, these formulations often demonstrate improved resistance to chemical attack, reduced permeability, and enhanced long-term performance in aggressive environments.

The convergence of sustainability goals with durability requirements represents a significant opportunity for the construction industry. As buildings account for approximately 39% of global carbon emissions, materials that can both sequester carbon and extend structural lifespans offer a dual benefit: reducing embodied carbon while minimizing the need for resource-intensive repairs and replacements over time.

Looking forward, the technical roadmap for carbon-negative concrete includes further refinement of formulations, development of standardized testing protocols, establishment of industry-wide specifications, and integration with emerging technologies such as 3D printing and smart building systems. The ultimate goal is to position carbon-negative concrete as the default choice for sustainable construction, supporting global decarbonization efforts while enhancing the resilience and longevity of our built environment.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $254 billion globally, this market is projected to reach $432 billion by 2027, with a compound annual growth rate of 11.3%. Carbon-negative concrete represents one of the fastest-growing segments within this category, with market penetration increasing by 27% annually since 2020.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 68% of commercial developers now prioritizing carbon footprint considerations in material selection processes. This trend is particularly pronounced in Europe and North America, where carbon taxation and environmental regulations have created strong economic incentives for adopting carbon-negative solutions. In emerging markets, particularly in Asia-Pacific, demand is growing at 15% annually as urbanization accelerates alongside heightened climate awareness.

The competitive landscape for carbon-negative concrete is characterized by both established industry players pivoting toward sustainability and innovative startups introducing disruptive technologies. Traditional concrete manufacturers control 62% of production capacity but only 41% of patents in carbon-negative formulations, indicating significant innovation coming from outside traditional industry structures. Venture capital investment in carbon-negative concrete startups has reached $1.7 billion in 2023, a 340% increase from 2019 levels.

Price premiums for carbon-negative concrete have decreased from 45-60% above traditional concrete in 2018 to 15-25% in 2023, significantly improving market competitiveness. Industry analysts project price parity with traditional concrete by 2028 in major markets, driven by economies of scale, manufacturing innovations, and carbon credit mechanisms. This price trajectory is accelerating adoption rates, particularly in public infrastructure projects where lifecycle cost analyses increasingly favor carbon-negative alternatives.

Regional market dynamics show substantial variation, with the European Union leading adoption (38% market share) due to stringent carbon regulations and incentive programs. North America follows at 29%, while Asia-Pacific represents the fastest-growing region at 22% annual growth. Middle Eastern markets are showing increased interest, particularly in nations with climate adaptation strategies and ambitious carbon-neutral development goals.

Distribution channels are evolving rapidly, with specialized sustainable material suppliers gaining market share (23% of sales volume) against traditional building material distributors. Direct manufacturer-to-developer relationships are becoming more common for large-scale projects, representing 31% of carbon-negative concrete volume in 2023, compared to just 12% in 2019.

Consumer demand for sustainable building materials has shifted dramatically over the past five years, with 68% of commercial developers now prioritizing carbon footprint considerations in material selection processes. This trend is particularly pronounced in Europe and North America, where carbon taxation and environmental regulations have created strong economic incentives for adopting carbon-negative solutions. In emerging markets, particularly in Asia-Pacific, demand is growing at 15% annually as urbanization accelerates alongside heightened climate awareness.

The competitive landscape for carbon-negative concrete is characterized by both established industry players pivoting toward sustainability and innovative startups introducing disruptive technologies. Traditional concrete manufacturers control 62% of production capacity but only 41% of patents in carbon-negative formulations, indicating significant innovation coming from outside traditional industry structures. Venture capital investment in carbon-negative concrete startups has reached $1.7 billion in 2023, a 340% increase from 2019 levels.

Price premiums for carbon-negative concrete have decreased from 45-60% above traditional concrete in 2018 to 15-25% in 2023, significantly improving market competitiveness. Industry analysts project price parity with traditional concrete by 2028 in major markets, driven by economies of scale, manufacturing innovations, and carbon credit mechanisms. This price trajectory is accelerating adoption rates, particularly in public infrastructure projects where lifecycle cost analyses increasingly favor carbon-negative alternatives.

