The Role of Ethylene Vinyl Acetate in Modern Fabrication

EVA Technology Evolution and Objectives

Ethylene Vinyl Acetate (EVA) has undergone significant evolution since its introduction in the 1950s. Initially developed as a copolymer of ethylene and vinyl acetate, EVA has transformed from a niche material to a versatile component in modern fabrication. The technology's progression has been driven by the increasing demand for flexible, durable, and cost-effective materials across various industries.

In the early stages, EVA was primarily used in packaging and adhesives. However, as manufacturing techniques improved, its applications expanded to footwear, sports equipment, and solar panel encapsulation. The technology's objectives have consistently focused on enhancing material properties, such as flexibility, impact resistance, and weatherability, while maintaining cost-effectiveness.

A key milestone in EVA technology was the development of foam injection molding in the 1970s, which revolutionized the footwear industry. This advancement allowed for the creation of lightweight, cushioned soles that significantly improved comfort and performance in athletic shoes. Subsequently, the focus shifted towards improving EVA's thermal properties and UV resistance, crucial for its application in solar panel encapsulation.

In recent years, the objectives of EVA technology have expanded to address environmental concerns. Researchers are now exploring bio-based alternatives and recycling methods to reduce the material's environmental impact. Additionally, there is a growing emphasis on developing EVA formulations with enhanced fire retardancy and electrical insulation properties to meet the evolving safety standards in construction and electronics.

The current technological goals for EVA include improving its compatibility with other materials, enhancing its barrier properties for packaging applications, and developing grades with higher temperature resistance. These objectives aim to broaden EVA's applicability in advanced manufacturing processes and emerging industries.

As we look to the future, the evolution of EVA technology is expected to focus on smart and responsive formulations. This includes the development of EVA materials that can change properties in response to external stimuli, such as temperature or pressure. Such advancements could lead to innovative applications in fields like wearable technology and adaptive structures.

In conclusion, the evolution of EVA technology has been marked by continuous improvement and diversification of its properties and applications. From its humble beginnings as a simple copolymer to its current status as a crucial component in modern fabrication, EVA's journey reflects the dynamic nature of materials science and the ongoing pursuit of versatile, high-performance materials.

Market Demand Analysis for EVA Applications

The market demand for Ethylene Vinyl Acetate (EVA) applications has been experiencing significant growth across various industries. This versatile copolymer has found its way into numerous products and manufacturing processes, driving its increasing popularity and market expansion.

In the footwear industry, EVA has become a staple material for midsoles and insoles due to its excellent cushioning properties, lightweight nature, and durability. The global athletic footwear market, a major consumer of EVA, has been growing steadily, fueled by increasing health awareness and sports participation worldwide.

The solar energy sector has emerged as another key driver for EVA demand. As the global push for renewable energy intensifies, the production of photovoltaic modules has surged. EVA is crucial in the encapsulation of solar cells, providing protection against environmental factors and ensuring long-term performance. The rapid expansion of solar installations globally has significantly boosted the demand for EVA in this sector.

In the packaging industry, EVA's flexibility, clarity, and adhesive properties have made it an essential component in the production of flexible packaging materials. The rise of e-commerce and changing consumer preferences towards convenient, lightweight packaging solutions have further accelerated the demand for EVA-based packaging materials.

The automotive sector represents another substantial market for EVA applications. Its use in the production of car interiors, gaskets, and sound-dampening components has grown as manufacturers seek lightweight, durable materials to improve fuel efficiency and reduce vehicle weight.

The construction industry has also contributed to the increasing demand for EVA. Its applications in waterproofing membranes, adhesives, and sealants have gained traction due to EVA's excellent weather resistance and bonding properties. The global construction boom, particularly in developing economies, has further amplified this demand.

In the medical field, EVA's biocompatibility and flexibility have led to its adoption in various medical devices and pharmaceutical packaging. The growing healthcare sector, coupled with the need for advanced medical materials, has opened new avenues for EVA applications.

Market analysts project the global EVA market to continue its upward trajectory, driven by these diverse applications and the material's adaptability to emerging technologies. The increasing focus on sustainable and recyclable materials may present both challenges and opportunities for EVA manufacturers, potentially shaping future market dynamics and innovation in EVA formulations.

EVA Technical Challenges and Limitations

Despite its widespread use in modern fabrication, Ethylene Vinyl Acetate (EVA) faces several technical challenges and limitations that impact its performance and applicability. One of the primary concerns is its thermal stability. EVA begins to degrade at temperatures above 230°C, which restricts its use in high-temperature applications. This thermal limitation can lead to the release of acetic acid, potentially causing corrosion in processing equipment and affecting the quality of the final product.

Another significant challenge is EVA's susceptibility to weathering and UV radiation. When exposed to sunlight for extended periods, EVA can undergo photodegradation, resulting in discoloration, loss of mechanical properties, and potential failure of the material. This limitation is particularly problematic in outdoor applications, such as solar panel encapsulation, where long-term durability is crucial.

