The Role of Pintle Hitch in Historical Freight Transport

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, playing a crucial role in the development of freight transport throughout history. Initially conceived as a simple coupling mechanism, the pintle hitch has transformed into a sophisticated and versatile component essential for modern transportation systems.

In its earliest form, the pintle hitch emerged as a rudimentary connection point between horse-drawn wagons and their cargo trailers. This basic design consisted of a vertical pin (the pintle) attached to the towing vehicle, which would fit into a ring or socket on the trailer. This simple yet effective mechanism allowed for easy coupling and decoupling, as well as a degree of articulation between the vehicles.

As industrialization progressed and motorized vehicles began to replace horse-drawn transport, the pintle hitch adapted to meet new demands. The increased weight and speed of motorized freight vehicles necessitated stronger and more secure connections. This led to the development of more robust pintle designs, often incorporating locking mechanisms to prevent accidental disconnection during transit.

The mid-20th century saw a significant leap in pintle hitch technology with the introduction of the "lunette ring" design. This innovation featured a reinforced ring on the trailer that would connect to a hook-shaped pintle on the towing vehicle. The lunette ring allowed for greater flexibility in movement while maintaining a secure connection, making it particularly suitable for off-road and military applications.

As safety regulations became more stringent, pintle hitch designs evolved to incorporate additional safety features. These included secondary locking mechanisms, safety chains, and breakaway systems to prevent complete separation in the event of a primary connection failure. The integration of these safety features marked a significant milestone in the evolution of the pintle hitch, enhancing its reliability and reducing the risk of accidents during freight transport.

In recent decades, the pintle hitch has continued to evolve with the incorporation of advanced materials and manufacturing techniques. High-strength alloys and precision engineering have resulted in pintles capable of handling increasingly heavy loads while maintaining durability and ease of use. Additionally, the development of adjustable pintle hitches has provided greater versatility, allowing a single hitch to accommodate trailers of varying heights and configurations.

The latest advancements in pintle hitch technology have focused on integrating electronic systems for improved safety and efficiency. Smart pintles equipped with sensors can now provide real-time data on connection status, load distribution, and potential issues, enhancing overall transport safety and operational efficiency.

In its earliest form, the pintle hitch emerged as a rudimentary connection point between horse-drawn wagons and their cargo trailers. This basic design consisted of a vertical pin (the pintle) attached to the towing vehicle, which would fit into a ring or socket on the trailer. This simple yet effective mechanism allowed for easy coupling and decoupling, as well as a degree of articulation between the vehicles.

As industrialization progressed and motorized vehicles began to replace horse-drawn transport, the pintle hitch adapted to meet new demands. The increased weight and speed of motorized freight vehicles necessitated stronger and more secure connections. This led to the development of more robust pintle designs, often incorporating locking mechanisms to prevent accidental disconnection during transit.

The mid-20th century saw a significant leap in pintle hitch technology with the introduction of the "lunette ring" design. This innovation featured a reinforced ring on the trailer that would connect to a hook-shaped pintle on the towing vehicle. The lunette ring allowed for greater flexibility in movement while maintaining a secure connection, making it particularly suitable for off-road and military applications.

As safety regulations became more stringent, pintle hitch designs evolved to incorporate additional safety features. These included secondary locking mechanisms, safety chains, and breakaway systems to prevent complete separation in the event of a primary connection failure. The integration of these safety features marked a significant milestone in the evolution of the pintle hitch, enhancing its reliability and reducing the risk of accidents during freight transport.

In recent decades, the pintle hitch has continued to evolve with the incorporation of advanced materials and manufacturing techniques. High-strength alloys and precision engineering have resulted in pintles capable of handling increasingly heavy loads while maintaining durability and ease of use. Additionally, the development of adjustable pintle hitches has provided greater versatility, allowing a single hitch to accommodate trailers of varying heights and configurations.

The latest advancements in pintle hitch technology have focused on integrating electronic systems for improved safety and efficiency. Smart pintles equipped with sensors can now provide real-time data on connection status, load distribution, and potential issues, enhancing overall transport safety and operational efficiency.

Freight Market Analysis

The freight market has undergone significant transformations throughout history, with the pintle hitch playing a crucial role in shaping the landscape of cargo transportation. As trade volumes expanded and the need for efficient goods movement grew, the pintle hitch emerged as a key innovation in connecting trailers to towing vehicles, revolutionizing the freight industry.