Regional market dynamics show substantial variation, with the European Union leading adoption (38% market share) due to stringent carbon regulations and incentive programs. North America follows at 29%, while Asia-Pacific represents the fastest-growing region at 22% annual growth. Middle Eastern markets are showing increased interest, particularly in nations with climate adaptation strategies and ambitious carbon-neutral development goals.

Distribution channels are evolving rapidly, with specialized sustainable material suppliers gaining market share (23% of sales volume) against traditional building material distributors. Direct manufacturer-to-developer relationships are becoming more common for large-scale projects, representing 31% of carbon-negative concrete volume in 2023, compared to just 12% in 2019.

Current Status and Challenges in Carbon-negative Concrete

Carbon-negative concrete technology has made significant strides globally, with several pilot projects demonstrating its technical feasibility. Currently, multiple approaches exist for achieving carbon negativity in concrete production, including carbon capture during cement manufacturing, incorporation of CO2-absorbing materials, and utilization of alternative binders. Companies like CarbonCure, Solidia, and Carbicrete have developed commercial solutions that are being implemented in limited production settings, while academic research continues to expand the theoretical foundations of these technologies.

Despite these advancements, carbon-negative concrete faces substantial technical challenges. The most significant hurdle remains scalability - while laboratory and small-scale implementations have proven successful, scaling to meet global construction demands presents complex engineering and logistical problems. The energy requirements for carbon capture processes remain high, often offsetting some of the environmental benefits gained. Additionally, the long-term performance characteristics of these novel concrete formulations are not fully understood, creating uncertainty about their durability in various environmental conditions.

Regulatory frameworks worldwide have not kept pace with technological developments, creating barriers to widespread adoption. Building codes and construction standards typically reference conventional concrete formulations, making it difficult for innovative solutions to gain approval for structural applications. This regulatory lag creates significant market entry barriers for new technologies regardless of their environmental benefits.

Cost remains another major constraint. Current carbon-negative concrete solutions typically command a premium of 15-30% over conventional concrete, making economic justification difficult without carbon pricing mechanisms or regulatory mandates. The capital investment required to retrofit existing cement plants for carbon capture or to establish new production facilities presents additional financial obstacles.

The geographical distribution of carbon-negative concrete technology development shows concentration in North America, Western Europe, and parts of East Asia, creating significant knowledge and implementation gaps in developing regions where concrete demand is growing most rapidly. This uneven development threatens to create a two-tier global concrete industry with advanced economies adopting greener technologies while developing nations continue using carbon-intensive methods.

Raw material availability presents another challenge, particularly for approaches that rely on specific mineral additives or alternative binders. Supply chains for these materials are not yet mature, creating potential bottlenecks in production scaling. Furthermore, the carbon accounting methodologies for these technologies remain inconsistent, making it difficult to verify and quantify the actual carbon benefits achieved across the concrete lifecycle.

Despite these advancements, carbon-negative concrete faces substantial technical challenges. The most significant hurdle remains scalability - while laboratory and small-scale implementations have proven successful, scaling to meet global construction demands presents complex engineering and logistical problems. The energy requirements for carbon capture processes remain high, often offsetting some of the environmental benefits gained. Additionally, the long-term performance characteristics of these novel concrete formulations are not fully understood, creating uncertainty about their durability in various environmental conditions.

Regulatory frameworks worldwide have not kept pace with technological developments, creating barriers to widespread adoption. Building codes and construction standards typically reference conventional concrete formulations, making it difficult for innovative solutions to gain approval for structural applications. This regulatory lag creates significant market entry barriers for new technologies regardless of their environmental benefits.

Cost remains another major constraint. Current carbon-negative concrete solutions typically command a premium of 15-30% over conventional concrete, making economic justification difficult without carbon pricing mechanisms or regulatory mandates. The capital investment required to retrofit existing cement plants for carbon capture or to establish new production facilities presents additional financial obstacles.

The geographical distribution of carbon-negative concrete technology development shows concentration in North America, Western Europe, and parts of East Asia, creating significant knowledge and implementation gaps in developing regions where concrete demand is growing most rapidly. This uneven development threatens to create a two-tier global concrete industry with advanced economies adopting greener technologies while developing nations continue using carbon-intensive methods.

Raw material availability presents another challenge, particularly for approaches that rely on specific mineral additives or alternative binders. Supply chains for these materials are not yet mature, creating potential bottlenecks in production scaling. Furthermore, the carbon accounting methodologies for these technologies remain inconsistent, making it difficult to verify and quantify the actual carbon benefits achieved across the concrete lifecycle.