EVA's moisture absorption properties also present challenges in certain applications. While its ability to absorb moisture can be beneficial in some cases, it can lead to dimensional instability and reduced mechanical strength in others. This characteristic requires careful consideration in applications where moisture resistance is critical, such as in electrical insulation or packaging materials.

The material's relatively low mechanical strength compared to some other polymers is another limitation. EVA's softness and flexibility, while advantageous in many applications, can be a drawback when high tensile strength or rigidity is required. This restricts its use in structural applications or in scenarios where high load-bearing capacity is necessary.

EVA's chemical resistance is also a point of concern. While it demonstrates good resistance to certain chemicals, it can be degraded by strong acids, aromatic hydrocarbons, and chlorinated solvents. This limits its applicability in environments where exposure to these substances is likely, such as in certain industrial or chemical processing applications.

The processing of EVA presents its own set of challenges. The material's low melting point and tendency to stick to processing equipment can lead to difficulties in extrusion and molding processes. Achieving consistent quality and avoiding defects such as bubbles or uneven distribution of vinyl acetate content requires precise control of processing parameters.

Lastly, the environmental impact of EVA is an emerging concern. While EVA is recyclable, the recycling process can be complex due to the presence of additives and the material's cross-linked structure in some applications. As sustainability becomes increasingly important in manufacturing, finding efficient and eco-friendly ways to recycle or dispose of EVA products at the end of their lifecycle remains a challenge for the industry.

Current EVA Fabrication Techniques

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to UV radiation and stress-cracking. The vinyl acetate content can be varied to modify the properties of the material, making it suitable for a wide range of applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, pressure-sensitive adhesives, and sealants. The adhesive strength and performance can be tailored by adjusting the EVA composition and incorporating additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good thermal insulation properties, and ability to be crosslinked. It is commonly used in footwear, sports equipment, and building insulation. The foam structure and properties can be controlled through the EVA formulation and processing conditions.

- EVA in solar panel encapsulation: EVA is a popular material for solar panel encapsulation due to its transparency, weather resistance, and ability to protect solar cells. It helps to improve the durability and efficiency of photovoltaic modules by providing a protective barrier against moisture and environmental factors.

- Modification and blending of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties or create new materials with specific characteristics. This includes crosslinking, grafting, and compounding with fillers or other polymers to improve mechanical properties, flame retardancy, or other desired attributes for various applications.

02 EVA in solar panel encapsulation

EVA is widely used as an encapsulant material in solar panels. It provides excellent adhesion to solar cells and glass, protects the cells from environmental factors, and enhances the overall performance and durability of photovoltaic modules.Expand Specific Solutions03 EVA foam applications

EVA foam is utilized in various products due to its lightweight, shock-absorbing, and cushioning properties. Applications include footwear (especially in midsoles), sports equipment, packaging, and automotive components.Expand Specific Solutions04 EVA in adhesives and sealants

EVA is employed in the formulation of hot melt adhesives and sealants. Its low melting point, good adhesion properties, and flexibility make it suitable for bonding various materials in industries such as packaging, woodworking, and construction.Expand Specific Solutions05 EVA blends and composites

EVA is often blended with other polymers or materials to create composites with enhanced properties. These blends can improve characteristics such as impact resistance, flame retardancy, or processability, expanding the range of applications for EVA-based materials.Expand Specific Solutions

Key Players in EVA Manufacturing

The market for Ethylene Vinyl Acetate (EVA) in modern fabrication is in a mature growth stage, with a global market size expected to reach $9.7 billion by 2027. The technology has widespread applications across various industries, including packaging, solar panels, and footwear. Major players like DuPont de Nemours, LyondellBasell, and Celanese International Corp. have established strong positions in the market, leveraging their advanced R&D capabilities and extensive product portfolios. Chinese companies such as China Petroleum & Chemical Corp. and Jiangsu Sopo Chemical Co., Ltd. are also making significant strides, particularly in the Asia-Pacific region. The competitive landscape is characterized by ongoing innovation in product formulations and manufacturing processes, with a focus on enhancing EVA's performance characteristics and sustainability.

China Petroleum & Chemical Corp.

Celanese International Corp.

Innovative EVA Formulations and Properties

- Incorporating olefinic bisoleamides, such as N,N'-ethylenebisoleamide, into ethylene copolymers with high vinyl acetate content to improve film forming properties without negatively impacting clarity, allowing for enhanced slip characteristics and easier film separation and cutting.

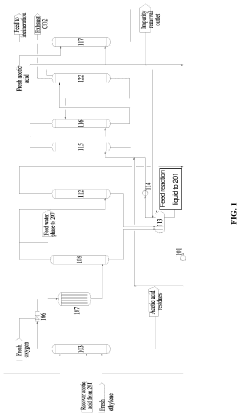

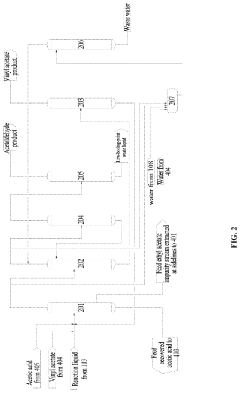

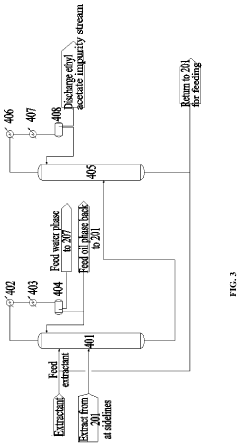

- A method involving a gas phase oxidation process with a system integration that includes specific towers and reactors for ethylene recovery, acetic acid evaporation, oxygen mixing, and separation processes, utilizing acetic acid as an extractant in the rectifying and separating towers to enhance the separation of vinyl acetate from ethyl acetate.