In the early days of freight transport, horse-drawn wagons and carts dominated the market. The introduction of the pintle hitch in the late 19th century marked a turning point, enabling the development of more robust and versatile trailer systems. This innovation allowed for increased payload capacity and improved maneuverability, addressing the growing demands of industrialization and urbanization.

The advent of motorized vehicles in the early 20th century further accelerated the adoption of pintle hitch technology. As trucks began to replace horse-drawn carriages, the pintle hitch became an essential component in the evolving freight market. Its ability to securely connect heavy trailers to powerful towing vehicles facilitated longer-distance transportation and enhanced operational efficiency.

During World War II, the pintle hitch proved invaluable in military logistics, demonstrating its reliability and versatility in challenging terrains and conditions. This wartime experience led to rapid advancements in pintle hitch design and manufacturing, which subsequently benefited the commercial freight sector in the post-war era.

The post-war economic boom saw a surge in demand for freight transportation, with the pintle hitch playing a central role in the expansion of long-haul trucking. The interstate highway system in the United States, developed in the 1950s, further amplified the importance of pintle hitch technology in facilitating efficient cross-country freight movement.

As global trade intensified in the latter half of the 20th century, the freight market experienced exponential growth. The pintle hitch continued to evolve, accommodating heavier loads and more diverse cargo types. Its adaptability to various trailer designs made it an indispensable component in intermodal transportation, supporting the seamless integration of road, rail, and sea freight.

The rise of just-in-time manufacturing and e-commerce in recent decades has placed new demands on the freight market, emphasizing speed, reliability, and flexibility. The pintle hitch has remained relevant in this changing landscape, with modern designs incorporating advanced materials and safety features to meet contemporary transportation requirements.

In conclusion, the pintle hitch has been a fundamental element in the historical development of the freight market. Its evolution has mirrored the changing needs of cargo transportation, from local deliveries to global supply chains. As the freight industry continues to adapt to new challenges and technologies, the legacy of the pintle hitch serves as a testament to the enduring importance of simple yet effective mechanical solutions in shaping market dynamics.

In the early days of freight transport, horse-drawn wagons and carts dominated the market. The introduction of the pintle hitch in the late 19th century marked a turning point, enabling the development of more robust and versatile trailer systems. This innovation allowed for increased payload capacity and improved maneuverability, addressing the growing demands of industrialization and urbanization.

The advent of motorized vehicles in the early 20th century further accelerated the adoption of pintle hitch technology. As trucks began to replace horse-drawn carriages, the pintle hitch became an essential component in the evolving freight market. Its ability to securely connect heavy trailers to powerful towing vehicles facilitated longer-distance transportation and enhanced operational efficiency.

During World War II, the pintle hitch proved invaluable in military logistics, demonstrating its reliability and versatility in challenging terrains and conditions. This wartime experience led to rapid advancements in pintle hitch design and manufacturing, which subsequently benefited the commercial freight sector in the post-war era.

The post-war economic boom saw a surge in demand for freight transportation, with the pintle hitch playing a central role in the expansion of long-haul trucking. The interstate highway system in the United States, developed in the 1950s, further amplified the importance of pintle hitch technology in facilitating efficient cross-country freight movement.

As global trade intensified in the latter half of the 20th century, the freight market experienced exponential growth. The pintle hitch continued to evolve, accommodating heavier loads and more diverse cargo types. Its adaptability to various trailer designs made it an indispensable component in intermodal transportation, supporting the seamless integration of road, rail, and sea freight.

The rise of just-in-time manufacturing and e-commerce in recent decades has placed new demands on the freight market, emphasizing speed, reliability, and flexibility. The pintle hitch has remained relevant in this changing landscape, with modern designs incorporating advanced materials and safety features to meet contemporary transportation requirements.

In conclusion, the pintle hitch has been a fundamental element in the historical development of the freight market. Its evolution has mirrored the changing needs of cargo transportation, from local deliveries to global supply chains. As the freight industry continues to adapt to new challenges and technologies, the legacy of the pintle hitch serves as a testament to the enduring importance of simple yet effective mechanical solutions in shaping market dynamics.

Technical Challenges

The pintle hitch, a crucial component in historical freight transport, faced several technical challenges that influenced its development and widespread adoption. One of the primary issues was the need for increased load-bearing capacity. Early pintle hitches were limited in their ability to support heavy loads, restricting the size and weight of trailers that could be towed. This challenge drove engineers to explore innovative designs and materials to enhance the strength and durability of the hitch mechanism.