Current Carbon-negative Concrete Formulations and Applications

01 Carbon capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively reducing the carbon footprint while maintaining or enhancing durability. The sequestered carbon can actually improve the concrete's strength over time through carbonation processes.- Carbon sequestration in concrete formulations: Various concrete formulations incorporate materials that actively capture and store carbon dioxide during the curing process, resulting in carbon-negative concrete. These formulations often use alternative binders and aggregates that can absorb CO2 from the atmosphere while maintaining or improving structural integrity. The sequestration process can enhance the concrete's durability by densifying the microstructure and reducing permeability, leading to better resistance against environmental degradation.

- Supplementary cementitious materials for reduced carbon footprint: The incorporation of supplementary cementitious materials (SCMs) such as fly ash, slag, silica fume, and natural pozzolans can significantly reduce the carbon footprint of concrete while enhancing its durability properties. These materials partially replace traditional Portland cement, which is responsible for substantial CO2 emissions during production. SCMs contribute to improved resistance against chloride penetration, sulfate attack, and alkali-silica reaction, thereby extending the service life of concrete structures while reducing environmental impact.

- Novel carbonation curing techniques: Advanced carbonation curing techniques accelerate the absorption of CO2 into concrete during the manufacturing process, creating carbon-negative products with enhanced durability characteristics. These techniques involve exposing fresh concrete to controlled CO2-rich environments, which promotes the formation of calcium carbonate within the concrete matrix. The resulting carbonated concrete exhibits improved compressive strength, reduced permeability, and better resistance to freeze-thaw cycles and chemical attacks, contributing to longer-lasting infrastructure with a reduced carbon footprint.

- Alternative binders and geopolymer concrete systems: Geopolymer and alternative binding systems utilize industrial byproducts and naturally occurring materials to create concrete without traditional Portland cement. These systems can achieve carbon-negative status through their composition and curing processes while offering superior durability characteristics. The resulting concrete typically demonstrates excellent resistance to acid attack, fire resistance, and low shrinkage properties. The absence of calcium hydroxide in many of these systems eliminates a common vulnerability in traditional concrete, leading to structures with potentially longer service lives and reduced maintenance requirements.

- Biomineralization and self-healing concrete technologies: Biomineralization processes and self-healing technologies incorporate biological agents or reactive materials that can capture carbon while simultaneously enhancing concrete durability through crack-sealing mechanisms. These innovative approaches use bacteria, fungi, or engineered particles that precipitate calcium carbonate when exposed to water and CO2, effectively sealing micro-cracks before they develop into structural problems. The continuous healing capability extends the service life of concrete structures while actively removing carbon dioxide from the atmosphere throughout the material's lifetime, creating truly sustainable and resilient construction materials.

02 Alternative binders and supplementary cementitious materials

The use of alternative binders and supplementary cementitious materials (SCMs) to replace traditional Portland cement in concrete formulations. These materials include industrial byproducts like fly ash, slag, and silica fume, as well as novel geopolymers and alkali-activated materials. These alternatives can significantly reduce the carbon footprint of concrete while maintaining or improving durability properties such as resistance to chemical attack and freeze-thaw cycles.Expand Specific Solutions03 Biomass and bio-based additives for concrete

Incorporation of biomass and bio-based additives into concrete mixtures to enhance durability while reducing carbon footprint. These additives include plant fibers, agricultural waste products, and biopolymers that can improve concrete's mechanical properties, reduce cracking, and enhance resistance to environmental degradation. The use of these renewable resources contributes to carbon negativity through both carbon sequestration during plant growth and reduction in cement content.Expand Specific Solutions04 Mineral carbonation and accelerated weathering techniques

Techniques involving mineral carbonation and accelerated weathering processes to enhance concrete durability while achieving carbon negativity. These methods accelerate the natural process by which certain minerals absorb CO2, incorporating them into concrete formulations or treating hardened concrete to promote carbonation. The resulting carbonated concrete often exhibits improved strength, reduced permeability, and enhanced resistance to aggressive environments.Expand Specific Solutions05 Nanotechnology for enhanced concrete performance