Environmental Impact of EVA Production

The production of Ethylene Vinyl Acetate (EVA) has significant environmental implications that warrant careful consideration. The manufacturing process of EVA involves the use of petrochemical feedstocks, primarily ethylene and vinyl acetate monomer, which are derived from fossil fuels. This reliance on non-renewable resources contributes to the depletion of finite energy sources and increases the carbon footprint associated with EVA production.

During the polymerization process, various chemical additives and catalysts are employed, some of which may pose environmental risks if not properly managed. The emission of volatile organic compounds (VOCs) is a particular concern, as these can contribute to air pollution and the formation of ground-level ozone. Additionally, the energy-intensive nature of EVA production results in substantial greenhouse gas emissions, primarily carbon dioxide, further exacerbating climate change concerns.

Water usage and potential contamination are also critical environmental factors in EVA manufacturing. The production process requires significant amounts of water for cooling and cleaning purposes, potentially straining local water resources. Moreover, if not adequately treated, wastewater from EVA plants may contain trace amounts of chemicals and monomers that could harm aquatic ecosystems if released into natural water bodies.

The disposal and end-of-life management of EVA products present another set of environmental challenges. While EVA is theoretically recyclable, the practical recycling of EVA-containing products is often complicated by the presence of other materials in composite structures. This difficulty in recycling can lead to increased landfill waste or incineration, both of which have negative environmental impacts.

However, it is important to note that the environmental impact of EVA production must be balanced against its benefits in various applications. For instance, EVA's use in solar panel encapsulation contributes to the growth of renewable energy technologies, potentially offsetting some of its production-related environmental costs. Furthermore, ongoing research and development efforts are focused on improving the sustainability of EVA production through the use of bio-based feedstocks, more efficient manufacturing processes, and enhanced recycling technologies.

As the demand for EVA continues to grow across multiple industries, addressing these environmental concerns becomes increasingly crucial. Manufacturers are under pressure to adopt cleaner production methods, implement more effective waste management strategies, and explore alternatives to traditional petrochemical-based EVA. The future of EVA production will likely involve a delicate balance between meeting market demands and minimizing environmental impact through technological innovation and sustainable practices.

EVA Recycling and Sustainability Initiatives

As the global focus on sustainability intensifies, the recycling and sustainable use of Ethylene Vinyl Acetate (EVA) have become critical aspects of modern fabrication processes. The polymer industry has recognized the need to address the environmental impact of EVA production and disposal, leading to the development of various recycling and sustainability initiatives.

EVA recycling presents unique challenges due to its cross-linked structure and the presence of various additives. However, innovative technologies have emerged to overcome these obstacles. Mechanical recycling methods have been refined to process EVA waste into reusable materials for applications such as flooring, playground surfaces, and sports equipment. This approach not only reduces waste but also conserves resources by minimizing the need for virgin EVA production.

Chemical recycling techniques have also shown promise in breaking down EVA into its constituent monomers or other valuable chemical feedstocks. These processes, including pyrolysis and solvolysis, enable the recovery of high-quality raw materials that can be reintroduced into the manufacturing cycle. Such circular economy approaches are gaining traction among manufacturers and environmental agencies alike.

In addition to recycling, sustainability initiatives in EVA production focus on reducing energy consumption and greenhouse gas emissions. Advanced manufacturing processes, such as supercritical CO2-assisted extrusion, have been developed to lower the environmental footprint of EVA production. These methods not only decrease energy requirements but also minimize the use of harmful solvents, aligning with green chemistry principles.

Bio-based alternatives to traditional EVA are being explored as part of sustainability efforts. Researchers are investigating the potential of renewable resources, such as plant-derived monomers, to create bio-EVA with comparable properties to petroleum-based EVA. While still in early stages, these developments hold promise for reducing the industry's reliance on fossil fuels.

Extended producer responsibility (EPR) programs are being implemented in various regions, encouraging manufacturers to take accountability for the entire lifecycle of their EVA products. These initiatives promote eco-design principles, facilitating easier disassembly and recycling of EVA-containing products at the end of their useful life.

Collaborative efforts between industry stakeholders, research institutions, and regulatory bodies are driving progress in EVA sustainability. International standards and certifications for recycled EVA content and sustainable production practices are being established, providing a framework for consistent evaluation and improvement across the global supply chain.

As the demand for sustainable materials continues to grow, these recycling and sustainability initiatives are poised to reshape the role of EVA in modern fabrication. The ongoing research and development in this area not only address environmental concerns but also open new avenues for innovation and market differentiation in the polymer industry.