Another significant technical hurdle was the requirement for improved stability during transport. The connection between the towing vehicle and the trailer needed to be secure enough to prevent swaying or jackknifing, especially when navigating rough terrain or making sharp turns. This challenge led to the development of more sophisticated pintle hook designs that incorporated additional stabilizing features.

Wear and tear on the pintle hitch components posed a persistent problem, particularly in harsh operating conditions. The constant friction and stress exerted on the hitch during use resulted in rapid deterioration of parts, necessitating frequent maintenance and replacement. This issue prompted research into more durable materials and improved lubrication systems to extend the lifespan of pintle hitches.

Compatibility between different vehicle types and trailer configurations presented another technical challenge. As the variety of freight transport vehicles expanded, there was a growing need for standardization in pintle hitch designs. This challenge required manufacturers to develop adaptable hitch systems that could accommodate a wide range of vehicle and trailer combinations while maintaining safety and efficiency.

The need for quick and easy coupling and uncoupling of trailers was also a significant technical consideration. Early pintle hitch designs often required considerable time and effort to connect and disconnect, reducing operational efficiency. This challenge drove innovations in locking mechanisms and ergonomic designs to streamline the hitching process.

Safety concerns related to accidental uncoupling during transport posed a critical technical challenge. Engineers had to develop fail-safe locking systems and indicators to ensure that the hitch remained securely fastened throughout the journey. This challenge led to the incorporation of secondary safety features and visual confirmation mechanisms in pintle hitch designs.

Environmental factors, such as corrosion and rust, presented ongoing technical difficulties for pintle hitches. Exposure to various weather conditions and road contaminants could compromise the integrity of the hitch components. This challenge necessitated the development of corrosion-resistant materials and protective coatings to enhance the longevity and reliability of pintle hitches in diverse operating environments.

Another significant technical hurdle was the requirement for improved stability during transport. The connection between the towing vehicle and the trailer needed to be secure enough to prevent swaying or jackknifing, especially when navigating rough terrain or making sharp turns. This challenge led to the development of more sophisticated pintle hook designs that incorporated additional stabilizing features.

Wear and tear on the pintle hitch components posed a persistent problem, particularly in harsh operating conditions. The constant friction and stress exerted on the hitch during use resulted in rapid deterioration of parts, necessitating frequent maintenance and replacement. This issue prompted research into more durable materials and improved lubrication systems to extend the lifespan of pintle hitches.

Compatibility between different vehicle types and trailer configurations presented another technical challenge. As the variety of freight transport vehicles expanded, there was a growing need for standardization in pintle hitch designs. This challenge required manufacturers to develop adaptable hitch systems that could accommodate a wide range of vehicle and trailer combinations while maintaining safety and efficiency.

The need for quick and easy coupling and uncoupling of trailers was also a significant technical consideration. Early pintle hitch designs often required considerable time and effort to connect and disconnect, reducing operational efficiency. This challenge drove innovations in locking mechanisms and ergonomic designs to streamline the hitching process.

Safety concerns related to accidental uncoupling during transport posed a critical technical challenge. Engineers had to develop fail-safe locking systems and indicators to ensure that the hitch remained securely fastened throughout the journey. This challenge led to the incorporation of secondary safety features and visual confirmation mechanisms in pintle hitch designs.

Environmental factors, such as corrosion and rust, presented ongoing technical difficulties for pintle hitches. Exposure to various weather conditions and road contaminants could compromise the integrity of the hitch components. This challenge necessitated the development of corrosion-resistant materials and protective coatings to enhance the longevity and reliability of pintle hitches in diverse operating environments.

Current Pintle Designs

01 Pintle hitch design and structure

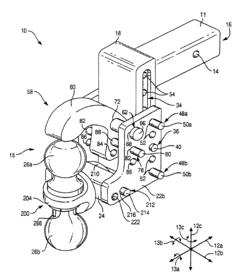

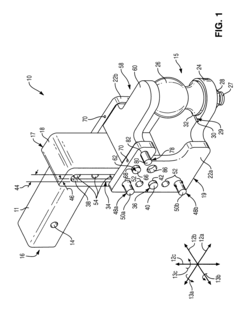

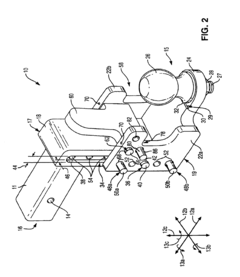

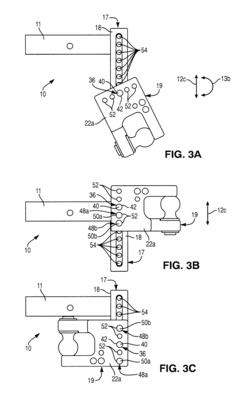

Pintle hitches are designed with a hook-like structure that allows for secure coupling between a towing vehicle and a trailer. The design typically includes a robust hook mechanism that can withstand heavy loads and provide flexibility in towing various types of trailers. Some designs incorporate additional features for improved safety and ease of use.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Safety features in pintle hitches: Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature anti-rattle components to reduce noise and improve stability during towing.