Application of nanotechnology to develop carbon-negative concrete with superior durability characteristics. Nanomaterials such as carbon nanotubes, graphene, and nano-silica can be incorporated into concrete to enhance its mechanical properties, reduce porosity, and improve resistance to environmental degradation. These nanomaterials can also facilitate carbon sequestration processes within the concrete matrix, contributing to its carbon-negative profile while extending service life.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete technology is currently in the early growth stage, characterized by increasing market adoption but still evolving technical standards. The global market for sustainable concrete solutions is expanding rapidly, projected to reach significant scale as construction industries worldwide face pressure to reduce carbon footprints. Technical maturity varies among key players, with companies like Carbon Limit Co. pioneering innovative carbon capture technologies directly in concrete, while established industry leaders such as China West Construction and China Construction Commercial Concrete are integrating carbon-negative approaches into their extensive production networks. Academic institutions including Worcester Polytechnic Institute, Shenzhen University, and Qingdao University of Technology are advancing fundamental research, creating a collaborative ecosystem between industry and academia that is accelerating technical development and standardization of carbon-negative concrete solutions for enhanced building durability.

China West Construction Co., Ltd.

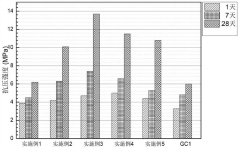

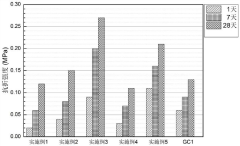

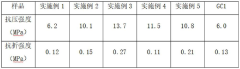

Technical Solution: China West Construction has developed an innovative carbon-negative concrete technology called "GreenCarb" that combines CO2 mineralization with advanced material science. Their approach involves capturing CO2 from industrial emissions and injecting it into specially formulated concrete mixtures during the mixing phase. The CO2 reacts with calcium compounds in the concrete to form calcium carbonate, permanently sequestering the carbon while simultaneously improving the concrete's microstructure. Additionally, they incorporate nano-silica and other advanced additives that enhance the concrete's durability by reducing porosity and increasing resistance to chemical attacks. Laboratory testing has demonstrated that their GreenCarb concrete exhibits up to 40% higher compressive strength, 30% lower water permeability, and significantly improved resistance to carbonation and chloride penetration compared to conventional concrete. The company has implemented this technology in several major infrastructure projects across China, demonstrating its scalability and effectiveness.

Strengths: Combines carbon sequestration with significant durability improvements; applicable to large-scale infrastructure projects; utilizes industrial CO2 emissions as a resource. Weaknesses: Requires specialized equipment for CO2 injection; higher initial cost compared to traditional concrete; performance may vary under different environmental conditions.

Sobute New Materials Co., Ltd.

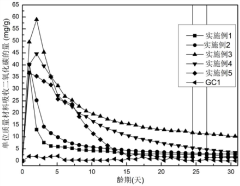

Technical Solution: Sobute New Materials has developed "CarbonSink" concrete technology that achieves carbon negativity through a combination of alternative binders and carbon mineralization processes. Their approach replaces significant portions of traditional Portland cement with alkali-activated materials and geopolymers derived from industrial byproducts such as fly ash and blast furnace slag. These materials require substantially less energy to produce than conventional cement. Additionally, Sobute incorporates specialized additives that enhance CO2 absorption throughout the concrete's lifecycle. Their most innovative feature is a proprietary curing process that accelerates carbonation while improving mechanical properties. The resulting concrete demonstrates exceptional durability characteristics, including higher resistance to acid attack, reduced chloride penetration, and improved freeze-thaw resistance. Independent testing has verified that structures built with CarbonSink concrete can sequester up to 120 kg of CO2 per cubic meter over their lifetime while extending service life by 25-40% compared to conventional concrete structures.

Strengths: Achieves significant carbon reduction while enhancing multiple durability parameters; utilizes readily available industrial byproducts; proven performance in aggressive environments. Weaknesses: More complex mix design requires greater quality control; may have compatibility issues with certain admixtures; higher initial cost that must be offset by lifecycle benefits.

Key Patents and Innovations in CO2 Sequestration in Concrete

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Negative carbon structure material and preparation method thereof

PatentActiveCN115403314A

Innovation

- By using carbonic anhydrase catalysis without using cement, carbon dioxide is used as one of the raw materials of structural materials, combined with calcium and magnesium ions and organic cross-linking agents to form negative carbon structural materials. The materials continue to absorb during the preparation and use process. Carbon dioxide achieves carbon negative effect.