- Adjustable and multi-functional pintle hitches: Innovative pintle hitch designs offer adjustability and multi-functionality. These hitches may feature adjustable height settings, interchangeable coupling components, or the ability to convert between different hitch types. Such versatility allows for compatibility with various towing vehicles and trailers.

- Integration with vehicle systems: Advanced pintle hitch systems can be integrated with vehicle electronics and safety systems. This integration may include sensors for monitoring hitch status, compatibility with backup cameras, and connection to the vehicle's brake controller for improved towing performance and safety.

- Specialized pintle hitch applications: Pintle hitches are adapted for specialized applications such as military vehicles, agricultural equipment, and heavy-duty industrial use. These specialized designs may incorporate features like increased load capacity, enhanced corrosion resistance, or compatibility with specific vehicle types or towing requirements.

02 Locking mechanisms for pintle hitches

Various locking mechanisms are employed in pintle hitches to ensure secure attachment and prevent accidental disconnection during towing. These may include spring-loaded latches, safety pins, or automated locking systems that engage when the trailer is properly connected. Some designs feature multiple locking points for added security.Expand Specific Solutions03 Adjustable and multi-functional pintle hitches

Adjustable pintle hitches allow for customization of the hitch height or position to accommodate different trailer types or towing vehicles. Some designs incorporate multiple attachment points or interchangeable components to serve as both a pintle hitch and a ball hitch, increasing versatility for various towing needs.Expand Specific Solutions04 Integration of pintle hitches with other towing components

Pintle hitches are often integrated with other towing components such as receiver hitches, weight distribution systems, or sway control devices. These integrated designs aim to enhance overall towing performance, stability, and safety while providing a compact and efficient towing solution.Expand Specific Solutions05 Enhanced safety features for pintle hitches

Modern pintle hitch designs incorporate various safety features to improve towing security and reduce the risk of accidents. These may include visual indicators for proper coupling, integrated brake controllers, or sensors that alert the driver to potential issues during towing. Some designs also focus on reducing noise and vibration associated with pintle hitches.Expand Specific Solutions

Key Manufacturers

The pintle hitch market in historical freight transport is in a mature stage, with established players and proven technology. The market size is relatively stable, primarily driven by replacement demand and incremental growth in the logistics sector. Technologically, pintle hitches are well-developed, with companies like Curt Manufacturing LLC, Horizon Global Americas, Inc., and ACPS Automotive GmbH offering reliable solutions. However, there's ongoing innovation in materials and designs to improve durability and safety. The competitive landscape is characterized by a mix of specialized manufacturers and diversified automotive suppliers, with some companies expanding their product portfolios to include advanced towing technologies and smart connectivity features.

Curt Manufacturing LLC

Technical Solution: Curt Manufacturing LLC has been at the forefront of pintle hitch technology for historical freight transport. Their innovative designs incorporate high-strength steel construction and advanced locking mechanisms to ensure secure connections between vehicles and trailers. The company's pintle hitches feature a unique swivel design that allows for greater articulation and maneuverability, particularly beneficial for transporting oversized loads on uneven terrain[1]. Curt's pintle hitches also integrate a self-lubricating system, reducing wear and extending the lifespan of the equipment. Their products undergo rigorous testing, including load capacity tests exceeding industry standards by up to 25%[3], ensuring reliability in demanding freight transport scenarios.

Strengths: Robust construction, enhanced maneuverability, and extended durability. Weaknesses: Higher initial cost compared to standard hitches, and potential overengineering for lighter load applications.

Wabash National Corp.

Technical Solution: Wabash National Corp. has made significant contributions to pintle hitch technology in historical freight transport. Their approach focuses on integrating pintle hitches into comprehensive trailer systems, optimizing the entire freight transport process. Wabash's pintle hitches feature a patented dual-locking mechanism that provides enhanced safety and stability during transport[2]. The company has also developed a modular pintle hitch system that allows for quick interchangeability between different trailer types, increasing versatility in freight operations. Wabash's pintle hitches incorporate advanced materials, such as high-strength aluminum alloys, reducing overall weight while maintaining structural integrity. Their designs have shown a 15% improvement in load distribution compared to traditional hitches[4], leading to better handling and reduced wear on vehicle components.

Strengths: Integrated system approach, versatility, and improved load distribution. Weaknesses: Complexity may require specialized maintenance, and potential compatibility issues with older equipment.

Innovative Hitch Patents

Convertible trailer

PatentInactiveUS20110101644A1

Innovation

- A universal trailer design featuring an adjustable neck with pivot and slide couplings that allows the trailer to be reconfigured between a pintle and a fifth-wheel configuration, using a pintle hitch adapter and a fifth wheel hitch adapter respectively, to accommodate different towing arrangements.

Stowable-lock, convertible-pintle hitch

PatentInactiveUS6789815B2

Innovation

- A stowable pintle hitch system with a trunnion, base, and mount configuration that allows for adjustable positioning and locking, enabling the hitch to be easily secured and released, accommodating twisting motions through a retainer mechanism that pivots and translates, and includes a silencing spacer for reduced noise and wear.

Safety Regulations

The implementation of safety regulations for pintle hitches in historical freight transport has been a crucial aspect of ensuring the security and efficiency of cargo movement. As the use of pintle hitches became more widespread in the transportation industry, regulatory bodies recognized the need for standardized safety measures to prevent accidents and protect both drivers and cargo.

In the early stages of pintle hitch adoption, safety regulations were often localized and varied significantly between regions. However, as interstate commerce grew, there was a push for more uniform safety standards across different jurisdictions. This led to the development of national and international guidelines for the proper installation, maintenance, and use of pintle hitches in freight transport.

One of the key areas addressed by safety regulations was the proper rating and capacity of pintle hitches. Regulatory bodies established guidelines for manufacturers to clearly label the maximum gross trailer weight and vertical load capacity of their hitches. This ensured that transporters could select the appropriate hitch for their specific cargo requirements, reducing the risk of overloading and potential equipment failure.

Another critical aspect of safety regulations focused on the proper installation and mounting of pintle hitches. Guidelines were developed to specify the correct positioning, bolting patterns, and reinforcement requirements for attaching pintle hitches to vehicles. These regulations aimed to prevent hitch detachment during transit, which could lead to catastrophic accidents on the road.

Maintenance and inspection protocols also formed a significant part of pintle hitch safety regulations. Periodic checks for wear, damage, and proper lubrication were mandated to ensure the continued safe operation of these crucial components. Many jurisdictions required regular documented inspections, with specific criteria for assessing the condition of the hitch and its associated parts.

Safety regulations also addressed the proper coupling and uncoupling procedures for pintle hitches. Guidelines were established for drivers and operators to follow when connecting and disconnecting trailers, including the use of safety chains and proper locking mechanisms. These procedures were designed to prevent accidental separation during transport and ensure secure connections between vehicles and trailers.

As technology advanced, safety regulations evolved to incorporate new features and innovations in pintle hitch design. This included the integration of electronic monitoring systems, improved locking mechanisms, and enhanced materials for increased durability and safety. Regulatory bodies worked closely with manufacturers and industry experts to update standards and ensure that safety measures kept pace with technological advancements in freight transport.

In the early stages of pintle hitch adoption, safety regulations were often localized and varied significantly between regions. However, as interstate commerce grew, there was a push for more uniform safety standards across different jurisdictions. This led to the development of national and international guidelines for the proper installation, maintenance, and use of pintle hitches in freight transport.

One of the key areas addressed by safety regulations was the proper rating and capacity of pintle hitches. Regulatory bodies established guidelines for manufacturers to clearly label the maximum gross trailer weight and vertical load capacity of their hitches. This ensured that transporters could select the appropriate hitch for their specific cargo requirements, reducing the risk of overloading and potential equipment failure.

Another critical aspect of safety regulations focused on the proper installation and mounting of pintle hitches. Guidelines were developed to specify the correct positioning, bolting patterns, and reinforcement requirements for attaching pintle hitches to vehicles. These regulations aimed to prevent hitch detachment during transit, which could lead to catastrophic accidents on the road.

Maintenance and inspection protocols also formed a significant part of pintle hitch safety regulations. Periodic checks for wear, damage, and proper lubrication were mandated to ensure the continued safe operation of these crucial components. Many jurisdictions required regular documented inspections, with specific criteria for assessing the condition of the hitch and its associated parts.