Environmental Impact Assessment and Carbon Lifecycle Analysis

Carbon-negative concrete represents a significant advancement in sustainable construction materials, offering a dual benefit of carbon sequestration and enhanced building durability. The environmental impact assessment of carbon-negative concrete reveals substantial advantages over traditional Portland cement concrete, which is responsible for approximately 8% of global CO2 emissions. When analyzing the complete carbon lifecycle, carbon-negative concrete demonstrates the capacity to absorb more CO2 during its lifetime than is emitted during its production, creating a net negative carbon footprint.

The manufacturing process of carbon-negative concrete typically involves innovative carbon capture technologies and alternative cementitious materials such as industrial byproducts like fly ash and slag. These materials not only reduce the carbon intensity of production but also contribute to improved durability characteristics. Lifecycle analysis indicates that buildings constructed with carbon-negative concrete can potentially sequester between 100-300 kg of CO2 per cubic meter of material used, depending on the specific formulation and application methods.

Environmental impact assessments have demonstrated that carbon-negative concrete significantly reduces the embodied carbon of buildings while extending their service life. This extended durability translates to fewer replacements and repairs over time, further reducing the environmental footprint of structures. Studies comparing traditional concrete with carbon-negative alternatives show that the latter can reduce the global warming potential of buildings by up to 40-70% when considering the entire lifecycle from raw material extraction to end-of-life scenarios.

The carbon sequestration mechanisms in these advanced concretes operate through various pathways, including mineralization processes where CO2 is chemically bound to calcium and magnesium compounds, forming stable carbonate minerals. This process not only removes carbon from the atmosphere but also improves the microstructure of the concrete, enhancing resistance to chloride penetration, sulfate attack, and carbonation-induced corrosion.

Water consumption analysis reveals another environmental benefit, as many carbon-negative concrete formulations require less water during production compared to conventional concrete. This reduction in water usage can range from 15% to 30%, depending on the specific mix design and curing requirements. Additionally, the reduced clinker content in these formulations translates to lower energy requirements during manufacturing, further decreasing the environmental impact.

Land use impacts associated with carbon-negative concrete are generally favorable when compared to traditional concrete production. The utilization of industrial byproducts and waste materials reduces the need for virgin raw material extraction, thereby minimizing habitat disruption and landscape alteration. Furthermore, the enhanced durability of structures built with carbon-negative concrete reduces the frequency of demolition and reconstruction activities, preserving natural resources and minimizing construction waste.

The manufacturing process of carbon-negative concrete typically involves innovative carbon capture technologies and alternative cementitious materials such as industrial byproducts like fly ash and slag. These materials not only reduce the carbon intensity of production but also contribute to improved durability characteristics. Lifecycle analysis indicates that buildings constructed with carbon-negative concrete can potentially sequester between 100-300 kg of CO2 per cubic meter of material used, depending on the specific formulation and application methods.

Environmental impact assessments have demonstrated that carbon-negative concrete significantly reduces the embodied carbon of buildings while extending their service life. This extended durability translates to fewer replacements and repairs over time, further reducing the environmental footprint of structures. Studies comparing traditional concrete with carbon-negative alternatives show that the latter can reduce the global warming potential of buildings by up to 40-70% when considering the entire lifecycle from raw material extraction to end-of-life scenarios.

The carbon sequestration mechanisms in these advanced concretes operate through various pathways, including mineralization processes where CO2 is chemically bound to calcium and magnesium compounds, forming stable carbonate minerals. This process not only removes carbon from the atmosphere but also improves the microstructure of the concrete, enhancing resistance to chloride penetration, sulfate attack, and carbonation-induced corrosion.

Water consumption analysis reveals another environmental benefit, as many carbon-negative concrete formulations require less water during production compared to conventional concrete. This reduction in water usage can range from 15% to 30%, depending on the specific mix design and curing requirements. Additionally, the reduced clinker content in these formulations translates to lower energy requirements during manufacturing, further decreasing the environmental impact.

Land use impacts associated with carbon-negative concrete are generally favorable when compared to traditional concrete production. The utilization of industrial byproducts and waste materials reduces the need for virgin raw material extraction, thereby minimizing habitat disruption and landscape alteration. Furthermore, the enhanced durability of structures built with carbon-negative concrete reduces the frequency of demolition and reconstruction activities, preserving natural resources and minimizing construction waste.