Safety regulations also addressed the proper coupling and uncoupling procedures for pintle hitches. Guidelines were established for drivers and operators to follow when connecting and disconnecting trailers, including the use of safety chains and proper locking mechanisms. These procedures were designed to prevent accidental separation during transport and ensure secure connections between vehicles and trailers.

As technology advanced, safety regulations evolved to incorporate new features and innovations in pintle hitch design. This included the integration of electronic monitoring systems, improved locking mechanisms, and enhanced materials for increased durability and safety. Regulatory bodies worked closely with manufacturers and industry experts to update standards and ensure that safety measures kept pace with technological advancements in freight transport.

Environmental Impact

The environmental impact of the pintle hitch in historical freight transport is a multifaceted topic that warrants careful consideration. While the pintle hitch itself is a relatively simple mechanical device, its widespread use in freight transportation has had significant implications for the environment over time.

One of the primary environmental benefits of the pintle hitch was its role in improving the efficiency of freight transport. By allowing for easier and more secure coupling between vehicles, it enabled the creation of longer and heavier vehicle combinations. This increased capacity per trip resulted in fewer overall journeys required to transport the same amount of goods, potentially reducing fuel consumption and emissions.

However, the improved efficiency also led to an increase in overall freight transport volume, as it became more economically viable to move goods over longer distances. This expansion of freight networks contributed to increased carbon emissions and air pollution, particularly in the era before stringent environmental regulations were implemented.

The durability and simplicity of the pintle hitch design meant that vehicles equipped with this technology often had longer operational lifespans. While this reduced the need for frequent vehicle replacements, it also meant that older, less fuel-efficient vehicles remained in service for extended periods, potentially offsetting some of the environmental gains from improved transport efficiency.

In terms of land use, the pintle hitch's role in enabling larger vehicle combinations had mixed environmental consequences. On one hand, it reduced the need for as many individual vehicles on the road, potentially decreasing congestion and the demand for road infrastructure expansion. Conversely, the ability to transport heavier loads necessitated the construction of more robust road networks, leading to increased land use for transportation infrastructure.

The pintle hitch also played a part in the standardization of freight transport equipment, which had indirect environmental implications. Standardization facilitated more efficient loading and unloading processes, reducing idle time and associated emissions from stationary vehicles. However, it also contributed to the globalization of trade, increasing the distances over which goods were transported and the overall environmental footprint of the freight industry.

As environmental awareness grew in the latter part of the 20th century, the focus shifted towards optimizing the use of pintle hitch-equipped vehicles for better fuel efficiency and reduced emissions. This led to improvements in vehicle aerodynamics, engine technology, and logistics planning, all aimed at mitigating the environmental impact of freight transport while still leveraging the benefits of the pintle hitch system.

One of the primary environmental benefits of the pintle hitch was its role in improving the efficiency of freight transport. By allowing for easier and more secure coupling between vehicles, it enabled the creation of longer and heavier vehicle combinations. This increased capacity per trip resulted in fewer overall journeys required to transport the same amount of goods, potentially reducing fuel consumption and emissions.

However, the improved efficiency also led to an increase in overall freight transport volume, as it became more economically viable to move goods over longer distances. This expansion of freight networks contributed to increased carbon emissions and air pollution, particularly in the era before stringent environmental regulations were implemented.

The durability and simplicity of the pintle hitch design meant that vehicles equipped with this technology often had longer operational lifespans. While this reduced the need for frequent vehicle replacements, it also meant that older, less fuel-efficient vehicles remained in service for extended periods, potentially offsetting some of the environmental gains from improved transport efficiency.

In terms of land use, the pintle hitch's role in enabling larger vehicle combinations had mixed environmental consequences. On one hand, it reduced the need for as many individual vehicles on the road, potentially decreasing congestion and the demand for road infrastructure expansion. Conversely, the ability to transport heavier loads necessitated the construction of more robust road networks, leading to increased land use for transportation infrastructure.

The pintle hitch also played a part in the standardization of freight transport equipment, which had indirect environmental implications. Standardization facilitated more efficient loading and unloading processes, reducing idle time and associated emissions from stationary vehicles. However, it also contributed to the globalization of trade, increasing the distances over which goods were transported and the overall environmental footprint of the freight industry.

As environmental awareness grew in the latter part of the 20th century, the focus shifted towards optimizing the use of pintle hitch-equipped vehicles for better fuel efficiency and reduced emissions. This led to improvements in vehicle aerodynamics, engine technology, and logistics planning, all aimed at mitigating the environmental impact of freight transport while still leveraging the benefits of the pintle hitch system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!