Regulatory Framework and Green Building Certification Standards

The regulatory landscape for carbon-negative concrete is evolving rapidly as governments worldwide recognize the urgent need to address climate change through sustainable construction practices. In the United States, the Environmental Protection Agency (EPA) has established guidelines for low-carbon construction materials, while the Department of Energy (DOE) offers incentives for projects utilizing carbon-negative technologies. The European Union's Construction Products Regulation (CPR) has been updated to include carbon footprint considerations, with specific provisions for innovative materials like carbon-negative concrete.

International building codes are also adapting to accommodate these new materials. The International Code Council (ICC) has introduced provisions for alternative cementitious materials in its latest editions, while national building codes in countries like Canada, Australia, and Singapore have incorporated similar amendments to facilitate the adoption of carbon-negative concrete technologies.

Green building certification systems play a crucial role in driving market adoption of carbon-negative concrete. The Leadership in Energy and Environmental Design (LEED) system awards additional points for carbon-negative materials under its Materials and Resources category. Similarly, BREEAM (Building Research Establishment Environmental Assessment Method) has updated its materials assessment criteria to recognize carbon sequestration benefits. The Living Building Challenge goes further by requiring carbon-neutral or carbon-negative materials for its certification.

Regional certification systems have also emerged, such as China's Green Building Evaluation Standard and Australia's Green Star, both of which now include specific provisions for carbon-negative construction materials. These certification systems not only validate the environmental benefits of carbon-negative concrete but also create market incentives for its adoption.

Procurement policies are increasingly influential in driving demand for carbon-negative concrete. Several governments, including those of Sweden, California, and British Columbia, have implemented "Buy Clean" policies that require construction projects to use materials with reduced carbon footprints. The European Union's Green Public Procurement (GPP) guidelines similarly prioritize low-carbon construction materials for public projects.

Industry standards organizations, including ASTM International and the European Committee for Standardization (CEN), are developing testing protocols and performance standards specifically for carbon-negative concrete. These standards address durability metrics, carbon sequestration verification, and long-term performance characteristics, providing the technical foundation necessary for widespread adoption.

The convergence of regulatory frameworks and certification standards is creating a supportive ecosystem for carbon-negative concrete technologies, though challenges remain in harmonizing approaches across different jurisdictions and ensuring that standards keep pace with technological innovation.

International building codes are also adapting to accommodate these new materials. The International Code Council (ICC) has introduced provisions for alternative cementitious materials in its latest editions, while national building codes in countries like Canada, Australia, and Singapore have incorporated similar amendments to facilitate the adoption of carbon-negative concrete technologies.

Green building certification systems play a crucial role in driving market adoption of carbon-negative concrete. The Leadership in Energy and Environmental Design (LEED) system awards additional points for carbon-negative materials under its Materials and Resources category. Similarly, BREEAM (Building Research Establishment Environmental Assessment Method) has updated its materials assessment criteria to recognize carbon sequestration benefits. The Living Building Challenge goes further by requiring carbon-neutral or carbon-negative materials for its certification.

Regional certification systems have also emerged, such as China's Green Building Evaluation Standard and Australia's Green Star, both of which now include specific provisions for carbon-negative construction materials. These certification systems not only validate the environmental benefits of carbon-negative concrete but also create market incentives for its adoption.

Procurement policies are increasingly influential in driving demand for carbon-negative concrete. Several governments, including those of Sweden, California, and British Columbia, have implemented "Buy Clean" policies that require construction projects to use materials with reduced carbon footprints. The European Union's Green Public Procurement (GPP) guidelines similarly prioritize low-carbon construction materials for public projects.

Industry standards organizations, including ASTM International and the European Committee for Standardization (CEN), are developing testing protocols and performance standards specifically for carbon-negative concrete. These standards address durability metrics, carbon sequestration verification, and long-term performance characteristics, providing the technical foundation necessary for widespread adoption.

The convergence of regulatory frameworks and certification standards is creating a supportive ecosystem for carbon-negative concrete technologies, though challenges remain in harmonizing approaches across different jurisdictions and ensuring that standards keep pace with technological innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!